Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

The establishment of a hydrogen economy has long been in the works, but due to several reasons, such as lack of technology, infrastructure, or investments, the industry struggled with this energy transition. Over the past decade, however, the global push towards decarbonization, along with developments in existing technologies, has accelerated the top hydrogen trends. Hydrogen fuel cells have the biggest impact, aiding in zero-emissions heavy-duty vehicles, which currently contribute to greenhouse gas (GHG) emissions.

The scalability and affordability of renewable energy systems, as well as advancements in electrolyzers, allow for sustainable hydrogen production. The following top 10 hydrogen economy trends reduce human dependence on fossil fuels and streamline the efficiency of industrial operations.

This article was last updated in August 2024.

What are the Top Hydrogen Trends (2025)?

- Hydrogen Fuel Cells

- Renewable Hydrogen

- Advanced Electrolysis

- X-to-Hydrogen-to-X

- Hydrogen Carriers

- Carbon Capture, Utilization & Storage

- Hydrogen Distribution

- Hydrogen Liquefaction & Compression

- Combined Heat & Power

- Hydrogen Propulsion

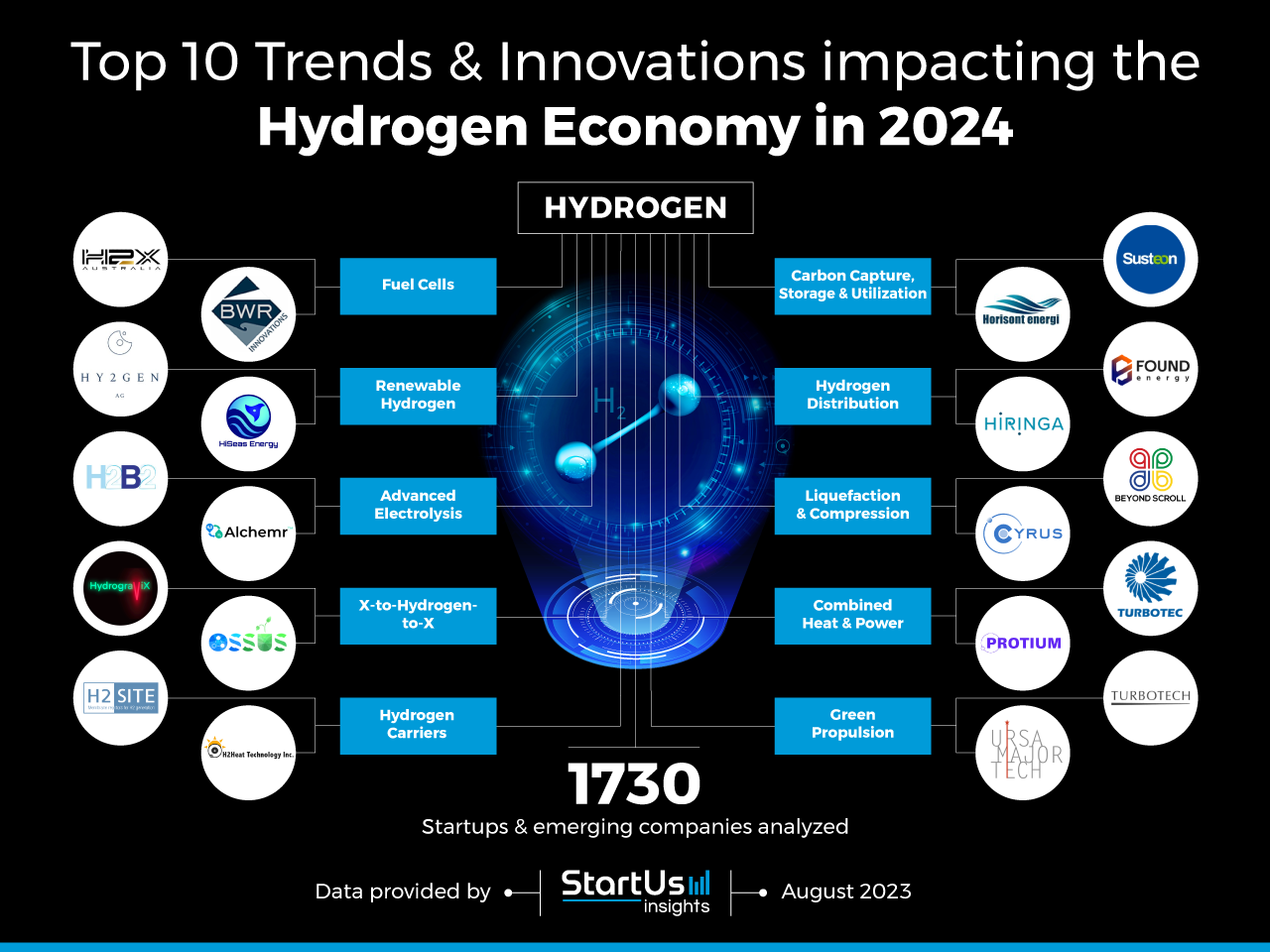

Innovation Map outlines the Top 10 Hydrogen Trends & 20 Promising Startups

For this in-depth research on the Top Hydrogen Trends and startups, we analyzed a sample of 1730 global startups & scaleups. This data-driven research provides innovation intelligence that helps you improve strategic decision-making by giving you an overview of emerging technologies in the hydrogen industry. In the Hydrogen Innovation Map, you get a comprehensive overview of the innovation trends & startups that impact your company.

These insights are derived by working with our Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 4.7M+ startups & scaleups globally. As the world’s largest resource for data on emerging companies, the SaaS platform enables you to identify relevant technologies and industry trends quickly & exhaustively.

Want to explore all Hydrogen innovations & trends?

