Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

The industrial design sector faces a multitude of challenges, encompassing the need for sustainable practices and the complexities of user-centric design. In response, a fusion of technology-driven trends emerges as a substantial solution. From 3D printing and biomimicry to augmented and virtual reality (AR & VR), each trend plays a key role in overcoming obstacles that have long hindered the industry’s progress. Read more to explore how these trends in industrial design contribute to a more agile, sustainable, and user-focused industrial landscape.

Top 10 Industrial Design Trends in 2024

- 3D Printing

- AR & VR

- Sustainable Design

- Advanced Materials

- Internet of Things (IoT)

- Cloud-powered Computer-aided Design (CAD)

- Generative Design

- Human-Centered Design (HCD)

- Biomimicry

- Big Data

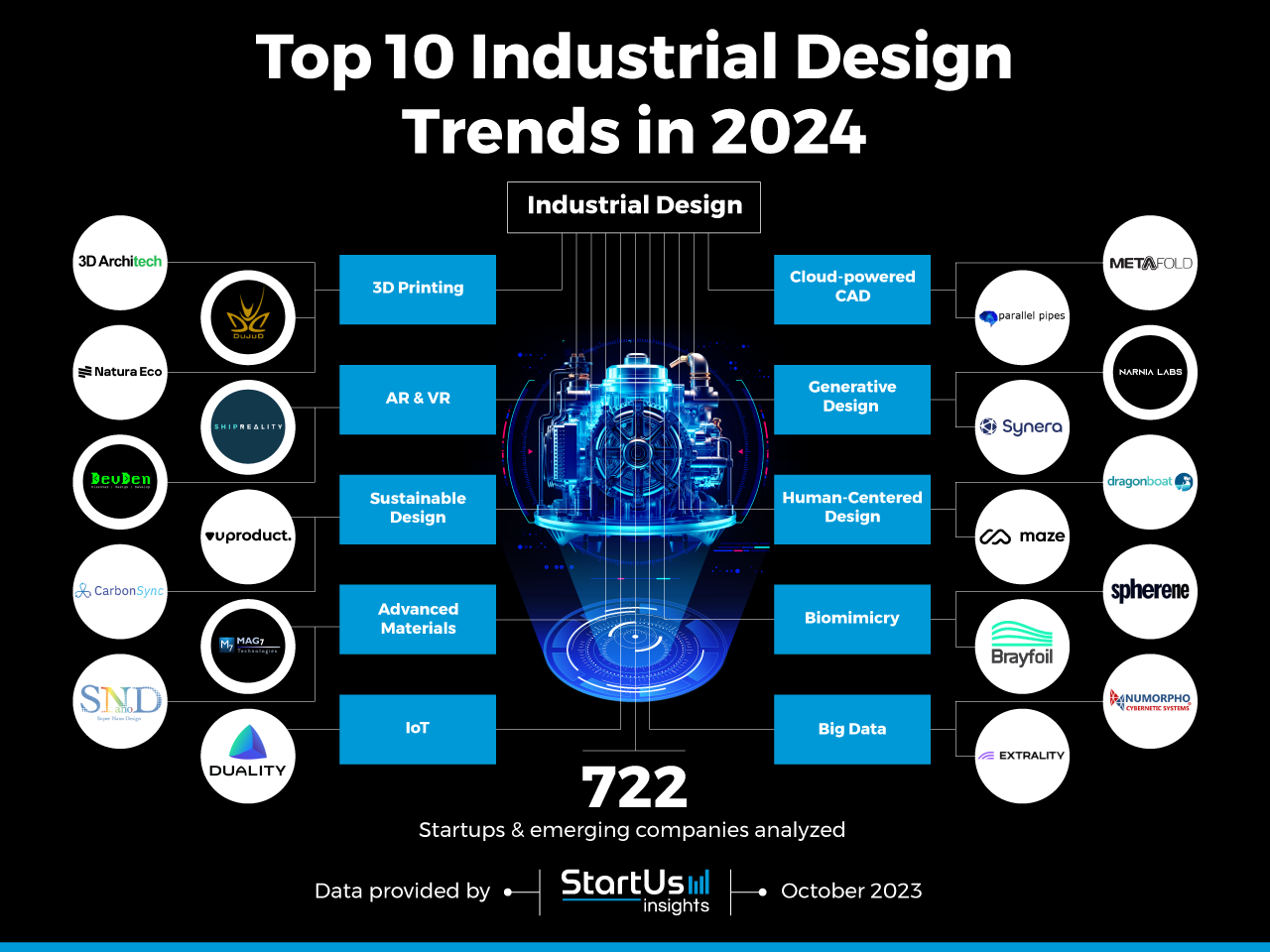

Innovation Map outlines the Top 10 Industrial Design Trends & 20 Promising Startups

For this in-depth research on the Top Trends in Industrial Design, we analyzed a sample of 722 global startups & scaleups. This data-driven research provides innovation intelligence that helps you improve strategic decision-making by giving you an overview of emerging technologies in the industrial design industry. In the Industrial Design Innovation Map, you get a comprehensive overview of the innovation trends & startups that impact your company.

These insights are derived by working with our Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 3 790 000+ startups & scaleups globally. As the world’s largest resource for data on emerging companies, the SaaS platform enables you to identify relevant technologies and industry trends quickly & exhaustively.

