Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

Our Innovation Analysts recently looked into emerging technologies and up-and-coming startups working on innovative Industry 4.0 solutions. As there is a large number of startups working on a wide variety of solutions, we want to share our insights with you. This time, you will discover 5 promising end of arm tooling solutions.

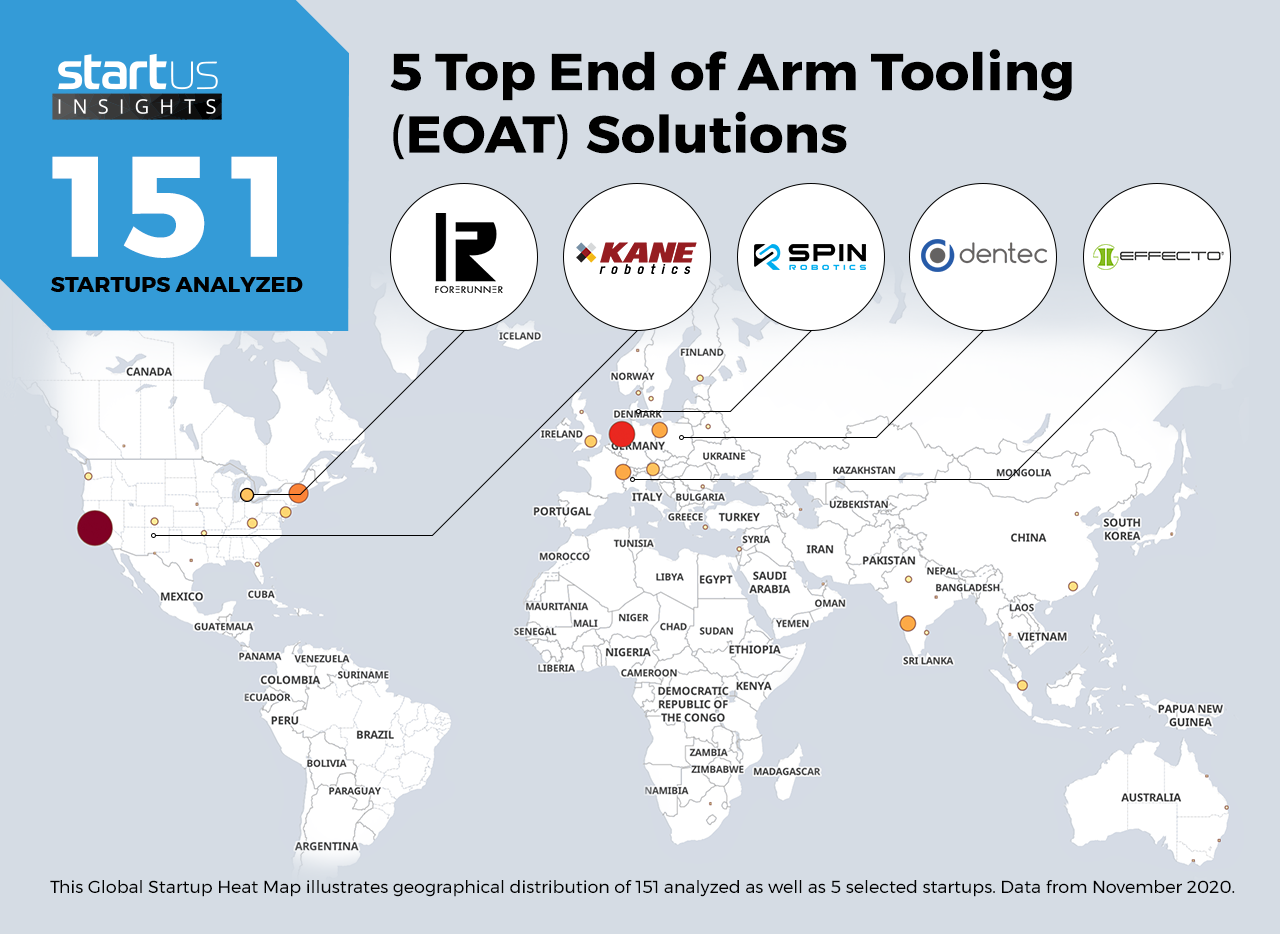

Heat Map: 5 Top End Of Arm Tooling Solutions

Using the StartUs Insights Discovery Platform, covering 1.379.000+ startups & scaleups globally, we looked at innovation in the field of advanced robotics. For this research, we identified 151 relevant solutions and picked 5 to showcase below. These companies were chosen based on a data-driven startup scouting approach, taking into account factors such as location, founding year, and relevance of technology, among others. Depending on your specific criteria, the top picks might look entirely different.

