Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

We’ve published a brand-new, data-rich report on the Latest Material Industry Trends.

Read the Updated 2025 Material Industry Trend Report!

Advancements in Industry 4.0 and evolving demands in energy, automotive, logistics, manufacturing, and construction drive the need for innovative materials. Trends include sustainable solutions, lightweight materials, 3D printing, surface engineering, smart materials, nano-formulations, and advanced composites. AI, ML, and data management speed up material development and reduces market entry time from decades to years.

This article was last updated in January 2025.

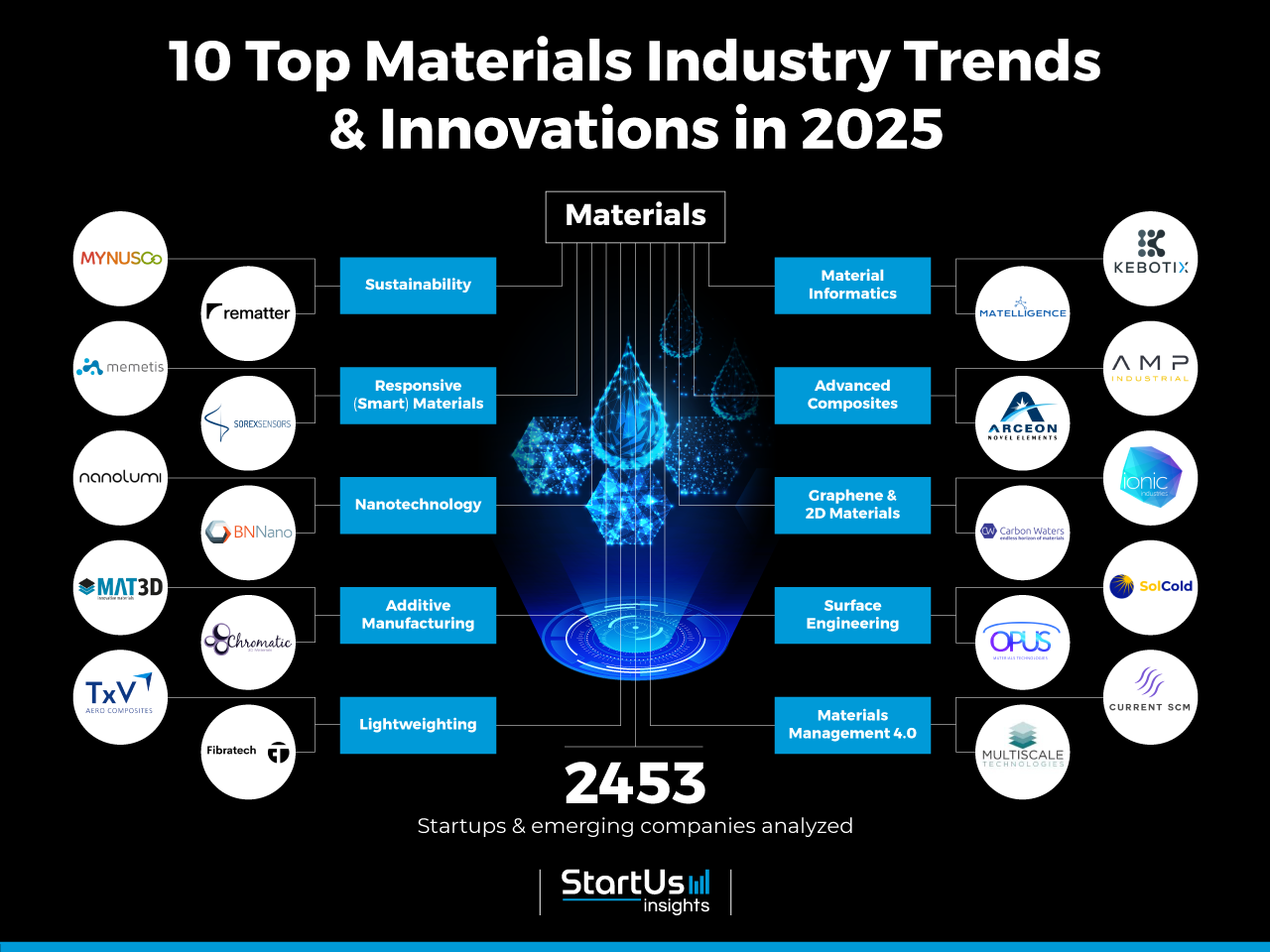

Innovation Map outlines the Top 10 Materials Trends & 20 Promising Startups

For this in-depth research on the Top Material Trends & Startups, we analyzed a sample of 2453 global startups & scaleups. This data-driven research provides innovation intelligence that helps you improve strategic decision-making by giving you an overview of emerging technologies in the materials industry. In the Material Industry Innovation Map, you get a comprehensive overview of the innovation trends & startups that impact your company.

What are the Trends in the Materials Industry (2025)?