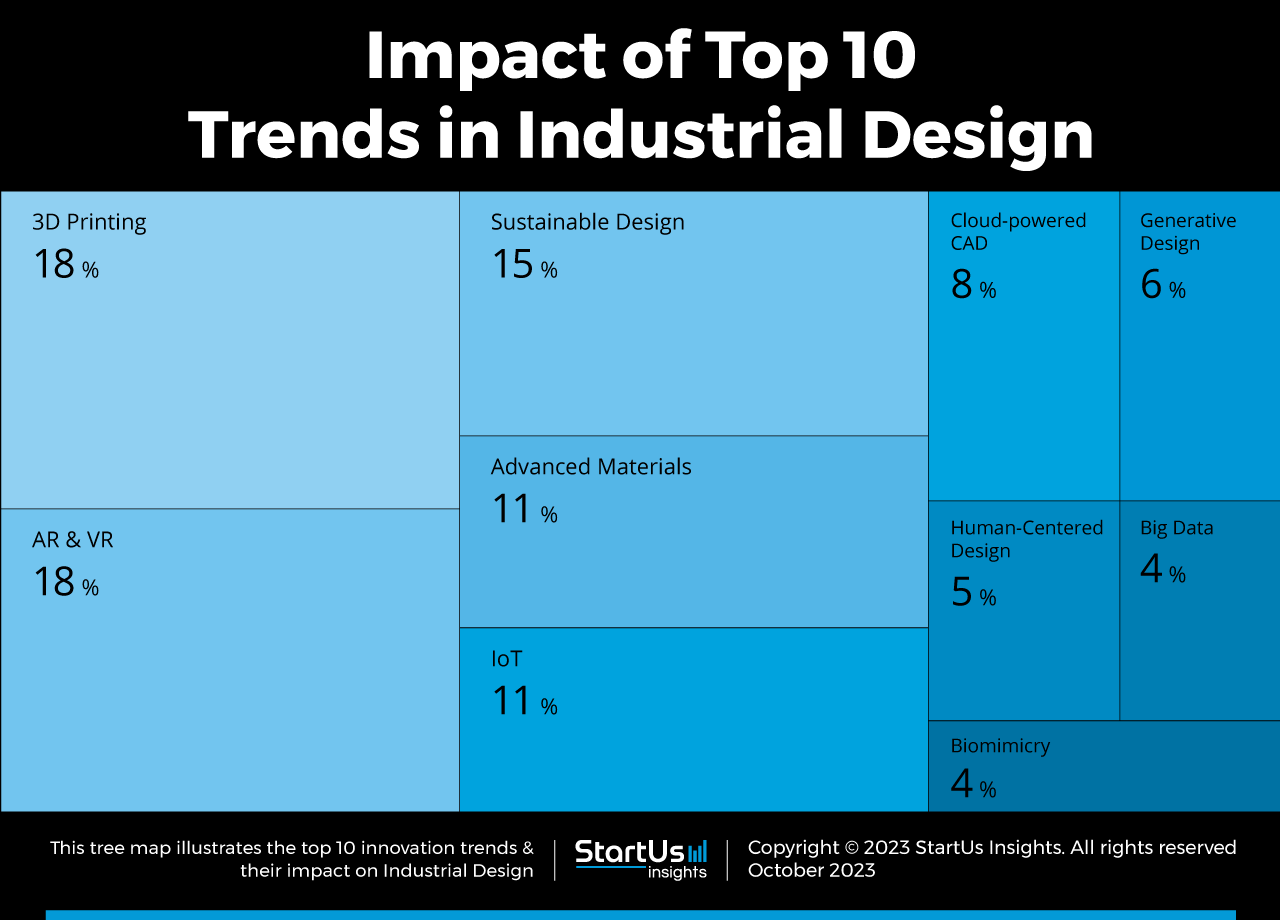

Tree Map reveals the Impact of the Top Industrial Design Trends in 2024

Based on the Industrial Design Innovation Map, the Tree Map below illustrates the impact of the Top 10 Industrial Design Trends in 2024. The current focus on 3D printing is driving adaptive manufacturing, encouraging product customization while minimizing material wastage. Simultaneously, the integration of AR and VR allows engineers and designers to create virtual prototypes that enhance understanding of designs. Sustainable design and biomimicry further signify a deliberate shift towards ecologically responsible practices, aligning products with environmentally conscious values. The synergy of advanced materials and generative design contributes to heightened creativity and elevated product performance standards.

Additionally, IoT connectivity streamlines operations by offering real time insights for design optimizations. Cloud-powered CAD facilitates collaborative design, fostering efficient workflows. Meanwhile, the adoption of human-centered design places a priority on user needs, ensuring the creation of intuitive and inclusive products. In parallel, big data plays a crucial role in decision-making, predicting design trends, and optimizing supply chains for enhanced resource utilization. These trends offer strategic advantages for business-to-business (B2B) stakeholders across diverse sectors, including manufacturing, healthcare, automotive, and more.

