Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

Staying ahead of the technology curve means strengthening your competitive advantage. That is why we give you data-driven innovation insights into industry 4.0. This time, you get to discover five hand-picked collaborative manufacturing robot startups.

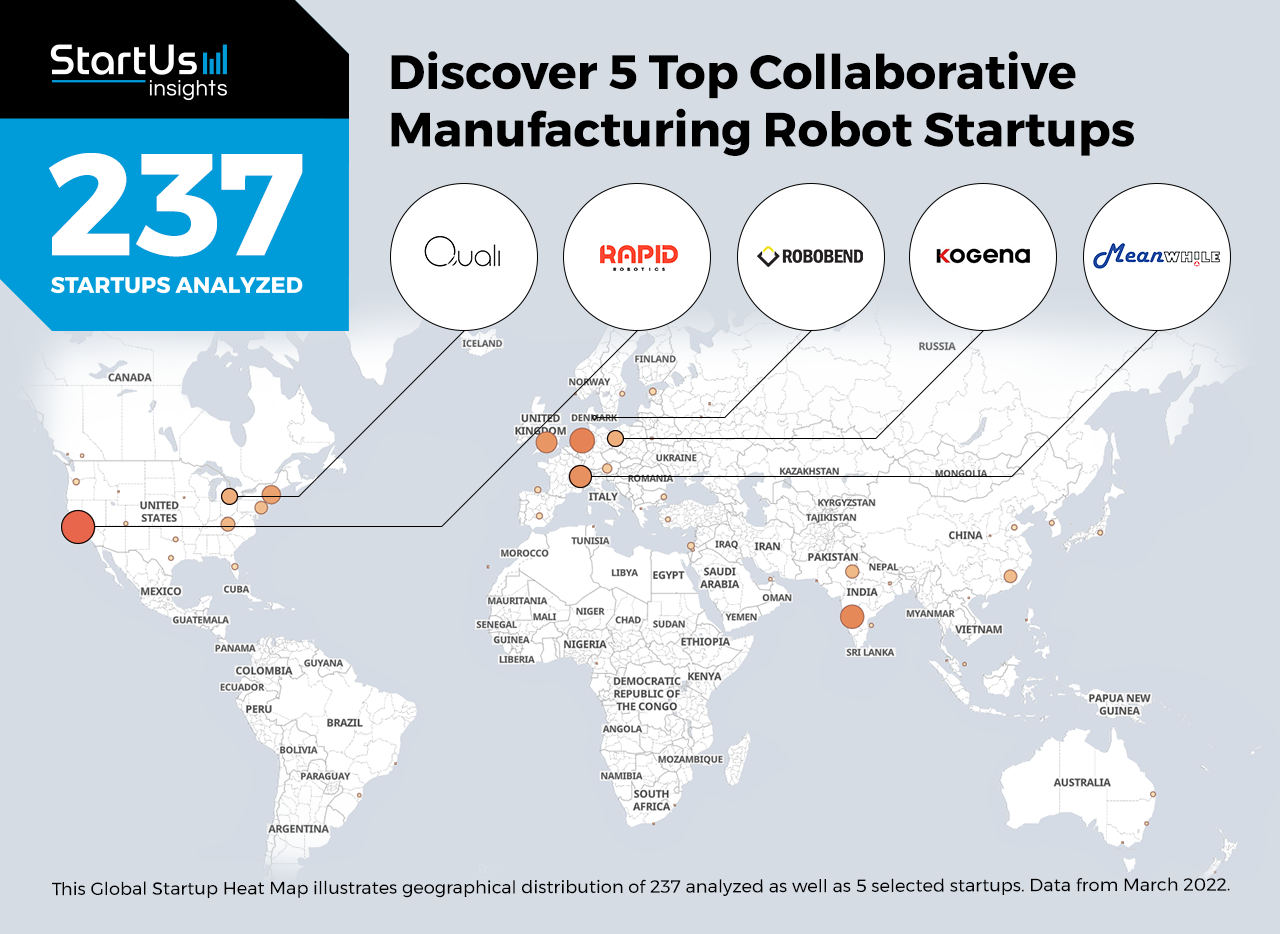

Out of 237, the Global Startup Heat Map highlights 5 Top Collaborative Manufacturing Robot Startups

The insights of this data-driven analysis are derived from the Big Data & Artificial Intelligence (AI)-powered StartUs Insights Discovery Platform, covering 2 093 000+ startups & scaleups globally. The platform gives you an exhaustive overview of emerging technologies & relevant startups within a specific field in just a few clicks.

