Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

Smart or digital factories leverage the internet of things (IoT), artificial intelligence (AI), robotics, and more to create a connected and automated production environment. Through this, manufacturers streamline production, identify bottlenecks, and improve maintenance scheduling. This industry report provides you with an overview of the top 10 smart factory trends impacting manufacturers in 2023. They range from cybersecurity and connectivity technologies to additive manufacturing and autonomous factories. Read more to explore all the trends and discover how you can integrate them into your production runs.

Innovation Map outlines the Top 10 Smart Factory Trends & 20 Promising Startups

For this in-depth research on the Top Smart Factory Trends & Startups, we analyzed a sample of 1273 global startups & scaleups. This data-driven research provides innovation intelligence that helps you improve strategic decision-making by giving you an overview of emerging technologies in the manufacturing industry. In the Smart Factory Innovation Map, you get a comprehensive overview of the innovation trends & startups that impact your company.

These insights are derived by working with our Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 3 790 000+ startups & scaleups globally. As the world’s largest resource for data on emerging companies, the SaaS platform enables you to identify relevant technologies and industry trends quickly & exhaustively.

Tree Map reveals the Impact of the Top 10 Smart Factory Trends

Based on the Smart Factory Innovation Map, the Tree Map below illustrates the impact of the Top 10 Smart Factory Trends in 2023. Startups and scaleups are developing data processing, management, and security solutions tailored for industrial settings. For instance, platforms for cybersecurity, factory data management, and machine vision are key enablers of smart factories. Manufacturers are also leveraging digital twins and predictive maintenance to optimize operations and maintenance schedules. IoT connectivity technologies like machine-to-machine (M2M) and human-to-machine (H2M) aid data exchange in connected factories, eliminating data silos and improving efficiency. Further, manufacturing execution systems (MES) simplify production control and monitoring. Lastly, 3D printing and fully autonomous factories are allowing manufacturers to reduce dependence on manual labor and implement automated production lines.

