Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

Customer concerns around plastic waste and stringent government policies drive plastic recyclers to enhance recycling efficiency and reduce emissions. The global plastic recycling trends for 2025 and beyond show significant investments in chemical recycling solutions, which complement traditional mechanical recycling techniques and expedite recycling processes. Startups also develop advanced mechanical recycling solutions using AI-driven systems to optimize plastic sorting and processing. Plastic manufacturers, collectors, and recyclers further increase transparency in materials flow to improve overall plastic waste management. These efforts align industry practices with regulatory and consumer demands for sustainability.

This article was last updated in August 2024.

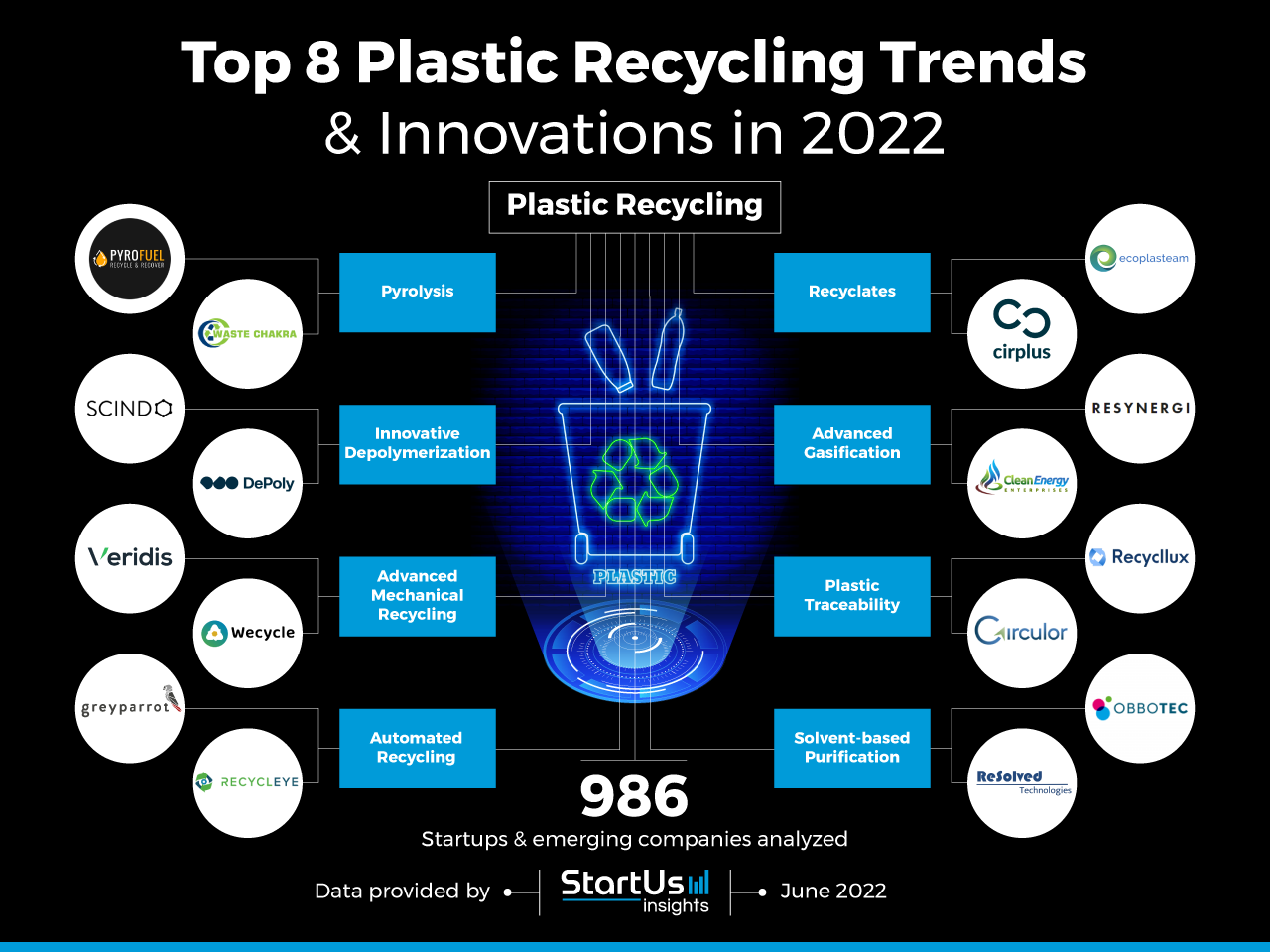

Innovation Map outlines the Top 8 Plastic Recycling Trends & 16 Promising Startups

For this in-depth research on the top global mobility trends and startups, we analyzed a sample of 986 global startups & scaleups. This data-driven research provides innovation intelligence that helps you improve strategic decision-making by giving you an overview of emerging technologies in the plastic recycling industry. In the Plastic Recycling Innovation Map, you get a comprehensive overview of the innovation trends & startups that impact your company.

Top 8 Plastic Recycling Trends in 2025

- Pyrolysis

- Innovative Depolymerization

- Advanced Mechanical Recycling

- Automated Recycling

- Recyclates

- Advanced Gasification

- Plastic Traceability

- Solvent-based Recycling

These insights are derived by working with our Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 4.7M+ startups & scaleups globally. As the world’s largest resource for data on emerging companies, the SaaS platform enables you to identify relevant technologies and industry trends quickly & exhaustively.

