Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

The concept of the fourth industrial revolution, introduced in 2011, marks a significant evolution from decades of industrial automation characterized by lower functionality and complexity. Innovations in technology, software, and hardware drive the development of Industry 4.0 technologies, previously confined to research labs. Enhanced human-machine, machine-machine, and human-human connectivity now profoundly influence global production systems and processes. Emerging industry 4.0 trends and technologies play a crucial role in achieving connected manufacturing, enabling the transition to smart and autonomous factories. This shift impacts various industries by optimizing efficiency, increasing flexibility, and fostering innovation.

This article was last updated in August 2024.

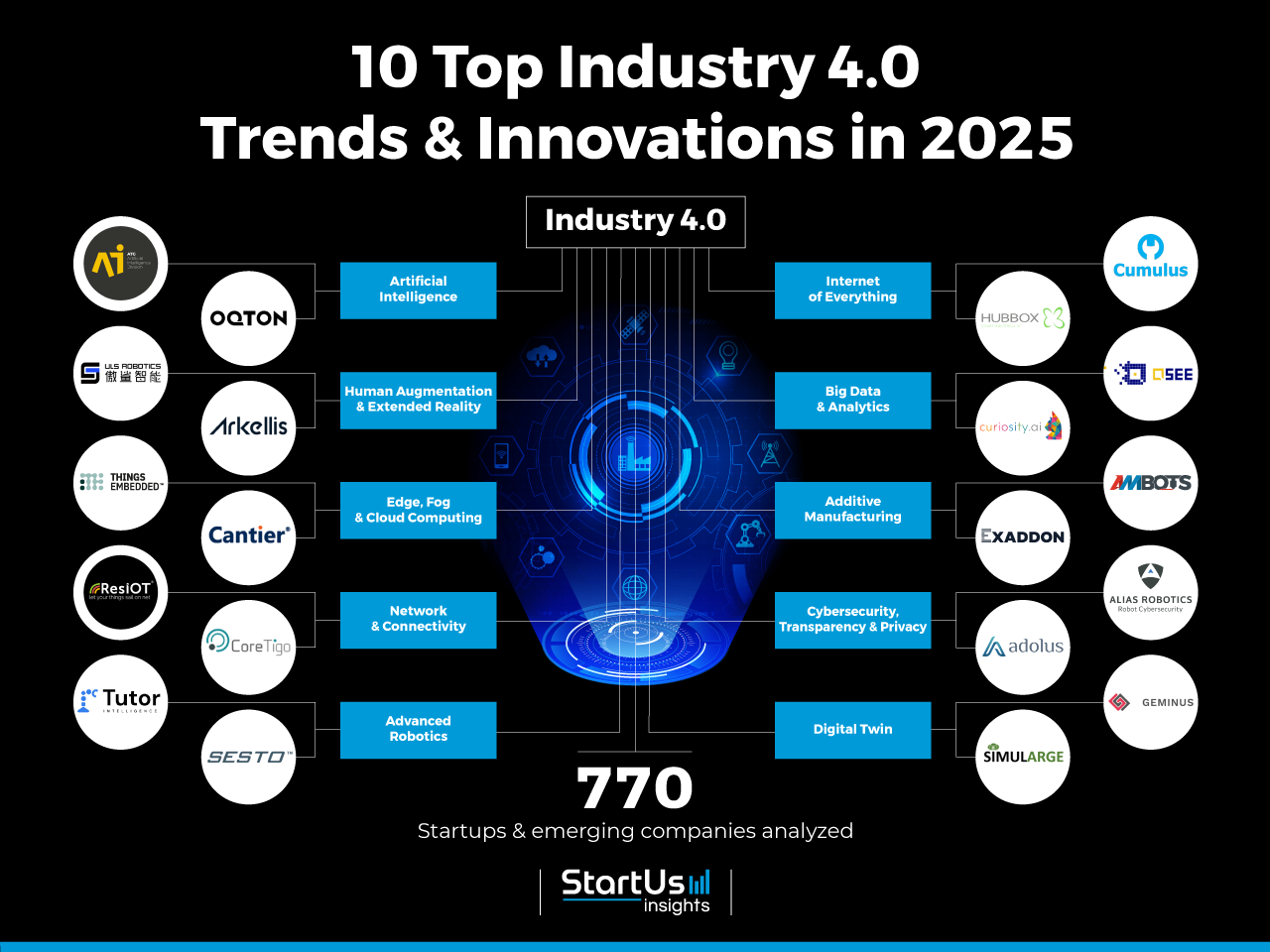

Innovation Map outlines Top 10 Industry 4.0 Trends & 20 Promising Startups

For this in-depth research on the Top Industry 4.0 Trends & Startups, we analyzed a sample of 770 global startups & scaleups. This data-driven research provides innovation intelligence that helps you improve strategic decision-making by giving you an overview of emerging technologies advancing Industry 4.0. In the Industry 4.0 Innovation Map, you get a comprehensive overview of the innovation trends & startups that impact your company.

Top 10 Industry 4.0 Trends in 2025

- Artificial Intelligence

- Human Augmentation & Extended Reality

- Edge, Fog & Cloud Computing

- Network & Connectivity

- Advanced Robotics

- Internet of Everything

- Big Data & Analytics

- Additive Manufacturing

- Cybersecurity, Transparency & Privacy

- Digital Twin

Want to explore all industry 4.0 innovations & trends?

These insights are derived by working with our Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 4.7M+ startups & scaleups globally. As the world’s largest resource for data on emerging companies, the SaaS platform enables you to identify relevant technologies and industry trends quickly & exhaustively.

