Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

The global reverse logistics market is projected to reach USD 1.16 trillion by 2032, reflecting a compound annual growth rate (CAGR) of 4.8%. Additionally, the emerging reverse logistics technology trends are driven by increased e-commerce activities and the adoption of circular economy practices.

Technological advancements, like artificial intelligence (AI), cloud, and blockchain, further drive the market by improving the efficiency of return processes. As businesses navigate this evolving landscape, staying abreast of these trends is crucial for industry leaders, innovation managers, and corporations to optimize operations and stay ahead of the curve.

What are the Top 10 Reverse Logistics Technology Trends in 2025?

- Recommerce

- Tracking and Traceability

- Circular Economy

- Automated Return Processing

- Enhanced Customer Experience

- Refurbishment Centers

- Returns Forecasting

- Fraud Detection

- Returnable Packaging

- Robotics

Methodology: How We Created the Reverse Logistics Trend Report

For our trend reports, we leverage our proprietary StartUs Insights Discovery Platform, covering 7M+ global startups, 20K technologies & trends plus 150M+ patents, news articles, and market reports.

Creating a report involves approximately 40 hours of analysis. We evaluate our own startup data and complement these insights with external research, including industry reports, news articles, and market analyses. This process enables us to identify the most impactful and innovative trends in the logistics industry.

For each trend, we select two exemplary startups that meet the following criteria:

- Relevance: Their product, technology, or solution aligns with the trend.

- Founding Year: Established between 2020 and 2025.

- Company Size: A maximum of 200 employees.

- Location: Specific geographic considerations.

This approach ensures our reports provide reliable, actionable insights into the reverse logistics innovation ecosystem while highlighting startups driving technological advancements in the industry.

Innovation Map outlines the Top 10 Reverse Logistics Trends & 20 Promising Startups

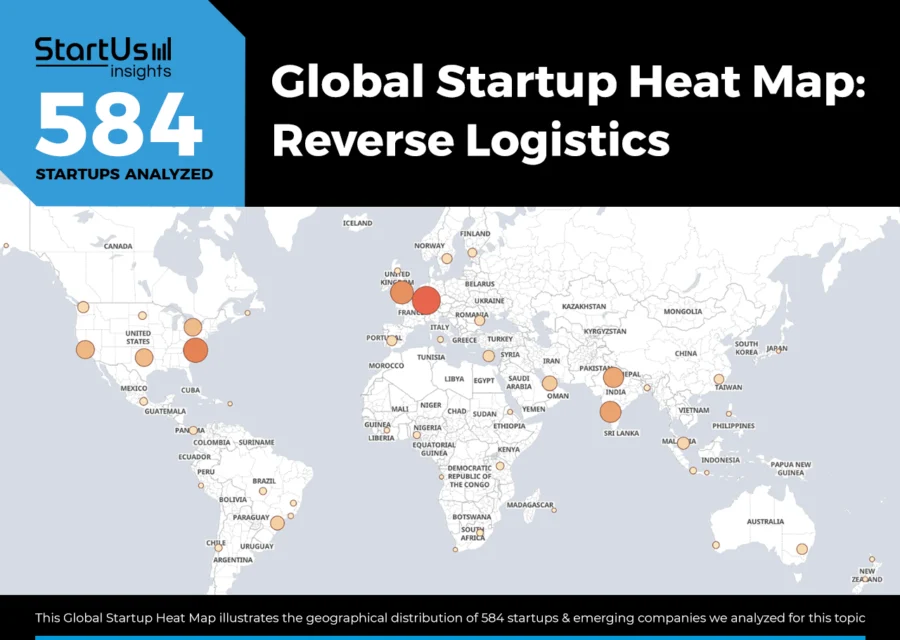

For this in-depth research on the Top Reverse Logistics Technology Trends & Startups, we analyzed a sample of 584 global startups & scaleups. The Reverse Logistics Innovation Map created from this data-driven research helps you improve strategic decision-making by giving you a comprehensive overview of the reverse logistics industry trends & startups that impact your company.