- Sustainable Materials

- Smart & Responsive Materials

- Nanotechnology

- Additive Manufacturing

- Lightweighting

- Material Informatics

- Advanced Composites

- Graphene & 2D Materials

- Surface Engineering

- Materials Management 4.0

Want to explore all Materials innovations & trends?

These insights are derived by working with our Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 4.7M+ startups & scaleups globally. As the world’s largest resource for data on emerging companies, the SaaS platform enables you to identify relevant technologies and industry trends quickly & exhaustively.

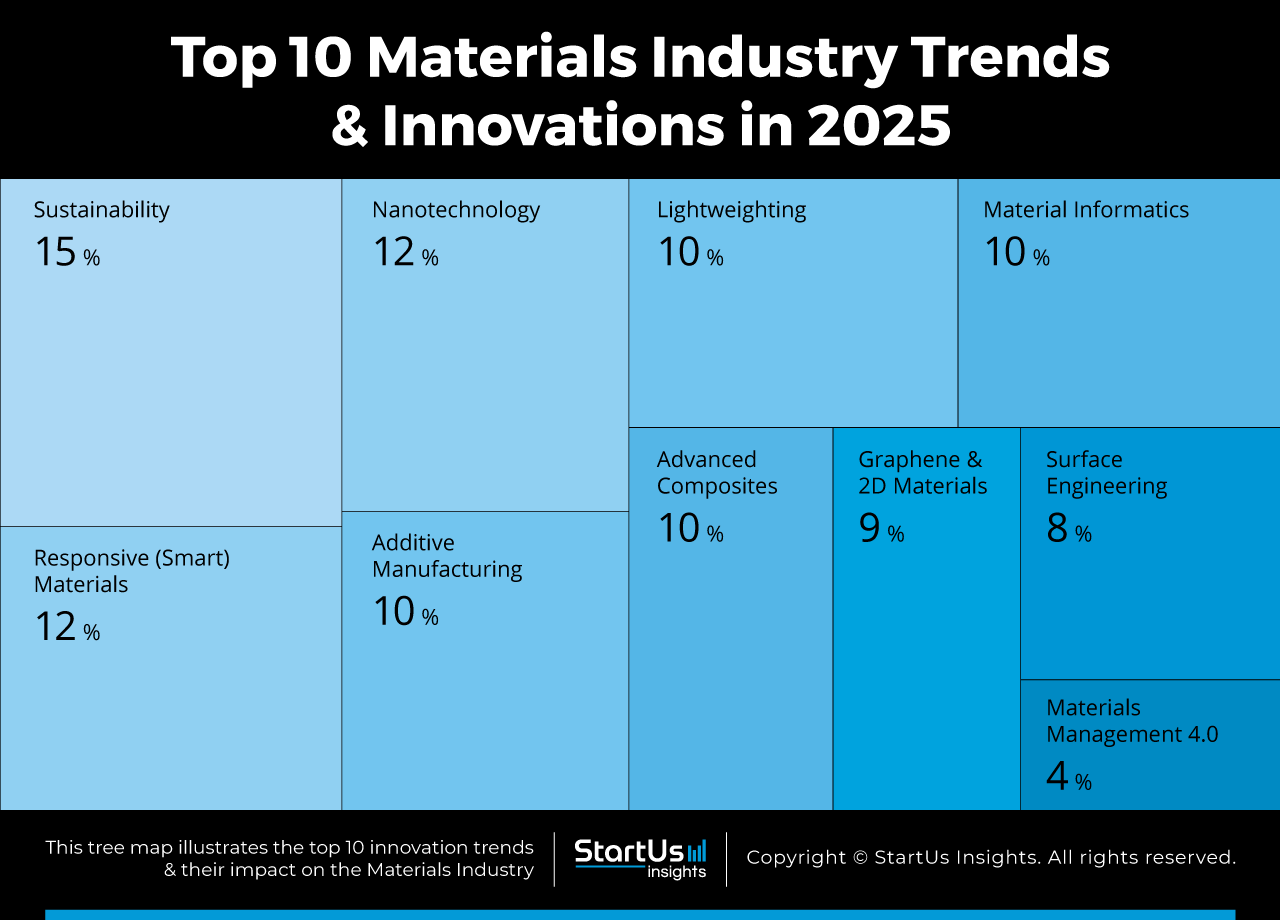

Tree Map reveals the Impact of the Top 10 Materials Industry Trends

Based on the Materials Innovation Map, the Tree Map below illustrates the impact of the Top 10 advanced materials technologies in 2025. Startups now develop sustainable, responsive, and smart materials that also offer improved physical properties.

For example, biodegradable plastics, thermally adaptive fabric, and flexible displays. Novel formulations, including nanomaterials and biomaterials, impart new functionalities to existing materials while expanding the scope of innovation.