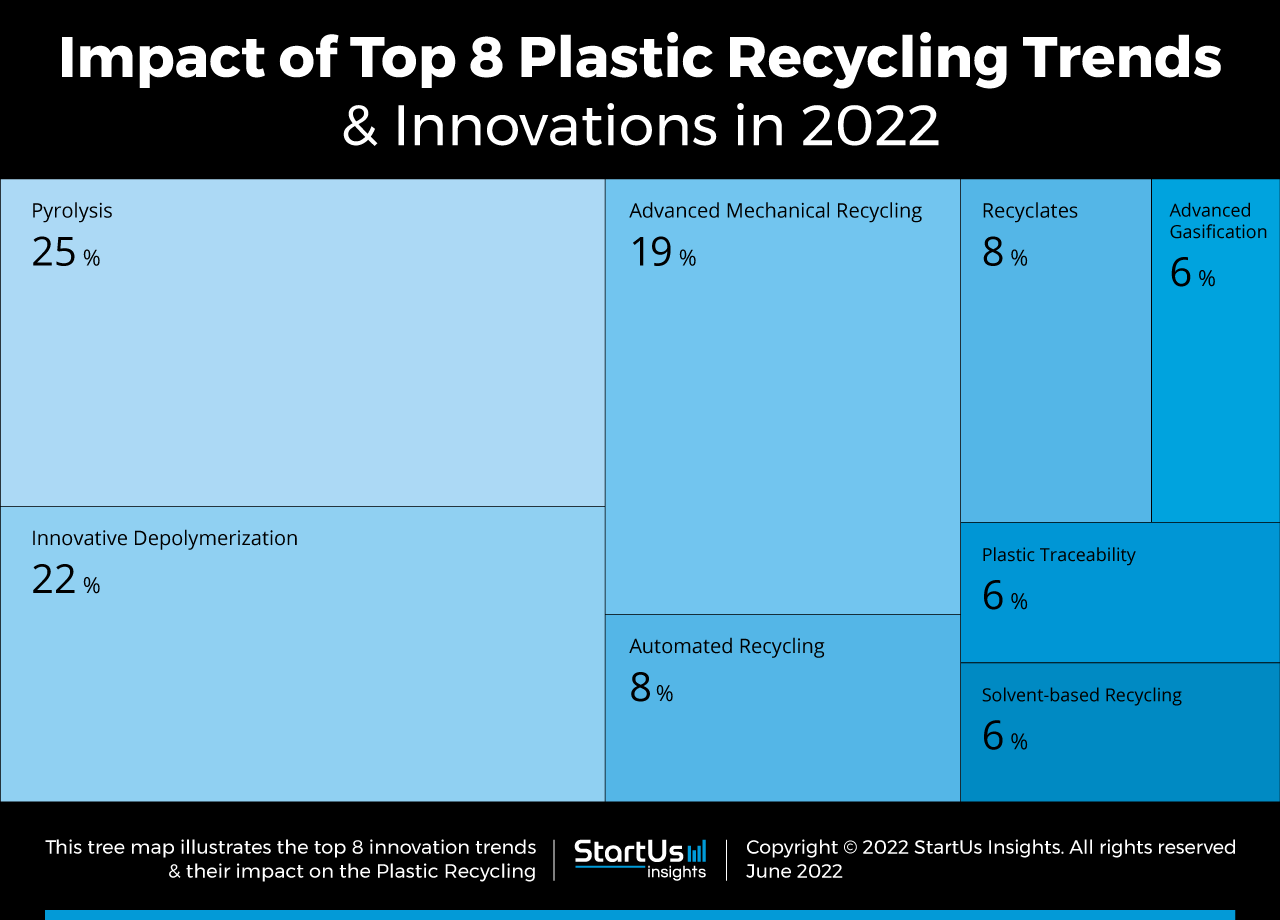

Tree Map reveals the Impact of the Top 8 Plastic Recycling Trends

Based on the Plastic Recycling Innovation Map, the Tree Map below illustrates the impact of the Top 8 Plastic Recycling Trends in 2025. Chemical plastic recycling technologies like pyrolysis, chemical depolymerization, gasification, and solvent-based purification (SBP) have a huge impact on the industry. Following this, advanced mechanical recycling systems are leveraging AI and material quality grading solutions to improve operations at recycling facilities.

Additionally, plastic recycling startups are leveraging blockchain and geospatial intelligence to track plastic waste, improving plastic reverse logistics efforts. These solutions, in turn, significantly increase material recovery rates at recycling plants.

