Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

Textile industry trends are driven by sustainability and digital transformation in the global fashion and manufacturing landscape. Adapting to shifting consumer values and technological advances, the industry is embracing smart textiles, circular production models, AI-powered design tools, and more.

Amid this evolution, the global textile industry market is predicted to increase from USD 2.12 trillion in 2025 to USD 4.01 trillion by 2034, expanding at a compound annual growth rate (CAGR) of 7.35% from 2025 to 2034. This trend report highlights the key innovations redefining the future of textiles and shows how you can apply these solutions to stay ahead in a competitive market.

What are the Top 10 Textile Industry Trends in 2025?

- Sustainable Fabrics

- Textile Recycling & Upcycling

- Customization & Personalization

- Artificial Intelligence (AI) & Data Analytics Integration

- Functional & Technical Textiles

- Artisanal & Heritage Fabrics

- Novel Dyeing & Printing Techniques

- Textile Production Automation

- Smart Textiles

- Supply Chain Transparency

Methodology: How We Created the Textile Industry Trend Report

For our trend reports, we leverage our proprietary StartUs Insights Discovery Platform, covering 7M+ global startups, 20K technologies & trends plus 150M+ patents, news articles, and market reports.

Creating a report involves approximately 40 hours of analysis. We evaluate our own startup data and complement these insights with external research, including industry reports, news articles, and market analyses. This process enables us to identify the most impactful and innovative trends in the textile sector.

For each trend, we select two exemplary startups that meet the following criteria:

- Relevance: Their product, technology, or solution aligns with the trend.

- Founding Year: Established between 2020 and 2025.

- Company Size: A maximum of 200 employees.

- Location: Specific geographic considerations.

This approach ensures our reports provide reliable, actionable insights into the textile innovation ecosystem while highlighting startups driving technological advancements in the industry.

Innovation Map outlines the Top 10 Textile Industry Trends & 20 Promising Startups

For this in-depth research on the Top Textile Industry Trends & Startups, we analyzed a sample of 10 875 global startups & scaleups. The Textile Industry Innovation Map created from this data-driven research, helps you improve strategic decision-making by giving you a comprehensive overview of the textile industry trends & startups that impact your company.

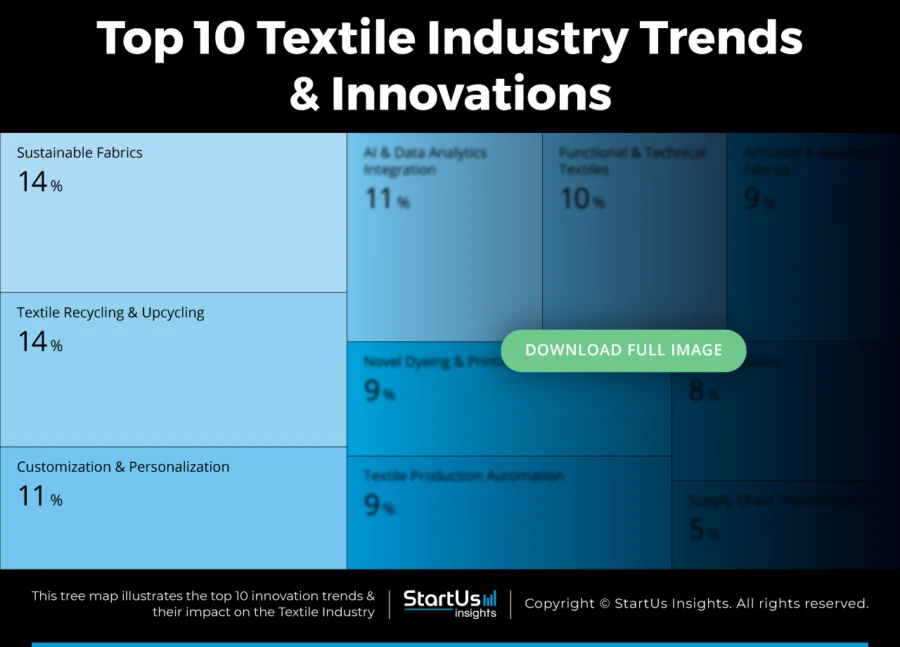

Tree Map reveals the Impact of the Top 10 Trends in the Textile Industry

The Textile Industry Tree Map highlights the Top 10 Textile Trends shaping 2025. These include plant-based materials, glass fiber textiles, digital traceability, small-batch upcycling, and industrial-scale sorting and recycling.