The Global Startup Heat Map below highlights 5 startups & scaleups developing innovative end of arm tooling solutions. Moreover, the Heat Map reveals regions that observe a high startup activity and illustrates the geographic distribution of all 151 companies we analyzed for this specific topic.

Effecto – Precision Grippers

Nowadays, startups design products in various kinds of shapes and sizes. Activities such as pick and place, movement between assembly stations, and logistics operations display a significant scope for automation. Industry 4.0 techniques enable organizations to save costs and improve productivity. Startups leverage advanced robotics technologies to develop robotic grippers and other EOAT solutions for the manufacturing industry.

Italian company Effecto offers grippers as end effectors for robots. The startup’s portfolio has a wide range of products, including parallel, angular, and toggle grippers. The grippers are customizable with two or three fingers and find applications in cleanrooms and assembly lines, as well as in picking and sorting operations in logistics. Additionally, the startup offers pneumatic swivel units, tool changers, and collision sensors for the robotic arms.

Kane Robotics – Turnkey Robotic Automation

All collaborative robots, or cobots, require intelligent software and durable hardware to function alongside human workers. Software plays a vital role in improving the efficiency of robotic systems, allowing developers to upgrade the capabilities of cobots. Innovations in the materials industry also enable robotics companies to use lightweight materials and increase the durability of cobots, as well as improve their versatility. Startups develop innovative hardware and software solutions to improve the handling capabilities of end of arm tooling solutions.

The US-based startup Kane Robotics manufactures turnkey robotic automation solutions with customized end of arm tooling. With the help of cobot-based instruments and related technology, the startup combines machine capabilities to increase productivity and efficiency. Some of the applications for which the startup offers end of arm tooling solutions include sanding, grinding and finishing, drilling, countersinking, and spraying epoxies, powders, and abrasives.

Spin Robotics – Screwdriver End Effector

Manual assembly of products that involve various small and essential components takes a considerable amount of time. Automation of such activities reduces labor costs and enables organizations to produce more in the given time frame. Startups develop screwdriver end of arm tooling solutions, particularly for applications in the electronics industry.

Danish startup Spin Robotics develops a screwdriver end effector tool for collaborative robots. The startup’s solution has several built-in features that enhance robot integration, such as easy to mount and program qualities. The tool enables pick and place screwdriving applications that involve picking from an automatic screw feeder next to a cobot. The safety shield provides a safe environment for the workers. The tool also has a built-in safety sensor that stops it when it comes into contact with any object.

Forerunner 3D Printing – 3D Printed End of Arm Tooling

Rapid prototyping is a cross-functional concept that enables manufacturing companies to test and finalize designs before commercially manufacturing the product. EOAT solutions significantly benefit from 3D printing as it reduces replacement time in case of faults. To this end, startups develop 3D printed solutions for end of arm tooling.

The US-based startup Forerunner 3D Printing provides additive manufacturing (AM) solutions for end of arm tooling prototypes in manufacturing. With the help of the HP Multijet Fusion 3D printing system, the startup produces nylon components significantly faster than other printing technologies in the market. Some of the startup’s products include hinges, gripper mechanisms, wire runs, and mounts for sensors printed directly in the components.

Dentec – Vacuum & Suction Tooling

The main advantage that grippers with suction cups provide is the safe and gentle handling of challenging surfaces that would otherwise be impossible to be handled by a human. Advances in robotics, such as multiple swivel robotic arms and lightweight robotic arms, reduce damages and wastage of materials due to improper handling for industries such as glass manufacturing and food processing. Startups develop end of arm tooling solutions that use vacuum-based and suction-based robotics.

Polish startup Dentec provides automation and industrial robotics solutions. The startup’s portfolio includes suction cups for handling dry sheets and glass panels, as well as wooden boards and cardboard packaging. The startup also produces vacuum components as the end of arm tooling solutions, including blowers and vacuum pumps, ejectors, vacuum grippers, filters, valves, regulators, cables, and accessories.

What about the other 146 solutions?

While we believe data is key to creating insights it can be easy to be overwhelmed by it. Our ambition is to create a comprehensive overview and provide actionable innovation intelligence and enable you to achieve your goals faster. The 5 end of arm tooling solutions showcased above are promising examples out of 151 we analyzed for this article. To identify the most relevant solutions based on your specific criteria, get in touch.

![Future of Robotics: 12 Trends Powering the Next Wave [2025-2030]](https://www.startus-insights.com/wp-content/uploads/2025/06/Future-of-Robotics-SharedImg-StartUs-Insights-noresize-420x236.webp)