Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

Our Innovation Analysts recently looked into emerging technologies and up-and-coming startups working on solutions for the manufacturing sector. As there is a large number of startups working on a wide variety of solutions, we want to share our insights with you. This time, we are taking a look at 5 promising robotics startups.

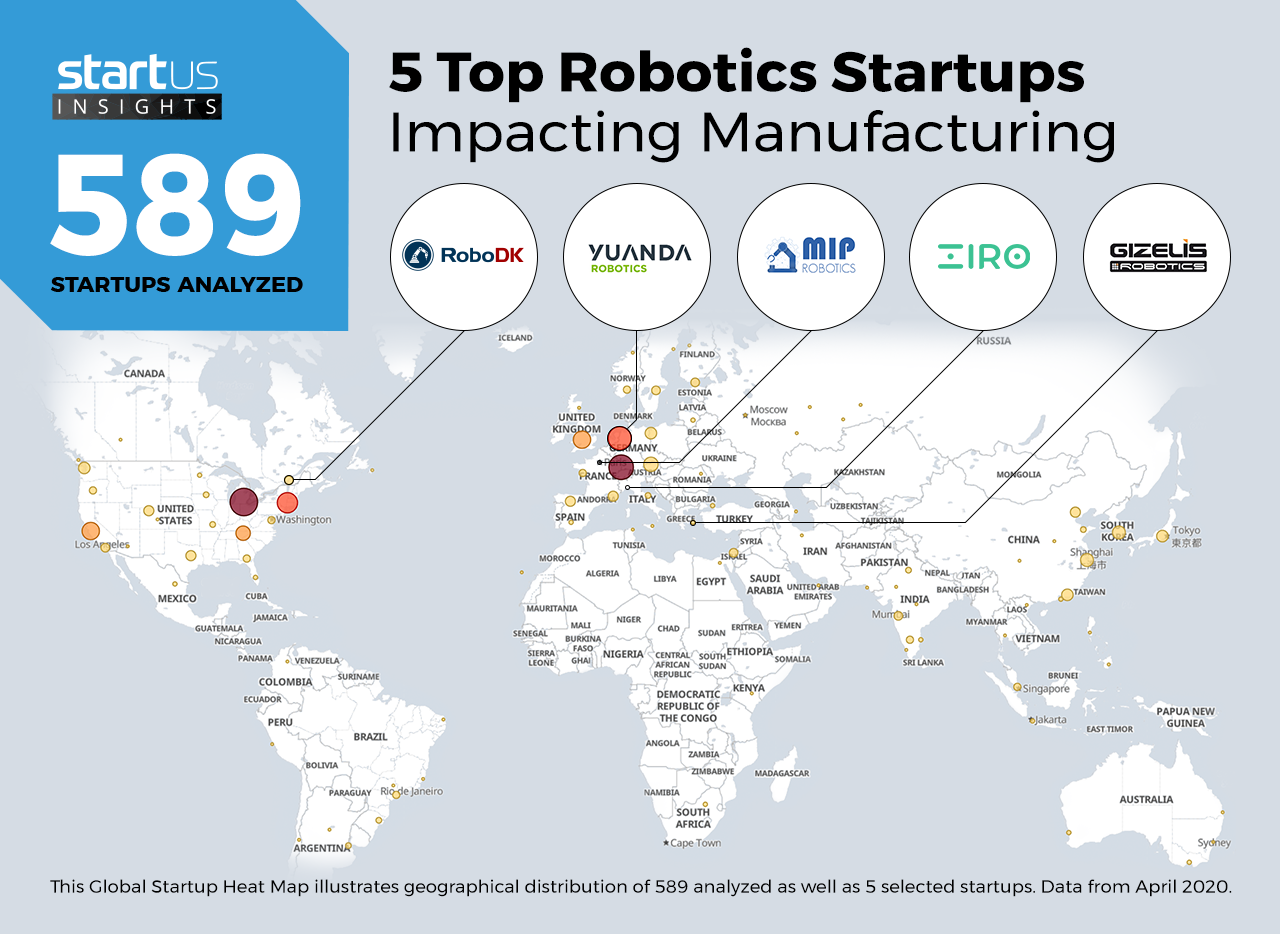

Heat Map: 5 Top Robotics Startups

Using our StartUs Insights Platform, covering 1.116.000+ startups & emerging companies, we looked at innovation in the field of robotics in manufacturing. For this research, we identified 589 relevant solutions and picked 5 to showcase below. These companies were chosen based on a data-driven startup scouting approach, taking into account factors such as location, founding year, and technology among others. Depending on your specific criteria, the top picks might look entirely different.