Additive manufacturing, advanced composites, and 2D materials also lead to the development of various lightweight materials. Along with materials informatics and management, surface engineering impacts several industries from energy, automotive, and construction, to biotechnology, healthcare, and textiles.

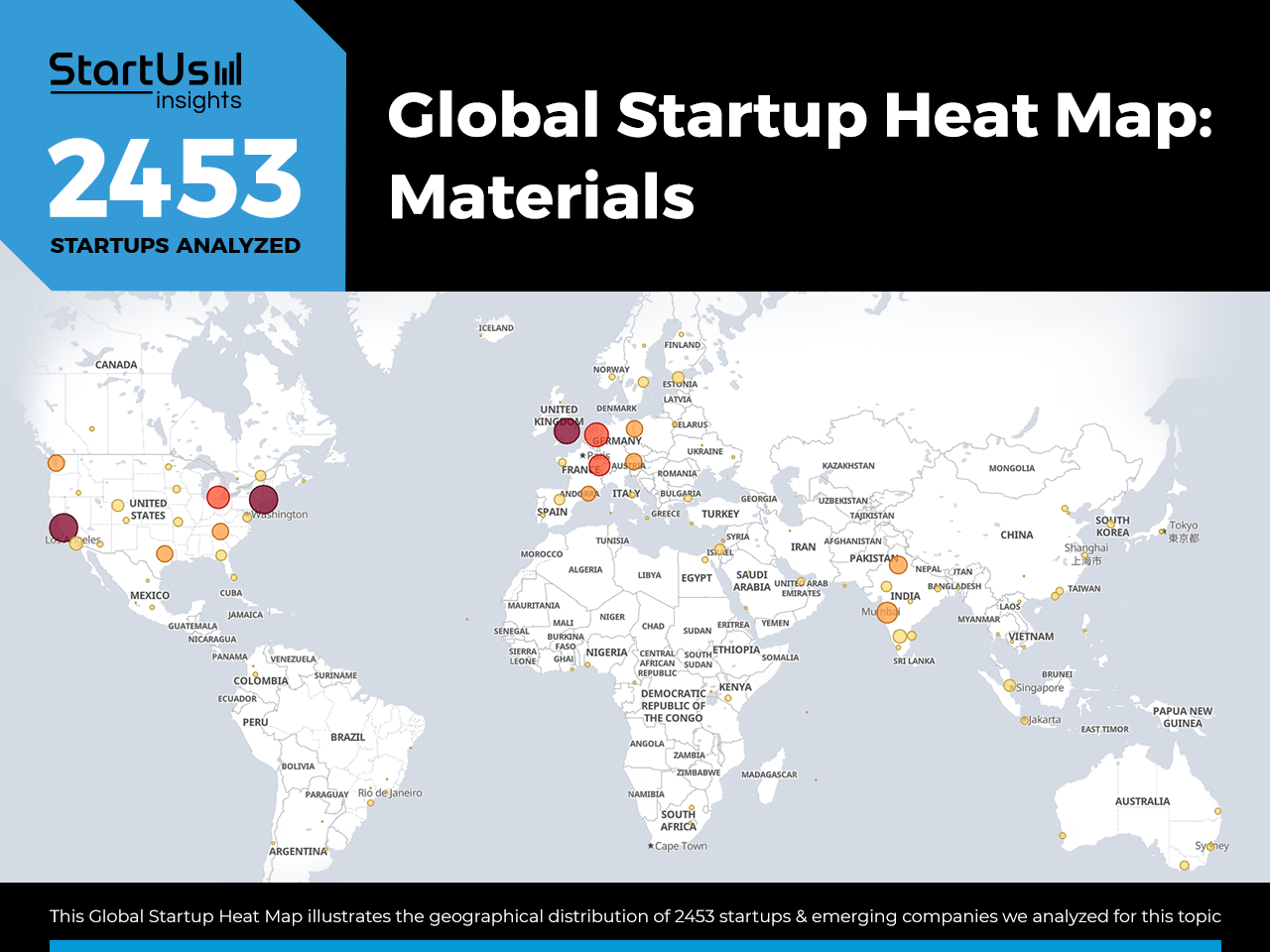

Global Startup Heat Map covers 2453 Materials Startups & Scaleups

The Global Startup Heat Map below highlights the global distribution of the 2453 exemplary startups & scaleups that we analyzed for this research. Created through the StartUs Insights Discovery Platform, the Heat Map reveals that Europe & the US are home to most of these companies while we also observe increased activity in South-East Asia, Australia as well India.

Below, you get to meet 20 out of these 2453 promising startups & scaleups as well as the solutions they develop. These 20 startups were hand-picked based on criteria such as founding year, location, funding raised, and more. Depending on your specific needs, your top picks might look entirely different.

Top 10 Materials Industry Trends in 2025

1. Sustainable Materials

The substantial waste generated during the use and production of materials has led governments to implement various environmental regulations. Industries across the board, including construction, automotive, packaging, and manufacturing, are reevaluating their processes in terms of material lifecycle.

