Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

The manufacturing sector is transitioning to implement industry 4.0 concepts, with a focus on industrial automation. Early adopters are already reaping the benefits of smart manufacturing, especially during the COVID-19 pandemic, which is accelerating automation. Industrial companies and factories are exploring the use of connectivity technologies such as the industrial internet of things (IIoT) and 5G, as well as artificial intelligence (AI), advanced analytics, and robotics. These technologies improve factory and plant productivity and operations efficiency. Moreover, they allow companies and brands to capture the market share with improved speed to market. The increasing necessity for ensuring worker safety and factory hygiene impacts companies resuming operations. To this end, we present the top 10 industrial workplace trends and 20 startups and scaleups that are transforming the future of the industrial workplace.

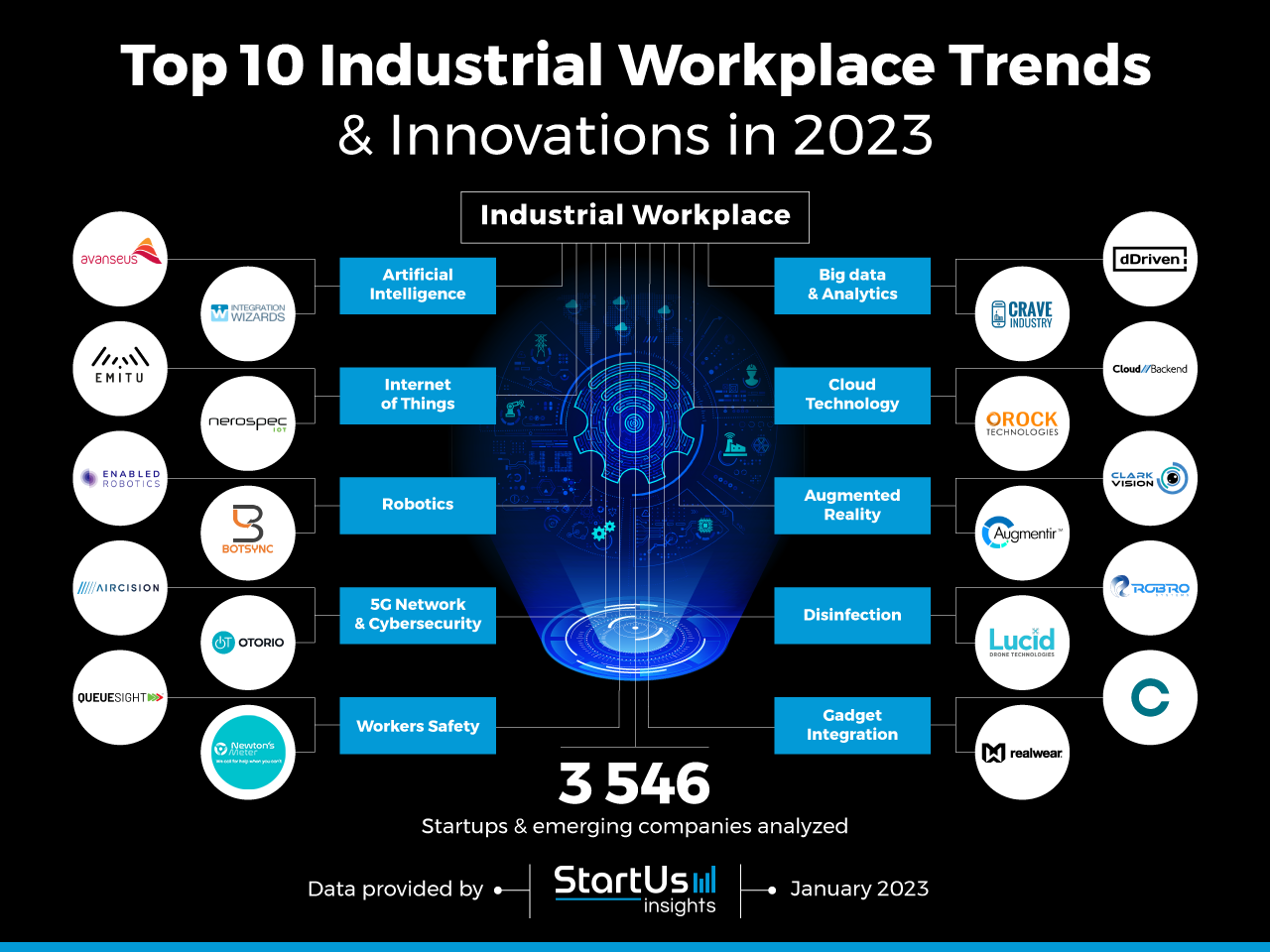

Innovation Map outlines the Top 10 Industrial Workplace Trends & 20 Promising Startups

For this in-depth research on the Top Industrial Workplace Trends & Startups, we analyzed a sample of 3 546 global startups and scaleups. The result of this research is data-driven innovation intelligence that improves strategic decision-making by giving you an overview of emerging technologies & startups impacting the industrial workplace. These insights are derived by working with our Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 2 500 000+ startups & scaleups globally. The platform quickly delivers an exhaustive overview of emerging technologies within a specific field as well as identifies relevant startups & scaleups early on.

In the Innovation Map below, you get an overview of the Top 10 Industrial Workplace Trends & Innovations that impact manufacturing & industrial companies worldwide. Moreover, the Industrial Workplace Innovation Map reveals 20 hand-picked startups, all working on emerging technologies that advance their field. To explore custom insights, simply get in touch with us.