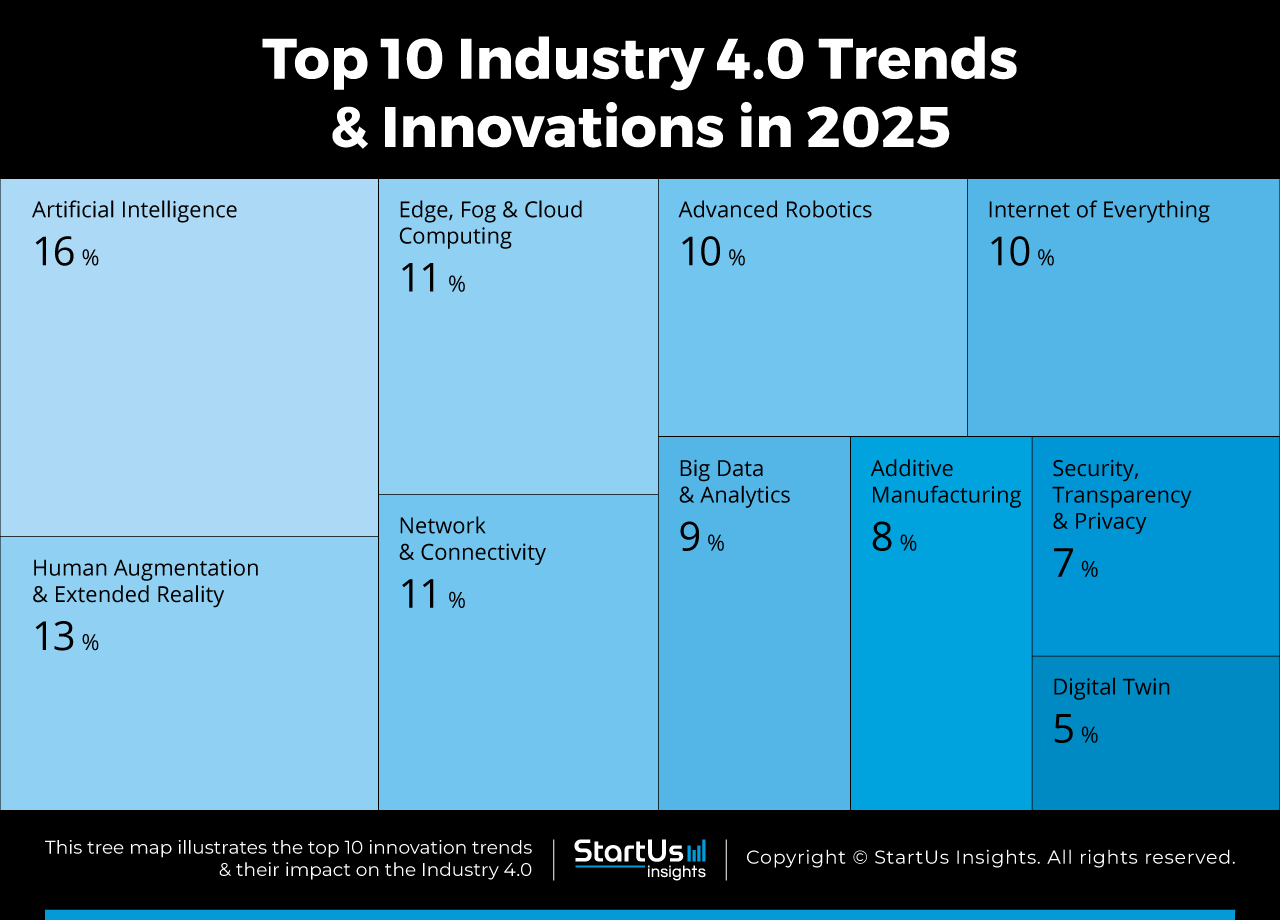

Tree Map reveals the Impact of the Top 10 Industry 4.0 Technology Trends in 2025

The Tree Map below illustrates the top 10 industry 4.0 future trends that will impact companies in 2025. Employing artificial intelligence (AI) techniques across devices and processes forms the top industry 4.0 trend. Increasingly, emerging companies develop wearable solutions for the industrial workplace to ensure the safety and efficiency of the manufacturing process.

Collecting data by implementing cloud and edge computing and designing cybersecurity solutions allow companies to establish the building blocks for setting up smart factories. Advanced robotic solutions comprising autonomous mobile robots, cobots, and swarm robotics, as well as robotic software development are also a major part of industry 4.0 trends.