To reduce their carbon footprint, these sectors are increasingly adopting sustainable materials, aiming to decrease the planet’s waste burden. Sustainable materials not only support circular systems but also facilitate the implementation of a circular economy.

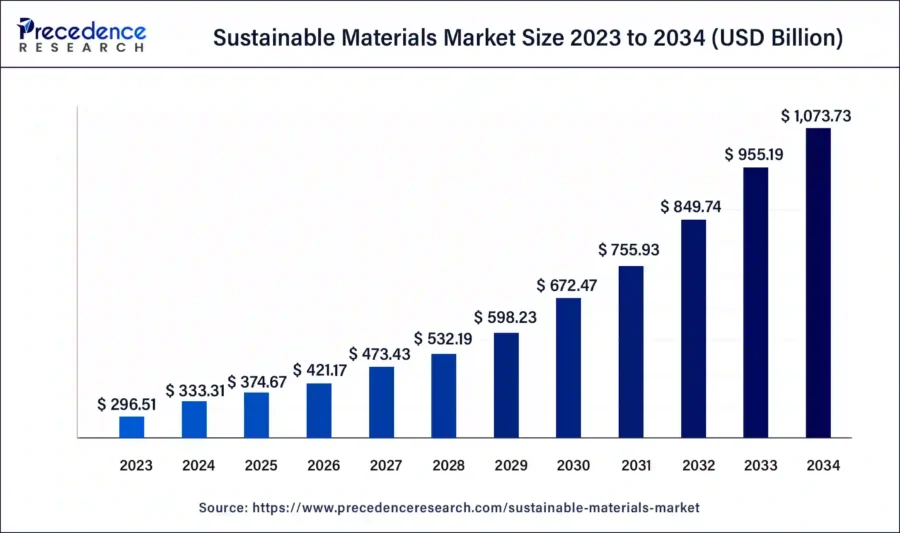

Also, the global sustainable materials market is valued at approximately USD 333.31 billion in 2024 and is expected to grow to around USD 1073.73 billion by 2034, with a CAGR of 12.41% from 2024 to 2034.

Source: Precedence Research

MYNUSCo produces Biocompound Materials

Indian material technology startup MYNUSCo intends to assist the automotive, logistics, packaging, hospitality, and consumer goods industries with their sustainability objectives. The startup produces biodegradable and recyclable compounds based on agricultural waste and renewable resources.

Its products contribute to conserving natural deposits and forests while also ensuring scalability and adaptability for existing manufacturing processes.

Rematter makes Sustainable Floor Slabs

Rematter is a Swiss startup that manufactures sustainable floor slabs. They are constructed from a frame of solid timber beams with rammed earth infills and the connections are dry-joined or screwed. This allows for easy disassembly and re-use of components.

The slab material also features high mechanical characteristics like fire resistance and enhanced strength as well as has a lower carbon footprint. Rematter’s slabs enable builders to make sustainable buildings and ensure efficient material recovery at the end of life.

2. Responsive & Smart Materials

To meet specific industrial use case requirements, novel materials under development are being tailored with application-specific characteristics. Advances in materials science are enabling the creation of smart materials with programmable properties that react to external stimuli.

Startups are designing materials and products with diverse qualities, including thermo-, electro-, and photo-chromism, piezoelectricity, shape memory, self-healing, and phase-change attributes.

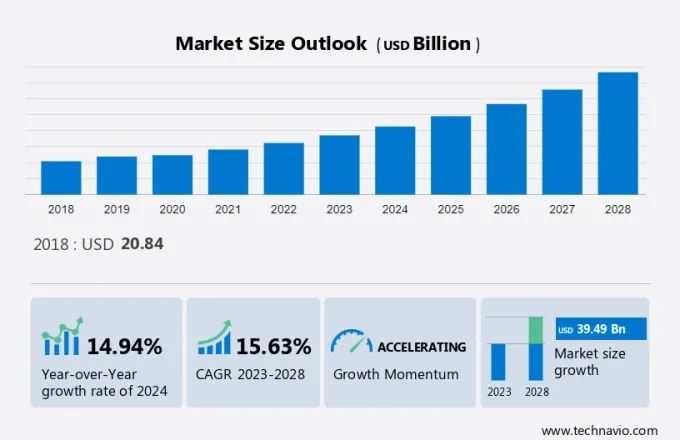

The piezoelectric smart materials market, a segment of this field, is estimated to grow at a CAGR of 15.63% between 2024 and 2028, with the market size forecasted to increase by USD 39.49 billion, highlighting the rapid advancement and growing demand for smart materials.

Source: Technavio

Memetis offers High-Performace Actuators

German startup Memetis creates ultra-compact miniature actuators based on shape memory alloys. The startup enables a memory effect in its materials, which also sustain extreme deformations, and later revert to their original shape.

