Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

Our Innovation Analysts recently looked into emerging technologies and up-and-coming startups working on solutions for the engineering sector. As there is a large number of startups working on a wide variety of solutions, we decided to share our insights with you. This time, we are taking a look at 5 promising Additive Manufacturing startups.

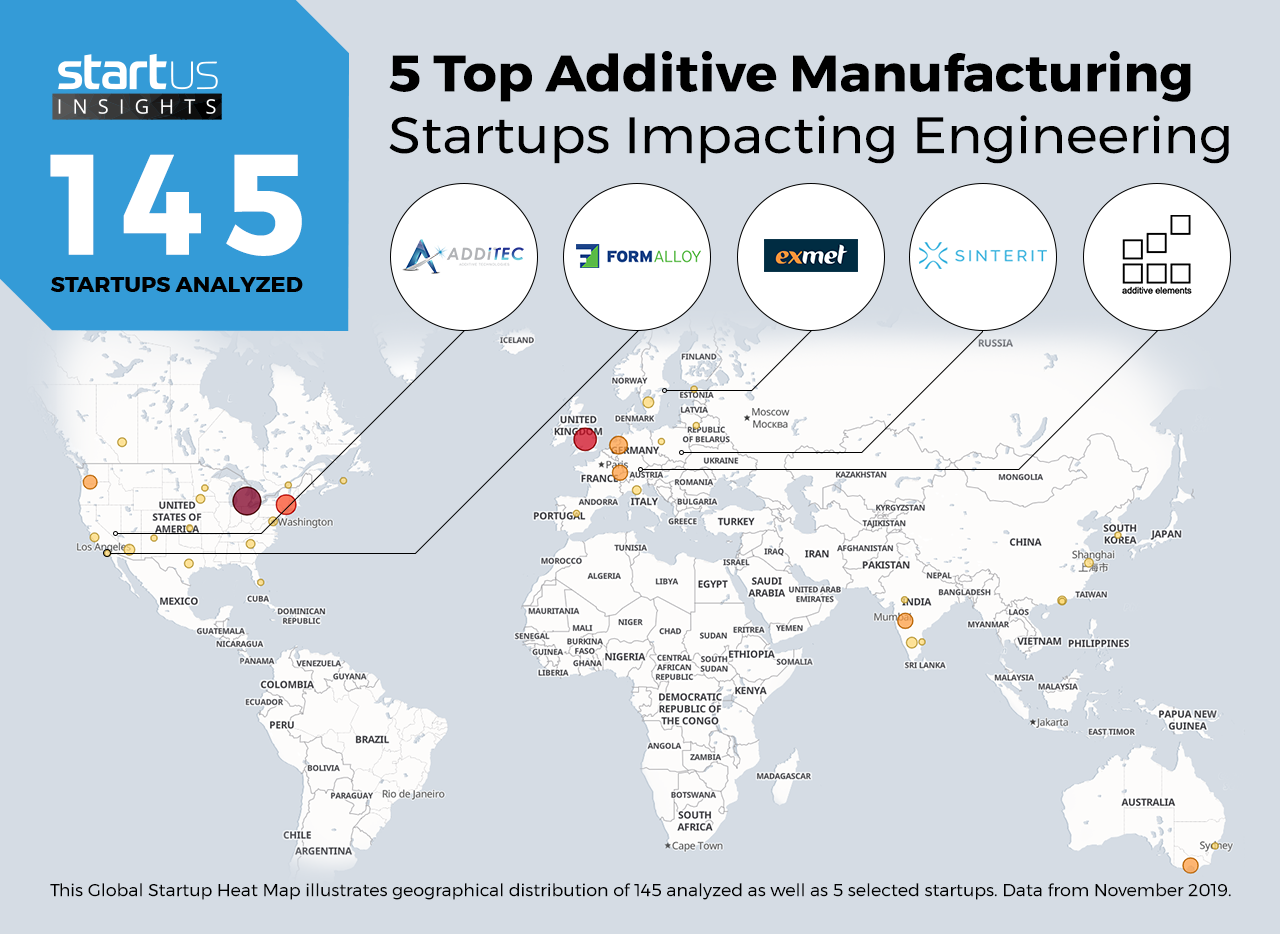

Heat Map: 5 Top Additive Manufacturing Startups

For our 5 top picks, we used a data-driven startup scouting approach to identify the most relevant solutions globally. The Global Startup Heat Map below highlights 5 interesting examples out of 145 relevant solutions. Depending on specific needs, your top picks might look entirely different.