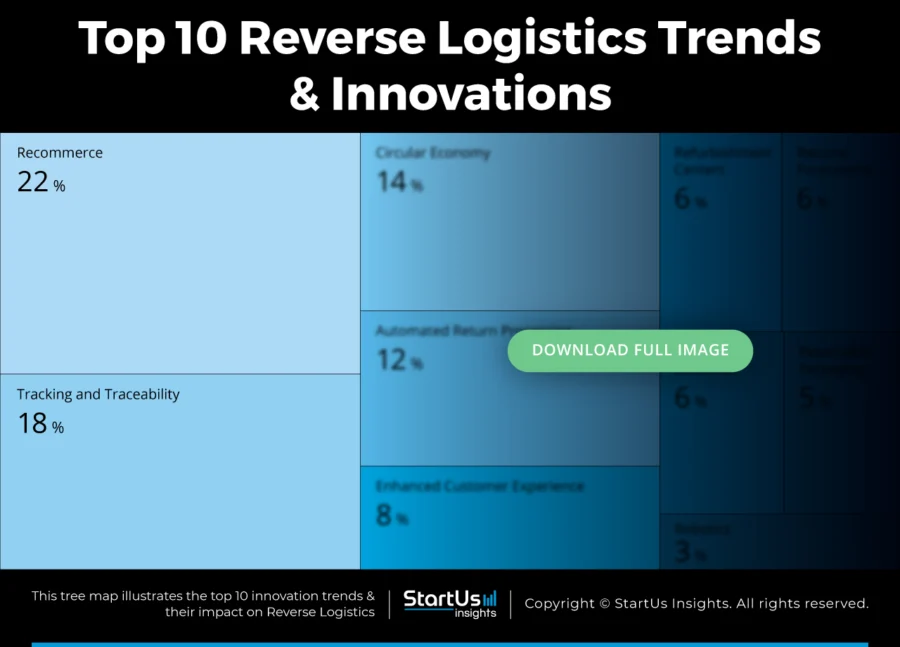

Tree Map reveals the Impact of the Top 10 Reverse Logistics Trends

Reverse logistics is rapidly evolving with trends like re-commerce and refurbishment centers enabling resale and reuse, while automated return processing, robotics, and fraud detection improve speed and accuracy.

Returns forecasting and tracking technologies also improve operational efficiency, while returnable packaging supports sustainability goals. These innovations align with the industry’s transition to a circular economy. Further, enhanced customer experience remains central to driving loyalty for brands.

Global Startup Heat Map covers 584 Reverse Logistics Startups & Scaleups

The Global Startup Heat Map showcases the distribution of 584 exemplary startups and scaleups analyzed using the StartUs Insights Discovery Platform. It highlights high startup activity in the US and India, followed by the UK and Germany. From these, 20 promising startups are featured below, selected based on factors like founding year, location, and funding.

Want to Explore Reverse Logistics Innovations & Trends?

Top 10 Emerging Reverse Logistics Technology Trends [2025 and Beyond]

1. Recommerce

Reverse commerce, or re-commerce, turns returned goods into revenue-generating assets. This way, businesses are able to view returns not as losses and refurbish or resell products to recapture value and reduce waste.

For instance, Optoro utilizes a software platform to manage and resell returned and excess merchandise.

Further, integrating recommerce into reverse logistics ensures that returned items are efficiently collected, assessed, and redirected for resale and thus streamlines processes.

Source: Codup

Automated sorting systems and robotics enhance the speed and accuracy of processing returned items, while AI provides insights into consumer behavior and product performance. These technologies enable businesses to optimize inventory management, forecast returns, and make informed decisions on refurbishing and reselling products.

Source: Euromonitor

Recommerce also aligns with growing consumer preferences for sustainable practices. By extending the lifecycle of products, businesses are able to reduce their environmental impact and appeal to eco-conscious customers.

For example, returns are projected to surpass GBP 27 billion, with over half of clothing purchases being returned in the UK. Companies like ACS in Scotland repair and resell returns by partnering with tech firms to sort secondhand clothing.

In the UK, apparel returns cost the industry GBP 7 billion in 2022, with some online platforms seeing return rates as high as 50%.

The re-commerce sector has witnessed major expansion in recent years. According to OfferUp’s 2024 Recommerce Report, 85% of shoppers now regularly buy and/or sell secondhand items. This surge is fueled by consumer demand for affordability, sustainability, and convenience.

OfferUp’s report also shows that 58% of shoppers prefer secondhand apparel and 53% find reselling enjoyable. Reflecting these activities, the recommerce market is projected to grow 55% by 2029, reaching USD 291.6 billion and accounting for 8% of total retail sales.

rScan automates Merchandise Resale Software

US-based startup rScan develops a mobile application that enables businesses to efficiently resell returned retail products through major e-commerce platforms.

The app streamlines the resale process by allowing businesses to scan product barcodes and automatically retrieve detailed product information. It then lists the items across marketplaces such as Amazon, eBay, and Shopify.

Moreover, the app incorporates features like AI-driven pricing suggestions, integrated shipping label generation, and real-time sales analytics to improve operational efficiency.

rScan facilitates the resale of returned goods to address challenges in reverse logistics. It also reduces waste while providing businesses with a viable way to start and grow their resale businesses.

Circular applies AI-Powered Resale Platform

Norwegian startup Circular provides AI-powered resale software that automates pricing, item registration, seller management, and reporting for second-hand businesses.

The software uses historical sales data, brand value, item condition, and local demand to generate real-time price recommendations that increase profit and reduce manual effort.

Moreover, the software speeds up listings through photo-based classification, captures key item details, and generates barcodes automatically.

The AI-powered resale software tracks top sellers, monitors consignor performance, and identifies growth areas through advanced analytics.

Additionally, Circular processes automated payouts, handles accounting, and offers a branded self-service seller portal to reduce administrative tasks and increase transparency.

It also enables resale businesses to streamline operations across reverse logistics chains and scale sustainable second-hand commerce.

Renow optimizes AI-driven Recommerce Platform

Finnish startup Renow delivers an AI-powered recommerce platform that automates the return, inspection, and resale of consumer products.

The recommerce platform guides customers through return initiation via the Return App. The application collects product data and dynamically routes items to local warehouses for inspection using the Inspection App.