Its property supports the performance of the actuators even in small or dense installation spaces. Memetis offers solutions for consumer electronics, telecommunications, optical technology, mobility, and industry 4.0.

Sorex Sensors develops Film Bulk Acoustic Resonator (FBAR) Technology

Sorex Sensors is a UK-based startup developing high-sensitivity micro-electromechanical system (MEMS) sensors on silicon wafers using a thin-film piezoelectric material. The startup utilizes FBAR technology to create a piezoelectric effect.

The piezoelectric effect enables the startup to accurately detect temperature and mass changes on a femtogram scale. This allows small-scale devices with low-power requirements to respond to external stimuli. Some use cases of this solution include thin-film metrology as well as gas and particulate monitoring.

3. Nanotechnology

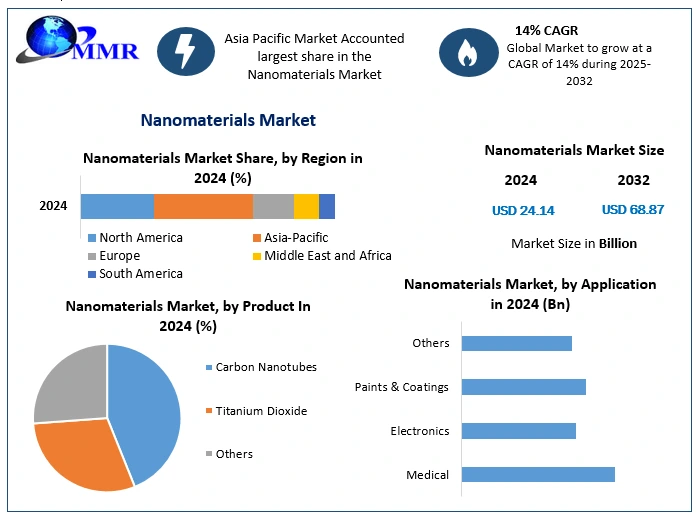

Nanotechnology advancements reveal that materials at the nanoscale exhibit different characteristics from their bulk counterparts. The global nanomaterials market, valued at USD 22.6 billion in 2024, is expected to grow at a CAGR of 14.3% from 2025 to 2035, reaching an estimated USD 98.3 billion by 2035.

The emergence of nanofibers, nanotubes, allotropes, quantum dots, and other nanomaterials offers immense potential for value addition.

Source: Maximize Market Research

These nanomaterials enhance the performance of industrial products at an atomic level. Companies, especially in electronics, energy, mobility, and manufacturing, are leveraging nanomaterials to maintain a competitive edge.

Nanolumi makes Perovskite Nanocrystals

Singaporean material technology startup Nanolumi intends to overcome the weaknesses of QD technology for electronic displays with its reliable and safe perovskite nanocrystals. The startup combines cadmium-free origin, broad light spectrum coverage, purer color performance, and high-volume mass-production suitability.

BNNano provides Enhanced Boron Nitride Nanotubes

The US-based startup BNNano manufactures boron nitride nanotubes with superhydrophobic, high electrical insulation as well as high thermal and mechanical stability characteristics. The startup offers its nanomaterial as powders, master alloys, masterbatches, and custom mixes.

It finds applications in the aerospace, automotive, defense, and textile industries as well as for radiation protection and thermal management.

4. Additive Manufacturing

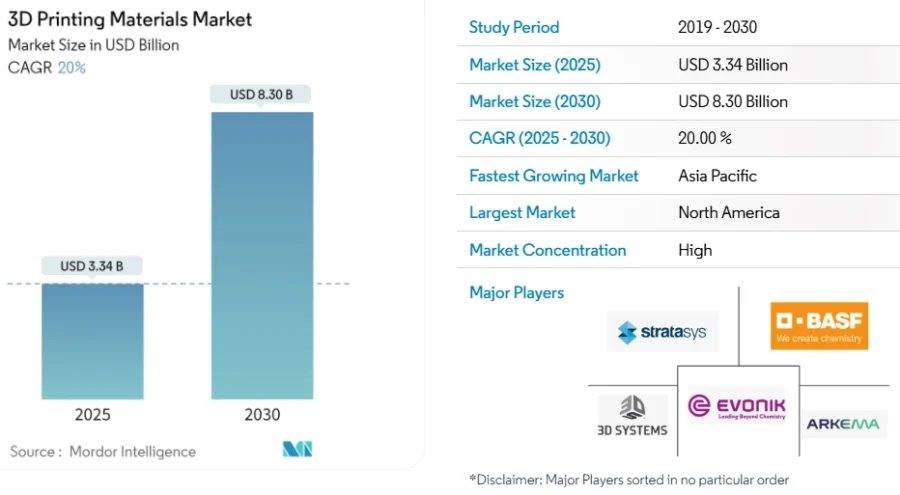

Emerging additive manufacturing facilities are evolving beyond traditional thermoplastics, focusing on materials that offer greater flexibility, customization, functionality, and produce less waste. The advancement of 3D printing technologies is driving improvements in metals, alloys, ceramics, fibers, and their compounds.