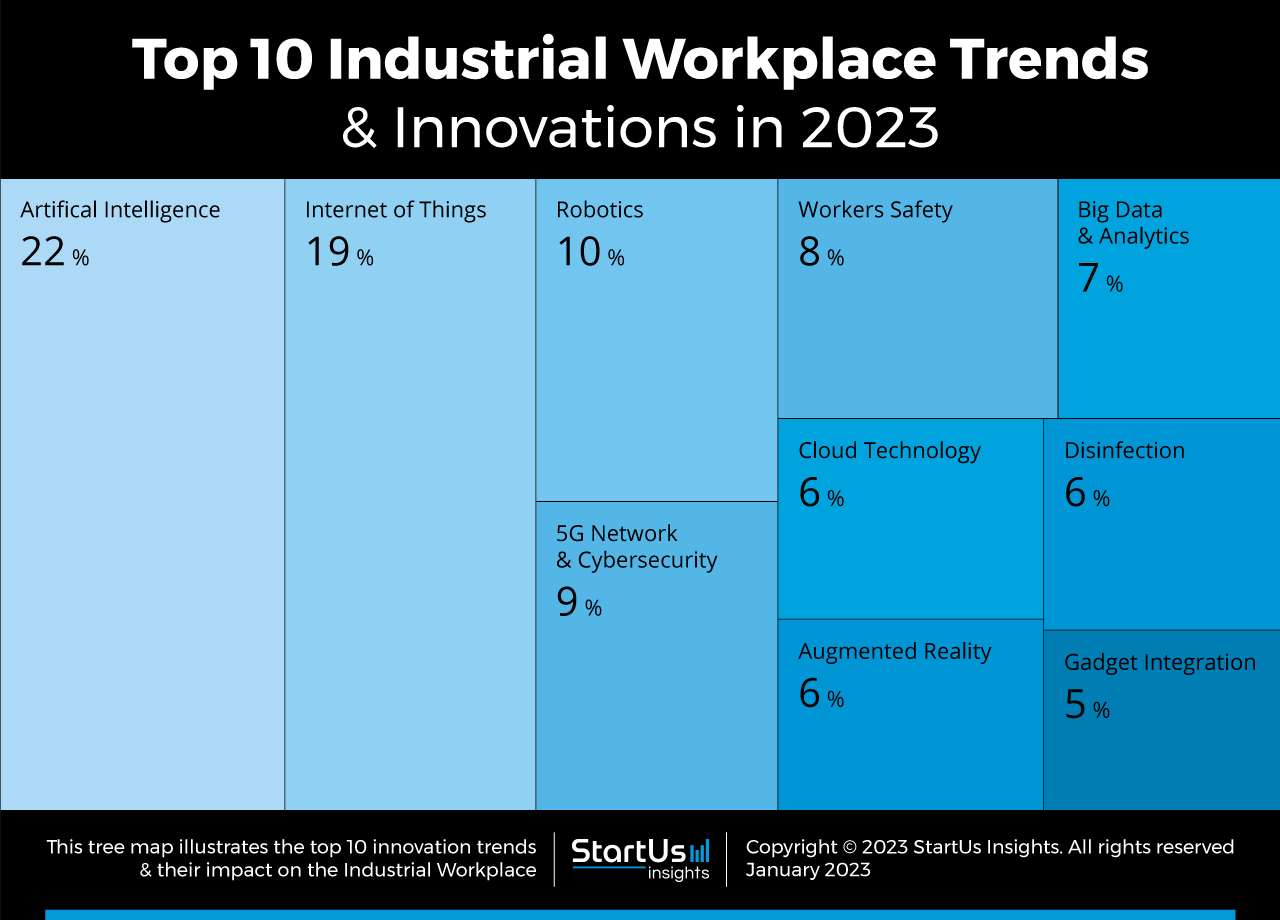

Tree Map reveals the Impact of the Top 10 Industrial Workplace Trends

Based on the Industrial Workplace Innovation Map, the Tree Map below illustrates the impact of the Top 10 Industrial Workplace Trends in 2023. AI, the Internet of Things (IoT), big data, and advanced analytics play a prominent role in the digital transformation of the manufacturing sector. Improved network and cloud connectivity ensures efficient data flow, enables accurate remote process management, and also optimizes manufacturing processes. Collaborative robots and industrial mobile robots further ensure the continuity of operations and automate material delivery on the factory floor. Industrial safety is becoming paramount and the adoption of augmented and virtual reality (AR & VR) and wearables creates a safe and connected workforce. Startups are also working on solutions that aid factories to maintain clean, sanitized, and socially distanced workplace protocols.

