Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

Staying ahead of the technology curve means strengthening your competitive advantage. That is why we give you data-driven innovation insights into the manufacturing sector. This time, you get to discover 5 hand-picked startups developing digital twin solutions.

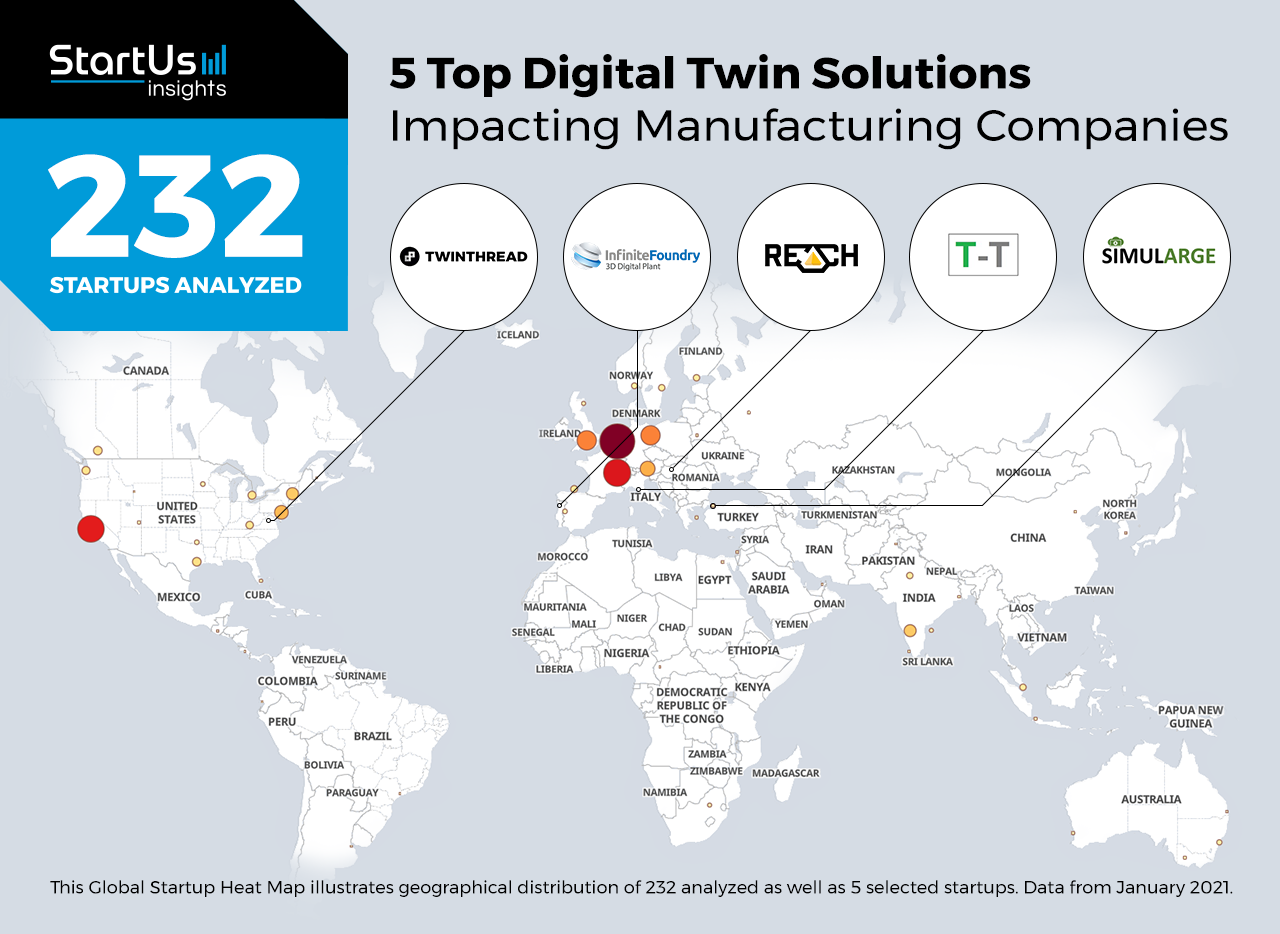

Global Startup Heat Map: 5 Top Digital Twin Solutions

The 5 digital twin startups you will explore below are chosen based on our data-driven startup scouting approach, taking into account factors such as location, founding year, and relevance of technology, among others. This analysis is based on the Big Data & Artificial Intelligence (AI)-powered StartUs Insights Discovery Platform, covering over 1.3 million startups & scaleups globally.