3D printing is also fostering the development of new, durable polymer filaments with enhanced conductance, melting, and chemical resistance properties. The 3D printing materials market is expected to reach USD 6.92 billion by 2029. This growth reflects the increasing demand for innovative materials in additive manufacturing.

Source: Mordor Intelligence

MAT3D offers Composite Polymeric Materials

Italian startup MAT3D is developing new polymeric materials for additive manufacturing that offer strengthened functional attributes. The startup’s materials replace high-performance plastics for metal 3D printing. Its solutions also include a variety of resins with increased electrical, magnetic, anti-bacterial, and thermo-mechanical properties for industrial markets.

Chromatic 3D Materials manufactures 3D Printed Polyurethanes

US-based startup Chromatic 3D Materials produces a set of durable high-performance polyurethane elastomers for 3D printing, which are simultaneously adaptable and resilient. The startup offers a great degree of customization and compatibility with additives while also ensuring the quality of the final products. Chromatic 3D Materials’ products cater to the automotive, manufacturing, and consumer goods markets, among others.

5. Lightweighting

Industries ranging from aerospace to mobility are seeking innovative ways to reduce excess weight, thereby enhancing fuel efficiency and handling. This has led to research into materials like aluminum, magnesium, titanium, high-strength plastics, and carbon fiber. These materials allow industries to lessen the environmental and operational impacts of heavier parts.

Additionally, lightweighting innovations in materials provide safety and reliability levels comparable to heavier alternatives. The global lightweight materials market size is expected to be valued at USD 276.4 billion by 2030 at a CAGR of 8.3% during the forecast period (2023-2030).

TxV Aero advances Aerospace Composites Manufacturing

The US-based startup TxV Aero designs and engineers custom laminate materials and finished composite parts for applications in commercial aerospace. Using advanced technology, the startup fabricates lightweight thermoplastic assemblies with tailored features, including ply orientation, pad-ups, near-net shapes, and more. Further, TxV Aero works on retrofit aerospace applications to increase overall productivity.

Fibratech makes Composite Automotive Wheels

Polish startup Fibratech intends to overcome the lightweighting and performance limitations of aluminum in the mobility sector. It develops hybrid composite-metallic wheels for vehicles, augmented with carbon fiber. Fibratech’s material attains general mass reduction, stiffness increase, and design customization, compared to widely used forged aluminum wheels.

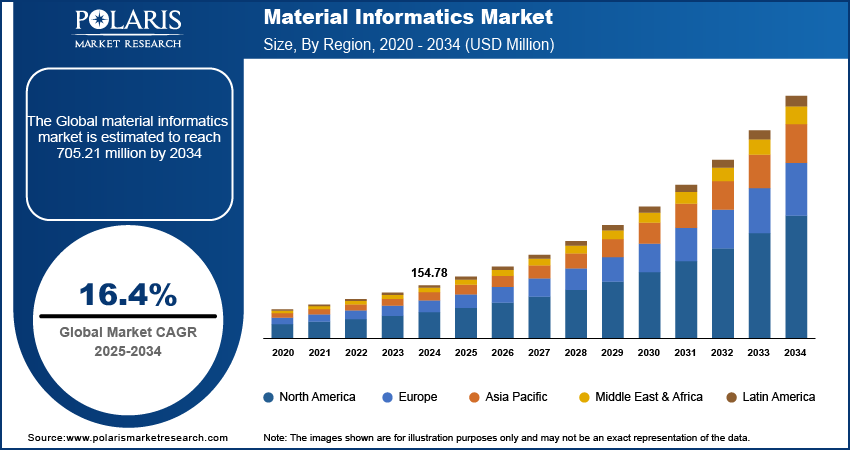

6. Material Informatics

Large companies today are adopting a data-driven approach to materials, utilizing informatics, computational techniques, and machine learning (ML), and artificial intelligence (AI). This approach enables them to systematically organize and model materials data.

The material informatics market, valued at USD 154.78 million in 2024, is expected to grow from USD 179.92 million in 2025 to USD 705.21 million by 2034, with a CAGR of 16.4% during 2025–2034.

Source: Polaris Market Research

Material Informatics not only optimizes the extraction of scientific insights from complex materials data but also accelerates research and development (R&D) timelines, saving time and labor.

Kebotix provides a Self-Driving Material Discovery Lab

The US-based startup Kebotix develops a self-driving laboratory solution for materials research to accelerate new materials exploration. The startup leverages big data, AI-based decision-making, dedicated robotics, and a convenient interface to streamline cycles for scientists.

Kebotix is particularly interested in tackling challenges in sustainability, public health, and hazardous industrial substances.

Matelligence enables AI-based Materials Screening

Canadian startup Matelligence provides material science experts with data-driven tools for materials discovery. Its solution comprises computational techniques with patented AI algorithms to lower the number of required scientific experiments and expedite screening procedures.