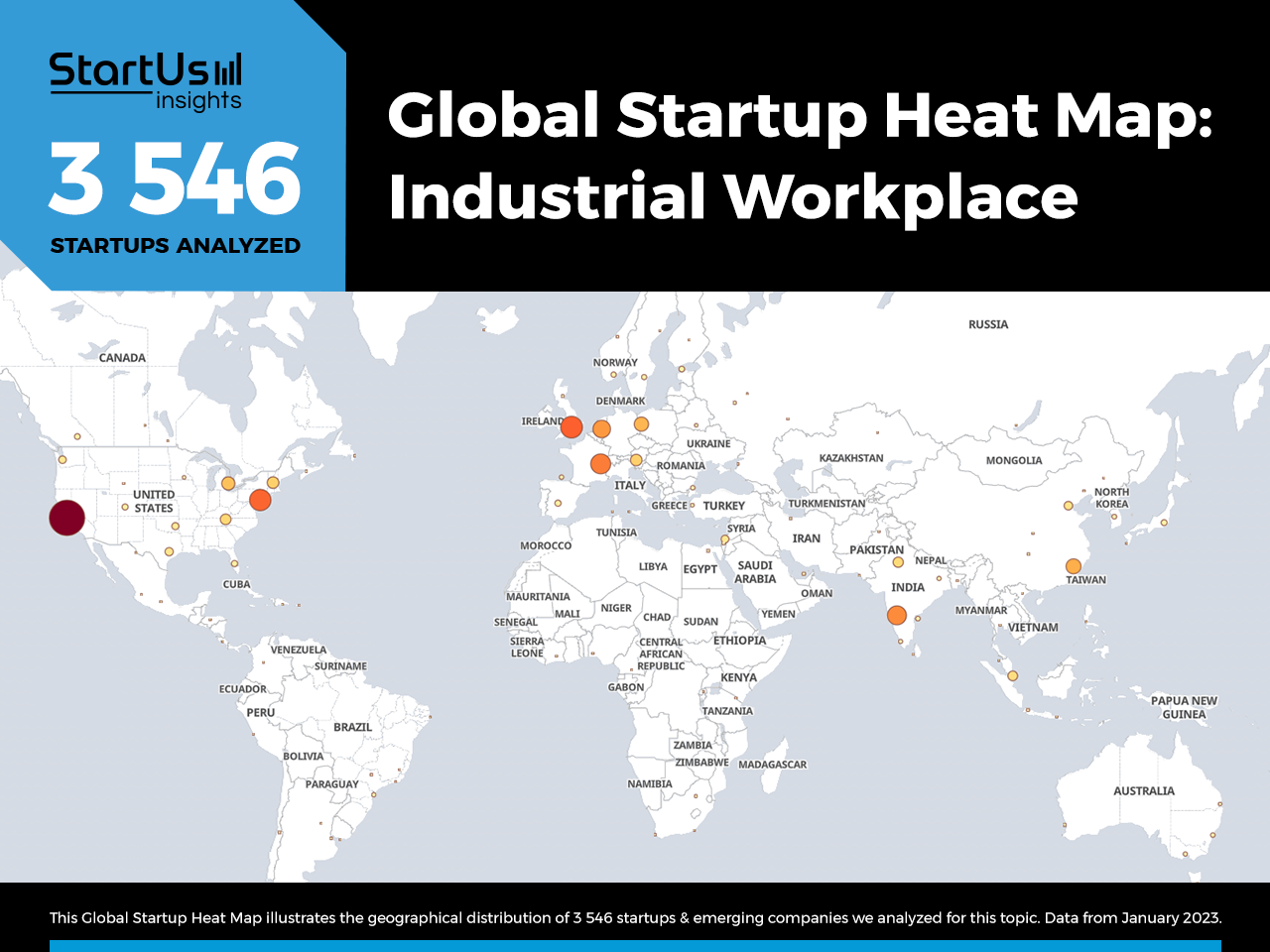

Global Startup Heat Map covers 3 546 Industrial Workplace Startups & Scaleups

The Global Startup Heat Map below highlights the global distribution of the 3 546 exemplary startups & scaleups that we analyzed for this research. Created through the StartUs Insights Discovery Platform, the Heat Map reveals that the US and Europe are home to most of these companies while we also observe increased activity in China as well India, particularly in Mumbai.

Below, you get to meet 20 out of these 3 546 promising startups & scaleups as well as the solutions they develop. These 20 startups were hand-picked based on criteria such as founding year, location, funding raised, and more. Depending on your specific needs, your top picks might look entirely different.

Top 10 Industrial Workplace Trends

1. Artificial Intelligence

Utilizing AI to build predictive algorithms allows factories to fulfill their dynamic demand and supply requirements. Predictive maintenance eliminates unplanned downtime using machine learning (ML) and deep neural networks. AI and ML also facilitate the rapid analysis of complex data sets and bridge the gap between people and machines on the factory floor. AI-based tools further enable industries to implement and comply with safety protocols at the workplace. Startups are integrating AI into wearable devices and other IoT sensors to create solutions that reduce manufacturing costs and increase productivity.

Avanseus develops an AI-based Predictive Maintenance Solution

Singaporean startup Avanseus deploys a full-stack AI-based predictive maintenance solution that predicts machine failures. The software audits the condition and performance of machinery in real-time to track the signals that suggest a deterioration and estimate timelines for equipment failure. The prognostic system reduces maintenance costs, minimizes downtime, and prevents equipment degradation for industrial assets.

Integration Wizards offers a Computer Vision-based Monitoring Software

Indian startup Integration Wizards offers IRIS AI, a computer vision software solution that replaces manual monitoring of the workforce. IRIS AI integrates with the closed-circuit television (CCTV) networks and leverages deep neural networks to detect, for example, a face mask or to measure the distance between workers in real-time. The software also sends alerts to the relevant authorities when it detects violations of safety gear usage and non-compliance with COVID guidelines.