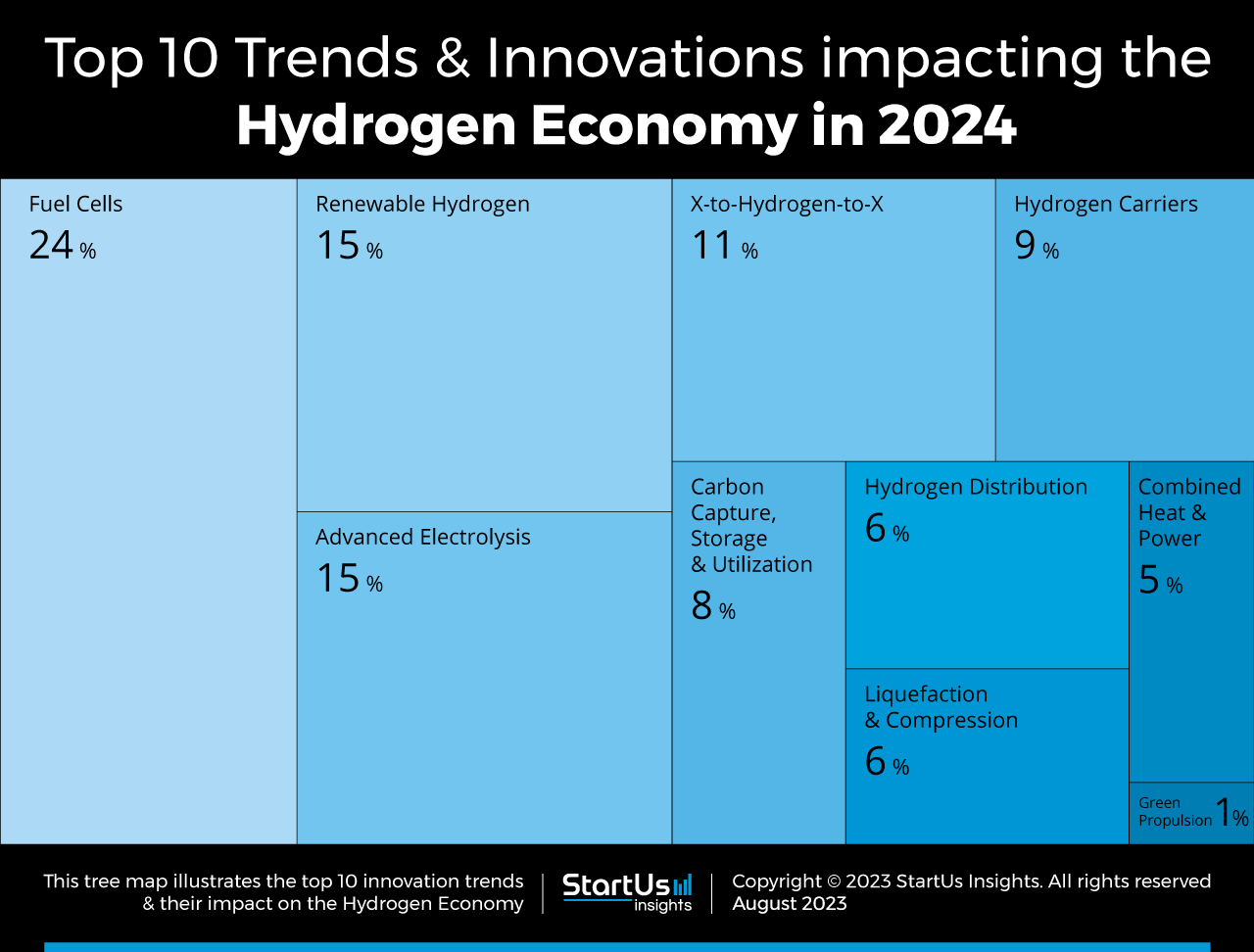

Tree Map reveals the Impact of the Top 10 Hydrogen Innovation Trends

The Tree Map below illustrates the impact of the Top 10 Hydrogen Economy trends on companies in 2025. The hydrogen economy will be bolstered by the applications of fuel cells, fuel cell vehicles, and energy demand. In particular, renewable hydrogen and carbon capture, utilization, and storage (CCUS) have a major influence on all other trends because of their inter-relationship with clean hydrogen production.

Biomass gasification, among the set of X-to-Hydrogen-to-X technologies, provides another sustainable method for creating hydrogen. Besides, hydrogen distribution and storage go hand-in-hand as distribution relies directly on the fuel’s proper storage and handling capabilities. Finally, other important applications of hydrogen include combined heat and power (CHP) and green propulsion, which demonstrate the versatility of hydrogen as an energy carrier.