Matellligence’s platform primarily targets clean energy, electronics, and manufacturing, among other sectors.

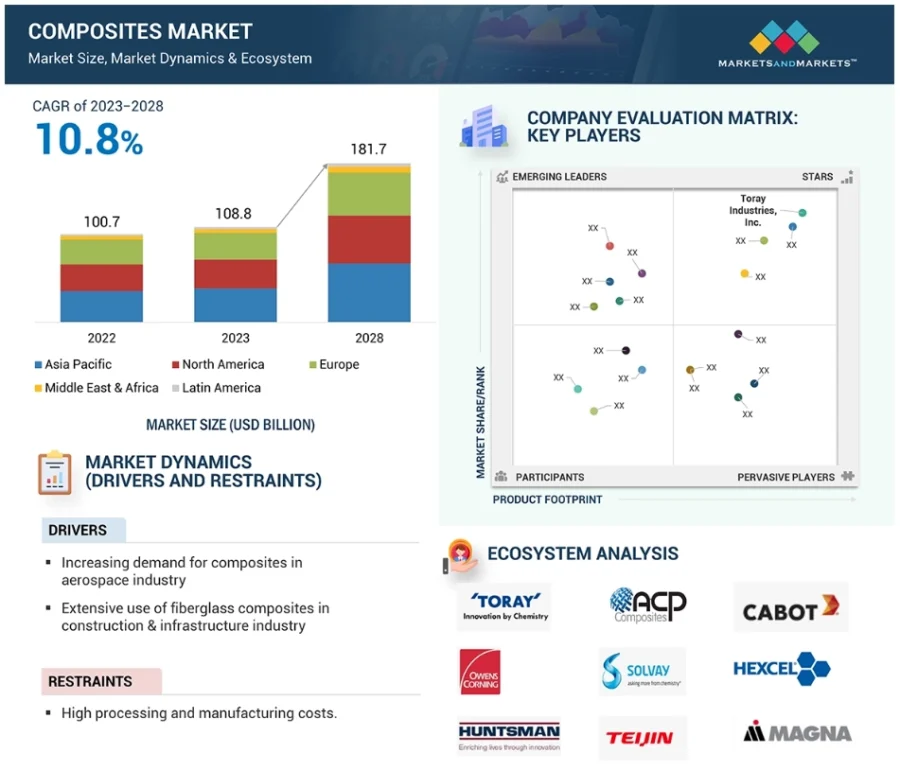

7. Advanced Composites

Advanced composites, a significant trend in the materials industry, are engineered materials made from two or more constituent materials with significantly different physical or chemical properties. These composite solutions are known for their exceptional strength-to-weight ratio, corrosion resistance, and durability.

Key benefits include enhanced performance, longevity, and lightweight properties, leading to energy efficiency and reduced environmental impact. They find extensive applications across various industries – aerospace for aircraft components, automotive for lightweight and fuel-efficient vehicles, construction for durable structures, and more.

Advanced composites’ adaptability and superior properties make them a pivotal material choice in modern engineering and design. The global composites market is projected to reach USD 168.6 billion by 2027, growing at a CAGR of 8.2% from 2022 to 2027.

Source: Markets and Markets

AMP Industrial offers Continuous-Fiber Composites For Propellers

The US-based startup AMP Industrial fabricates advanced composites for unmanned aerial systems (UAS). The startup leverages unidirectional continuous fiber-reinforced thermoplastics (CFR-TP) to make its composites. They feature a high strength-to-weight ratio and material toughness, as well as support customizable materials design for high-performance applications.

ARCEON creates High-Temperature Resistant Composites (HTRC)

Dutch startup ARCEON creates innovative high-temperature resistant composites for satellites, rockets, and engine parts. Its products withstand temperatures exceeding 1000 degrees Celsius, retain a low coefficient of thermal expansion, contain lightweight materials, and also reinforce mechanical robustness and durability.

8. Graphene & 2D Materials

Advancements in nanotechnology have enabled materials science companies to develop pathways for two-dimensional (2D) materials. These materials, known for their excellent thermal conductivity and mechanical strength, enhance the capabilities of various industrial applications.

While most 2D materials like germanene, silicene, stanene, and phosphorene are still in the research phase, graphene stands out as the first successfully commercialized 2D material. Graphene offers improved tensile strength, intra-sheet bonding, surface durability, electron mobility, flexibility, and thermal resistance.

It finds applications in several industries, including electronic displays, supercapacitors, automotive, construction paints, and plastics manufacturing. Moreover, the global graphene market, estimated at USD 268.9 million in 2023, is expected to grow to USD 2.7 billion by 2030, with a CAGR of 38.9% from 2023 to 2030.