In this application, AI assists in grading and instant relisting across multiple sales channels. This method reduces manual handling, lowers logistics costs, and increases inventory turnover. The approach further offers direct-to-consumer resale or sustainable liquidation of unsellable goods.

2. Tracking and Traceability

Solutions to track and trace products across the supply chain allow companies to handle returns more effectively, transparently, and sustainably. Using reliable tracking systems is also becoming necessary as the number of product returns rises due to the growth of e-commerce and increased customer expectations.

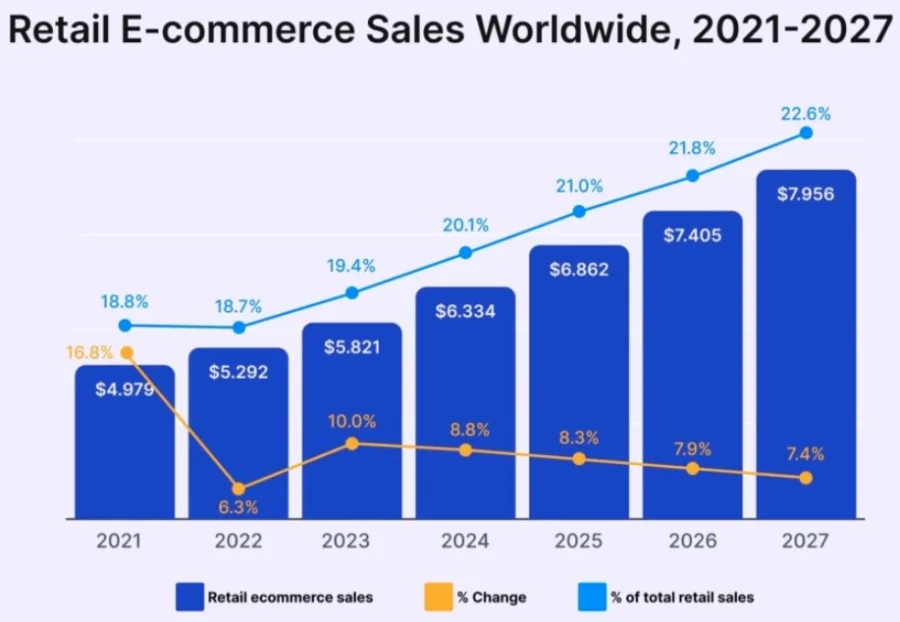

Statista predicts that global e-commerce sales will exceed USD 4.3 trillion in 2025. Additionally, the number of online shoppers reached 2.77 billion in 2025 (33% of the global population), and is expected to reach 2.86 billion by 2026.

Source: SellersCommerce

Improved traceability enables businesses to minimize their environmental effect by ensuring appropriate recycling, refurbishing, or disposal of returned goods. Further, traceability plays a crucial role in building consumer trust and brand loyalty.

Customer loyalty is directly impacted by clear and effective returns. 95% of buyers say that a bad return experience will discourage them from making another purchase.

These activities highlight the strategic value of monitoring systems in effectively handling returns, reducing expenses, and improving customer satisfaction.

Sensors and smart tags are the most used Internet of Things (IoT) devices in reverse logistics. They gather and send information about the location, state, and movement of goods throughout the supply chain. This real-time data makes proactive decision-making and prompt problem-solving easier.

Radio-frequency identification (RFID) also enables automatic item identification and tracking to speed up processing times and reduce manual errors.

At the same time, blockchain improves trust and accountability in reverse logistics operations by offering a decentralized, unchangeable ledger. This ledger guarantees data integrity and transparency for businesses and customers..

akksel offers a Track & Trace Platform for Used Batteries

Swiss startup akksel builds a Track & Trace platform for reverse logistics of discarded electric vehicles and industrial-scale batteries, anchored by two core tools, CIRCUs and MAPLe.

CIRCUs enable manufacturers, recyclers, and authorities to track battery redemption and plan compliant logistics. It also monitors regulatory workflows through role-based dashboards.

MAPLe functions as a global marketplace for used batteries, allowing businesses to list, price, and trade battery modules and cells. MAPLe has components with AI-powered matching and blockchain-secured transactions.

Moreover, the Track & Trace platform automates battery classification and applies scenario-based price recommendations. It also generates documentation aligned with national and international regulations.

akksel integrates storage, dismantling, and transport workflows while ensuring secure data exchange, compliance, and real-time analytics.

Further, the startup streamlines traceability and enables second-life or recycling pathways to support circular battery use and reduce the environmental and human impact of battery waste.

Revivack delivers Blockchain-Led Product Recovery Traceability

Revivack, a Spanish startup, has developed a blockchain-based traceability platform that enables brands and recovery partners to track product returns and manage take-back operations. Their proprietary Revivack Circular Pass validates circular recovery processes that offer transparency and trust in the circular economy.

The traceability platform assigns each product a RePass, which stores origin and recovery details and displays pickup and processing points. All data is securely recorded on a blockchain ledger, ensuring transparency and immutability throughout the supply chain.

Through the R-Code system, businesses plan take-back routes, trigger pickups, and link buyback or donation programs directly to enterprise resource planning (ERP) systems.