The Global Startup Heat Map below reveals the distribution of the 237 exemplary startups & scaleups we analyzed for this research. Further, it highlights five robotics startups that we hand-picked based on criteria such as founding year, location, funding raised, and more. You get to explore the solutions of these five startups & scaleups in this report. For insights on the other 232 collaborative manufacturing robot solutions, get in touch with us.

Rapid Robotics offers a Robotic Machine Operator

Founding Year: 2019

Location: San Francisco, USA

Partner for End-of-Arm Tooling (EOAT)

US-based startup Rapid Robotics builds Rapid Machine Operator (RMO), an AI-powered pre-trained robotic machine operator. It is a six-axis cobot pre-loaded with industrial robotic programming. RMO automates various manufacturing processes like injection molding, heat staking, ultrasonic welding, and pad printing. It automatically moves between tasks and is suitable for time-bound high-mix manufacturing facilities. Further, RMO is integrated with no-code cobot software that provides a control interface to the user. These features allow manufacturers to improve production efficiency and quality.

Kogena develops a Cobot Monitoring Platform

Founding Year: 2018

Location: Wroclaw, Poland

Work with Kogena for Predictive Machine Maintenance

Polish startup Kogena develops a cloud-based platform for monitoring collaborative robots. It facilitates data collection, monitoring, and analysis of cobots. The platform uses raw data and algorithms to provide tailored maintenance to every robot. Additionally, it predicts possible failures and prevents unplanned disruption of manufacturing processes. This allows manufacturers to address the issue of growing employee shortage and enable predictive maintenance for robotic systems.

Meanwhile provides Autonomous Mobile Robots (AMR)

Founding Year: 2017

Location: Villeurbanne, France

Reach out for Mobile Collaborative Robots

French startup Meanwhile develops collaborative robots for the manufacturing industries. The startup’s robots include AI-based indoor navigation that modifies its route and behavior based on surroundings, enabling full autonomy. Its AMR, XuP-Lift, transports boxes between storage and production lines. Another robot, Evy-Box, is equipped with an AI-based raising and lowering system that allows automatic loading and unloading. Meanwhile’s robots improve productivity on the manufacturing floor while reducing the workload for operators.

RoboBend facilitates Automated Sheet Metal Bending

Founding Year: 2017

Location: Odense, Denmark

Partner for High-Precision Sheet Metal Bending Robot

Danish startup RoboBend makes a sheet metal bending robot. It offers an integrated, plug-and-play unit that combines a feeder, rail system, control interface, robotic arm, and smart barrier system. This ensures the correct placing and movement of metal in the press brake as well as improves the precision and quality of the bent sheet metal. The robot also switches between manual and automatic bending. RoboBends’ robot offers consistent throughput and provides high capacity even for smaller batch orders, in turn, increasing profits.

Quali AI provides Intelligent Manufacturing Robots

Founding Year: 2017

Location: Kitchener, Canada

Collaborate for Turnkey Robotics Solutions

Canadian startup Quali AI offers collaborative robots for manufacturing facilities. Its robots leverage computer vision, sensors, and integrated software to perform bin picking, sorting, and packing of packaged goods and machined parts. Further, the robots’ force sensors detect human workers and reduce industrial workplace accidents. Quali AI’s tailored robotic systems, in turn, allow manufacturers to improve material handling efficiency while relieving workers from repetitive and non-ergonomic tasks.

Discover more Industry 4.0 Startups

Industry 4.0 startups such as the examples highlighted in this report focus on industrial workplace safety, production automation, process monitoring, and predictive maintenance. While all of these technologies play a major role in advancing the industry, they only represent the tip of the iceberg. To explore industrial technologies in more detail, simply let us look into your areas of interest. For a more general overview, download our free Industry 4.0 Innovation Report to save your time and improve strategic decision-making.

![Future of Robotics: 12 Trends Powering the Next Wave [2025-2030]](https://www.startus-insights.com/wp-content/uploads/2025/06/Future-of-Robotics-SharedImg-StartUs-Insights-noresize-420x236.webp)