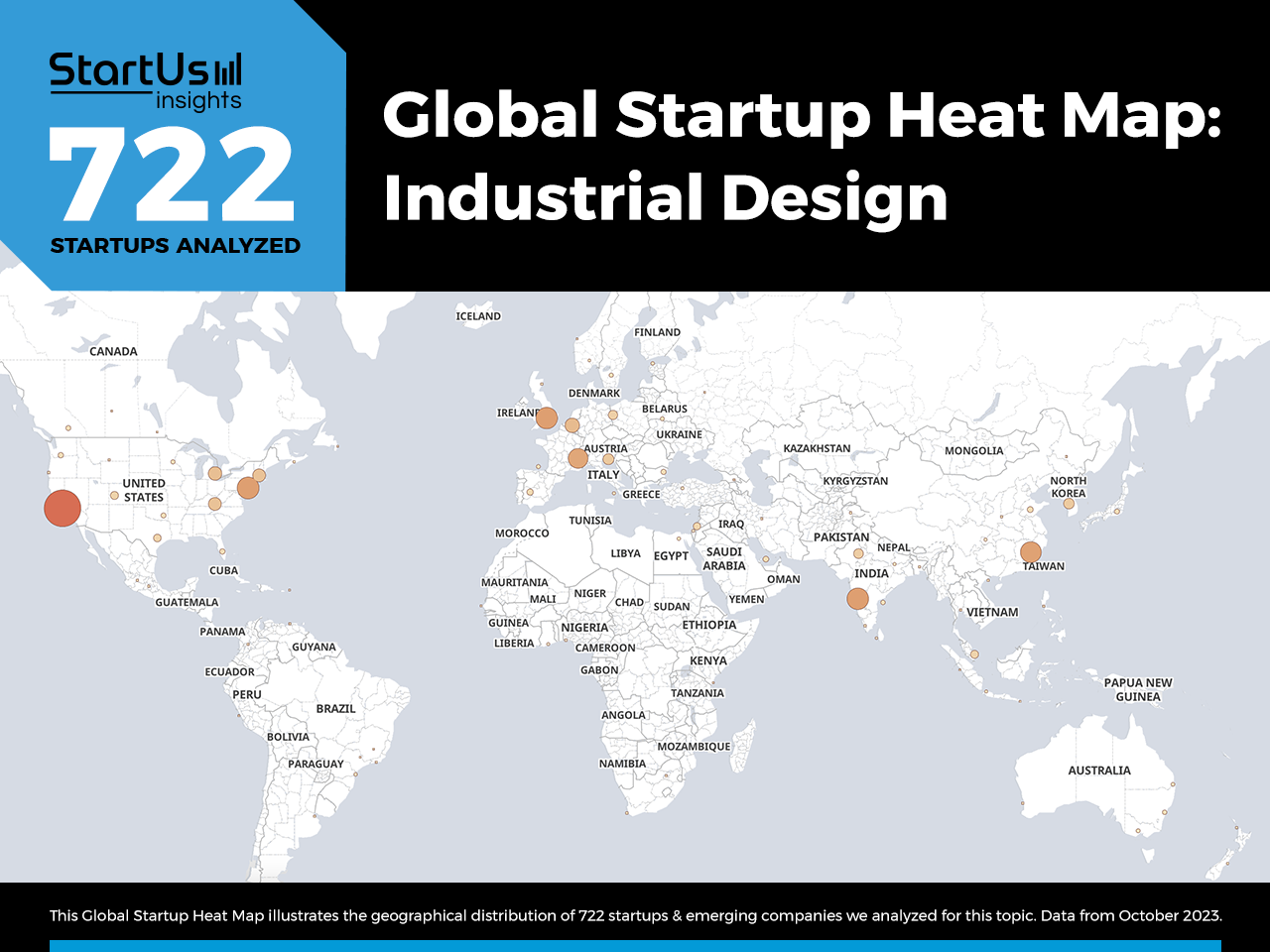

Global Startup Heat Map covers 722 Industrial Design Startups & Scaleups

The Global Startup Heat Map below highlights the global distribution of the 722 exemplary startups & scaleups that we analyzed for this research. Created through the StartUs Insights Discovery Platform, the Heat Map reveals high startup activity in the US, followed by India and the UK.

Below, you get to meet 20 out of these 722 promising startups & scaleups as well as the solutions they develop. These industrial design startups are hand-picked based on criteria such as founding year, location, funding raised & more. Depending on your specific needs, your top picks might look entirely different.

Interested in exploring all 700+ industrial design startups & scaleups?

Top 10 Trends in Industrial Design (2024)

1. 3D Printing

Recent technological breakthroughs in 3D printing are revolutionizing industrial design. Continuous liquid interface production (CLIP) and digital light processing (DLP) are ushering in a new era of rapid, layerless printing. They facilitate the creation of prototypes with smoother and more uniform surfaces. Metal 3D printing, utilizing techniques like selective laser melting (SLM), is achieving remarkable progress in producing intricate metal parts with enhanced strength and functionality.

These innovations are not only reducing prototyping costs but also accelerating product development cycles. Novel 3D printing technologies thus enable the creation of complex, customized designs that meet the demands of tight production schedules and address scalability challenges in mass manufacturing.

3D Architech offers Gel-based 3D Printing

US-based startup 3D Architech develops a proprietary gel-based 3D printing technology. Gel-based printing aids high-resolution net-shape metal manufacturing and supports various materials like metals, ceramics, and multi-materials. Further, it fosters design flexibility, sustainability, and complexity of metal production. These features benefit jewelry producers, heat exchangers, motors, and medical tools.