Moreover, Revivack provides downloadable recovery certificates, public reports, and shareable impact metrics to verify each product’s final destination.

Additionally, the startup connects recovery agents, streamlines return logistics, and certifies recovery through 3TR (traceability, transparency, and trust) chains. This enables real-time traceability and compliance while promoting circular product design and waste-free consumption.

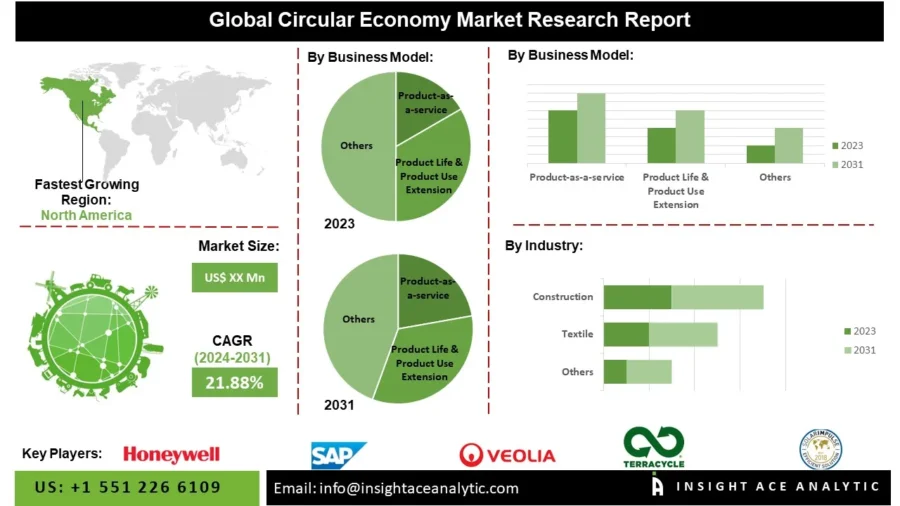

3. Circular Economy

According to the OECD, business models for the circular economy rely on reverse supply chains to close material loops and encourage direct reuse, repair, and remanufacturing. For scaling this, the cross-border movement of end-of-life products is critical.

Source: InsightAce Analytic

Moreover, stricter environmental regulations passed by governments force businesses to manage waste and lower their carbon impact. Companies must manage waste, build for durability, and lower their carbon footprint due to these regulations.

For instance, the EU’s Ecodesign rule forbids the destruction of unsold items and requires that things be made circular – that is, long-lasting, repairable, and recyclable. Brands that exhibit a dedication to sustainability through open and accountable processes are also preferred by today’s eco-conscious consumers.

Companies with open, ethical business processes, sustainability is a crucial factor for the current consumers, particularly Gen Z. Therefore, businesses that prioritize sustainability in reverse logistics will see an increase in brand recognition and consumer loyalty.

Surveys show that 92% of consumers trust environmentally responsible brands, and 88% are more likely to remain loyal to companies supporting environmental or social causes.

Recovering parts and materials from returned goods also results in substantial cost savings and new revenue sources for businesses. Automation, data analytics, and tracking innovations enable effective reverse logistics operations to improve resource optimization.

Reusing and recycling materials also effectively reduces trash disposal and procurement costs. Showing a dedication to sustainability also improves brand reputation and increases consumer loyalty.

Reverse Systems organizes Material Management System

French startup Reverse Systems develops a material management system (MMS 4.0) that integrates circular economy principles into industrial production. This system enables real-time characterization, tracking, and reuse of strategic materials.

The MMS 4.0 uses a patented process that applies artificial intelligence (AI) and predictive analytics to generate a live digital catalog of material offcuts. This allows manufacturers to optimize bar layouts, anticipate waste, and plan reuse directly from the design stage.

Additionally, the system increases operational efficiency by providing operators with real-time visibility through modules such as real, simulation, history, and forecast. These models enable the identification of reusable scraps, simulation of production scenarios, and diagnosis of inefficiencies.

Further, the system ensures the traceability of material flows, connects with existing ERP systems and supports compliance with European Union ecodesign regulations through a built-in digital passport.

Octa builds Circular Marketplace

Brazilian startup Octa operates a digital circular economy platform that connects vehicle fleets, dismantling centers, insurers, and mechanics to streamline reverse logistics in the automotive sector.

The startup facilitates end-of-life vehicle decommissioning through its Octa Auto solution, which catalogs vehicles for permanent removal.

Moreover, Octa Desmonte links dismantlers to these vehicles and manages the resale of reusable parts. Octa Pecas centralizes requests for automotive parts and sources quote from a network of certified suppliers.

Additionally, Octa Cursos provides training programs to standardize dismantling processes and educate stakeholders.

Further, Octa Plus offers exclusive benefits such as discounts and expert content to improve user engagement.

4. Automated Return Processing

The volume of product returns has increased due to e-commerce’s continued rapid growth, which poses serious difficulties for logistics companies and merchants.

E-commerce returns have increased to USD 890 billion, according to Cleverence (2024), which presents significant difficulties for online retailers that now have to handle larger return volumes and the related operational complexities.