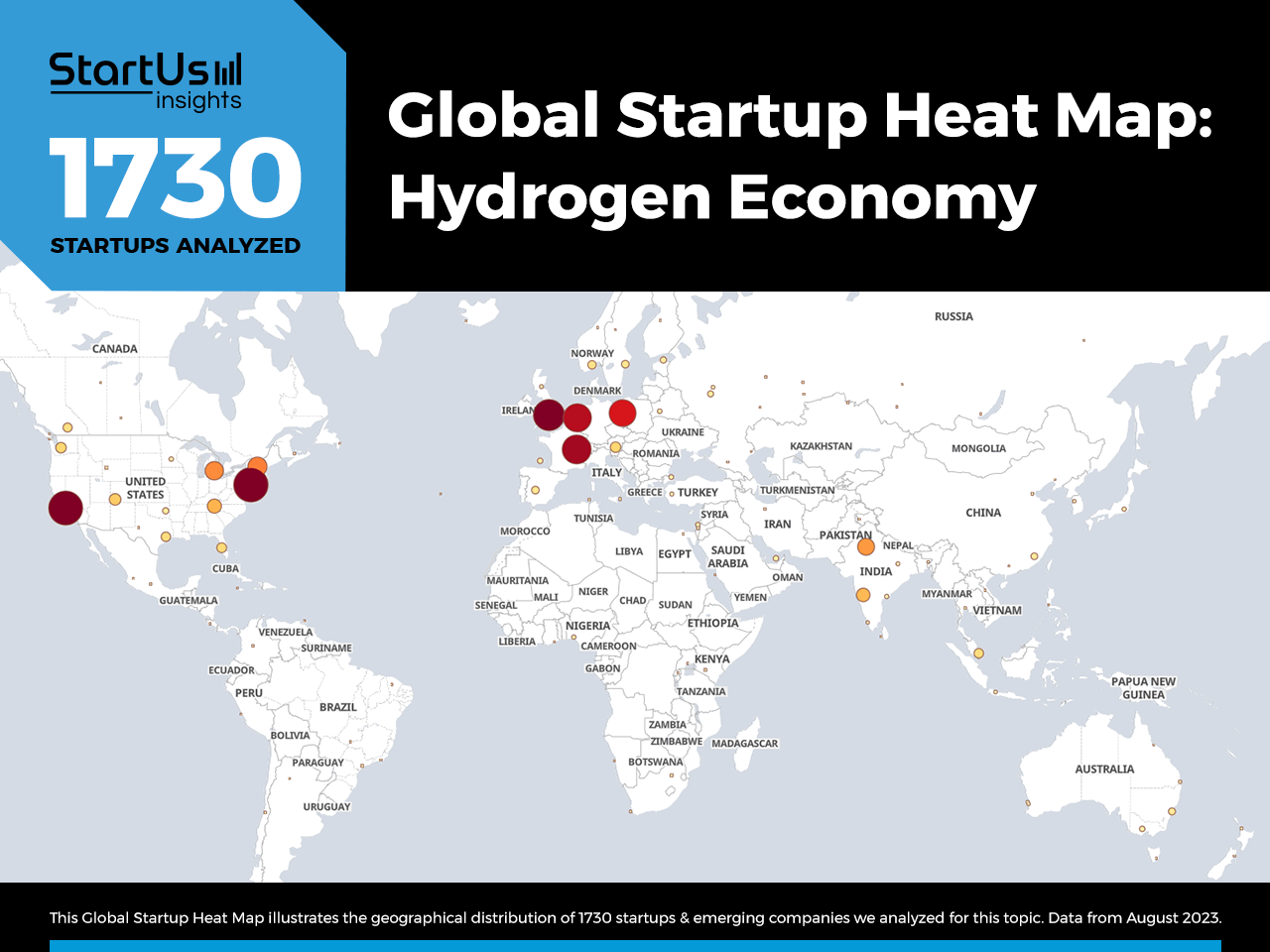

Global Startup Heat Map covers 1730 Hydrogen Startups & Scaleups

The Global Startup Heat Map below highlights the global distribution of the 1730 exemplary startups & scaleups that we analyzed for this research. Created through the StartUs Insights Discovery Platform, the Heat Map reveals that the US & Europe are home to most of these companies while we also observe increased activity in India.

Below, you get to meet 20 out of these 1730 promising startups & scaleups as well as the solutions they develop. These new hydrogen technology startups were hand-picked based on criteria such as founding year, location, funding raised, and more. Depending on your specific needs, your top picks might look entirely different.

Top 10 Hydrogen Trends in 2025

1. Hydrogen Fuel Cells

Hydrogen fuel cells offer immediate power generation and assist in demand response. This is crucial as hydrogen mitigates the gap between power generation fluctuations in renewable energy systems (RES) and a fully renewable-powered grid. Acting as a power source and reserve energy for months, these cells address demand response issues.