DUJUD advances Metal 3D Printing

US-based startup DUJUD prints dielectrics at micron-scale using proprietary technology. Due to temperature sensitivity, it is difficult to integrate semiconductors, polymers, and metals into one 3D printing system. DUJUD combines hybrid metal-dielectric and micron-scale room temperature direct metal 3D printing schemes to address these constraints.

The startup’s approach enables monolithic 3D-printed electronic systems to achieve a larger design space. Also, it leads to higher metal adhesion quality, better electrical resistivity, and lower retooling costs. All these features allow industrial designers to realize thin metal projects for manufacturers of sensing and flexible electronics.

NaturaEco makes Construction 3D Printers

Serbian startup NaturaEco develops multifunctional construction 3D printers for design projects. Traditional construction methods often need complex and intricate geometric designs. The startup offers proprietary gantry systems with 3 or 4 axes that translate complex digital designs into physical structures.

The startup’s technology also bypasses time-consuming prototyping, offering solutions that enhance efficiency, flexibility, sustainability, and innovation in the construction process. Overall, the modular printing machines focus on mass full-scale construction projects to deliver higher operational revenue for design firms, material suppliers, and construction companies.

2. Augmented Reality & Virtual Reality

The limitations of traditional 2D drawings and 3D CAD models are being overcome through immersive technologies like AR and VR. Metaverse integration, VR-aided exploration of generative designs, and VR CAD are pushing the boundaries of design possibilities. For example, VR-assisted CAD allows designers to explore and manipulate 3D creations in a more intuitive and immersive experience.

Further, AR-powered smart glasses overlay 3D models onto physical workspaces to deliver tangible interaction with virtual elements. These immersive technologies offer advanced visualization, collaboration, and creative freedom, enhancing product quality while enhancing workflows for designers, architects, and engineers.

ShipReality develops a 3D Engineering Platform

US-based startup ShipReality builds an end-to-end 3D engineering platform merging extended reality (XR) visualization, generative design, and cloud-based CAD. Its 3D pathfinding algorithm leverages advanced graph theory to find optimal routes within 3D spaces in real time for optimized design.

The platform also incorporates mixed reality SLAM (simultaneous localization and mapping) for precise tracking and mapping in complex industrial locations. This way, the platform delivers spatial intelligence and contributes to more informed design decisions, ensuring safety across aerospace, mining, and nuclear industries.

DevDen aids in 3D Product Visualization

Indian startup DevDen implements immersive technologies to visualize 3D models of products and components using AR, VR, and XR. Its solutions allow industrial designers to gain visual acuity and detect design flows before the product goes into production. The AR/VR solutions also provide step-by-step instructions to employees during the assembly process, enhancing workers with realistic training experience.

Meanwhile, inspection teams benefit from it by overhauling digital information over physical objects in real-time. All these opportunities not only increase the quality and reliability but also reduce product returns, catering to manufacturing teams and industries.

3. Sustainable Design

Addressing social and environmental implications, sustainable design for mass production is gaining momentum with the support of technological advancements. Life cycle assessment (LCA) software solutions evaluate the environmental impact of products throughout their life, guiding informed decision-making.

Circular design principles, such as cradle-to-cradle (C2C), also prioritize recyclability and reuse. This contributes to reduced environmental impact, enhanced resilience, and improved resource efficiency. Sustainable industrial design reflects corporate responsibility to improve brand reputation and also results in long-term cost savings.

vu product manufactures Edible Bio Plastic

UK-based startup vu product creates an edible bio-based alternative to plastic. Since massive plastic production pollutes the environment and takes a long time to break down, the startup brings innovation from the agricultural industry. For raw materials, it uses potato waste to design product prototypes ethically. By using edible bio-based plastic at early design stages, vu product caters to manufacturers and suppliers as well as attracts environmentally conscious consumers.