Top 10 Smart Factory Trends in 2023

- Cybersecurity

- Manufacturing Execution Systems

- Digital Twin

- Predictive Maintenance

- 3D Printing

- Factory Data Management

- Machine Vision

- Machine-to-Machine

- Autonomous Factories

- Human-to-Machine

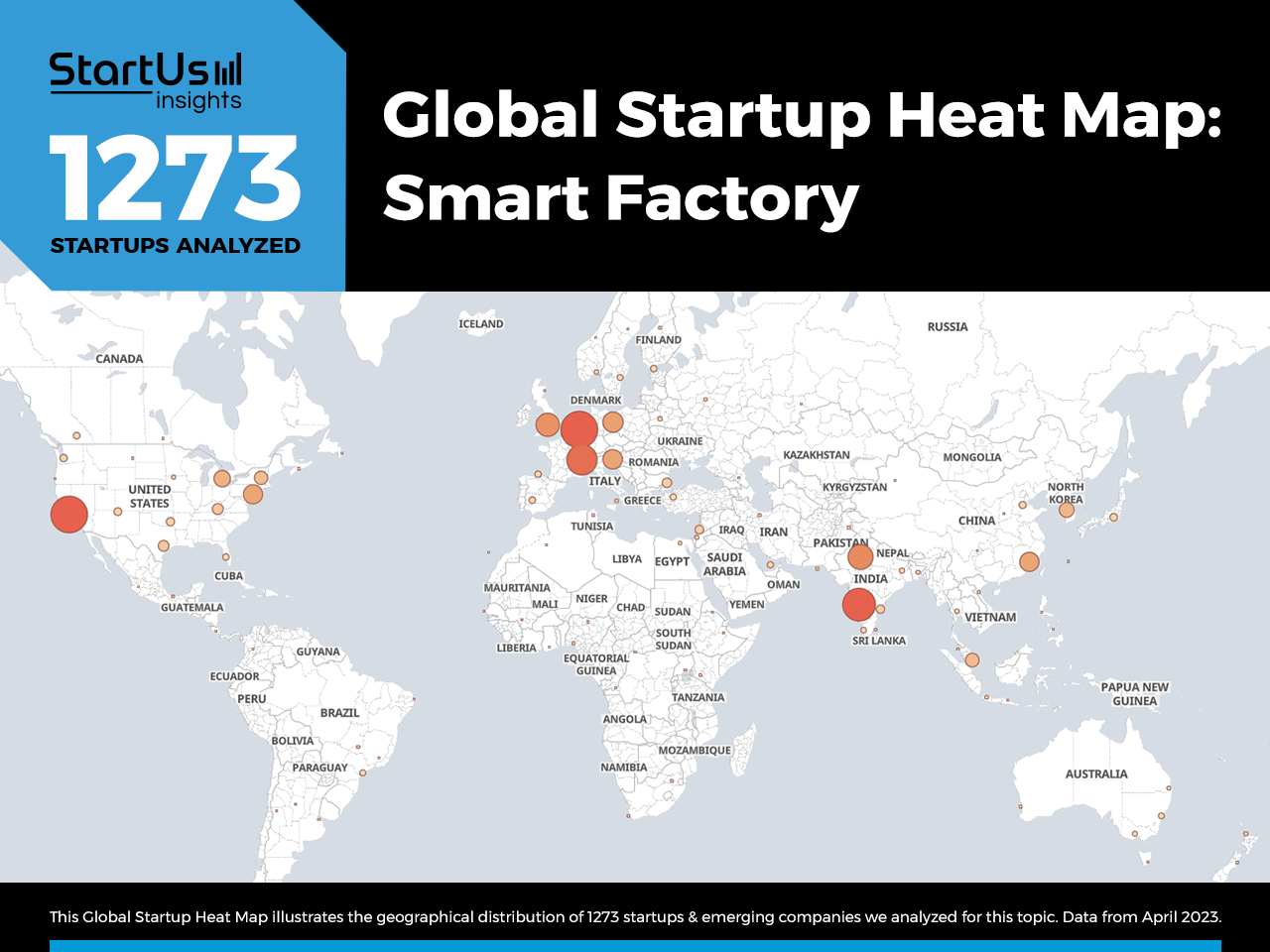

Global Startup Heat Map covers 1273 Smart Factory Startups & Scaleups

The Global Startup Heat Map below highlights the global distribution of the 1273 exemplary startups & scaleups that we analyzed for this research. Created through the StartUs Insights Discovery Platform, the Heat Map reveals high startup activity in Western Europe and the US, followed by India. Below, you get to meet 20 out of these 1273 promising startups & scaleups as well as the solutions they develop. These smart factory startups are hand-picked based on criteria such as founding year, location, funding raised, & more. Depending on your specific needs, your top picks might look entirely different.

Top 10 Smart Factory Trends in 2023

1. Cybersecurity

Transitioning to digital ecosystems positions factories in a vulnerable environment that is prone to malicious attacks. This leads to sensitive data leaks and the takeover of operational and information technology (OT/IT) devices, causing downtimes. To tackle this, startups are developing cybersecurity solutions tailored for industrial settings. They feature continuous network and device monitoring, automated risk detection and response, advanced access control, data encryption, and more. Manufacturers leverage such solutions to protect their intellectual property (IP) as well as operational and client data. Integrating cybersecurity solutions also allows them to ensure data compliance. Cybersecurity thus enables factories to mitigate unwanted legal costs, damage to reputation, and production disruption.

BreachQuest provides Continuous Asset Monitoring

BreachQuest is a US-based startup that offers Priori, a cybersecurity platform for the manufacturing industry. It continuously monitors connected assets to provide instant information upon detecting threats and affected endpoints, accelerating risk response. This allows factories to improve ransomware response, digital forensics, and incident response planning. Consequently, the startup allows them to mitigate massive expenses associated with data recovery and legal complications.