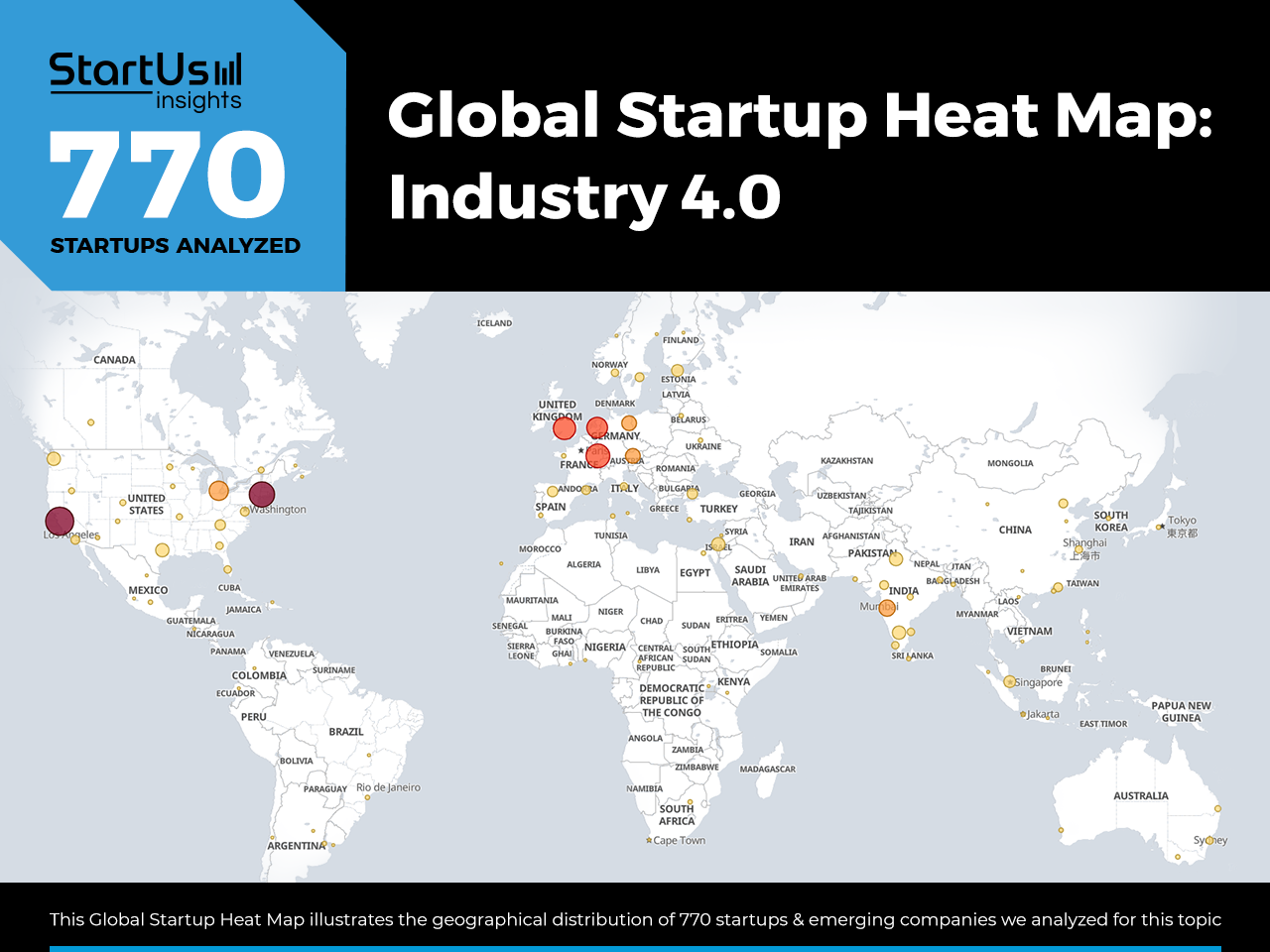

Global Startup Heat Map covers 770 Industry 4.0 Startups & Scaleups

The Global Startup Heat Map below highlights the global distribution of the 770 exemplary startups & scaleups that we analyzed for this research. Created through the StartUs Insights Discovery Platform, the Heat Map reveals that the United States is home to most of these companies while we also observe increased activity in India as well as Europe, particularly in France and Germany.

Below, you get to meet 20 out of these 750+ promising startups & scaleups as well as the solutions they develop. These 20 startups were hand-picked based on criteria such as founding year, location, funding raised, and more. Depending on your specific needs, your top picks might look entirely different.

Top 10 Current Trends in Industry 4.0 (2025)

1. AI and Industry 4.0

AI and machine learning are driving innovations across industries and functional areas. The development of AI-specific hardware and novel algorithms enhances existing systems and address manufacturing challenges. Factories are progressively incorporating AI into their production systems and processes.

The advent of advanced AI has opened doors for predictive maintenance, cognitive computing, swarm intelligence, context-aware computing, smart machines, hardware accelerators, and generative design. These technologies are steering manufacturing facilities towards fully automated, lights-out manufacturing. Efficient supply chain management is now a reality, thanks to AI-driven algorithms. These algorithms excel in forecasting demands and automating inventory control, thereby streamlining operations.