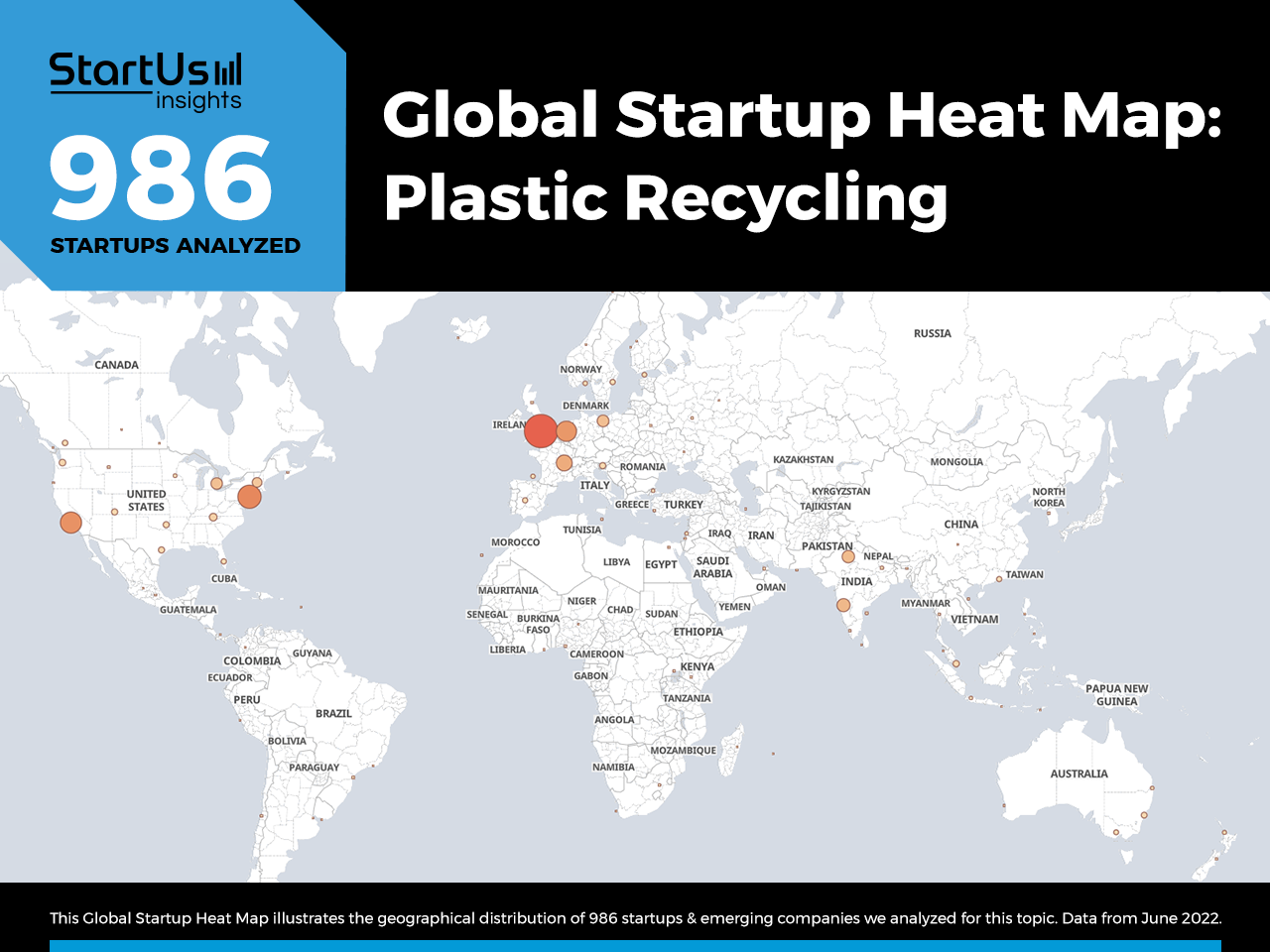

Global Startup Heat Map covers 986 Plastic Recycling Startups & Scaleups

The Global Startup Heat Map below highlights the global distribution of the 986 exemplary startups & scaleups that we analyzed for this research. Created through the StartUs Insights Discovery Platform, the Heat Map reveals that the UK and the US have a high concentration of plastic recycling startups.

Below, you get to meet 16 out of these 986 promising startups & scaleups as well as the solutions they develop. These 16 startups are hand-picked based on criteria such as founding year, location, funding raised, and more. Depending on your specific needs, your top picks might look entirely different.

Top 8 Plastic Recycling Trends for 2025

1. Pyrolysis

Thermal degradation of hydrocarbon plastic waste in the absence of oxygen generates pyrolytic oil. Pyrolysis plants further process this oil to produce pyrolytic fuel similar to gasoline or diesel. Other byproducts of the process include petrochemicals, liquid petroleum gas, and carbon ash residue. Advances in pyrolysis technology, such as fast and ultra-fast pyrolysis, allow plastic waste recyclers to recycle massive amounts of waste flows within shorter periods.

Plastic recycling companies also develop solutions to reduce energy consumption and emissions in plastic pyrolysis plants to enable sustainable operations. Moreover, pyrolytic fuel replaces diesel in internal combustion engines. This provides an additional revenue stream for recycling facilities and supports the transition to a low-carbon economy.

Pyrolyze manufactures Portable Pyrolysis Plants

Dutch startup Pyrolyze makes a 3 kg plastic pyrolysis demonstrator plant that efficiently converts mixed waste plastics or motor oil into fuel and carbon ash. The portable design on wheels allows it to be easily transported anywhere.

It has a single automated distillation line and PLC control system to research different settings batch by batch. It produces diesel and lighter oils, carbon ash, and syngas from common plastics in just 5 hours. Pyrolyze also offers a 350 liter per day waste motor oil pyrolysis plant that efficiently converts used motor oil into diesel, naphtha, and gas.