The industry also adopts performance tracking systems, AI-powered real-time analytics, high-performance engineered textiles, antimicrobial fabric, and more. These trends reflect how the industry leverages technologies to redefine sustainability, efficiency, and customer engagement.

Global Startup Heat Map covers 10 875 Textile Startups & Scaleups

The Global Startup Heat Map showcases the distribution of 10 875 exemplary startups and scaleups analyzed using the StartUs Insights Discovery Platform. It highlights high startup activity in India and the US, followed by France and Turkey. From these, 20 promising startups are featured below, selected based on factors like founding year, location, and funding.

Want to Explore Textile Innovations & Trends?

Top 10 Emerging Textile Industry Trends [2025 and Beyond]

1. Sustainable Fabrics

The fashion industry emits about 10% of global carbon dioxide and generates 20% of industrial wastewater pollution. Annually, 92 million tons of garments are discarded into landfills. Sustainable fabrics, such as organic cotton, hemp, and lyocell, reduce reliance on petroleum-based synthetics to reduce the carbon footprint.

Additionally, modern consumers choose brands that offer transparency and practice ethical sourcing. For example, Nairobi Fashion Week highlights designers who upcycle secondhand textiles. Their work promotes sustainable fashion and celebrates African heritage.

This growing demand for eco-conscious fashion is expanding the sustainable fabric market.

Presently, the market is valued at USD 36 billion in 2025 and is projected to reach USD 161.63 billion by 2037. The market grows at a CAGR of 13%. This sustainable fabric market growth presents economic opportunities for brands investing in sustainable materials.

Source: Research Nester

Biotechnology innovations enable textile manufacturers to develop fibers from renewable resources such as algae, mushrooms, and agricultural waste. For example, Bloom Labs recycles protein-based fibers, like wool and silk, into polyester-like materials. This reduces reliance on virgin materials.

Moreover, recycling post-consumer textile waste into new fibers reduces landfill waste and conserves resources. Ganni has entered a four-year agreement to use cycora, a recycled polyester made from post-consumer textile waste that replaces 20% of Ganni’s annual polyester use.

Mycelium and seaweed-based materials also offer biodegradable options for textiles. Ecovative’s Forager, a mycelium-based leather, replaces animal leather and features in Patrick McDowell’s designs.

Moreover, Keel Labs’ Kelsun, a seaweed fiber, appears in Stella McCartney’s collection and highlights marine-based textiles.

Biotech Materials offers Plant-based Materials

Croatian startup Biotech Materials produces plant-based leather alternatives by converting alcohol industry byproducts into durable textiles.

Under the Sabant brand, the startup collects spent barley malt and gin distillation residues, dehydrates, and mills them into fine powder.

It then blends the powder with recycled cotton and polyester to create materials like Beer Skin and Gin Skin. These materials offer customizable textures, colors, and finishes, making them suitable for garments, accessories, footwear, and interior design applications.

This way, Biotech Materials reduces textile waste and reliance on animal and synthetic materials, which drives sustainable practices.

Verretex manufactures Glass Fiber Textiles

Swiss startup Verretex develops regenerated glass fiber textiles. It employs a proprietary upcycling process that restores the surface properties of post-consumer fiberglass waste. This enables the production of high-performance nonwoven materials.

Moreover, the startup’s upcycling process involves surface-cleaning techniques at the microscopic level. This ensures that the fibers regain mechanical integrity comparable to virgin materials.

Additionally, the process reduces CO2 emissions and supports the circular economy by converting composite waste into valuable resources.

Verretex provides sustainable, cost-effective alternatives to virgin fibers for the automotive, construction, and renewable energy industries. Further, this contributes to environmental conservation and resource efficiency.

2. Textile Recycling & Upcycling

The fashion market produces over 100 billion garments annually, with a major portion ending up in landfills or being incinerated. Recycling and upcycling efforts divert this waste and reduce environmental pollution.

The industry is also moving away from the traditional linear model of take, make, and dispose to a circular economy. This emphasizes designing garments for longevity, repairability, and recyclability.