ATG Artificial Intelligence Division – Smart Company 4.0

ATG Artificial Intelligence Division is an Italian startup that offers a solution for smart company 4.0. The startup’s solution features 3 modules – forecast, predictive maintenance, forecast, and classification of waste. The startup’s forecasting feature allows manufacturers to identify patterns and trends in industrial process data using machine learning.

The startup also utilizes AI and IoT to enable predictive maintenance of industrial assets. These modules allow manufacturers to predict unplanned energy consumption peaks and machine failures to minimize downtime and implement sustainable actions. Its waste classification solution further allows to prevent quality issues and identify defect topology.

Oqton – AI-Powered Data Integration

The US-based startup Oqton develops FactoryOS, an AI-powered platform for integrating manufacturing system data in order to streamline factory production and output. Machines, systems, and data from manufacturing facilities are usually kept as independent data silos, making it difficult to derive actual value from them.

The cloud-based platform integrates and uses data from all stages of the industrial ecosystem such as design, production, and supply chain. Over time, the AI learns continuously from these data inputs to generate critical insights for improving overall productivity.

2. Human Augmentation & Extended Reality

Technologies such as wearables and exoskeletons are enhancing human capabilities, both physically and cognitively. These advancements are a significant trend in Industry 4.0. Industrial mobile devices, intuitive user interfaces, and portable machine control screens are making this technology more accessible.

XR technologies like mixed reality (MR), augmented reality (AR), and virtual reality (VR) are transforming industrial manufacturing systems. From research and development to full-scale production and post-production processes, these technologies are in use. They are shifting the nature of human-machine interaction towards machine-enabled workers. Through XR, real-time visualization of data and designs is possible, which promotes collaboration and innovation.

ULS Robotics – Exoskeleton Technology Platform

ULS Robotics is a Chinese startup developing an exoskeleton technology platform. Many workers on the shop floor encounter fatigue, weakness, and other physical discomforts due to the repetitive and monotonous nature of their tasks.

The use of exoskeletons on the shop floor helps workers in doing their tasks efficiently while reducing or eliminating any physical strain. Exoskeletons usually provide support for the waist, upper limb (with 4 degrees of freedom), and lower limb (with 12 degrees of freedom).

Arkellis Technologies – Industrial Metaverse

Arkellis Technologies is an Indian startup that makes a low-code framework for the industrial metaverse. It enables companies to use out-of-the-box AR and VR app development for businesses across verticals. The framework also features development tools, including tools for use cases like training, repair, maintenance, visualization, onboarding, and more.

By enabling companies to integrate life-size digital twins with data integration, the framework accelerates production workflows. This, in turn, speeds the time-to-market and enables them to mitigate expensive in-house product development from scratch.

3. Edge, Fog & Cloud Computing in Industry 4.0

The industrial Internet of Things (IIoT) generates a vast amount of data, propelling the adoption of edge, fog, and cloud computing in Industry 4.0. Custom hardware and software solutions such as connected clouds, distributed clouds, distributed computing and storage, and hybrid computing are shaping this trend.

Technologies like low code development platforms, microservices, mobile computing, and multi-access edge computing are advancing the integration of edge, fog, and cloud computing across various industries. This layered approach ensures efficient data handling, from immediate processing at the edge to in-depth analysis in the cloud.

Things Embedded – Industrial Edge Computing

UK startup Things Embedded specializes in industrial edge computing solutions. Its edge computer product line includes embedded box PCs, industrial PCs, rugged computers, panel PCs, single board computers, and industrial motherboards. Each product caters to specific needs in industries like military, medical, digital signage, and more, emphasizing reliability and robust performance. Additionally, the startup provides AI edge computers, including NVIDIA jetson computers, which are essential for AI-driven tasks in edge computing environments.

Cantier Systems – Cloud Computing

Cantier Systems offers Cantier MES 4.0, a cloud computing solution for industry 4.0. It integrates AI-powered capabilities with IIoT and manufacturing intelligence to enable real-time data collection and analysis. This solution enhances manufacturing operations by improving traceability, visibility, quality, and overall equipment effectiveness (OEE). Key benefits include real-time traceability, reduced cycle time, improved yield, and increased capacity.