Fuel cells find applications in marine, land, and aviation operations, including ships, trains, planes, drones, cars, trucks, and buses. In particular, heavy industrial vehicles become the primary focal point in the hydrogen economy because of their considerable contribution to greenhouse gas emissions. Businesses are increasingly adopting hydrogen fuel cells to minimize carbon footprint and adhere to environmental regulations, promoting a green economy.

H2X designs Hydrogen Fuel Cell Vehicles

Australian startup H2X designs and develops hydrogen fuel cell-powered vehicles. The startup’s vehicles utilize both hydrogen fuel cell and battery-electric technologies, achieving zero-emissions mobility. They require only 5 minutes for refueling and also provide a longer range per refill than battery-powered vehicles. Additionally, the vehicles come with an antimicrobial finish on all regular touch surfaces, ensuring additional safety for all occupants. H2X’s product offerings include hydrogen fuel cell cars, vans, and heavy industrial vehicles.

BWR Innovations develops Portable Hydrogen Fuel Cells

US-based startup BWR Innovations provides portable hydrogen fuel cell solutions. Sol Source SFC110 Fuel Cell Generator is BWR Innovations’ fuel cell-powered sanitization product. It is a portable fuel cell generator and heater that inactivates a variety of biological contaminants, including viruses, bacteria, parasites, and fungi.