MON5 aids in Plant Monitoring

MON5 is an Italian startup that develops a cybersecurity solution for industrial plants. It allows businesses to monitor their infrastructure and devices in real-time and receive performance analysis. Moreover, the startup processes all data inside business perimeters and requires no additional hardware integrations. This, along with its actionable analytics, enables manufacturers to ensure data security and mitigate cost-intensive security integrations.

2. Manufacturing Execution Systems

Factory managers already utilize manufacturing execution systems to track and control production pipelines. However, innovations in IoT, cloud computing, AI, and more enable them to improve MES performance. For instance, startups combine data from existing systems, like enterprise resource planning (ERP) and supply chain management (SCM), as well as IoT devices. This provides floor operators with a holistic view of production environments. Advanced MES solutions also leverage predictive analytics to enable predictive maintenance and improve inventory management. Moreover, manufacturing execution systems create production schedules based on targets, available resources, and other factors as well as improve product quality monitoring, reducing reworks and defects.

OPALYTICA simplifies Production Scheduling

OPALYTICA is a French startup that makes Jikko, an MES platform. It uses sensors for production data acquisition, programmable logic controllers (PLC) for data manipulation, and SCADA for monitoring and supervising. Jikko also features various modules for part traceability, overall equipment effectiveness (OEE) improvement, manufacturing scheduling, and more. These features allow plant operators to track and document the transition of raw materials into finished products. Moreover, Jikko’s comprehensive approach allows them to identify quality risks, predict future breakdowns, and improve communication.

STABILIS.IO enables Continuous Improvement

STABILIS.IO is a Polish startup that creates a low-code MES platform for continuous improvement. It integrates with existing factory infrastructure, including ERP and computerized maintenance management systems (CMMS). The platform then collects real-time data from production lines and automates information flow between devices and IT systems. This allows manufacturers to monitor production processes. The platform also enables them to record the working time of assets and workers, analyze various production parameters, and detect bottlenecks. These features, in turn, reduce resource wastage and personnel costs while enabling real-time control of production processes.

3. Digital Twin

While real-time visibility into operations and assets are critical in running smart factories, it is also important to model and visualize production lines to promptly identify issues. To aid this, startups develop digital twin platforms that source data from existing data management systems and industrial IoT devices. They utilize this data to create real-time models of factory environments. Some startups further combine predictive analytics with digital twins to forecast production issues and demand variations to drive decision-making while others leverage virtual and augmented reality (VR/AR). Moreover, digital twins allow factory operators and managers to simulate various production scenarios and configurations to streamline production processes.

Basetwo makes a Factory Digital Twin Creation Platform

Basetwo is a Canadian startup that develops TwinOps, a digital twin platform for smart factories. It allows businesses to build, test, and operationalize the digital twins of their plants. The platform visualizes model performance using various metrics to optimize processes. Additionally, it allows manufacturers to perform real-time virtual what-if scenarios to predict process dynamics under novel conditions. It automatically determines process setpoints that maximize key performance indicators (KPIs) under different constraints, accelerating performance reporting. These features reduce uncertainty in production floors, simplify cross-team collaborations as well as reduce time and resources.

ReSpace builds AR-powered Factory Digital Twins

ReSpace is a Swedish startup that makes ReSpace Twin, a smartphone app to construct interactive digital twins. It allows companies to use existing virtual-only digital twins or data from building information models (BIM) to build 3D models of factories. This data is also overlaid on physical environments and the app allows operators to annotate models with text, conversations, documents, images, and more. Moreover, the app features smart positioning that ensures precise alignment of 3D objects in physical space and intelligent streaming for smartphones to handle large models. This allows manufacturers to visualize all 3D and sensor data on demand for investigating various production parameters, like flows in pipes.