Moreover, consumers are favoring sustainable and ethically produced clothing. Brands that incorporate recycled and upcycled materials are meeting this demand and gaining a competitive advantage.

As a result, both industry practices and consumer preferences are driving scalable recycling innovations.

Presently, the textile recycling market size is forecasted to reach USD 5.67 billion by 2030, after growing at a CAGR of 5.54% during 2025-2030.

Mechanical recycling solutions physically break down textiles into fibers to produce new yarns or fabrics. For instance, Renewcell utilizes mechanical recycling to create Circulose. It is a branded material made from recycled textiles. In such a fiber-to-fiber recycling process, textiles are recycled back into fibers without major quality loss through chemical recycling.

Other methods, enzymatic and biological recycling, use enzymes and microorganisms to break down natural fibers like cotton into reusable materials.

Additionally, thermo-mechanical recycling combines heat and mechanical processes and melts synthetic textiles to recover them in pellet form for new products. Companies, like Reju, employ thermo-mechanical recycling to process polyester-rich textiles and produce high-quality recycled polyester.

Rebirth Studios enables Digital Traceability and Small-batch Upcycling

German startup Rebirth Studios offers rebirthOS, a platform that converts pre-consumer textile waste into small-batch, upcycled merchandise.

The platform identifies surplus or defective fabrics generated during manufacturing, and materials that remain unused yet retain high quality. It then matches these materials with underutilized production facilities across Europe.

Further, by leveraging these resources, the startup facilitates the creation of new products without relying on virgin textiles.

Each item includes a QR code that provides transparent data on material origin, production processes, and sustainability metrics.

Nouvelles Fibres Textiles enhances Industrial-Scale Sorting and Recycling

French startup Nouvelles Fibres Textiles operates an industrial facility that converts post-consumer and post-industrial textile waste into recycled fibers.

The startup integrates automated sorting technology with tearing machinery to classify garments by fiber composition and color and to remove non-textile components like buttons and zippers. It then converts the sorted materials into industrial-grade fibers suitable for spinning, nonwovens, and composite applications.

Moreover, this integrated process enables the production of recycled fibers that meet the needs of the fashion industry.

By ensuring traceability and compliance, Nouvelles Fibres Textiles supports the textile industry’s shift towards circularity. This approach reduces environmental impact and improves supply chain resilience.

3. Customization & Personalization

Modern consumers, particularly Gen Z, seek products that reflect their style. If a product is customizable, 75% of Gen Z is likely to purchase it.

Innovations in digital printing, AI-driven design, and 3D modeling are enabling customized textiles efficiently.

The market’s growth trajectory mirrors the increase in demand for personalized clothing.

The custom apparel market size is projected to increase by USD 2.45 billion at a CAGR of 8.4% between 2025 and 2029.

Source: Technavio

On-demand production through microfactories further allows for manufacturing only what is needed. This reduces overproduction and transportation emissions. Unspun uses its Vega 3D weaving technology to produce custom-fit garments near the consumer.

Rapid liquid printing (RLP) also enables the creation of stretchable textiles in a gravity-free gel suspension. Fashion brand Coperni uses RLP to produce innovative designs, such as the Swipe bag.

AI is innovating textile design by generating patterns and styles based on consumer preferences. Platforms, like MYCloth, utilize AI to refine consumer inputs and generate personalized designs.

Further, online configurators allow consumers to personalize textiles and select colors, patterns, and materials to match their preferences. These tools streamline the design process and also improve customer engagement.

Easenory Technology deploys Performance Tracking Systems

Hong Kong-based startup Easenory Technology develops textile-based sensor systems that integrate into sportswear to monitor athletic performance.

The startup embeds stretchable and washable sensors, including inertial measurement units, strain gauges, pressure sensors, and heart rate monitors into garments. These sensors wirelessly transmit biomechanical and physiological data to a central hub and an AI-powered mobile application for real-time analysis.

Knitwise provides On-demand, Fully Knitted Apparel

US-based startup Knitwise builds an on-demand knitwear platform that enables customers to design and sell fully customized apparel without inventory risk.

The startup employs knit-to-shape technology to produce made-to-order garments. This allows businesses to create designs using online tools or templates and to order as few as one piece.

Moreover, the technology eliminates overproduction and reduces material waste compared to traditional cut-and-sew methods.