2. Internet of Things

IIoT is a disruptive industrial workplace trend and plays a vital role in the digital transformation of the manufacturing sector. Looking beyond the COVID-19 pandemic, industries are adopting solutions to continue operations while safeguarding the health of the workers. Industrial workplaces are leveraging IoT to expand remote monitoring and operations options to maintain safer factories. Manufacturing companies keep track of the condition and health of operations on the factory floor through IoT sensors and devices, improving overall equipment effectiveness (OEE).

Emitu provides Real-Time Visibility for Industrial Assets

Portuguese startup Emitu provides real-time visibility and condition monitoring of industrial operations and assets. The startup’s IoT platform combines the data from sensors and enterprise systems to create data visualizations and generate actionable insights. Emitu also allows industrial workplaces to make data-driven decisions and automate processes to increase operational efficiency.

Nerospec IoT develops Industrial Sensors

South African startup Nerospec IoT develops a wide range of sensor solutions including temperature sensors, vibration sensors, and pressure sensors. The startup’s sensors replace the manual monitoring of vibration or temperature measurements for machinery, which are typically unreliable. Nerospec offers customizable solutions suitable for all types of industrial and enterprise customers.

3. Robotics

Industrial workplaces are seeing a global wave of robotics and automation enter factory environments, creating value for manufacturers and advancing industry 4.0 integration. Robotics and industrial automation include deploying driverless, automated guided vehicles (AGVs) as well as collaborative robots, known also as cobots, that work alongside humans on the factory floor. Robotics-as-a-Service solutions are also gaining traction in manufacturing and logistics workplaces. Further, mobile robots ensure the safe transport of materials in the factory, requiring minimum human intervention, worker movement, and interaction.

Enabled Robotics builds Robotic Arm Systems

Danish startup Enabled Robotics offers a range of specialized robotic arm systems that feature increased mobility. The startup’s mobile cobots are capable of solving complex tasks. In machine tending applications, Enabled Robotics’ robots offer industrial workplaces the advantage of operating and servicing multiple machines and integrating logistics and transportation.

Botsync offers Autonomous Mobile Robots (AMRs)

Singaporean startup Botsync builds MAG, an AMR to automate the point-to-point material movement for the manufacturing and logistics industries. The startup’s mobile robots are designed to work in collaboration with humans to lift pallets or integrate with existing conveyor lines. MAG offers a typical runtime of 8 hours and carries payloads up to 500 kgs.

4. 5G Networks & Cybersecurity

The rollout of 5G networks is expected to grow at scale over the next few years, allowing manufacturers to improve network latency and enable real-time communication on higher bandwidths. 5G technology boosts the exchange of large amounts of data and enhances the use of sensors, which is crucial for industry 4.0 solutions. It also enables cloud computing as well as track and trace capabilities for industrial facilities. To protect against cyber hacking, data breaches, and sensitive information on the cloud, manufacturers seek smart factory solutions that strengthen their industrial cybersecurity strategies.

Aircision provides Laser-based 5G Communication Technology

Dutch startup Aircision provides laser-based 5G communication technology to improve industrial infrastructure and development. The startup is testing free-space optics and laser beam technologies to achieve the roll-out of 5G. Aircision’s laser beam technology costs lesser than optical fiber systems, allowing industrial workplaces to optimize costs.

OTORIO offers an Industrial Cybersecurity Platform

OTORIO is an Israeli startup that empowers industry 4.0 transformation with its end-to-end industrial cybersecurity platform. The platform provides control systems to allow continuous management, automated analysis of cyber threats, and remediation of cyber risks. OTORIO’s risk assessment, monitoring, and management solutions also enable reliable, safe, and efficient digital production processes.

5. Industrial Worker Safety

Improving worker safety standards and the availability of personal protective equipment (PPE) is rapidly gaining importance in the industrial workplace. Post-pandemic, workers require employers to make workplaces safe. To this end, startups develop IoT- and wearables-based solutions to reduce industrial workplace hazards and promote safety throughout the production line. For example, wearable devices alert workers when they get close to AGVs or other workers in large warehouses.