The device disinfects rooms of up to 600 sq. ft without leaving residual chemicals or toxins. This allows for emission-free sanitization of facilities and equipment, including medical personal protective equipment (PPE). Users also monitor the products from their computers or mobile devices.

2. Renewable Hydrogen

Large-scale decarbonization is achievable through the production of hydrogen from renewable energy sources. Green hydrogen, produced using renewable energy systems, eliminates carbon emissions common in traditional hydrogen production. Options for hydrogen production include photocatalytic and thermochemical water splitting using solar energy.

Startups employ solar concentrators to achieve high radiation levels, splitting water into hydrogen and oxygen. Wind turbines also contribute to green hydrogen production via electrolysis. Further, industries are adopting renewable hydrogen to fuel transportation fleets and replace conventional energy sources in manufacturing, fostering a green economy.

HiSeas Energy leverages Offshore Wind Turbine Platforms for Hydrogen Production

US-based startup HiSeas Energy develops offshore wind turbines to power electrolyzers. The HiSeas Free-Floating Offshore Wind Turbine (FFWOT) platform provides a low-cost, low-mass, and stable platform for turbines up to 40 MW. Energy delivery to shore is completed using liquid organic hydrogen carriers (LOHC), with green hydrogen supplied from the electrolysis of water. Each electrolysis/LOHC platform is attached to the startup’s turbines via sea floor power cables.

HY2GEN develops Solar-Powered Hydrogen

German startup HY2GEN utilizes solar energy to produce green hydrogen. The startup’s project, SUNRHYSE, powers a 30 MW electrolysis plant using green electricity via solar panels. In the process, HY2GEN supplies hydrogen for the mobility and maritime sectors. The aim of this project is to enable competitive pricing of hydrogen, ensure transportation and distribution, as well as establish power storage facilities to supplement the grid. The startup is involved in several other projects, like HYNOVERA, which synthesizes e-fuels through biomass gasification through green hydrogen.

3. Advanced Electrolysis

Advanced electrolysis technologies enhance the scalability of hydrogen production units. Proton exchange membrane (PEM) electrolyzers, favored for reduced operating and capital expenditures, cater to both industrial and residential needs. Other prevalent electrolyzers include solid oxide electrolyzers (SOE), which avoid the use of precious metal catalysts due to low operating temperatures, and anion-exchange membrane (AEM) electrolyzers, which utilize hydroxide ions. The efficiency of these electrolyzers hinges on bipolar plates, electrode materials, and the catalysts used. Advanced electrolysis is pivotal in sectors requiring high-purity hydrogen, such as semiconductor manufacturing and food processing.

Alchemr designs AEM Electrolyzers

US-based startup Alchemr offers AEM electrolyzers to produce hydrogen. Its AEM technology allows for low electrolyte degradation with the use of thin durable membranes, resulting in optimal hydrogen production. These electrolyzers do not require noble metals as catalysts, thus reducing capital expenditures. The AEM electrolyzers are connected to RES power inputs or scaled up for large-size hydrogen production, with a capacity of up to 100 MW.

H2B2 engineers Large-Scale Electrolyzers

Spanish startup H2B2 develops scalable electrolyzers for both residential and industrial use. EL580N is the startup’s large-scale electrolyzer, with the capacity to produce 1 251 kgs of hydrogen per day. The startup custom-builds the electrolyzer according to regional standards while integrating it into a 40 ft container. It comes with CE marking as well as hazard and operability studies (HAZOP) conducted, along with an option for ETL stamps. In addition, the startup manufactures a wide array of other electrolyzers, ranging from small- to medium-scale.

4. X-to-Hydrogen-to-X

The hydrogen economy relies heavily on hydrogen and its chemical intermediaries. These intermediaries, such as e-methanol, are beneficial, producing low carbon emissions and integrating directly into internal combustion engines. By-products of hydrogen production, such as methanol and methane, reintroduce hydrogen into circulation.