4. Network & Connectivity

Network and connectivity are among the main driving forces in enabling Industry 4.0. Technological advancements such as edge-to-cloud, gigabit ethernet time-sensitive networks, low-power wide-area network (LPWAN), 5G, and machine-to-machine communication (M2M) are pushing factories to adopt IIoT, transforming them into Industry 4.0 facilities.

These technologies are continually enhancing communication between machines and humans, as well as data transmission. Innovations in this area are increasing speed, bolstering security and efficiency, and reducing network connectivity costs. The integration of various connectivity solutions is creating a cohesive, responsive, and adaptive industrial environment. This integration is a crucial factor in the evolution of smart factories.

Ublsoftware – Long Range Wide Area Networks (LoRaWAN)

Ublsoftware offers ResIOT, an advanced hardware and software ecosystem for LoRaWAN and LPWAN networks in industrial settings. The system integrates sensors to collect data. It is then transmitted to gateways and displayed on user-friendly dashboards. ResIOT also features secure data transmission using AES-128 encryption. By providing an efficient and scalable network solution, ResIOT enhances industrial and urban environments with advanced connectivity and data-driven insights, transforming them into smart, automated ecosystems.

Coretigo – Wireless IIoT Communication

Israeli startup Coretigo offers a wireless IIoT communication service based on the IO-Link Wireless standard. IO-link is a communication protocol that works point to point and is usually wired. The IO-Link Wireless design allows it to handle a large number of devices while maintaining low latency and high reliability. Coretigo aids in wireless communication between sensors, actuators, and controllers.

5. Advanced Robotics

Advancements in robotics make the processes in Industry 4.0 faster, more efficient, and safer. Autonomous robots, collaborative robots (cobots), humanoid robots, mobile robots, cloud robotics, APIs, pick-and-place robots, and robot swarms are among the key robotic technologies impacting manufacturing.

The use of robots enhances precision and agility, while also boosting the ability to swiftly develop customizable robots. Autonomous mobile robots (AMRs) independently navigate facilities, optimizing workflow and space utilization. This frees up the human workforce to concentrate on non-repetitive or high-value tasks.

Tutor Intelligence – AI Cobot

Tutor Intelligence is a US-based startup that makes an AI cobot for Industry 4.0. It leverages 3D AI vision to process surrounding data and automate conveyor loading, end-of-line (EoL) packing, and kitting. It does not require specific product data or 3D models.

Further, the startup follows an on-demand, leasing business model that makes the robot affordable for small and medium industrial businesses. This, in turn, improves the adoption of industry 4.0.

Sesto Robotics – Autonomous Mobile Robots

Singapore-based startup Sesto Robotics offers SESTO Element, a multi-purpose autonomous mobile robot. Autonomous robots are essential for industrial automation facilities and allow the human workforce to focus on higher-level tasks, such as factory management.

The compact mobile platform of SESTO Element is customizable with different types of top modules and is based on the nature of the tasks. The company also offers SESTO Prime, an autonomous mobile robot equipped with a 7-axis robotic arm.

Find out how 10 emerging technologies shape your industry!

6. Internet of Everything

In manufacturing, real-time connectedness forms the backbone of the Internet of Everything (IoE). This connectedness spans machine-machine, human-machine, and human-human interactions. It encompasses the Internet of Industrial Things ( IIoT), Internet of Skills, Internet of Services, Internet of Systems, and Shop Floor IoT.

The amalgamation of real-time data, machine intelligence, and human skills accelerates manufacturing processes. This results in more efficient and cost-effective operations. A unified framework for the Internet of Things (IoT) and interoperability are vital for seamless Industry 4.0 implementation. Moreover, IoE enables real-time monitoring and control of all connected assets. This leads to optimized resource utilization, further enhancing the efficiency of manufacturing processes.