Carbon Sync simplifies Product Climate Impact Measurement

US-based startup Carbon Sync provides a life cycle assessment tool to design sustainable product prototypes. Its LCA software calculates packaging resources, raw materials, and other processes necessary for the design value chain. It also shares, exports, and sends feedback from multiple stakeholders for seamless collaboration.

Additionally, customers receive a comparative analysis of different prototype versions to select the best-performing net zero emissions before mass production. This approach promotes responsible design planning and execution, benefiting engineers, manufacturers, and supply chain managers.

4. Advanced Materials

The integration of high-performance alloys, composites, and innovative materials like graphene is driving structural innovations. Two-dimensional materials like graphene enhance durability and conductivity, while smart materials such as shape memory alloys and thermochromic materials enable adaptive designs with energy-harvesting functions.

Besides, nanomaterials, influencing the miniaturization trend in electronics, offer enhanced electrical conductivity and thermal properties. Manufacturers incorporating these advanced materials into their portfolio are steering the market towards sustained innovation.

Mag7 Technologies manufactures Advanced Materials and Coatings

US-based startup Mag7 Technologies specializes in advanced materials and coatings that enhance industrial design across sectors like aerospace, defense, and energy. The startup leverages pre-ceramic polysilazane polymers and graphene to develop materials with extreme heat endurance, enhanced strength, and environmental remediation. They find applications in high-performance coatings, ceramic matrix composites, and inorganic-organic hybrid materials.

Super Nano Design advances the Mass Production of Nanomaterials

Japanese startup Super Nano Design leverages supercritical hydrothermal synthesis technology. This technology allows the mass production of custom-made nanomaterials with precise control of nanoparticle properties, including mechanical, thermal, and electrical characteristics.

Whether seeking improved structural integrity, advanced coatings, or novel surface modifications, the nanomaterials open new avenues for industrial applications. The use of metal salts and uniform-sized particles further accelerates scalable production with cost-competitive advantages for manufacturers.

5. Internet of Things

IoT drives design for mass production by providing a comprehensive understanding of product performance, user behavior, and manufacturing processes. Embedding sensors in products and production machinery allows designers to gather real-time data on usage patterns, environmental conditions, and equipment efficiency. This data further enables them to identify areas for improvement in product design, ensuring that final products meet user needs and withstand operational challenges.

Additionally, IoT data enables predictive maintenance, allowing designers to anticipate potential issues in the production line and proactively design solutions. Moreover, by analyzing data on resource utilization and production bottlenecks, designers optimize manufacturing processes for efficiency and cost-effectiveness. The insights derived from IoT data play a crucial role in informing design decisions, streamlining production workflows, and enhancing the overall quality and scalability of mass-produced products.

Duality offers Digital Twin Simulations

US-based startup Duality builds a digital twin simulation platform to test product models to improve real-world results digitally. High-volume production of aircraft, robots, and self-driving cars requires highly accurate ML models to operate safely. Duality’s platform, Falcon, powered by a 3D simulator and virtual sensors, enables rapid design and validation of autonomy algorithms in photorealistic environments. This achieves real-time deterministic simulation of complex scenarios and ensures faster deployment for robotics, AI, and more.

6. Cloud-powered CAD

Cloud-powered CAD brings the cloud’s computational capacity to handle resource-intensive tasks. They include complex simulations, high-fidelity rendering, and intricate design computations. With cloud computing, designers are liberated from local hardware constraints, allowing faster processing of demanding processes.

Geographically dispersed teams further benefit from streamlined collaboration through cloud-based platforms. This approach accelerates design for manufacturability (DFM) finalization. The transition towards scalable, subscription-based models, in turn, optimizes resource allocation and enhances financial efficiency, marking a departure from capital-intensive infrastructures.

Metafold simplifies Design Processing

Canadian startup Metafold offers a cloud-based platform to elevate industrial design capabilities for additive manufacturing. With a focus on simplicity and speed, it allows designers, engineers, and developers to create intricate parts efficiently and harness geometric powers for 3D printing.