The Global Startup Heat Map below highlights the 5 startups & scaleups our Innovation Researchers curated for this report. Moreover, you get insights into regions that observe a high startup activity and the global geographic distribution of the 232 companies we analyzed for this specific topic.

Simularge develops Digital Twins with Less Data

Digital twin technology creates virtual models of industrial assets by combining dynamic real-time sensing and data visualization. Some of the promising use cases of digital twins include model-driven design, virtual prototyping, virtual system validation, throughput optimization, and evolutionary design. The use of digital twins is propelling manufacturing towards hyper-automation.

Turkish startup Simularge develops a patented approach for making digital twins without the requirement of big data. Generally, large amounts of data are needed for making effective digital twins and ensure minimal under-utilization of input parameters. Simularge’s algorithms identify and monitor changes in the raw materials of the production process. This enables the rapid creation of digital twins and faster adaptation.

TREE-TOWER works on CAD-CAE Integration Software

Engineering research & development (R&D) teams develop designs that are subject to technical flaws. Computer-aided design (CAD), integrated with computer-aided engineering (CAE), enables manufacturers to design prototypes that improve both product design and functionality. Startups are developing integrated solutions that automatically update links in both environments, saving valuable time and reiteration costs for R&D teams.

Italian startup TREE-TOWER enables smart flexible manufacturing with the help of a suite of technologies. The startup leverages digital twins and virtual reality (VR) to enable rapid prototyping and testing of new designs and materials. The startup builds software to integrate computer-aided design and engineering tools that further enable the additive manufacturing of the final designs.

TwinThread enables Predictive Operations

Predictive analytics platforms gather data from sensors in various field installations and integrate it using artificial intelligence (AI). This enables engineers to quickly learn about the condition of their machines and build preventive and predictive maintenance solutions. By integrating digital twins with predictive maintenance, startups allow manufacturing companies to improve safety, extend the life of installations, and reduce costs associated with operations and maintenance.

The US-based startup TwinThread leverages digital twins and digital threads to empower manufacturers to learn faster from the wealth of manufacturing data already available in their enterprise. The startup’s solution for connected factories includes a real-time predictive analytics platform that generates insights, forecasts, and alerts about manufacturing processes. TwinThread’s Predictive Operations Platform is purpose-built for the manufacturing industry. It includes out-of-the-box applications as well as pre-built templates addressing more than 25 specific use cases.

Infinite Foundry creates 3D Virtual Plants

Combining augmented and virtual reality (AR/VR) technologies with digital twins of production facilities increase the functionality of implementing digital twins. For example, engineers and plant operators utilize AR/VR to remotely instruct and monitor factory workers. Reality technologies further enhance the overall efficiency of manufacturing facilities while reducing travel costs and man-hours spent on process optimization.

Portuguese startup Infinite Foundry creates digital twins for production facilities, as well as for smart cities and athletes. The startup enables manufacturing companies to create production plant designs, monitor production processes, and optimize factory operations. For example, Infinite Foundry utilizes virtual reality to improve overall efficiency and implement VR-based training for engineers. The 3D plant model also facilitates a real-time animation of the production process for the assessment of manufacturing bottlenecks.

REACH Solutions facilitates Smart Factories

More machines and equipment are now connected to each other for predictive maintenance and monitoring. To advance this, manufacturing companies are looking for ways to efficiently integrate the various Industrial Internet of Things (IIoT) devices to improve overall productivity. When implemented with a digital twin, it allows engineers and managers to take decisions about factory operations in real-time. Moreover, it allows them to plan contingencies for any interruptions to production.

REACH Solutions is a Hungarian startup developing the Real-time Events-based Analytics and Collaboration Hub (REACH). The IoT platform supports any IoT deployment as a unifying platform to collect, organize, and activate data from any source. Moreover, the platform makes the data available for engineers and operators for targeted execution and performance customization. Some of the applications enabled by the REACH platform include continuous takt time monitoring, real-time overall equipment efficiency (OEE) visualizations, and real-time manufacturing asset tracking.

Discover more startups

To keep you up-to-date on the latest technology and emerging solutions, we provide you with actionable innovation intelligence – quickly and exhaustively. You can download our free Manufacturing Innovation Reports and discover new business opportunities or save your time & let us look into your areas of interest. We provide you with an exhaustive overview of new startups, scaleups & emerging technologies that matter to you.