Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

This article provides an overview of 10 on-demand manufacturing solutions – including AI-powered process control, generative design, and polymorphic molding. These companies leverage advancements in multi-material 3D printing and automated, data-driven production platforms to streamline supply chains and reduce lead times. Each company enhances manufacturing precision, scalability, and supply chain agility as well as illustrates the critical role of AI, machine learning, and recyclable materials in transforming modern manufacturing.

Continue reading to gain up-to-date and data-driven insights on:

- Profiles of 10 Emerging On-Demand Manufacturing Solutions

- How to Scout Best On-Demand Manufacturing Solutions Easily

Key Takeaways

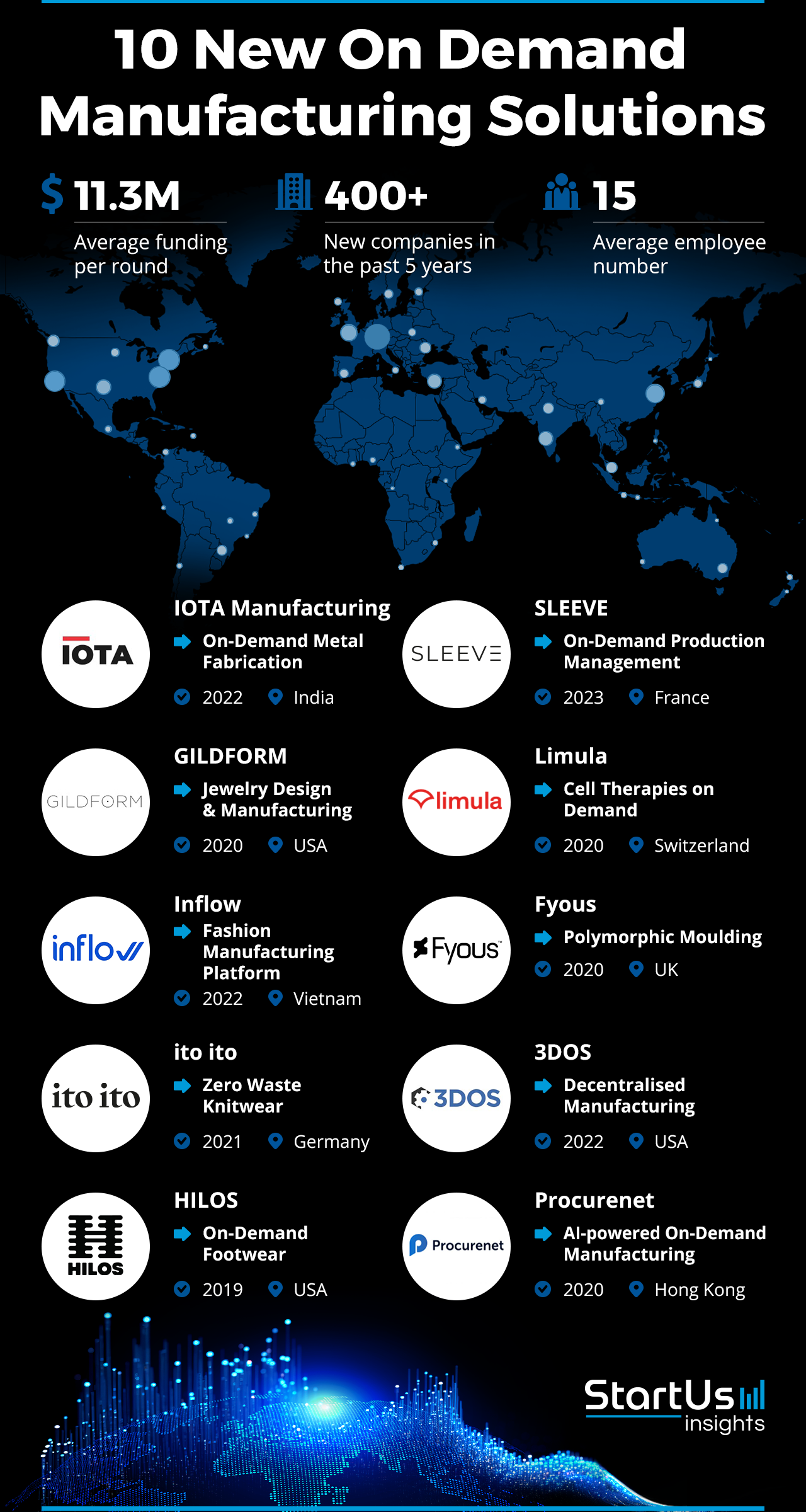

Drawing insights from the Big Data & AI-powered StartUs Insights Discovery Platform that provides data on over 4.7+ million emerging companies globally, we explore the evolving landscape of the on-demand manufacturing industry. This sector is marked by key trends and a substantial workforce, shaping its future. We updated this report 5 days ago. Missing information? Contact us to add your insights. Here are some key insights at a glance:

- Current On-Demand Manufacturing Trends: Some trends include additive manufacturing, advanced robotics, industrial Internet of Things (IIoT), AI, big data, and analytics.