The conversion of waste to hydrogen is a critical step toward decarbonization. Startups are currently achieving this through various processes including gasification, pyrolysis, fermentation, and reforming. These waste-to-hydrogen solutions address the waste crisis while producing hydrogen with minimal carbon emissions. Maximizing the utility of renewable energy and aiding in balancing the energy grid are additional benefits of these solutions. This approach ensures a sustainable and efficient energy future.

Hydrogravix develops a Parallel Mass Transfer Electric Power Generator

Hydrogravix develops Hydrocycler, a technology that operates in a closed-loop system. This system uses electrolysis to split water into hydrogen and oxygen and then recombines them to generate electricity and produce water. This system establishes a self-sustaining cycle of energy and water supply. The Hydrocyler is a parallel mass transfer electric power generator.

Ossus Biorenewables utilizes Wastewater for Hydrogen Production

Indian startup Ossus Biorenewables produces biohydrogen from wastewater. The startup’s device, OB HYDRACEL, is a self-powered solution that produces hydrogen from effluents at industrial sites. It is a retrofittable device, with its own power generator and designed to resemble pipelines. OB HYDRACEL is directly attached to effluent pipelines in factories and industrial venues. The device enables both the purification of wastewater and the production of hydrogen at industrial sites.

5. Hydrogen Carriers

Transporting hydrogen typically involves liquid or gaseous forms, but the handling and operating constraints of pure hydrogen strain storage containers. Hydrides or compounds of hydrogen, known as hydrogen carriers, form through chemical reactions with metals or chemicals. These carriers are typically easy to transport over long distances. Storage of these carriers is convenient, and startups are researching and developing ways to increase the purity and efficiency of the separation process to recover the hydrogen.

Metal hydrides, such as magnesium hydrides, have the capacity to chemically store hydrogen in their metallic lattice. LOHC, chemical hydrides, and nanostructures are under development for hydrogen transport. This technology plays a crucial role in linking hydrogen production sites with end-use sectors, thereby facilitating a global hydrogen economy.

H2SITE facilitates On-Site Hydrogen Production

Spain-based startup H2SITE offers on-site hydrogen production solutions that produce renewable hydrogen for small and medium companies. The startup utilizes feedstocks like ammonia and methanol as hydrogen carriers. Its membrane reactor technology allows industries, power generators, and vehicles to reduce hydrogen costs by producing hydrogen on-site. Apart from SMEs, H2SITE also caters to the natural gas, mobility, and distributed energy resource sectors.

Hydrogen First provides Flat Composite Pressure Containers

Polish startup Hydrogen First develops flat composite overwrapped pressure vessels designed for hydrogen storage. These vessels feature a structure reminiscent of a quilted mattress, reinforced with studs throughout their thickness. They can store hydrogen in gaseous, liquid, or supercritical states and offer greater flexibility in customizing the shape of the fuel storage system. Hydrogen First’s flat composite vessels are utilized as hydrogen carriers in both automobiles and airplanes.

6. Carbon Capture, Utilization & Storage

Incorporating Carbon Capture, Utilization & Storage (CCUS) technologies into hydrogen production significantly reduces its environmental impact. These technologies, often associated with blue hydrogen, are integrated into large-scale production venues to decrease carbon emissions. They also convert these emissions into usable feedstock for other processes, such as fertilizer production and enhanced oil recovery (EOR).

The formation of solid carbon by-products from hydrogen production waste is another effective reuse method. Additionally, redirecting gaseous carbon emissions for use in other industrial processes ensures zero waste and emission loops. This approach paves the way for fossil fuel-dependent industries to transition towards greener practices.

Susteon leverages CCUS to produce Blue Hydrogen

US-based startup Susteon provides blue hydrogen using CCUS technologies. The startup develops compact distributed H2 generators to create high-purity pressurized hydrogen while capturing CO2. This technology is based on a catalytic nonthermal plasma that activates methane to produce syngas. The syngas is purified and compressed to generate high-pressure, high-purity, carbon-free hydrogen. The startup also develops nano-catalysts for carbon-free methane pyrolysis, producing blue hydrogen.