Newton’s Meter provides an AI-powered Wearable Safety System

Singaporean startup Newton’s Meter develops an AI-powered wearable safety system for industrial workforces. In the event of an accident or emergency, the device automatically sends an SOS alert and the GPS location of the employee. The startup utilizes nano microprocessors to detect injuries from a fall or slip. The wearable device also allows for manual operations, enabling workers to send alerts with the click of a button.

Crafted Design develops a Social Distancing Tool

Crafted Design is a US-based startup developing QueueSight, a social distancing tool. The tool leverages sensors and an AR graphics engine to provide immediate feedback. QueueSight comprises ceiling-mounted sensors and a visual engine with on-floor projections. When social distancing is compromised, the sensors send data to overhead projectors, which then display colors on the floor to instantly alert that the workers are too close to one another.

6. Big Data & Analytics

The increase in connectivity technologies results in IoT devices collecting a lot of data from machines. Big data and analytics make it possible to extract actionable insights from the data and improve factory processes. Data analytics is the driving force that aids manufacturers in better decision-making to maximize the efficient use of resources. It is also the key to profitability and productivity as organizations are able to better understand their machine and resource utilization.

dDriven builds a Data Analytics Platform for IoT Device Integration

Singaporean startup dDriven offers UNLSH, a data analytics platform that allows companies to make sense of the data generated from information technology (IT), operating technology (OT), and IoT assets. The platform solves the bottleneck of blending and structuring fragmented data for conducting analytics and generating reports. UNLSH also features end-to-end capabilities to ingest, structure, and contextualize data. The platform then provides data visualization to deliver essential insights for driving digital transformation in large manufacturing operations.

Crave Industry develops an AI-based Industrial Data Analytics Platform

Brazilian startup Crave Industry provides an AI-based industrial data analytics platform to optimize process efficiency and assist decision-making. The startup’s platform collects, structures, and configures heterogeneous data concerning the business and factory. The platform also enables building a digital twin of the complete industrial processes to intuitively visualize data in real-time.

7. Cloud Technology

The manufacturing sector is increasingly adopting hybrid cloud technologies. Cloud environments allow industrial organizations to have an on-premise and private IT infrastructure that addresses data sovereignty issues. Further, edge computing enables IoT devices to run advanced deep learning algorithms with low power consumption, overall footprint, and operating cost. This also eliminates the latency of a cloud-based network as the processing is done right at the edge without the need to transfer data to the cloud. In smart and connected factories, cloud computing eases the communication between machines and between machines and humans.

Cloud Backend offers Application-Ready Environments

Swedish startup Cloud Backend provides an application-ready environment and customized services that enable system integrators to deploy edge computing applications close to the data sources. The startup’s edge database platform-as-a-service (PaaS) model offers low-latency cloud capacities for industrial applications. Its applications include the collection and analysis of machine data as well as improving production line connectivity.

ORock provides a Hybrid Cloud Connectivity Platform

The US-based startup ORock offers a hybrid cloud connectivity platform that provides businesses the agility to adapt and operate hybrid cloud environments. ORock’s hybrid cloud solution is also deployed at speed, allowing companies to seamlessly connect between clouds. The hybrid connectivity and infrastructure-as-a-service (IaaS) model enable industrial companies to protect confidential data, maintain regulatory compliance, and reduce IT costs.

8. Augmented Reality

The COVID-19 pandemic highlights several critical challenges facing industrial facilities, mainly owing to reduced worker availability. Industrial organizations adopt connected worker technologies and remote assistance tools to connect with field engineers to carry out tasks. Solutions based on AR provide remote support to keep businesses operating and workers safe on the factory floors. AR and VR solutions also allow industrial companies to efficiently train their employees with hands-on training and remote assistance.

Clark Vision offers AR Headsets for Industrial Workers

Romanian startup Clark Vision offers AR headsets that improve industrial worker efficiency and safety, as well as optimize factory processes. The startup’s AR glasses support industrial workers with the initial diagnosis and enable remote maintenance with guidance for self-service. The headset features a camera and thermal vision sensors that integrate with a heads-up display (HUD).