- On-Demand Manufacturing Industry Statistics: The sector comprises 2.7K+ organizations worldwide, with 400+ new companies founded in the last five years, marking 2020 as the average founding year. These emerging companies typically employ around 15 people each. Further, the average funding received per round by these companies during the same period is USD 11.3 million.

- 10 Top On-Demand Manufacturing Solutions to Watch:

- IOTA Manufacturing – On-Demand Metal Fabrication

- GILDFORM – Jewelry Design & Manufacturing

- Inflow – Fashion Manufacturing Platform

- ito ito – Zero Waste Knitwear

- HILOS – On-Demand Footwear

- SLEEVE – On-Demand Production Management

- Limula – Cell Therapies on Demand

- Fyous – Polymorphic Moulding

- 3DOS – Decentralised Manufacturing

- Procurenet – AI-powered On-Demand Manufacturing

Discover 10 out of 400+ Emerging On Demand Manufacturing Solutions

In this section, we highlight 10 emerging companies reshaping the on-demand manufacturing landscape. These companies leverage polymorphic molding for flexible and cost-effective parts manufacturing and AI-powered B2B platforms for optimized workflows. Further, these innovators specialize in on-demand manufacturing of cell therapies for personalized medical treatments, and fashion production management platforms that reduce overproduction and enhance sustainability. Each company sets a new standard and responds to industry needs with efficiency, speed, and innovation.

Note on Signal Strength

One of the unique metrics we feature for each company is Signal Strength, a proprietary data point generated by our Discovery Platform. It gauges the extent to which a company’s influence has permeated the global ecosystem of startups, scaleups, and emerging companies. This proprietary metric serves as a valuable guidepost for understanding a company’s standing in the broader market landscape.

1. IOTA Manufacturing

- Founding Year: 2022

- Employee Range: 51-200

- Location: India

- Signal Strength: Strong

- What they do: IOTA Manufacturing delivers an on-demand metal fabrication platform that enables instant quoting, design for manufacturing (DFM) analysis, and online ordering and shipment. The platform leverages AI-driven selection to match each project with a suitable manufacturer from its network of partners and in-house facilities. It also employs a two-stage technical feasibility check to validate designs. Additionally, the platform offers climate-neutral express shipping enhancing efficiency and sustainability for scalable metal fabrication needs.

2. GILDFORM

- Founding Year: 2020

- Employee Range: 2-10

- Location: US

- Signal Strength: Very Strong

- What they do: GILDFORM provides an on-demand jewelry design and manufacturing platform that enables brands to develop customized jewelry from concept to creation. The platform initiates the design phase by converting user-provided sketches or reference images into precise 3D models. This solution also features AI-driven tools to optimize design parameters and offer data-driven insights to improve operations.

3. Inflow

- Founding Year: 2022

- Employee Range: 51-200

- Location: Vietnam

- Signal Strength: Very Strong

- What they do: Inflow develops an on-demand fashion manufacturing platform to optimize the supply chain process for fashion brands. The platform leverages a centralized production system that links brands directly with a vast network of small and medium-sized manufacturers. This minimizes latency and communication overhead. It enables brands to adapt to market changes through scalable production options, from small test orders to large-scale manufacturing. The platform also uses machine learning and AI to optimize inventory management and production planning, minimizing waste and increasing efficiency.

4. ito ito

- Founding Year: 2021

- Employee Range: 2-10

- Location: Germany

- Signal Strength: Medium

- What they do: ito ito offers an on-demand knitwear production platform that optimizes resource efficiency and eliminates waste. The platform utilizes a distributed network of knitting machines connected via cloud-based infrastructure to control production parameters. Moreover, it uses organic yarns and recyclable materials with a transparent supply chain architecture. This provides traceability of production data, including cost structures, resource consumption, and delivery routes.

5. HILOS

- Founding Year: 2019

- Employee Range: 11-50

- Location: United States

- Signal Strength: Very Strong

- What they do: HILOS provides a platform that combines 3D printing and generative design with traditional manufacturing to create footwear and minimize material waste. The platform allows design teams to utilize parametric modeling and generative algorithms. This solution enables the production of small-batch orders with rapid turnaround times, facilitated by streamlined digital-to-physical workflows. The company’s approach decreases lead times and manufacturing costs while aligning with sustainable production practices.