4. Predictive Maintenance

Smart factories are transitioning from computerized maintenance management systems (CMMS) to assisted maintenance solutions. With data sourced from IIoT devices, OT systems, and logical controllers, manufacturers now apply predictive analytics to forecast machine issues. This empowers maintenance planning and enables factories to transition to data-driven, condition-based maintenance workflows. Consequently, predictive maintenance reduces maintenance costs preventing expensive repairs and replacements while also reducing the frequency of scheduled maintenance. For workers, this technology improves workplace safety by identifying potential hazards due to asset breakdown. As a result, predictive maintenance solutions increase overall floor productivity.

Utpatti enables Decentralized Predictive Maintenance

Utpatti is a German startup that makes decentralized AI for smart maintenance. The startup’s predictive maintenance application utilizes existing sensor data and applies its AI engine to predict potential failures and optimize machine maintenance. The application also alerts maintenance engineers of potential breakdowns to monitor equipment health and schedule planned maintenance. This allows factories to improve breakdown response time, increase OEE, and avoid over-maintenance.

Borneo Analytics facilitates Process Optimization

Borneo Analytics is a Spanish startup that creates a process optimization platform for unit manufacturing. It integrates into existing ERP systems and maintains bidirectional communication with machine centers. This allows manufacturers to launch tasks and dynamically modify production planning for processes that vary constantly. Moreover, the platform’s machine learning-assisted dynamic planning enables real-time production monitoring and enables predictive maintenance for a longer equipment lifetime. As a result, the startup reduces internal non-conformities and eliminates human errors associated with manual data entry in factories.

5. 3D Printing

The primary applications of 3D printing in industrial settings are rapid prototyping, low-volume production runs, and maintenance support, among others. Additionally, integrating additive manufacturing production lines imparts improved control and enables more streamlined operations for manufacturers. For example, automated 3D printing lines require only initial design, and the entire production is completed without human intervention while generating critical data required for production control. This digital production ecosystem allows manufacturers to greatly improve inventory management, generate parts on demand, and reduce material wastage. Further, startups leverage advanced robotics and AI to completely automate 3D printing farms, delivering autonomous factories, on demand for manufacturers.

Handddle builds Lean Micro-Factories

Handddle is a French startup that builds lean micro-factories using 3D printing. The startup’s 3D printers enable smart manufacturing units that feature smart sensors, insulated production environments, real-time environment analysis, and integrated air filtration systems. Coupled with the startup’s Handddle App platform, manufacturers improve 3D printer and materials stock management, smart production scheduling, events monitoring, and multi-site production monitoring. This way, the startup enables lean, automated, and smart production lines to accelerate production efficiency. Defense equipment and automotive manufacturers leverage the startup’s solution to implement distributed and secure production.

TEXTURA 3D maintains a Cloud Manufacturing Network

TEXTURA 3D is an Italian startup that builds a 3D-printer-based cloud manufacturing network. The startup’s interconnected print farms leverage various 3D printing technologies, like fused deposition modeling (FDM), to produce parts and components on demand. This allows manufacturers to develop customized mechanical components, implement ultra-fast production, and reduce prototyping time without incurring expensive capital costs.

6. Factory Data Management

Shifting to digital factories requires businesses to deal with massive datasets. That is why factory data management systems are critical to ensure smooth operations in smart factories. With them, manufacturers are able to better monitor, control, and manage data sharing across systems and enable centralized data management, mitigating siloes. This, in turn, improves visibility into operations and assets as well as powers data-driven decision-making and continuous improvement. Efficient data management systems are also necessary to implement analytics and AI solutions in factories. Therefore, startups provide on-premise or cloud-based platforms tailored for factory data management. This allows manufacturers to mitigate in-house product development costs and accelerate implementation time.