Additionally, its one-click compression simulation delivers fast performance analysis while ensuring precise dimensional accuracy down to the millimeter for optimal part design. This delivers enhanced capabilities with reduced costs, catering to industrial designers, manufacturers, and research & development (R&D) teams.

Parallel Pipes integrates Cloud-based Multiphysics

US-based startup Parallel Pipes addresses product development needs through a tailored computer-aided engineering (CAE) platform. Its physics-based optimization platform considers overall product cost, allowable material selection, manufacturing processes, geometric adjustments, and more. This enables the rapid development of products with precise intent.

The platform also includes versatile environments covering structural mechanics, fluid dynamics, multi-body dynamics, thermodynamics, electromagnetics, acoustics, and optics. This way, Parallel Pipes identifies inefficiencies in product design to minimize costs and optimize processes for engineers, business owners, and risk management teams.

7. Generative Design

Generative design represents a departure from traditional approaches with AI acting as a collaborative design co-pilot rather than a mere tool. Through iterative processes, algorithmic engines explore numerous design permutations based on predefined parameters and constraints to create novel industrial designs.

The resource-optimized designs created with generative AI models are both aesthetically pleasing and structurally efficient. Industries adopting generative design benefit from minimized material usage and enhanced performance, aligning with sustainable practices.

NARNIA LABS enables AI-powered Product Design

South Korean startup NARNIA LABS delivers AI-powered generative design using deep learning. Focused on streamlining workflows, rendering concepts faster, and bridging design quality gaps, its software transforms raw ideas into photorealistic renders. The software also predicts engineering feasibility and recommends designs aligned with customer preferences.

Further, the software verifies whether designs meet engineering and manufacturing requirements to ensure feasibility. Lastly, it introduces an AI design library that converts 2D work into 3D designs, enabling easy editing in 3D. By leveraging generative AI, the platform empowers designers and creative directors to focus on creativity while addressing inefficiencies.

Synera creates Product Engineering Software

German startup Synera develops a low-code platform to empower engineers and designers with generative design. It integrates CAE tools into a simple visual editor without the need for extensive coding. This open and integrated environment ensures a smooth transition into generative design practices for engineers.

The automated approach also frees engineers from recurring tasks such as documentation, sketching, and modeling. Besides, moving beyond document-based engineering models injects agility into the iterative nature of generative design. All these together facilitate efficient workflows, rapid innovations, and customization for engineers.

8. Human-Centered Design

At the core of HCD is a deep understanding of end-users – their behaviors, preferences, and aspirations. Leveraging user-centric analytics, industrial designers gain insights to optimize design elements for efficient and cost-effective manufacturing. This symbiotic relationship ensures that design decisions are data-driven and tailored for large-scale production.

Moreover, reduced product development cycles, decreased post-launch modifications, and increased user adoption rates are major benefits of this integrated approach in industrial design. This resonates across design teams, engineering departments, marketing strategists, and business leaders.

Dragonboat simplifies Product Development

US-based startup Dragonboat designs a platform to elevate product management practices. It promotes a human-centered design by aligning product decisions with business goals, customer needs, and development strategies. The platform also enables top-down alignment of OKRs (objectives and key results) and strategies across all levels of the organization.

The platform’s centralized request portal organizes ideas in a flexible structure for a comprehensive overview of the requirements. The platform thus empowers manufacturers with actionable insights to optimize decision-making for improved efficiency and innovation.

Maze delivers Customer Insights for Product Research

US-based startup Maze develops an AI-powered platform to conduct effective product research. It encompasses a drag-and-drop interface in prototype testing, card sorting, feedback surveys, and interview studies. By gaining deep insights into user needs and preferences, designers tailor their creations to meet and exceed user expectations. Supported by visually-rich, customizable reports the platform sheds light on design metrics, path analysis, and heatmaps. These reports allow managers to communicate design metrics to stakeholders better, facilitating data-driven decision-making.