Waste Chakra makes a Decentralized Plastic Pyrolysis Machine

Waste Chakra is an Indian startup that manufactures a decentralized plastic pyrolysis machine. The startup’s mobile plastic recycling machine processes plastics of varying sizes within a small footprint. It needs only 1 kilogram of plastic as the minimum requirement to start the recycling process. Additionally, the machine features a solar-powered running mode for sustainable operations. This allows small and medium recycling businesses to leverage pyrolysis without large capital investments.

2. Innovative Depolymerization

Breaking down plastic waste into its monomer allows recyclers to recover a great fraction of materials from the waste source. This is due to the shorter recycling loop in depolymerization techniques. To recover monomer components from waste streams, startups leverage both chemical and biological means.

For example, enzymatic recycling uses bacterial catalysts to break down plastic waste into high-quality monomers. This allows plastic recyclers to ensure the quality of the recyclates and generate high commercial value as monomers directly replace fossil-fuel-based raw materials in plastic manufacturing industries.

Scindo offers Enzymatic Plastic Recycling

Scindo is a UK-based startup that develops an enzymatic plastic recycling solution. The startup’s biological platform breaks down plastic polymers into high-value molecules. They find use as affordable feedstock in the chemicals, biotech, and pharma industries, among others. This enables recyclers to drive plastic waste away from incineration and landfills, driving a circular economy as well as a high-profit revenue stream.

DePoly facilitates Chemical Depolymerization

Swiss startup DePoly chemically recycles polyethylene terephthalate (PET) plastics into raw monomers. The startup’s proprietary solution mitigates pre-sort, pre-wash, and materials separation processes as well as supports multi-layer items and multi-color fibers.

Moreover, DePoly’s solution produces purified terephthalic acid (PTA) and mono-ethylene glycol (MEG) pure enough for re-polymerization. This allows PET makers to replace fossil-fuel-based raw materials with plastic waste as a feedstock to generate high-quality PET.

3. Advanced Mechanical Recycling

Mechanical recycling is the most profitable means to manage waste plastics. Since the waste stream quality significantly impacts the efficiency of mechanical recycling processes, the industry sees innovations in waste collection, sorting, and separation. This includes AI-assisted systems to speed up plastic waste classification at processing sites and more effective reverse logistics to ensure high-quality waste flow.

Such solutions allow plastic recyclers to increase the quality of secondary raw materials and convert the otherwise low-quality streams into high-quality second-life plastics. Other advances in mechanical recycling include robot-assisted conveyor belts to accelerate waste classification and quality grading, improving operations.

Veridis provides Plastic Analysis

Veridis is a Dutch startup that uses thermal scanning to analyze plastic quality. The startup’s product, MADSCAN, leverages differential scanning calorimetry to map how the heat capacity of plastic materials varies by temperature.

It then detects transitions such as melts, glass transitions, phase changes, and curing at high accuracy. Besides, MADSCAN is a scale-free device that requires minimal sample preparation and optimal sample size. This provides plastic recyclers with unique material fingerprints, allowing them to optimize processes and increase the commercial value of their flows.

Wecycle advances Sustainable Recycling

Norwegian non-profit startup Wecycle maintains a local recycling facility in Oslo. The startup leverages open-source recycling machines from the Precious Plastic model and community-based recycling. Wecycle’s plastic recycling process supports a varying mix of plastic waste.

Its shredder tears down the plastic into flakes, which the startup’s injector heats to mold the plastic into new products such as colored tiles. This significantly reduces the carbon footprint of plastic collection and recycling, enabling sustainable operations.

4. Automated Recycling

AI-enabled solutions in the plastic recycling industry automate processing lines and improve waste separation. This enables plastic recyclers to tackle worker scarcity while enhancing operational efficiency. Plastic recycling startups further offer automated chemical recycling plants that minimize manual interventions. As a result, it reduces the workers’ exposure to high heat and increases their safety.