Moreover, manual return procedures are time-consuming, labor-intensive, and prone to errors. They frequently result in higher operating expenses and unsatisfied customers. Automation, on the other hand, speeds up the returns cycle and makes it possible to process returned goods and issue refunds or replacements more quickly.

Automated return processing thus lowers labor and operating costs by optimizing warehouse space use, minimizing errors, and improving the customer experience.

Further, quicker return and refund processing enhances customer experiences to improve repeat business and customer loyalty. 65% of customers say the speed and ease of refunds affect where they choose to buy from. Businesses are also able to scale operations with automated systems to manage higher return quantities without massive investments.

Automation makes it easier to gather and examine return data. This allows brands to better understand the trends in returns and analyze customer behavior to drive decision-making and stay ahead of the market.

Float simplifies Return Management for Fashion Brands

Danish startup Float builds returns management software that automates return processing, facilitates product exchanges, and delivers data-driven insights for fashion retailers.

Retailers use the platform through a branded self-service portal where customers initiate returns and exchanges. Moreover, the platform processes these requests automatically while capturing structured return reasons.

Additionally, the returns management software turns refund requests into exchanges by presenting real-time options, which allows retailers to retain sales and improve customer loyalty.

Float uses data intelligence to track product performance, identify fit-related trends, and update size guidance directly on product pages to reduce return rates.

Further, the startup streamlines return workflows, automates exchange processes, and provides actionable insights to allow fashion brands to recover revenue and improve reverse logistics operations.

G2 Reverse Logistics supports Reverse Logistics Platform

US-based startup G2 Reverse Logistics builds AI-powered software that automates return processing, disposition routing, and recommerce decisions across supply chains in the circular economy.

Its DecisionAI engine manages each return autonomously, analyzes real-time market data, determines the most profitable recovery path, and adapts to changing conditions without human input.

Moreover, the startup streamlines complex workflows through its returns management system, which automates analysis, routing, and visibility across and beyond fulfillment centers.

With its recommerce platform, G2 Reverse Logistics routes returned and excess inventory to optimal resale or recovery channels. This reduces waste and reclaims value through AI.

It also combines autonomous decision-making with end-to-end automation to reduce handling costs, speed up processing, and support sustainable, profitable reverse logistics.

5. Enhanced Customer Experience

Customers expect transparent and hassle-free return processes in the e-commerce landscape. 92% of consumers say they will buy again if the product return process is easy. Moreover, processing a single return costs between USD 21 and 46.

By prioritizing customer-centric return policies and processes, logistics companies are able to convert potential dissatisfaction into opportunities for engagement. This builds trust and encourages repeat business.

For example, offering omnichannel return options – like in-store drop-offs, courier pickups, and locker returns – offers customers flexibility and convenience while reducing friction. Some retailers even leverage predictive models to offer instant refunds to trusted customers. This improves the speed and satisfaction of the return journey.

The implementation of technologies like AI, machine learning (ML), and advanced analytics is crucial for improving customer experience. AI and ML algorithms predict return patterns to enable proactive inventory management and personalized customer interactions.

Further, advanced analytics provide insights into return reasons and facilitate continuous improvement in product quality and customer service. Integrating reverse logistics systems with customer relationship management (CRM) platforms also ensures a cohesive and responsive customer experience.

Moreover, companies that communicate sustainability initiatives create deeper emotional loyalty with environmentally conscious consumers. Personalized return incentives, like store credit bonuses or product recommendations based on past behavior, further increase customer retention and satisfaction.

ReturnBear facilitates Localized Returns Management

Canadian startup ReturnBear builds a returns management platform for global e-commerce brands. It improves the customer experience by offering localized drop-off options, instant refund verification, and cross-border logistics.

ReturnBear operates a branded consumer returns portal that automates return policies, allowing customers to initiate returns smoothly. Customers choose between package-free, label-free drop-off points or cost-efficient mail-in methods. This improves convenience and reduces return logistics costs.

Additionally, the startup verifies items on the spot at drop-off locations to prevent fraud and issues refunds within seconds while allowing merchants to retain revenue through exchanges and store credit.

ReturnBear efficiently processes and grades returned inventory, consolidating it for resale or other outcomes. It also manages all cross-border documentation, including pre-clearance and shipping manifests, streamlining international returns for businesses.

Further, the startup reduces return logistics costs, speeds up refunds, and simplifies international returns which allow brands to deliver a better reverse logistics experience.

Reveni Unified enhances eCommerce Platform

Reveni is a Spanish startup that builds a return and exchange platform. It improves the post-purchase experience for e-commerce brands by offering instant refunds and real-time exchanges.

Additionally, the platform provides centralized international returns management and streamlines global operations for retailers.

ReturnBear operates a customizable branded portal that enables customers to initiate returns. Simultaneously, its proprietary machine learning model assesses fraud risk in real-time, approving refunds or exchanges instantly without impacting merchant cash flow.

Reveni’s return and exchange platform syncs with inventory systems to update stock in real-time. This offers accurate product availability and minimizes stockouts during exchanges.

Reveni unifies global returns into a single interface, automates reverse logistics workflows, and generates insights from return data to support operational decisions.