Knitwise offers a range of products, including sweaters, beanies, and blankets. These are crafted from premium cotton blends and shipped in recyclable packaging.

4. AI & Data Analytics Integration

Real-time textile quality inspection is essential for the immediate identification of defects during production. Additionally, continuous data collection and analysis streamline operations by providing insights into textile production processes.

The integration of data analytics and AI in textile manufacturing enables real-time quality inspection, supports immediate troubleshooting, and facilitates ongoing process optimization through continuous data analysis. This reduces human errors, increases production efficiency, and offers consistent product quality.

The rapid adoption reflects how AI and data analytics are no longer optional and are becoming core drivers in modern textile production.

The global AI market in the textile industry is expected to be worth around USD 21.4 billion by 2033, growing at a CAGR of 24.6% from 2025 to 2033.

Source: Market.Us

Further, AI-powered machine vision leverages high-resolution cameras and deep learning to detect misweaves, stains, or color inconsistencies. For example, THT Textile uses an AI-driven system to scan fabrics at high speeds, detect minute defects, reduce waste, and improve quality.

Automated fabric classification leverages AI to categorize fabrics by texture, weave, and material composition. This streamlines sorting and improves inventory management. For instance, FrontierCool develops an application that assists manufacturers in identifying fabric details through images.

Additionally, AI generates and adjusts design patterns to improve precision and reduce manual errors. Shimmy Technologies Group streamlines apparel design-to-manufacture by addressing workflow inefficiencies.

Smart inventory management also integrates AI to monitor inventory levels, predict stock requirements, and automate restocking.

OpenSeam offers AI-powered Real-time Analytics for Sewing Operations

US-based startup OpenSeam develops an AI-powered analytics platform for textile manufacturing that captures real-time performance data from industrial sewing machines.

The startup installs compact sensors at each workstation, which gather time-stamped operational metrics every five milliseconds. It then transmits them via Wi-Fi to a centralized system for immediate analysis.

This setup enables textile factories to monitor machine utilization, operator efficiency, and production bottlenecks without manual input.

Notably, the system identifies lost time hidden in downtime and provides actionable insights to rebalance workloads and enhance productivity.

Moreover, OpenSeam integrates with any industrial sewing machine to enable fast deployment across facilities of all sizes.

BioRaptor provides AI-driven Bioprocess Optimization

Israeli startup BioRaptor offers an AI-powered data analytics platform that streamlines bioprocess data management for the textile industry.

The platform ingests and harmonizes data from diverse sources into a centralized repository. This enables real-time monitoring and analysis of critical process parameters.

Further, BioRaptor facilitates anomaly detection, predictive modeling, and digital twin simulations by integrating machine learning algorithms. This allows textile businesses to optimize processes and reduce experimental failures.

5. Functional & Technical Textiles

Technical textiles offer properties like flame retardancy, water repellency, ultraviolet protection, and abrasion resistance. These features are crucial for applications in protective clothing and outdoor gear.

Moreover, the shift towards eco-friendly materials is driven by consumer awareness and environmental concerns. At New York Fashion Week Spring-Summer 2025, Christian Siriano showcases luxury garments made from Circ Lyocell, a recycled silk-like textile.

Functional textiles incorporate electronics by enabling features like health monitoring, temperature regulation, and interactive capabilities. This integration is vital in sectors like healthcare and sports.

This growing demand for high-performance and sustainable fabrics continues to push the boundaries of innovation across industries.

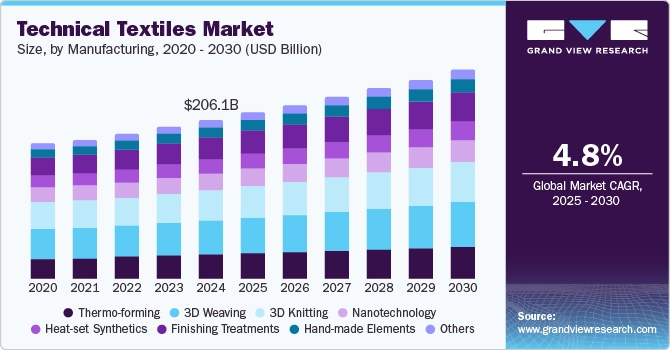

The global technical textiles market size is estimated to grow at a CAGR of 4.8% from 2025 to 2030.