The Global Startup Heat Map below highlights 5 startups & emerging companies developing robotics solutions. Moreover, the Heat Map reveals regions that observe a high startup activity and illustrates the geographic distribution of all 589 companies we analyzed for this specific topic.

HIRO Robotics – Vision Guidance Systems

Traditional robots follow specific patterns and sequences, limiting the flexibility of industrial manufacturing processes. Vision guidance systems enable robots to gather accurate information, such as position, size, shape, and more in real-time. This allows robots to adjust to the processes and deliver the required results while also reducing the need for manual intervention in the manufacturing process.

Italian startup HIRO Robotics develops HIRO VS4, a vision guidance system for industrial arms. Using this system, the startup focuses on gathering video stream data rather than images and using high-frequency commands to re-calibrate the arm, thereby achieving a higher level of accuracy and efficiency. Technology-wise, the robots combine advanced analytics, the Internet of Things (IoT), and cloud computing to provide precise results.

RoboDK – Simulation

Industrial robots need careful testing and calibration regularly to function accurately and efficiently. This is a tedious process that usually leads to production downtime. Through simulation of the installation, manufacturing facilities obtain the opportunity to perform calibration and testing virtually – away from the production floor, thereby saving valuable production time and effort.

Canadian startup RoboDK creates a simulator for industrial robots and robot programming. The startup’s solution lets users program their robots and simulate the process from their computer outside the production environment and save setup time and cost. This provides organizations with the freedom to test additional applications of robots without compromising on production time and accuracy.

MIP Robotics – Research & Development (R&D) Testing

One of the standard steps in the manufacturing process is to test and measure the quality of the product through repetitive and extensive research and development. When executed by robots, these tests generally run over a longer duration and capture data accurately. This allows scientists to focus on high-value innovation rather than menial testing tasks.

MIP Robotics is a French startup that builds easy-to-use industrial robots. The startup develops Junior 300, a robotic arm that works alongside humans in R&D testing, focusing on machine loading and product endurance testing. Junior 300 is suited for small structures and possesses a high degree of customization to meet various industrial and testing needs.

Gizelis Robotics – Robot Welding

Welding on an industrial scale involves high temperatures, radiation exposure, and gas emissions that are detrimental to the health of the workers. Robots function in these extreme conditions with ease without any reduction of quality. The robots also adjust parameters, thereby providing flexibility to handle different materials and operations.

Greece-based startup Gizelis Robotics works on robots for industrial welding. Roboweld, one of their products, is suitable for metal inert gas (MIG) and metal active gas (MAG) welding. The compactness of the robot and its flexible arm enables high precision and increases productivity. Moreover, it reduces the risk involved for humans, letting the robot bear the harsh conditions, and allows workers to focus on improving the output.

Yuanda Robotics – Collaborative Robotics (Cobots)

Cobots work alongside human workers and assist them in assembling, picking, placing, and other manufacturing operations. Also, they help reduce the physical burden of the process, lower stress, and increase productivity. Collaborative robots are amenable to repurposing and reprogramming, which makes them cost-effective as well.

Yuanda Robotics is a German startup that builds robotic arms that work seamlessly with humans in the manufacturing environment. The startup’s cobot is suitable for precision applications and easily integrates into the production process. An intelligent camera system and sensors in all axes make it accurate and secure to carry out functions in assembly, quality control, and machine tending.

What About The Other 584 Solutions?

While we believe data is key to creating insights it can be easy to be overwhelmed by it. Our ambition is to create a comprehensive overview and provide actionable innovation intelligence so you can achieve your goals faster. The 5 robotics startups showcased above are promising examples out of 589 we analyzed for this article. To identify the most relevant solutions based on your specific criteria, get in touch.