Sinterit – Selective Laser Sintering

Selective Laser Sintering (SLS) technology enables the creation of durable and geometrically sophisticated objects of varying sizes: from healthcare implants to airplane parts. Configurable layer height and laser beam width, combined with powder bed self-support, lead to enhanced powder fusion precision and sufficient chemical resistance. Polish startup Sinterit manufactures Lisa and Lisa Pro – 3D printers with a desktop 3D modeling software that utilizes the power of selective laser sintering. Both printers are suitable for low-volume printing of mechanically strong and movable parts for architecture, automotive, robotics, and healthcare.

Exmet – Electron Beam Melting

Electron Beam Melting (EBM) also leverages the flexibility of powder bed fusion but applies electron beams that facilitate relatively quick powder melting for automotive and aerospace applications. Creating vacuum conditions and high process temperatures, EBM allows for residual stress and reduced oxidation, as well as increased longevity. Swedish startup Exmet applies electron beam melting to produce parts from bulk metallic glasses with enhanced properties and accelerates the additive manufacturing treatment of amorphous metals. Based on EBM, they produce glassy alloys from various metals of different shapes that have a higher resistance to corrosion and metal fatigue.

FormAlloy – Powder Directed Energy Deposition

Powder Directed Energy Deposition (Powder DED) solves timing and precision challenges in additive manufacturing by employing rapid automatic powder deposition for metals and alloys with a high blowing rate. In this case, 3D printed parts benefit from the specific laser-enabled powder distribution system, aimed at strengthening non-printed deficient elements. Powder DED is mostly used in repairing and restoring worn industrial metal components. The US-based startup FormAlloy designs and develops powder DED additive manufacturing systems. With the use of variable-wavelength laser metal deposition, they arrange cost-effective production, repair, and cladding of metal parts. Besides, additional dynamic layer selection assists in checking the quality standards of the objects produced – in real-time.

Additec – Wire Directed Energy Deposition

Compared to Powder DED, Wire Directed Energy Deposition (Wire DED) has lower accuracy but allows for larger build volumes, with cheaper production and faster printing time under laser or electron beams. It utilizes metal wire-feed that is more material-efficient compared to powder and allows for additive manufacturing of heavy equipment. The US-based startup Additec creates large-scale builds for aerospace, nuclear, energy, automotive, and sports industries based on welding wire DED. They also provide deposition modules and printers that ensure clean wire laser metal deposition with relatively less waste and smart process controls that can identify flaws.

Additive Elements – Binder Jetting

Binder jetting is an adequate technology for printing high-volume and low-cost components and casts patterns. Thanks to a fast deposition of a liquid binding agent into powder and using multiple precise printing heads simultaneously at different fragments, binder jetting solves the timing problems for the serial production of analogous parts. German startup Additive Elements develops AE12 material systems for binder jetting additive manufacturing in automotive, robotics, and industrial parts. The poly-methyl methacrylate (PMMA) powder-based solution advances printing productivity, tensile strength, and density while facilitating full powder recycling.

What About The Other 140 Solutions?

While we believe data is key to creating insights it can be easy to be overwhelmed by it. Our ambition is to create a comprehensive overview and provide actionable innovation intelligence for your Proof of Concept (PoC), partnership, or investment targets. The 5 startups showcased above are promising examples out of 145 we analyzed for this article. To identify the most relevant solutions based on your specific criteria and collaboration strategy, get in touch.