It also reduces friction, speeds up refund processing, and converts returns into retained revenue. This allows brands to strengthen customer loyalty and streamline reverse logistics operations.

6. Refurbishment Centers

With average return rates of 20-30% and the cost of returns for manufacturers estimated at 9-15% of overall revenue, ECR Loss indicates that returns from online sales are having a major impact on business earnings. An estimated USD 100 billion is spent on returns each year in the US.

Therefore, reverse logistics companies now rely heavily on refurbishment centers to repair, recondition, or improve damaged, returned, or end-of-life products and extend product lifecycles.

In addition to reducing waste, refurbishment recovers value from goods that would otherwise degrade the environment. This allows businesses to reduce their carbon footprint, comply with regulations, and access new revenue streams.

Companies are further encouraged to integrate refurbishing by financial incentives like the possibility of increased profit margins on refurbished products and the opportunity to target price-sensitive consumer segments.

Refurbishing centers leverage AI and ML to evaluate returned goods, forecast the results of refurbishments, and streamline repair procedures. Moreover, advanced robotics and automation systems make it easier to disassemble, clean, and reassemble items to make refurbishment procedures more efficient and consistent.

For example, ABB’s GoFa cobots at Repartly streamline disassembly, cleaning, and reassembly. This reduces processing times by up to half while maintaining high quality.

Throughout the refurbishment process, IoT devices enable real-time product tracking and monitoring to ensure transparency and quality control. Blockchain also improves confidence and traceability in reconditioned items by providing safe and unchangeable records of product histories.

Make Aneew designs Circular Recycling Center

US-based startup Make Aneew operates a textile recovery platform that reclaims value from discarded garments through repair, remanufacturing, and recycling.

The platform collects post-consumer clothing and evaluates each item’s condition. Based on this assessment, the platform applies appropriate interventions like repairing minor flaws and remanufacturing structurally sound pieces into new designs. It also recycles irreparable items into raw materials.

Make Aneew’s approach thus enables scalable recovery of textile value, reduces landfill dependency, and supports circular design integration for brands.

Additionally, the startup integrates refurbishment capabilities directly into the reverse logistics chain, enabling faster reintegration of products into the market.

Make Aneew integrates refurbishment directly into the reverse logistics chain, enabling faster product reintegration into the market. This strategy further aligns with the industry’s move toward localized refurbishment centers. This reduces transportation time and environmental impact.

Refurb-UK offers Refurbishment as a Service

UK-based startup Refurb-UK delivers Refurbishment-as-a-Service (RaaS) solutions that extend the lifecycle of IT assets through refurbishment processes.

The startup systematically tests, data-wipes, upgrades, and cosmetically improves returned or end-of-life devices, integrating them back into operational use.

Moreover, the startup employs proprietary tools like SticKeys, a UV gel-based keyboard overlay, and Vinyl Skinz, precision-cut vinyl wraps, to restore both the functionality and aesthetics of devices.

Refurb-UK integrates refurbishment directly into the reverse logistics chain, enabling faster reintegration of products into the market.

The startup’s model addresses the growing demand for sustainable reverse logistics solutions. This offers organizations a method to minimize waste, increase customer engagement, and achieve environmental objectives.

7. Returns Forecasting

With predictive analytics, businesses are able to predict return volumes, spot trends, and take proactive measures to reduce related expenses. This improves operational efficiency, customer happiness, and inventory management. Accurate returns forecasting also ensures a competitive edge and sustainable operations.

Moreover, customers are increasingly demanding easy return procedures. Therefore, businesses must predict return patterns and modify their logistics appropriately. The financial ramifications of returns – such as the expense of restocking and possible revenue loss – highlight the necessity of precise forecasting to reduce the negative economic effects.

Returns forecasting also enables dynamic decision-making around product design and merchandising. For example, if a certain category of products shows high predicted return rates due to sizing issues or unmet expectations, businesses can take corrective actions early on.

Further, retailers are able to make better decisions about inventory and staffing during peak times by using predictive analytics providers like Clear Returns to assist them in anticipating return spikes.

Machine learning models are also being trained on customer feedback, historical return reasons, and seasonal patterns to refine forecast accuracy. Return prediction models are embedded in omnichannel retail platforms to ensure that reverse logistics processes remain agile and customer-focused.

Magic predicts Customer Return Intent

Swedish startup Magic develops a returns forecasting platform that enables retailers to predict and reroute product returns to local hubs or resell them on marketplaces.

Moreover, its machine learning algorithm analyzes data points to anticipate customer return behavior. This allows retailers to list predicted returns for resale before they physically arrive, thereby minimizing overstock and landfill waste.

Additionally, the returns forecasting platform features a dashboard that visualizes the overlap between returns and new orders, providing insights into operational bottlenecks.

By inputting a uniform resource locator (URL), the platform also calculates predicted emissions and financial losses and offers actionable recommendations to improve reverse logistics operations.

Further, Magic’s marketplace directory connects retailers with vetted local resell hubs across multiple countries. This facilitates just-in-time fulfillment and reduces shipping distances.

Pinch AI mitigates Return Policy Abuse

US-based startup Pinch AI develops an AI-powered returns management platform that enables retailers to forecast return patterns, detect abuse, and optimize reverse logistics operations.