Further, dynamic follow-up, contextual suggestions, and bias detection enable designers to adapt and iterate their designs based on real-time feedback. This ensures continuous improvement and alignment with user expectations. Overall, the user-centered design platform addresses key challenges associated with mass production such as efficiency, scale, and the need for broad market appeal.

9. Biomimicry

Biomimicry involves imitating and adapting nature’s designs, processes, and systems. This approach fosters a deeper understanding of ecological principles, leading to the development of products harmonizing with the natural world. Examples include self-healing materials inspired by regenerative abilities and advanced robotics mimicking animal locomotion.

The integration of biomimicry in smart textiles demonstrates its potential in wearable technology, showcasing nature-inspired designs. Industries from manufacturing to aerospace and robotics stand to gain efficiency and ecological consciousness through biomimetic designs.

spherene integrates Nature-inspired Algorithms

Swiss startup spherene offers a biomimicry-inspired technology based on its adaptive density minimal surfaces(ADMS) algorithm. The technology draws inspiration from solid materials to achieve maximum strength with minimal resources.

With this biomimetic approach, the startup yields highly adaptable and optimally curved geometries. By guiding the spherenes with specific boundary conditions, customers achieve reliable, repeatable, and verifiable results. These structures demonstrate material and energy-efficient designs, saving resources for manufacturers.

Brayfoil Technologies designs Biomimetic Wind Turbines

South African startup Brayfoil Technologies develops morphing wing technology. Taking cues from the efficiency of African birds of prey, its patented solution dynamically adjusts the shape of turbine blades during operation. This way, the startup manufactures longer blades with a biomimetic design for increased energy production.

10. Big Data

Big data, encompassing vast datasets from user interactions, market trends, and product performances, guides industrial design towards data-driven precision and innovation. Startups leverage advanced analytics and predictive modeling to reduce design flaws and enhance product efficacy.

Design teams, product managers, and business leaders harness big data and analytics to forecast trends, validate design hypotheses, and optimize resource allocation. This simplifies the design-to-market process, strengthening the competitive position of businesses.

Numorpho Cybernetic Systems facilitates Data-driven Product Design

US-based startup Numorpho Cybernetic Systems provides a manufacturing process platform driven by big data, analytics, and AI-enabled inference engines. It aims to create smart, connected, and sustainable products through knowledge-based engineering, data management, and cybernetics. The startup utilizes digital threads and digital twins to simulate real-world circumstances in a virtual environment.

Its approach facilitates collaborative product development, proactive issue resolution, and customer-centric solutions. Further, the startup’s data-driven simulations aid industrial designers by providing insights into real-world scenarios.

Extrality fosters Numerical Simulation

French startup Extrality integrates big data, AI, and the accuracy of physics to accelerate the design-to-post-processing journey. From uploading 3D geometries to defining boundary conditions and running simulations with a single click, Extrality’s platform simplifies the entire simulation process.

The platform delivers results, including volume, surface, evolution curves, and coefficients, within minutes. Extrality also leverages design data from past simulations and trials, incorporating concepts for solving physics partial differential equations (PDE). This enables product managers and design engineers to speed up time-to-market.

Discover all Industrial Design Trends, Technologies & Startups

The current technological trends in industrial design offer solutions to longstanding challenges and provide valuable benefits to involved parties. As we look towards the future, emerging technologies like quantum computing and augmented intelligence represent potential significant changes. These advancements, coupled with established trends such as 3D printing and IoT, create a dynamic landscape. The innovation path continues to evolve, promising even greater efficiency, creativity, and transformative possibilities in the realm of industrial design.

The Industrial Design Trends & Startups outlined in this report only scratch the surface of trends that we identified during our data-driven innovation & startup scouting process. Identifying new opportunities & emerging technologies to implement into your business goes a long way in gaining a competitive advantage.

![10 Top Digital Twin Startups and Companies for Industry 4.0 [2025]](https://www.startus-insights.com/wp-content/uploads/2025/06/Digital-Twin-Startups-for-Industry-4.0-SharedImg-StartUs-Insights-noresize-420x236.webp)