Source: Grand View Research

Smart health-monitoring textiles integrate sensors into fabrics to enable real-time heart rate, respiration, and body temperature monitoring. Moreover, thermoregulatory fabrics adapt to body temperature changes and offer comfort across varying environmental conditions.

Fabrics incorporating phase-change materials (PCMs) absorb, store, and release heat to maintain a stable temperature. This benefits outdoor enthusiasts and individuals with medical conditions affecting temperature regulation.

Antimicrobial and antiviral textiles inhibit the growth of bacteria, fungi, and viruses, which improves hygiene and safety. For instance, textiles infused with silver nanoparticles provide antimicrobial properties for medical applications and daily wear.

Further, the creation of textiles with three-dimensional and self-folding structures improves functionality and aesthetics. The OriStitch project offers a machine embroidery workflow that converts existing fabrics into self-folding 3D textiles.

Whizzo Textiles delivers High-Performance Engineered Fabrics

Indian startup Whizzo Textiles develops engineered textiles that integrate materials science with scalable manufacturing.

The startup employs woven, nonwoven, and composite technologies to create proprietary fiber blends. Its product portfolio encompasses technical textiles, fashion textiles, yarns, and fibers.

Technical textiles include geosynthetics, like geo-cells, geo-grids, and geo-membranes, for infrastructure applications. The startup also includes protective fabrics that offer flame retardancy and antistatic properties.

Fashion textiles range from athleisure and sportswear to women’s high fashion that utilizes materials such as georgette, viscose, and sustainable blends.

Moreover, yarn offerings comprise cotton, polyester, blended, and recycled variants. Fiber products include man-made options, like polyester and nylon, alongside natural fibers.

Swiss Precision Active specializes in Antimicrobial Fabrics

US-based startup Swiss Precision Active manufactures CopperActive Eco HealthTech textiles. These fabrics integrate embedded copper fibers within a cotton-spandex matrix to deliver durable antimicrobial protection.

The startup embeds copper directly into the fabric’s patented X-shaped fiber structure. This improves moisture-wicking by facilitating four-way capillary action. Moreover, the design reduces skin contact points, promotes faster drying, and increases comfort during extended wear.

Additionally, the fabric offers odor resistance, UPF 30+ sun protection, and thermal regulation, which make it suitable for healthcare professionals in high-risk environments. Swiss Precision Active combines antimicrobial efficacy with sustainable materials like organic cotton and bamboo.

6. Artisanal & Heritage Fabrics

Artisanal textiles use natural fibers and traditional dyeing methods. This reduces reliance on synthetic materials and harmful chemicals. It also supports eco-friendly practices and aligns with the textile industry’s shift towards sustainability.

Additionally, heritage fabrics preserve traditional crafts and provide economic opportunities for artisan communities.

The global handicrafts market, encompassing artisanal textiles, is projected to grow at a CAGR of 8.83% from 2025 to 2033, reaching an estimated value of USD 1.94 trillion by 2033.

Modern consumers also actively seek authentic products with traditional stories, which drives the growing demand for artisanal textiles.

Reviving indigenous fibers, like kala cotton in Kutch, promotes biodiversity and sustainable agriculture. Such initiatives reconnect farmers with traditional practices and encourage regenerative farming and ethical fashion supply chains.

Moreover, textile manufacturers embed sensors to improve supply chain transparency and verify product authenticity. This provides detailed data about a fabric’s origin and journey, which supports sustainable practices.

Punar designs Handcrafted, Sustainable Luxury Fabrics

Australian startup Punar produces sustainable luxury textiles by converting upcycled and recycled materials into handcrafted fabrics through traditional Indian weaving techniques.

The startup offers a range of products, including handwoven silk scarves, artisan throws, and cotton tea towels. These products are crafted using zero-emission handloom methods and natural dyes.

Further, its operations divert textile waste from landfills, save liters of water, and handweave fabric using natural dyes and zero chemicals.

Panublix creates a Heritage and Regenerative Textiles Platform

Panublix is a Filipino startup that develops regenerative tropical textiles by sourcing natural fibers from local farmers. These fibers are converted into eco-friendly yarns and fabrics through artisanal weaving techniques.