The platform employs machine learning algorithms and device fingerprinting to analyze customer behavior and transaction data. It also identifies high-risk return activities and informs adaptive return policies.

Pinch AI further provides real-time insights into return conditions and streamlines warehouse inspections by prioritizing returns based on abuse propensity.

Additionally, the platform enriches data to improve compliance reporting, which allows retailers to align with regulations such as the EU’s Ecodesign for Sustainable Products Regulation (ESPR).

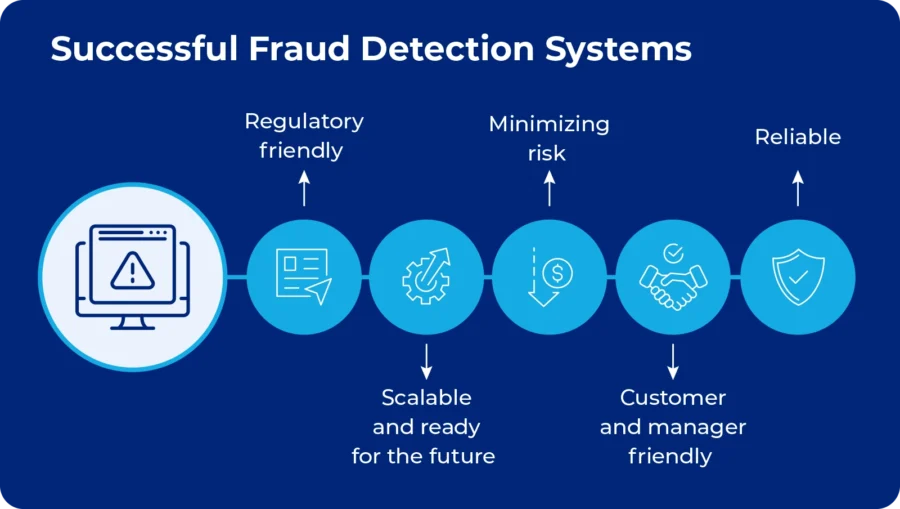

8. Fraud Detection

With fraudulent returns making up 15% of all retail returns in 2024 and causing losses of USD 103 billion, return fraud is a serious and growing problem for retailers. Additionally, fraud costs USD 13.7 for every USD 100 in returned goods, according to the National Retail Federation.

Due to the growing difficulties caused by fraudulent return operations, fraud detection has emerged as a crucial trend in reverse logistics. Instances of return fraud, like wardrobing, returning counterfeit goods, or empty packaging, have dramatically grown due to the growth of e-commerce and lax return procedures.

To protect assets and preserve operational integrity, companies are giving top priority to integrating effective fraud detection techniques into their reverse logistics processes.

Source: Scalefocus

Machine learning and artificial intelligence algorithms analyze vast datasets to find trends indicating fraudulent activities. To identify suspicious returns, these systems evaluate past purchases, frequency of returns, and product quality, among others.

For instance, predictive models assess return legitimacy using historical data and achieve 95% accuracy in forecasting fraudulent patterns, while real-time monitoring blocks suspicious transactions and reduces fraud rates.

Further, computer vision solutions improve fraud detection by comparing customer-uploaded photos of returned goods with real product photos. Further, blockchain improves accountability and transparency in the return process by providing safe and unchangeable recordings of product histories.

Omnichannel return fraud often exploits gaps between siloed systems. Unified platforms and cross-channel data integration are thus essential to prevent loopholes. Importantly, not all return abuse is intentional. Retailers must distinguish between malicious fraud and behavior stemming from confusing policies or inadequate return education.

Retailers like Optoro and Appriss Retail demonstrate that combining AI-driven fraud detection with unified data platforms reduces losses while maintaining customer trust.

Yofi offers Return Fraudster Flagging & Blocking

Yofi is a US-based startup that develops an AI-driven fraud detection platform. It allows retailers to identify and prevent return abuse while personalizing return policies based on customer behavior.

Additionally, the platform analyzes thousands of signals, including telemetry, behavioral patterns, device data, and return history. This assigns real-time risk scores, flags suspicious activity, and clusters related accounts using graph-based models.

The platform also integrates with other platforms and tools, including Shopify, Loop, and Slack. This enables merchants to automate interventions such as refund holds, in-store-only returns, and dynamic policy enforcement for high-risk users.

Additionally, Yofi’s consortium shares threat intelligence to proactively detect coordinated fraud networks and evolving abuse tactics.

Tailed enables Fraudulent Return Prevention

US-based startup Tailed develops an AI-powered return fraud prevention platform that detects and blocks fraudulent returns. This includes fake tracking identity (FTID) schemes before refunds are issued.

Moreover, the platform integrates directly with e-commerce platforms like Shopify and return management systems such as Loop and Narvar. It then analyzes every return by ingesting customer data, order information, and carrier tracking events to assign real-time fraud risk scores.

Further, the platform flags suspicious returns for manual review, sends detailed alerts via Slack, and automatically routes high-risk cases to a dedicated Needs Review tab. This eliminates the need for manual inspection.