Horisont Energi uses CCUS to synthesize Blue Hydrogen and Blue Ammonia

Norwegian startup Horisont Energi produces blue hydrogen. Arctic Blue Hydrogen is the startup’s product, which helps in delivering blue hydrogen to the hydrogen economy. With their carbon storage solution Polaris, the company utilizes hydrogen to produce blue ammonia for transportation and storage, enabling widespread usage of blue hydrogen. The ammonia is cracked back to hydrogen at the destination, and besides this, ammonia by itself provides 4.02 MWh of carbon-free energy per cubic meter.

7. Hydrogen Distribution

Transportation and distribution pose significant challenges in the hydrogen economy. Different distribution methods are being considered, depending on the production and usage sites. Hydrogen is regionally distributed through new pipelines or retrofitted natural gas pipelines. Trains and ships also transport hydrogen in liquid or gaseous form across regions.

Highway distribution of hydrogen is possible through tube trailers and liquid tankers. Handling hydrogen storage containers requires caution due to hydrogen’s flammability and material-embrittling nature. Hydrogen refueling stations mitigate the refueling challenges of hydrogen fuel cell vehicles, particularly trucks and buses.

Found Energy develops Hydrogen Energy Distribution Systems

US-based startup Found Energy develops technology that uses metallic aluminum to produce hydrogen on demand for energy transport. Its process safely extracts energy through rapid aluminum corrosion when exposed to water. Found Energy’s technology fills the gap in distribution and is testing its industrial-scale solution of 1-10 megawatts through adjustable and high-purity modular fuel packs. This enables renewable energy to compete with fossil fuels in, for example, heavy industry applications.

Hiringa Energy establishes a Hydrogen Refuelling Network

New Zealand-based startup Hiringa Energy accelerates the hydrogen economy by developing a hydrogen refueling network across New Zealand. Focused primarily on the heavy vehicles market, the startup devises a three-phase plan for the construction of the refueling network. The final goal is to provide access to over 100 refueling stations by 2030.

The refueling network includes centralized generation units with distributed refueling, distributed generation, and third-party generation with offtake. The startup factors in distance from hydrogen supply sites and frequency of aggregation of fleets to choose refueling sites.

8. Hydrogen Liquefaction & Compression

Developing containers for hydrogen storage is crucial for scaling the hydrogen economy. Cryogenic tanks, also known as dewars, store liquid hydrogen at -253 C, ensuring no leakages and preserving purity. Dewars range from Type I to Type IV, depending on the materials in the walls and their carrying capacity.

Compression involves pressurizing hydrogen gas, typically to 350-700 bar, making it suitable for storage and transport in cylinders for various applications. Compressed gas storage tanks are useful for storing high-pressure hydrogen gas. Handling hydrogen gas is easier compared to liquid hydrogen due to fewer temperature constraints. Cryo-compressed hydrogen involves storing high-pressure hydrogen to reduce boil-off when exposed to the atmosphere, making it cost-effective and manageable.

Beyond Scroll develops Oil-Free Scroll Compressors

Swiss startup Beyond Scroll builds oil-free scroll compressors to make green hydrogen production more efficient and cost-effective. Its technology compresses hydrogen from atmospheric pressure without contamination, reducing system components and maintenance costs. Beyond Scroll’s compact compressors operate at high speeds from low to medium pressures witn only (4% per MW of electrolizer power) of input power, addressing one of the main limitations of compression technology.

CYRUS develops Hydrogen Compressors

Greek startup CYRUS designs metal hydride hydrogen compressors (MHC) for transportation applications. The startup’s thermal-powered MHC absorbs hydrogen at low pressure and temperature and then desorbs it at higher pressure by raising the temperature with an external heat source. These compressors are suitable for operation in RES or industrial waste heat facilities and do not use critical raw materials. Additionally, due to zero noise and low ecological impact production, the compressors can be installed in residential areas.

9. Combined Heat & Power

Decarbonizing the Combined Heat & Power (CHP) sector aligns with the goals of the hydrogen economy. Blending hydrogen in existing natural gas pipelines heats both industrial and residential spaces. Safety standards permit up to 10% hydrogen in the mixture, ensuring the safe handling of gas in existing pipelines.