Clip Automation builds a Smart Factory Operating System (OS)

Clip Automation is a US-based startup that creates ClipSuite, a smart factory OS. It connects with existing sensors, cameras, OT/IT devices, and LiDAR systems to run custom models and applications on the edge. The OS’ low-code control accelerates the deployment of equipment and human-machine interfaces (HMIs) and enables remote planning and scheduling. It also features a Kanban-based issue management interface and provides AI-powered recommendations to send commands to machines. This allows factory operators to simplify root cause analysis, decrease per unit cost, improve OEE, and increase asset availability.

Vioneta offers Edge Computing Infrastructure for Manufacturing Plants

Vioneta is an Australian startup that builds an edge computing infrastructure for manufacturers. The startup’s distributed, microservices-based software architecture supports containerization for application portability and speeds up application deployment and orchestration. It is also hardware-agnostic and supports various IoT protocols for quick installation while ensuring low-latency performance and scalability. Moreover, Vioneta’s security-first approach makes edge data management more secure. With these features, factories improve data management at the edge to enable data-driven decision-making based on factory performance.

7. Machine Vision

Machine vision leverages computer vision and imaging techniques to interpret, analyze, and understand real-world visuals. In smart factories, machine vision-powered systems replace workers for repetitive tasks and automate processes. For example, quality management is one of the primary use cases of machine vision in manufacturing plants. By analyzing real-time images of products and process flows, such solutions identify issues in products and processes without human intervention. This allows floor operators to mitigate reworks and improve product quality. For this, startups develop sensors, camera systems, and specialized algorithms like object and pattern recognition. These solutions also find applications in inspection and assembly lines to identify missing parts and monitor production.

ArmourSense increases Worker Safety

ArmourSense is an Israeli startup that develops video analytics software to improve worker safety. The startup deploys its software on-premise and on edge to identify and predict hazardous situations. In production lines, it allows floor managers to view hazards, safety levels, and near misses as well as provides safety improvement recommendations through a mobile device or computer. Additionally, the software activates a siren upon detecting accidents and causes very less false alarms. This allows factories to eliminate accidents, protect workers, and reduce downtime.

XR Solutions enables AR-assisted Maintenance

XR Solutions is a Swedish startup that offers an AR-powered solution for industrial maintenance. The startup combines computer vision and augmented reality to deliver calculated performance instructions and guidance in daily workflows. This allows companies to standardize processes and improve business outcomes. Moreover, the solution enables them to plan operations, monitor upcoming activities, and measure the performance of industrial machines, reducing unplanned downtime and increasing factory throughput.

8. Machine-to-Machine

M2M connectivity simplifies data sharing between machines and other OT/IT devices in smart factories. As a result, it replaces manual intervention otherwise required to manage data or initiate a response for a trigger event. Consequently, M2M technologies allow manufacturers to automate various production parameters based on sensor and other device data. Real-time data exchange also provides machine operators and floor managers with real-time machine status, production parameters, and more. When combined with data processing algorithms, this data enables predictive maintenance and real-time product quality monitoring, among others. Lastly, M2M communication allows machines to automatically identify accident risks or safety issues and shut down operations, improving worker safety and reducing equipment damage.

Bitblue provides Blockchain-based M2M Micro-Transactions

Bitblue is a US-based startup that creates a blockchain-enabled backend platform for embedded devices. IoT devices require massive computing power to run blockchain nodes, limiting blockchain integration in connected industrial ecosystems. The startup’s platform functions as a middleware between blockchain networks and IoT devices to enable M2M micro-transactions. This Web3 connector for IoT enables more transparent and secure data transfer as well as high-throughput transactions.

ConnectedIO creates M2M-enabled Networking Devices

ConnectedIO is a US-based startup that manufactures M2M and IoT-enabled networking devices for industrial settings. The startup’s router, CR64NA, features a Linux-based OS and simplifies network management, delivering the service over the cloud or at the edge. Other features of the router include 4G support with a 3G fallback standard, multi-connectivity, and high bandwidth, up to 300 Mbps. The startup also provides CR42NA, CR44NA, ER2500T-VZ-CAT1, ER2500T-NA-CAT1, and CM4NA routers for specific use cases. These, along with ConnectedIO’s software, enable quick deployment and management of M2M devices in factories.