The startup offers cotton crochet yarns by weaving yarns blended with abaca or pineapple fibers, and handwoven textiles like Iloilo Cotton Hablon.

Additionally, the materials are processed at the Regional Yarn Production and Innovation Center (RYPIC), which produces cotton yarn and blends like cotton abaca and pineapple.

By collaborating with rural artisans and designers, Panublix offers a sustainable textile ecosystem that supports local communities and promotes biodiversity.

7. Novel Dyeing & Printing Techniques

Traditional dyeing processes are resource-intensive, consume large amounts of water and energy, and often involve harmful chemicals.

Textile production accounts for approximately 20% of global clean water pollution from dyeing and finishing. Dyeing also contributes over 3% of global CO₂ emissions, which makes it one of the most polluting industrial activities worldwide.

Solutions, like dope dyeing, incorporate pigments directly into synthetic fibers during production. This eliminates the need for post-production dyeing while reducing water and chemical usage significantly.

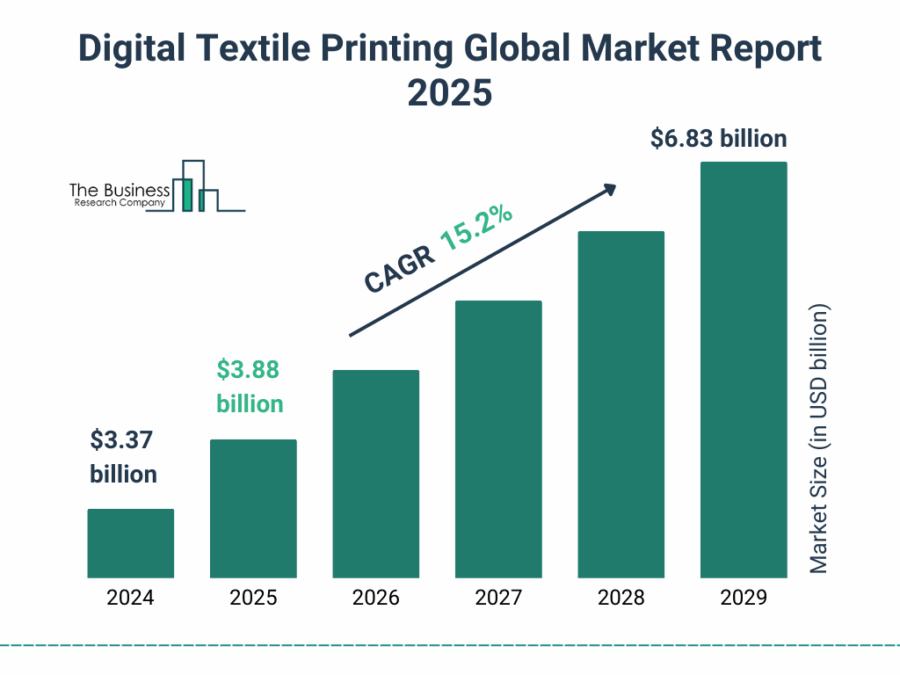

Moreover, digital textile printing allows for the precise application of dyes to reduce waste and enable customization. The digital textile printing market size is expected to reach USD 6.83 billion in 2029 at a CAGR of 15.2%.

Source: The Business Research Company

Further, biological dyeing utilizes microorganisms to produce dyes. This offers a biodegradable and less toxic alternative to synthetic dyes. For instance, Colorifix employs microbes to fix color onto fabrics and minimizes water and chemical use.

Further, pigment inks provide vibrant colors with high resistance that are suitable for various fabrics. Advances in pigment ink technology are increasing printing speeds in textile production.

AI also optimizes dyeing processes by adjusting parameters in real time and reducing resource consumption.

NANODYEX provides an Advanced Cationic Dyeing System

Indian startup NANODYEX develops a circular dyeing system that converts conventional cotton and cellulosic blend dyeing processes into environmentally sustainable operations.

The startup’s technology integrates a patented effluent dyestuff filtration system and a cationic dyeing method. This enables existing dyeing plants to retrofit their equipment without disruption.

NANODYEX converts dye waste into reusable materials and repurposes sludge into non-hazardous fertilizer. This eliminates freshwater pollution and promotes a zero-waste, circular model in the textile dyeing industry.

newera.bio creates Fermented Biodegradable Dyes

Australian startup newera.bio makes biodegradable dyes through precision fermentation to provide a full spectrum of high-performance colors for the textile industry.