6. SLEEVE

- Founding Year: 2023

- Employee Range: 2-10

- Location: France

- Signal Strength: Very Strong

- What they do: SLEEVE develops a SaaS B2B platform that digitizes and automates on-demand apparel production, directly connecting brands, factories, and fabric suppliers. The platform integrates the production process, from digital design to order management, inventory tracking, and real-time supply chain monitoring. It utilizes API-based integration to connect existing systems and automates production workflows through a centralized interface. SLEEVE provides real-time visibility into production stages by tracking components. This allows manufacturers to optimize production efficiency, reduce lead times, and enhance supply chain responsiveness.

7. Limula

- Founding Year: 2020

- Employee Range: 2-10

- Location: Switzerland

- Signal Strength: Very Strong

- What they do: Limula offers a platform for the on-demand production of autologous cell therapies, particularly for personalized cancer treatments. The platform consolidates multiple stages of cell therapy manufacturing within a single closed-loop system. Further, it integrates process analytics to monitor critical quality attributes in real time to ensure in-process control and traceability. The platform’s architecture supports parallel bioprocessing workflows and scalable throughput to optimize yield and reproducibility while minimizing human intervention and contamination risks. Limula addresses the complexities of personalized cell therapy manufacturing by enhancing operational efficiency.

8. Fyous

- Founding Year: 2020

- Employee Range: 2-10

- Location: UK

- Signal Strength: Very Strong

- What they do: Fyous uses polymorphic molding combined and 3D scanning to create accurate molds for tooling. By integrating with mobile-based 3D scanning technology, the company’s solution enables manufacturers to manufacture precision-engineered custom footwear for the healthcare industry. Moreover, this process leverages a shape-shifting tool that reconfigures its geometry to produce complex, bespoke midsoles from a single mold. This eliminates the need for traditional multi-tool setups. This process achieves the toolless design flexibility of 3D printing, yet drastically improves production efficiency by reducing cycle times compared to additive manufacturing.

9. 3DOS

- Founding Year: 2022

- Employee Range: 2-10

- Location: US

- Signal Strength: Very Strong

- What they do: 3DOS provides a decentralized manufacturing platform through its peer-to-peer (P2P) network for brands, influencers, artists, and inventors. By leveraging a 3D manufacturing network, the company ensures that products are made on demand while protecting intellectual property (IP) and facilitating royalty payments. The platform also eliminates the need for inventory and reduces waste while enabling users to finance and monetize excess manufacturing capacity. 3DOS thus offers a flexible, scalable approach to production that streamlines design-to-product for creators.

10. Procurenet

- Founding Year: 2020

- Employee Range: 51-200

- Location: Hong Kong

- Signal Strength: Very Strong

- What they do: Procurenet develops an AI-powered on-demand manufacturing platform that connects buyers with manufacturers to optimize supply chain management. The company evaluates manufacturers based on historical performance and compliance with global standards. The platform enables manufacturers to respond quickly to market demands while ensuring high-quality production.

Quick Tip to Find New On-Demand Manufacturing Solutions

Utilizing a SaaS platform like the Discovery Platform for identifying new on-demand manufacturing solutions provides significant benefits compared to traditional scouting methods:

- Streamlined Efficiency: The Discovery Platform offers advanced tools that streamline the scouting process. It replaces your hours of conventional desk research, saving time and resources in identifying on-demand manufacturing innovations.

- Access to Real-time Insights: Gain a competitive edge with up-to-date information on the latest trends in the on-demand manufacturing industry. The platform keeps you informed with near real-time updates on emerging on-demand manufacturing solutions and news, enabling you to make swift and informed decisions.

- Tailored Exploration: Customize your search to focus on specific niches within the on-demand manufacturing sector, such as additive manufacturing, polymorphic molding, or AI-powered manufacturing platforms. The platform’s diverse filtering options allow you to target your scouting efforts precisely, ensuring that you find the most relevant and groundbreaking companies in the field.

Ready to Explore All New On Demand Manufacturing Solutions?

We’ve explored the dynamic landscape of the on-demand manufacturing industry, examining the latest trends and spotlighting exceptional companies driving innovation. To dive deeper, download our free Manufacturing Report or schedule a demo of the Discovery Platform for a customized exploration of these groundbreaking developments. We’re looking to collaborate with knowledgeable insiders to enhance our analysis of startups and tech trends. Join us!