9. Autonomous Factories

The range of deep tech solutions available today enables manufacturers to completely automate their factory operations, resulting in lights-out, dark, or autonomous factories. They leverage technologies like IIoT, AI, machine learning, advanced robotics, and more to replace humans. However, high capital expenses are the main factor slowing down their implementation. To tackle this, startups offer retrofit solutions and modular autonomous production lines that integrate with existing manufacturing plants or work as standalone micro-factories. This allows businesses to mitigate massive costs associated with autonomous operations and save expenses associated with human resources.

MOLG advances Circular Manufacturing

MOLG is a US-based startup that enables circular manufacturing. The startup allows manufacturers to convert their existing production lines or establish new factory models. For this, MOLG leverages robot-first assembly, software-defined design processes, and automated testing and validation through simulations. It then runs and scales production on high-density deployable micro-factories for assembly and disassembly. The startup also develops an open standard, OriginMark, to track material composition, assembly hierarchy, and circularity, improving material traceability. The startup’s solution allows manufacturers to quickly integrate circular manufacturing without massive capital expenses.

Industrial Next enables Autonomous Automotive Manufacturing

Industrial Next is a Chinese startup that creates CyberRealm, a factory autonomy framework for automotive manufacturers. It combines sensing, learning, and automation technologies through three modules – CyberSight, CyberSpawn, and CyberGate. CyberSight is a smart camera with 30TOPS of computational performance and CyberSpawn is a GigE-style camera with built-in AI for delivering visual intelligence. CyberGate is an orchestration and logic controller that allows the full integration and no-code setup of the startup’s cameras. Through these modules, the startup enables automakers to automate vision-based tasks like quality inspection and matrix production.

10. Human-to-Machine

While M2M simplifies data sharing between machines and devices in factories, H2M technologies aid interaction between workers and assets as well as machine control. For this, manufacturers leverage advanced machine control interfaces, augmented reality glasses, and cobots, among others. For instance, AI-powered voice control systems enable voice commands in noisy environments to ensure hands-free operations on production floors. Such human-computer interaction (HCI) solutions are also critical to interact with automated systems as even autonomous factories require human inputs and oversight. Moreover, advanced H2M technologies displace workers from hazardous environments to ensure their safety.

bitvox provides Voice Control for Machines

German startup bitvox makes voice interfaces and digital assistants for the industrial sector. The startup’s solution allows workers to control machines and systems through voice. It also features multiple languages, automates documentation, and provides instructions for logistics, maintenance, and manufacturing processes. This enables hands-free operations, saving time and promoting efficiency.

Tienovix provides Holographic Guidance for Workers

Tienovix is a US-based startup that makes AR software for smart factories. It allows businesses to create, update, and upload best practices and standard operating procedures (SOP) to ensure enterprise-wide procedural conformance. In industrial environments, the software delivers precision holographic guidance to enable hands-free procedures for operators and reduce manual errors. The startup also designs the software’s implementation with other industrial systems and combines AI to offer real-time, interactive instructions. This allows workers to reduce rework, enhance technician productivity, lower training costs, and increase collaboration.

Discover all Smart Factory Trends, Technologies & Startups

While the trends mentioned in this research advance smart factory adoption, its high capital expenditure is limiting the rate of adoption. That is why startups are making solutions that leverage off-the-shelf components to digitize factories. Other innovations in smart factories include 5G integration for near real-time data transfer and high-performance computing (HPC) to bring data processing closer to the source. Blockchain is also enabling a more secure and transparent data ecosystem for manufacturing plants. The Smart Factory Trends & Startups outlined in this report only scratch the surface of trends that we identified during our data-driven innovation & startup scouting process. Identifying new opportunities & emerging technologies to implement into your business goes a long way in gaining a competitive advantage.