Cumulus – Internet of Industrial Maintenance

Cumulus is a US-based startup developing an internet of tools-enabled operations and maintenance management platform. The platform intends to replace the time-consuming nature of paper-based planning, execution, and reporting of maintenance activity.

The use of smart connected tools, along with their platform, leads to transparent and traceable records of all maintenance operations. This helps in reducing costs associated with quality control and improving overall productivity.

Hubbox – Remote Industrial Connectivity

Turkish startup Hubbox provides a secure industrial remote connection device for manufacturing companies. Currently, machines are still connected through a complex network of wires. Hubbox enables wireless connectivity between machines by creating a shop-floor internet of things solution.

The device comes with WAN, LAN, and WiFi interfaces and makes use of secure SSL certificates and advanced encryption methods. The device is also capable of communicating with ERP and creating ad-hoc M2M networks.

7. Big Data & Analytics

In the realm of Industry 4.0, the collection of industrial data on a large scale paves the way for factories to transition into advanced facilities. The complexity of big data lies in its value, which is realized only when captured, stored, and analyzed swiftly and cost-effectively.

Technological advancements have made it possible to harness this data for insightful observations into manufacturing systems. The availability of immediate and real-time data has opened up opportunities for prescriptive and predictive analytics across various levels of a company’s manufacturing facilities. Furthermore, it empowers businesses to leverage vast amounts of information for strategic insights. These technologies meticulously process and analyze data from a variety of sources, including sensors, machines, and systems, offering a holistic view of operations and enhancing decision-making and operational efficiency.

Qsee – Predictive Analytics

Qsee is an Israeli startup developing prescriptive and predictive analytics tools for manufacturers. The software is capable of predicting product quality outcomes for every production batch and even for single products. Downtimes cause unnecessary losses to manufacturing firms in terms of both money and time.

Qsee performs root-cause analysis on manufacturing units to identify hidden contributors to low productivity and sends alerts to prevent downtime.

Curiosity – Knowledge Extraction Tools

German startup Curiosity offers software platforms for extracting knowledge from structured and unstructured data. The platform integrates with the existing data infrastructure and provides accessible knowledge for users in any industrial setting.

Data integration challenges in manufacturing companies arise due to the vast range of technical terms, documents, and abbreviations. Curiosity combines all relevant data sources into a knowledge graph that later helps in building custom tools for search and exploration.

8. Additive Manufacturing in Industry 4.0

In the quest for new technologies to meet growing market demands, manufacturers have turned to additive manufacturing. Initially a prototyping technique, it is now transforming and decentralizing production. The goal of hybrid manufacturing is to merge additive and subtractive manufacturing.

Progress in material science and techniques like stereolithography and metal 3D printing have simplified the fabrication of complex structures and components. Additive manufacturing is paving the way for highly customizable and sustainable cloud-based production. Furthermore, the integration of additive manufacturing with digital designs and simulations enhances precision and reduces time-to-market.

AMBOTS – Autonomous Additive Manufacturing

The US-based startup AMBOTS develops an autonomous additive manufacturing solution by making use of swarm robots. Digital designs are split into smaller tasks that several different types of robots perform.

Currently, the speed of additive manufacturing is limited by the size of the product. AMBOTS addresses this bottleneck by making use of a proprietary chunk-based 3D printing method.

Exaddon – Micrometer 3D Metal Printing

Exaddon is a Swiss startup providing a metal additive manufacturing system, CERES, which prints at a micrometer scale. Producing micrometer-scale components is challenging with traditional manufacturing techniques such as lithography.

CERES uses electrochemical technology for achieving micro-manufacturing, conducting the process at room temperature while also eliminating post-processing. The system prints complex metal objects in sizes ranging from 1 micrometer up to 1000 micrometers.