Augmentir develops a Connected Workers Platform

Augmentir is a US-based startup developing an AI-powered connected workers platform for manufacturing companies. By leveraging AR technology, the platform guides and remotely supports workers to perform their tasks with augmented instructions. As a result, the platform improves workers’ safety, quality of work, and productivity while facilitating routine equipment maintenance and repair processes.

9. Disinfection

As factories around the world re-open after the pandemic, the focus will be on workforce safety, hygiene, cleanliness, and sanitization. Moreover, investment in disinfection robots, sanitization systems, and PPE is set to grow as we continue to live with this virus, and potentially others to follow. In addition to disinfection, industrial firms need to regularly sanitize their machines and equipment to prevent the infections spread.

Robro Systems offers a Computer Vision-based Handwash Monitoring System

Indian startup Robro Systems develops CleanoCheck, a handwash monitoring system that ensures proper washing protocols are adhered to at the workplace. CleanoCheck uses computer vision and deep learning algorithms to detect handwashing patterns. The visual inspection system then sends alerts to the concerned authorities when there it detects non-compliance. Further, the system collects hand hygiene data for further analysis and industrial movement and process optimization.

Lucid Drone Tech builds Disinfection & Cleaning Drones

Lucid Drone Technologies is a US-based startup that manufactures drones to perform disinfection and cleaning tasks. The startup’s disinfecting drone, D1, features electrostatic spray nozzles for efficient liquid distribution and optimal sanitization applications. D1 comes with a 2,5-gallon onboard tank capacity that carries disinfectant liquid solution and covers 200 000 square feet per hour.

10. Gadget Integration

Wearable devices are emerging as essential tools to increase the productivity and efficiency of workers in industrial settings. Exoskeletons safeguard and support industrial workers in performing manual and repetitive tasks, in turn, increasing overall efficiency. Wearables, equipped with sensors, report temperatures or identify high traffic hotspots on the shop floor. This further ensures industrial companies guarantee the safety of their workers during the pandemic. Gadget integration spans several technologies and is slowly gaining traction as one of the emerging industrial workplace trends.

Cyber Human Systems provides Wearables to Assist Industrial Workers

Spanish startup Cyber Human Systems develops wearable solutions that enable industrial workers to increase their capacity for mobility and movement. The startup’s arm and lumbar exoskeletons enhance the lift-endurance of workers. They further reduce shoulder and waist fatigue as well as minimize preventable workplace injuries. The exoskeletons provide up to 15 kg of lift assistance with both horizontal and vertical load movements.

RealWear offers a Hands-Free Wearable Computer for Industrial Workers

RealWear is a US-based startup that offers HMT-1, a hands-free wearable computer for industrial workers. The head-mounted device works with voice commands and finds applications in remote assistance, video calling, document navigation, and guided workflows. The hands-free remote inspection solution also enables users to provide assistance by remotely telecasting issues, even in noisy industrial environments.

Discover all Industrial Workplaces Technologies & Startups

Innovative technologies and emerging trends fueling digital transformation bring smart factory solutions within the grasp of industrial companies. The rising inclination towards advanced robotics and automation platforms paves the way for the next generation of industrial automation and further elevates factory-level efficiency. By leveraging emerging trends, manufacturing companies stand to gain a competitive advantage by improving worker safety and overall productivity.

The Industrial Workplace Trends & Startups outlined in this report only scratch the surface of trends that we identified during our in-depth research. Among others, AI and IoT will transform the sector as we know it today. Identifying new opportunities and emerging technologies to implement into your business early on goes a long way in gaining a competitive advantage. Get in touch to easily and exhaustively scout relevant technologies & startups that matter to you.

![10 Top Digital Twin Startups and Companies for Industry 4.0 [2025]](https://www.startus-insights.com/wp-content/uploads/2025/06/Digital-Twin-Startups-for-Industry-4.0-SharedImg-StartUs-Insights-noresize-420x236.webp)