Ionic Industries makes Graphene Materials

Australian startup Ionic Industries aspires to bridge the gap between graphene research and developing its commercial applications. The startup incorporates expertise and patented processes of graphene and graphene oxide manufacturing. Ionic Industries specializes in graphene additives for water treatment and nanofiltration, as well as for energy storage.

Carbon Waters offers Graphene Dispersions

French startup Carbon Waters focuses on liquid graphene applications for a diverse range of markets. The startup’s graphene dispersions provide barrier coatings, lubrication, and anti-corrosion properties for industrial surfaces and mechanisms.

Specific additives are developed for improving mechanical resistance of composites materials and optimizing curing processes. In addition, the solution improves thermal management for electronics and semiconductors as well as electrical conductivity for manufacturing and consumer devices.

9. Surface Engineering

Industrial surfaces, constantly subjected to wear and tear, corrosion, UV radiation, and other detrimental elements, necessitate coatings that provide enhanced durability. Such coatings are crucial for safeguarding assets in the automotive, industrial, agricultural, marine, and manufacturing sectors, and they play a key role in boosting productivity.

The surface vision and inspection market, valued at USD 25.46 billion in 2023, is expected to reach USD 27.70 billion in 2024 and grow at a CAGR of 8.89%, reaching USD 46.22 billion by 2030.

Additionally, advancements in engineering have enabled the development of surfaces with hydrophobic, omniphobic, self-cleaning, and smoothing properties. In the wake of the COVID-19 pandemic, surface engineers are intensifying their efforts to perfect antimicrobial coatings, aiming to provide more robust protection across both industrial and non-industrial environments.

SolCold develops Anti-Stokes Fluorescence Technology

Israeli startup SolCold develops a surface modification solution based on a nano filter and an active cooling paint. Using anti-stokes fluorescence technology, the startup transforms heat and radiation from the sun into a low-cost cooling system.

The startup’s technology creates a reverse relationship between solar activity and heat transfer. This solution caters to the transportation, construction, agriculture, and textile industries.

OPUS Materials offers Bespoke Material Technology

UK-based startup OPUS Materials engineers innovative anti-soiling and self-cleaning coatings for the aerospace, mobility, marine, and renewable energy industries. The startup’s solution improves fuel consumption and airflow, reduces corrosion, and optimizes material efficiency.

Additionally, OPUS Materials allows for creating coating materials by design and also supports the establishment of corresponding supply chains.

10. Materials Management 4.0

Industry 4.0 is driving the adoption of its methodologies in the management, handling, and processing of materials. This encompasses everything from autonomous mining and sophisticated automated fabrication to robotic handling and cloud computing.

Consequently, this leads to swift digitization and interconnection within the materials sector. The creation of new materials is occurring alongside their integration into the latest industrial technologies of the fourth industrial revolution.

Current SCM makes Material Management Software

Current SCM is a Canadian startup that develops material management software. It allows businesses to create virtual warehouses to easily store and track materials as well as leverage real-time inventory data. It also enables procurement teams to identify over and under scenarios and split orders based on current demand.

The startup’s software thus centralizes materials management by combining materials allocation, inventory tracking, material release and receiving, and grouping. This saves time and increases efficiency for industries like construction, energy, and agriculture.

Multiscale Technologies enables AI-powered Materials Innovation

Multiscale Technologies is a US-based startup that advances AI-powered materials innovation. The startup’s platform combines generative AI and a proprietary knowledge system for inverse materials design. This way, it enables high-throughput measurements with tiny samples.

The platform thus enables material manufacturers and researchers to reduce time to market, maximize cost savings, increase quality control, and enhance quality assurance. This way, it accelerates material design and optimizes manufacturing.

Discover all Materials Technologies & Startups

Swift progress in materials science is speeding up research and experimentation, improving the sustainability, lightweighting, nanomolecular, and programmable features of materials. Consequently, industries such as aerospace, automotive, manufacturing, energy, and packaging that quickly embrace these material trends are benefiting from these emerging innovations. Recognizing the advancements in materials innovations is crucial, given the extensive applications of new materials in industrial, commercial, and even household products.

The Materials Industry Trends & Startups outlined in this report only scratch the surface of trends that we identified during our in-depth research. Among others, sustainable and smart materials will transform the sector as we know it today. Identifying new opportunities and emerging technologies to implement into your business early on goes a long way in gaining a competitive advantage. Get in touch to easily and exhaustively scout relevant technologies & startups that matter to you.

WATCH THE VIDEO VERSION

WATCH THE VIDEO VERSION

![10 Top Startups Advancing Machine Learning for Materials Science [2025]](https://www.startus-insights.com/wp-content/uploads/2025/06/Machine-Learning-for-Materials-Science-SharedImg-StartUs-Insights-noresize-420x236.webp)

![10 Emerging AI Solutions for Material Science [2025]](https://www.startus-insights.com/wp-content/uploads/2025/06/AI-Solutions-for-Material-Science-SharedImg-StartUs-Insights-noresize-420x236.webp)