By engineering microbes to biosynthesize color molecules, the startup mimics natural pigment production in a brewery-like process. Its patented technology improves the colorfastness and vibrancy of these dyes and also addresses common limitations of traditional natural dyes.

Moreover, these dyes integrate into existing dyeing and printing workflows without requiring infrastructure changes. They offer environmental benefits by reducing water and chemical usage.

8. Textile Production Automation

Automation improves production speed and consistency. Advanced robotics and AI systems perform tasks like fabric cutting, sewing, and dyeing with high precision to reduce human errors and increase output.

A noteworthy example is that of Zara, which utilizes automated systems for fabric cutting, dyeing, and packing. This enables a rapid response to fashion trends and maintains its fast-fashion model.

Automated systems also offer consistent product quality by minimizing defects. Nike employs robotic automation in producing its Flyknit shoes. This offers precision and reduces material wastage.

Automation also leads to long-term cost savings by reducing labor expenses, minimizing waste, and optimizing resource utilization.

These real-world applications highlight how automation increases efficiency and strengthens brand competitiveness in a fast-evolving industry landscape.

Currently, the automation market in the textile industry is estimated to grow at a CAGR of 3.2% from 2025 to 2029.

Automated sewing robots perform consistent stitching with minimal supervision. For instance, SoftWear Automation’s Sewbots expanded its global deployments by automating t-shirt manufacturing facilities in Bangladesh and Vietnam.

Automated inspection systems also identify defects like misweaves or stains. Tukatech’s SMARTmark integrates AI inspection software for optimizing fabric utilization and ensuring defect-free marker planning during cutting.

Further, autonomous quality audits combine AI, vision systems, and predictive analytics to perform quality checks. Lectra launched an AI-powered Kubix Link for digital material quality assessment.

Silana enables Automated Sewing

Austrian startup Silana offers fully automated sewing robots that eliminate manual labor from the garment assembly process.

The complete robotic setup integrates multiple robotic cells, each executing specific tasks such as fabric separation, positioning, and stitching. This enables a smooth transition from fabric roll to finished garment without human intervention.

Additionally, the company’s automated sewing robots accommodate materials, including sustainable viscose. They also deliver improvements in production speed, cost efficiency, and defect reduction.

By facilitating local, on-demand manufacturing, Silana addresses labor shortages, reduces environmental impact, and improves supply chain transparency.

ADOTC provides Software-enabled Robotic Systems

German startup ADOTC develops software-powered robotic systems that automate textile production processes to facilitate on-demand manufacturing.

Its modular robotic sewing cells integrate sensors, grippers, and real-time monitoring software for continuous operation. The robotic system reduces waste and allows a single operator to manage multiple cells. It also supports lot-size-one production in micro-factories.

Additionally, ADOTC offers an automation-as-a-service model that allows textile manufacturers to increase production capacity and reduce costs. It also supports reshoring by bringing manufacturing closer to the end customer.

9. Smart Textiles

Smart textiles enable non-invasive health monitoring, which makes them invaluable in the healthcare and fitness sectors. E-textile systems monitor physiological signals during activities like cycling and swimming. For instance, Hexoskin is a smart shirt that tracks heart rate and breathing for athletes and astronauts to optimize performance.

These textiles also offer soldier safety and efficiency by integrating functionalities like health monitoring and environmental sensing.

As per Grand View Research, the global smart textiles market size is expected to reach USD 21.85 billion by 2030, registering a CAGR of 31.3%.

Moreover, smart textiles contribute to sustainability by integrating energy-harvesting capabilities. Solar cell fabrics generate electricity from light and enable applications like solar-powered clothing and accessories.

Innovations like digitally knitted e-textiles with near-field communication (NFC) enable battery-free health monitoring across the body.

Body-coupled fibers harness electromagnetic energy using the human body as part of the circuit. This eliminates the need for batteries.

Further, energy-harvesting fabrics generate power from sources while reducing reliance on external batteries. MXene-based fabrics convert body heat and solar energy into electricity. This enables continuous operation without external power sources.