Additionally, Tailed employs identity fingerprinting to prevent repeat offenders from placing new orders and monitors dark web forums to identify emerging threats targeting specific brands.

9. Returnable Packaging

By reducing the amount of packaging waste and dependency on disposable materials, returnable packaging reduces the carbon footprint of the logistics sector. Further, a growth in product returns due to e-commerce has made more effective and affordable reverse logistics solutions necessary.

Studies show that reusable packaging can reduce solid waste by up to 96% and lower CO2 emissions by 62%.

By lowering the expenses related to waste disposal and packaging materials, returnable packaging provides an effective solution. Additionally, businesses are being urged to implement circular economy-supporting practices by regulatory pressures and corporate sustainability programs.

Wooden pallets, metal containers, plastic totes, and custom-engineered packages of customers are returned, cleaned, and reused. This creates a closed-loop system in managing packaging and simplifies the reverse logistics process.

RFID and IoT devices have a critical role in simplifying package tracking. These devices ensure effective use and reduce losses by providing real-time visibility into the location and condition of packages.

Further, data analytics and machine learning algorithms improve operational efficiency by analyzing consumption trends and optimizing returnable packaging deployment. Cloud-based solutions also make it easier for supply chain partners to coordinate, share information, and manage inventories of returnable packaging.

XICLO enables the Returnable Packaging System

Columbian startup XICLO offers a returnable packaging system that replaces single-use containers with reusable alternatives for food delivery and retail operations.

The startup employs a closed-loop logistics model by providing businesses with durable, thermally insulated packaging designed for multiple uses. A digital platform tracks each package’s usage, while the startup oversees collection and sanitation processes to ensure safe reuse.

Additionally, the returnable packaging system integrates smart inventory tokens and app-based workflows to streamline adoption. Further, its packaging design maintains food quality and reduces environmental impact.

XICLO also enables businesses to reduce waste and carbon emissions while aligning with sustainability goals and improving customer experience.

Movopack manufactures Reusable Packaging

Movopack is an Italian startup that delivers reusable packaging solutions for e-commerce retailers. It eliminates single-use waste and improves reverse logistics efficiency.

Moreover, the startup supplies durable, foldable mailers crafted from recycled materials, which customers return via prepaid labels through existing postal networks. Each package undergoes industrial sanitization and re-enters circulation.

Further, Movopack’s model reduces CO₂ emissions, lowers water and energy consumption, and integrates with brand operations through a pay-per-use structure that includes logistics, cleaning, and redistribution.

10. Robotics

Due to the exponential growth in eCommerce, product returns have significantly increased. This forces businesses to integrate more effective and scalable ways to manage returns. Manual processing is impractical due to rising labor costs, high error rates, and the need for 24/7 operations, making automation a strategic alternative.

Robotic solutions also reduce errors and improve turnaround times when processing returns. Businesses are able to automate processes like sorting, examining, and repackaging returned goods by incorporating robotic technologies.

In addition to speeding up returns, automation improves accuracy and uniformity while lowering the possibility of human errors. As a result, companies optimize labor costs and resource allocation while simultaneously increasing customer satisfaction through faster return processing.

Automated guided vehicles (AGVs) and robotic arms are examples of advanced robotics systems used to manage the physical movement and manipulation of returned products. Machine learning and AI algorithms facilitate intelligent decision-making, like route optimization or quality issues.

Further, autonomous mobile robots (AMRs) enable touch-free, contactless return experiences while mitigating the need for manual labor. Additionally, warehouse management systems (WMS) improve coordination between robot operations to drive inventory management.

Moreover, automation systems are modular and scalable. This allows businesses to improve processing capacity during seasonal spikes. Beyond efficiency gains, robotic accuracy also minimizes waste and contributes to more sustainable returns management, which is a growing priority for ESG-conscious enterprises.

Smarcel deploys Mobile Parcel Locker Network

German startup Smarcel develops mobile robotic parcel lockers that automate last-mile delivery and reverse logistics operations.

It loads parcel lockers overnight at distribution depots and transports them to designated urban locations each morning. Throughout the day, customers collect or return parcels at these lockers, all managed through an integrated mobile app.

The mobile robotic parcel locker systems incorporate automated loading and dynamic shelving that adjusts to parcel dimensions.

Additionally, Smarcel employs AI-driven software to optimize locker placement based on real-time demand and traffic patterns.

Smarcel integrates robotic systems into the reverse logistics chain, enhancing the efficiency of handling returns and reducing reliance on manual labor. This also minimizes environmental impact by streamlining processes and decreasing waste.

Discover all Reverse Logistics Trends, Technologies & Startups

As supply chains grow smarter and sustainable, reverse logistics will be a key competitive differentiator. Looking ahead, the integration of AI, robotics, and circular economy principles will redefine how companies manage returns, reduce waste, and deliver value beyond the point of sale. Businesses that invest in these forward-thinking capabilities to thrive in the customer and planet-conscious economy.

The Current Trends in Reverse Logistics outlined in this report only scratch the surface of trends that we identified during our data-driven innovation & startup scouting process. Identifying new opportunities & emerging technologies to implement into your business goes a long way in gaining a competitive advantage.