Other startups provide automated plastic processing machines for consumer-facing businesses. This allows government authorities and recyclers to incentivize climate-friendly behavior, increasing brand value for companies.

Recycleye streamlines Automated Waste Sorting

Recycleye is a UK-based startup that develops an automated waste sorting system. The startup combines machine learning, computer vision, and robotics to automate waste analysis and sorting. This increases transparency in recycling conveyors and allows plastic recyclers to increase sort and pick efficiency at facilities as well as reduce operational costs.

Greyparrot enables Automated Waste Analysis

Greyparrot is a UK-based startup that facilitates automated waste analysis. The startup’s computer vision-powered waste recognition system integrates with conveyor belts in sorting facilities to classify waste streams. Further, it continuously monitors and analyzes the waste stream to provide an objective representation of waste composition in real-time.

The system’s companion application programming interface (API) enables third-party system integrations like picking robots. This allows plastic recycling facilities to improve recycling efficiency and automate operations.

Find out how 10 emerging technologies shape your industry!

5. Recyclates

Most of the plastic waste ends up in landfills and incinerators because they are not designed for recycling at their end of life. That is why various startups are developing materials optimized for recycling. These include mono-material plastics that increase recycling efficiency and recyclable, low-carbon plastic alternatives. Such materials coupled with efficient recycling processes improve plastic recyclate quality.

Since post-consumer plastic waste contributes significantly to the global waste problem, plastic collectors also take extra efforts to create post-consumer recycled (PCR) plastics. This allows plastic recyclers to generate high commercial value for their waste flows, allowing plastic manufacturers to reduce their dependence on fossil-fuel-based raw materials.

Ecoplasteam develops an Infinitely Recyclable Plastic

Ecoplasteam is an Italian startup that makes EcoAllen, an infinitely recyclable plastic. The startup utilizes layers of recycled plastic and aluminum to develop EcoAllen. This makes its price independent of oil market volatility, unlike virgin plastics. Besides, Ecoplasteam’s production process significantly reduces the cost of recycling and finds applications in the packaging, cosmetics, and construction industries.

cirplus maintains a Recycled Plastic Marketplace

German startup cirplus provides a recycled plastic marketplace. The startup’s online platform allows plastic recyclers to sell recyclates and waste feedstock. It also integrates data quality levels for recyclers to specify recyclate characteristics like color, recycling method, and more. This enables buyers to quickly find materials based on their requirements, increasing the reach and revenue for plastic recycling facilities.

6. Advanced Gasification

Unlike pyrolysis, gasification systems thermally treat plastic waste under oxygen starvation. Moreover, this technology supports a mixed waste stream that is otherwise non-recyclable. The syngas or synthesis gas generated from plastic waste gasification is a feedstock for electricity generation, chemical manufacturing, and hydrogen production.

Additionally, gasification power plants require less water and pollution control equipment than conventional coal-powered plants. Plastic recycling startups leverage advances in reactor systems to increase process yield and reduce the cost of operations. This ensures a better market penetration for the technology, diverting more plastics away from landfills and incinerators.

Resynergi builds Modular Gasification Systems

Resynergi is a US-based scaleup that develops modular gasification systems. The scaleup partners with the University of Minnesota to leverage its microwave-based technology in Resynergi’s gasification system. It has a small footprint and modular design, enabling easy on-site deployment and scaling. This system allows plastic recyclers and solid waste management facilities to avoid massive capital expenses and replace refined oil products.

Clean Energy Enterprises makes Gasification Chambers

Clean Energy Enterprises is a US-based startup that develops waste-to-energy solutions. The startup’s joint venture with Japan Blue Energy Corporation, Ways2H, provides gasification chambers for decentralized waste management.

Its self-sustainable thermal conversion system breaks down organic waste and plastic into hydrogen. The solution then collects the hydrogen to power mobility applications. Moreover, the chambers naturally self-balance to prevent overheating, improving throughput for recycling facilities.