9. Cybersecurity, Transparency & Privacy

The interconnectedness inherent in Industry 4.0 leads to an information flow that raises concerns about security, transparency, and privacy. As manufacturing practices evolve to become more personal and customizable, data management practices both within and outside the shop floor significantly influence a company’s appeal. Secure transmission and processing of sensitive industrial data are paramount to prevent cyberattacks on critical facilities.

Emerging developments in this field include digital ethics and privacy, privacy-enhancing technologies, self-adaptive security, zero-trust security, end-to-end communication security, DevSecOps, and blockchain. Balancing the focus on cybersecurity with transparency and privacy is essential. This balance contributes to a secure, reliable, and ethical digital industrial ecosystem, a cornerstone of Industry 4.0.

Alias Robotics – Robot Immune System

Spanish startup Alias Robotics develops a robot immune system (RIS), an endpoint protection platform for robots. This solution provides malware protection to robots and robotic components. The modular architecture of RIS gives the system flexibility and adaptability and caters to a variety of robots.

The company also offers a secure data recorder for investigating cyber attacks or malfunctions in robots. The use of industrial robots in all stages of manufacturing necessitates innovations like RIS.

Adolus – Secure Software Updates

Industry 4.0 makes use of smart, connected devices sourced from multiple vendors. These devices need to be updated constantly with the latest software, firmware, and configuration files. Adolus is a Canadian startup providing a secure update process for embedded devices. Cybercriminals potentially interfere with the upgrading process and compromise industrial facilities by tricking the staff into installing infected files.

Adolus develops FACT, which solves this problem by working with equipment vendors to collect unique fingerprints of the files and compares these fingerprints with the ones received by the manufacturers. FACT gives a confidence rating during installation as well as visibility over the upgrading processes in critical systems.

10. Digital Twin

Virtual models of industrial assets are created using digital twin technology, which combines dynamic real-time sensing and visualization data. This technology has promising use cases, including model-driven design, virtual prototyping, virtual system validation, throughput optimization, and evolutionary design.

The adoption of digital twins is driving Industry 4.0 manufacturing towards hyper-automation. These digital replicas offer valuable insights into every step of the manufacturing process. Furthermore, digital twins facilitate scenario testing and process optimization without risking actual assets, thereby enhancing innovation and safety.

Geminus – Industrial Process Twin

The US-based startup Geminus develops a digital twin solution for various industrial processes. The solution allows manufacturing facilities to standardize meticulous operation and maintenance practices to optimize output. The physics-constrained AI, which drives the Gemius digital twin, provides self-optimized design and operational intelligence.

The digital twin utilizes SCADA systems to integrate with operational data, historian software, sensor gateways, and enterprise asset management tools.

Simularge – Digital Twins With Less Data

Turkish startup Simularge develops a patented approach for making digital twins without the requirement of big data. Usually, huge amounts of data are needed for making effective digital twins and ensuring minimal under-utilization of input parameters.

Simularge’s algorithms enable the quick creation of digital twins and faster adaptation as they identify and monitor for changes in the raw materials of the production process.

Discover all Industry 4.0 Technologies & Startups

Rapid advancements in emerging technologies such as the industrial internet of things (IIoT), mobile robots, additive manufacturing, industrial connectivity, and AI-enabled solutions advance industrial automation. The trends in Industry 4.0 & startups outlined in this report only scratch the surface of trends that we identified during our in-depth research. Among others, volumetric displays, blockchain, and cloud computing technologies will transform the sector as we know it today. Identifying new opportunities and emerging technologies to implement into your business early on goes a long way in gaining a competitive advantage. Get in touch to easily and exhaustively scout relevant technologies & startups that matter to you.

WATCH THE VIDEO VERSION

WATCH THE VIDEO VERSION

![Future of Robotics: 12 Trends Powering the Next Wave [2025-2030]](https://www.startus-insights.com/wp-content/uploads/2025/06/Future-of-Robotics-SharedImg-StartUs-Insights-noresize-420x236.webp)