Blended hydrogen finds use in stationary gas turbines and generators, reducing greenhouse gas emissions during power generation. Novel combustion boilers and hybrid heat pumps also employ hydrogen for sustainable heating. Hydrogen CHP systems find particular use in settings with constant demand for both electricity and heat, such as manufacturing facilities, hospitals, and universities.

Turbotec designs Hydrogen Gas Turbines

Belgian startup Turbotec develops hydrogen gas turbines for CHP. The startup’s hydrogen-fuelled gas turbine, TURBOTEC HyTG-550, is designed as a marine propulsion and generator unit. The engine offers 550kW of electric power and a CHP unit that provides up to 950kW of thermal power. The turbine is modular and can fit in a 20-foot-high cube shipping container.

It is also suitable for parallelization to obtain the desired power output in a larger hybrid-electric system. Additionally, the startup offers HyTG-100, a hydrogen-fuelled gas turbine generator suitable for light hybrid-electric aviation and power generation in CHP or offshore units.

Protium Green Solutions develops Hydrogen-Based Industrial Heating Solutions

UK-based startup Protium Green Solutions, a green hydrogen energy services company, implements CHP solutions for hydrogen-based industrial heating. Project HyLADDIE is the startup’s pilot project implementing zero-emission industrial heating. The project will enact the installation and operation of dynamic combustion chambers (DCC) which use hydrogen as fuel.

The startup also provides hydrogen-ready burners, CHP systems, and boiler products to deliver zero-emission heat solutions using green hydrogen as a source. Besides CHP, the startup works on zero-emission aviation – specifically, Project Heart – the startup’s hydrogen-based aviation endeavor.

10. Hydrogen Propulsion

Hydrogen, with its decent energy-to-density ratio in liquid form, shows promise as a fuel for space propulsion. This involves using hydrogen fuel directly to power rockets, airplanes, and jets with liquid oxygen-hydrogen systems. Recent advancements in space technology involve blending hydrogen with other fuels to power turbines and propellants, achieving green propulsion. Hybrid-electric systems stand out in terms of achieving low-emission mobility. Research is underway on hydrogen peroxide, a hydrogen derivative, as an alternative fuel for its potential use in space vehicle propulsion.

Turbotech develops Hydrogen-Powered Turbogenerators

French startup Turbotech designs hybrid-electric propulsion systems for airplanes and electric-vertical take-off and landing (E-VTOL) vehicles. TG-R55 and TG-R90 are the startup’s turbogenerators that produce electric power onboard. When used in conjunction with batteries, they offer up to 10 times more range than full-electric plane systems.

The turbogenerators combine electric generators and turbines, fitted with integrated annular exchangers that enable exhaust gas energy recovery. The startup’s turbogenerators allow for lower weight expenditure on the vehicle, increasing travel efficiency. The startup also designs a low-emission turboprop engine, TP-R90.

Ursa Major Technologies designs Liquid Hydrogen Propulsion Systems

US-based startup Ursa Major Technologies engineers liquid hydrogen propulsion systems. Samus is the startup’s 50,000 lbf liquid hydrogen engine. It is a fuel-rich staged combustion upper-stage propulsion solution eligible for medium- and heavy-class space-launch applications. The solution produces zero emissions and its architecture is derived from the startup’s previous projects – an oxidizer-rich staged combustion engine and a 35 000 lbf liquid oxygen and kerosene engine.

Discover all Hydrogen Economy Trends & Startups

There is scope for innovation in hydrogen storage and distribution, where carriers developed using nanotechnology will play a big role. The hydrogen pipeline consists of blended hydrogen solutions, with retrofitted pipelines or a newly developed network on the horizon. The goal of these hydrogen trends is to establish an alternative to fossil fuel use for consumer, business, and industrial activities.

The Hydrogen Trends and startups outlined in this report only scratch the surface of trends that we identified during our data-driven innovation & startup scouting process. Identifying new opportunities & technologies to implement into your business goes a long way in gaining a competitive advantage.

WATCH THE VIDEO VERSION

WATCH THE VIDEO VERSION