7. Plastic Traceability

Around 91 percent of plastic products are lost due to a lack of visibility into their lifecycle. To tackle this, startups develop plastic traceability solutions that allow recyclers to track back their flow. Additionally, solutions to collect plastic directly from consumers, such as plastic recycling machines at malls, are gaining popularity. Startups leverage blockchain-based rewarding systems to promote customer-driven plastic waste discovery, generating more recycling opportunities.

Further, plastic recycling facilities partner with reverse logistics services to improve waste discovery and enable a constant material flow. These solutions, together, allow plastic recyclers to convert otherwise wasted plastics into high-value products. Besides, bridging this recycling gap significantly reduces the need for virgin materials, reducing resource consumption.

Recycllux simplifies Marine Plastic Tracking

Recycllux is a Belgian startup that enables marine plastic tracking. The startup combines earth observation data and machine learning to identify marine plastic litter spots. Additionally, it utilizes blockchain to incentivize collectors and encourage recycling. This allows authorities and plastic recycling facilities to trace marine plastics and offer additional income streams for collection and recycling partners.

Circulor facilitates Recycling Process Traceability

UK-based startup Circulor develops a recycling process traceability suite. It utilizes blockchain to track the origin of raw materials and the flow of materials through production processes and recycling supply chains. This enables increased visibility into individual items and facilitates end-of-life product handling. Consequently, the blockchain-based process data allows recyclers to ensure material quality and divert more plastics from landfills and incinerators.

8. Solvent-based Purification

Dyes and additives in plastic waste limit material recovery in mechanical recycling facilities. Selective solvent dissolution or solvolysis, on the other hand, removes impurities from post-industrial and post-consumer plastic waste. This results in the recovery of very high-quality plastics. Plastic recycling facilities use this technology to recover high-quality plastic polymers and replace virgin plastics in the manufacturing sector.

The technology also boosts the recycling efficiency of plants and allows them to keep high-value materials away from landfills. Startups leveraging the technology work to reduce the technology’s operating expenses and make the system easily scalable.

OBBOTEC advances Plastic Dissolution

OBBOTEC is a Dutch startup that recycles plastic using SPEX, a proprietary dissolution technology. It selectively extracts PE and PP plastics from plastic-rich waste streams using solvents. Additionally, the technology removes the additives and contaminants in the plastics, including color, plasticizers, and flame retardants.

The resulting plastic finds use in high-standard applications like food packaging. Moreover, the startup’s technology has a high yield, allowing plastic recyclers and processors to ensure high-value generation for their waste flows.

ReSolved Technologies provides Solvent-based Plastic Recycling

ReSolved Technologies is a Dutch startup that offers a hybrid solvent-based plastic recycling solution. The startup’s process generates near-virgin quality plastics from post-consumer waste streams such as e-waste and car scraps. Plastic recyclers utilize this solution to remove interior contaminants from plastic waste streams and enable closed-loop recycling.

Discover all Plastic Recycling Trends, Technologies & Startups

Advances in the plastic recycling sector increase the quantity and quality of recycled plastics. Additionally, plastic recycling startups make these innovations more affordable and scalable to address the ever-increasing volume of plastic waste. From reducing the quantity of plastic reaching landfills and oceans to material innovations like recyclable, low-carbon plastic alternatives and smart polymers are gaining attention. All solutions ultimately aim to reduce new virgin plastic extraction and build a circular economy.

The Plastic Recycling Trends & Startups outlined in this report only scratch the surface of trends that we identified during our data-driven innovation and startup scouting process. Among others, robotics, AI, and advanced analytics will transform the sector as we know it today. Identifying new opportunities and emerging technologies to implement into your business goes a long way in gaining a competitive advantage. Get in touch to easily and exhaustively scout startups, technologies & trends that matter to you!

![Explore the 10 Emerging Smart City Trends [2025-2026]](https://www.startus-insights.com/wp-content/uploads/2025/06/Smart-City-Trends-SharedImg-StartUs-Insights-noresize-420x236.webp)