Ednam Solutions designs Smart Garments for Menstrual Pain Relief

Indian startup Ednam Solutions develops smart textile garments that integrate discreet, washable heat therapy patches to alleviate menstrual discomfort.

Its Luna Alpha pants feature a fit-and-flare design made from high-stretch knit. They incorporate a built-in heat patch at the pelvic area, connected through a durable submarine-grade plastic port for easy washing.

Additionally, the Luna Flow pants offer a relaxed fit with side slits, crafted from a soft knit. It also embeds the same washable heat patch for targeted relief.

Further, both garments connect to external power banks and deliver over eight hours of continuous heat therapy. Users adjust the temperature settings through a mobile application.

Dressmart specializes in Muscle Activity Monitoring Garments

Canadian startup Dressmart manufactures smart garments that integrate textile-embedded sensors to monitor muscle activity during physical exercise.

The startup utilizes conductive fabrics and embedded electronics to capture real-time physiological data. This data includes heart rate, body temperature, and muscle engagement during workouts.

Additionally, a central processor within the garment collects and stores this data. The users then access and analyze the data through connected mobile phones or smartwatches via Bluetooth.

Further, the garment’s modular design allows for the separation of electronic components from the fabric. This facilitates easy maintenance and replacement.

10. Supply Chain Transparency

Governments, particularly in the European Union (EU), are implementing stringent regulations that mandate transparency in supply chains.

Transparency also serves as a differentiator in a crowded market. Brands that openly share their supply chain practices build stronger relationships with consumers and stakeholders.

Modern consumers are also conscious of the ethical and environmental implications of their purchases. Transparency allows clothing brands to showcase their commitment to sustainable practices, from sourcing to production.

Digital product passports (DPPs) provide detailed digital records of a product’s lifecycle, including material composition, production processes, and environmental impact. Nobody’s Child implements DPPs that provide information on sourcing, energy use, and sustainability metrics. This strengthens customer trust and supports circular fashion initiatives.

Additionally, blockchain offers a decentralized and tamper-proof method for real-time product tracking. This improves transparency and trust in the supply chain of textile production.

Further, Internet of Things (IoT) devices and smart sensors enable real-time monitoring of various stages of textile manufacturing, from fiber production to retail operations. They facilitate predictive maintenance, quality control, and supply chain efficiency.

ProDecipher provides Digital Traceability and Sustainability Tools

Swiss startup ProDecipher builds a modular sustainability operating system for the textile industry. It improves supply chain transparency by integrating blockchain, IoT, and real-time analytics.

The startup’s platform, ProTrace, tracks products from raw material sourcing to final garment production.

Moreover, the ProCert digital certification solution converts certifications into immutable blockchain-based tokens to ensure data integrity and regulatory compliance.

The ProEm module also monitors emissions and detects leaks, providing actionable insights for environmental management.

Together, these tools enable textile businesses to trace materials and verify sustainability claims. They also allow startups to meet evolving compliance standards, improve accountability, and inform decision-making throughout the supply chain.

Ettos creates Digital Product Passports

UK-based startup Ettos builds a supply chain traceability platform tailored for the fashion and textile industry. It connects textile brands and suppliers through a centralized B2B web interface.

This enables the mapping of entire product lifecycles from raw material sourcing to finished goods while managing compliance documentation and sustainability certifications.

Simultaneously, its B2C web application generates digital product passports, accessible via QR codes. These DPPs present consumers with detailed insights into product origins, environmental impact, and ethical standards.

The platform supports bill-of-material-level tracking and automates the collection of transaction certificates for material authenticity. It also integrates with existing enterprise systems through application programming interfaces (APIs).

Discover all Textile Trends, Technologies & Startups

As the textile industry evolves, 3D-printed fabrics, laser-cut textiles, and bio-fabrication are redefining design and production possibilities. Innovations like re-moldable materials enable dynamic, form-fitting applications. Additionally, the integration of nanotechnology, including antimicrobial silver and gold nanoparticles, improves fabric functionality and performance. These advances signal an era in textiles, offering unprecedented avenues for creativity and functionality.

The Textile Industry Trends & Startups outlined in this report only scratch the surface of the trends that we identified during our data-driven innovation & startup scouting process. Identifying new opportunities & emerging technologies to implement into your business goes a long way in gaining a competitive advantage.