Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

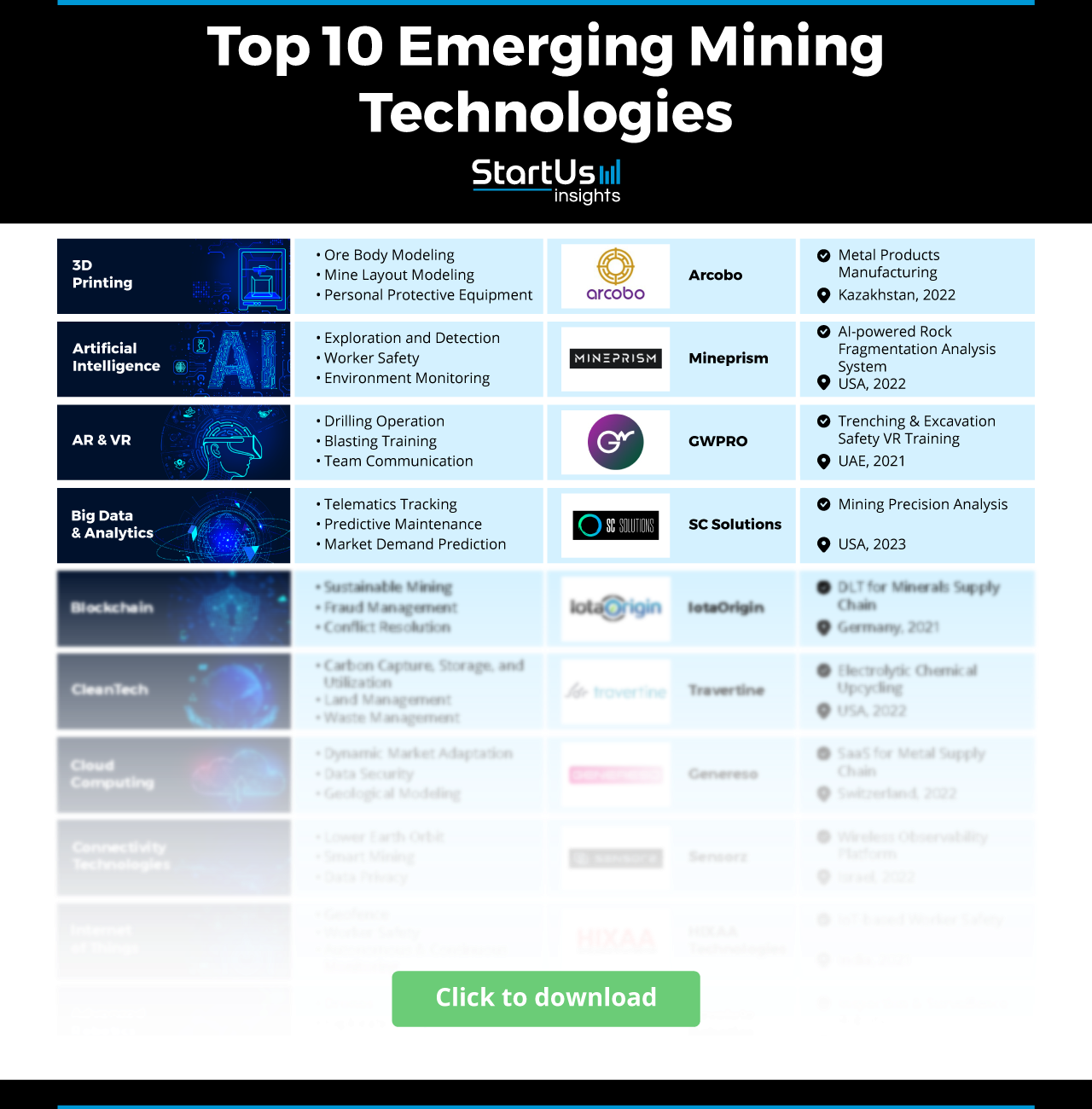

The mining industry is evolving as technological innovations address challenges such as resource depletion, environmental sustainability, and operational inefficiencies. Artificial intelligence (AI), Augmented Reality (AR), Virtual Reality (VR), and big data & analytics are transforming exploration and extraction processes, while cleantech solutions promotes eco-friendly practices. Robotics and 3D printing improve equipment maintenance and production workflows, while connectivity technologies and the Internet of Things (IoT) enhance real-time monitoring and decision-making. Further, cloud computing offers scalable solutions for data management, and AR and VR technologies facilitate immersive training and simulation in hazardous environments. Mining technology startups are leading the charge in these innovations.

For example, Mineprism develops an AI-powered system for rock fragmentation analysis. Similarly, IotaOrigin uses blockchain to create secure and transparent mineral supply chains. As the mining landscape changes, business decision-makers must incorporate these mining technology solutions to ensure long-term success.

Why should you read this report?

- Gain insights into the top 10 technologies impacting mining.

- Learn about three practical use cases for each technology.

- Meet 10 innovative startups advancing these technologies.

Key Takeaways

- Additive Manufacturing

- Use Cases:

- Ore Body Modeling

- Mine Layout Modeling

- Personal Protective Equipment (PPE)

- Startup to Watch: Arcobo

- Use Cases:

- Artificial Intelligence

- Use Cases:

- Exploration and Detection

- Worker Safety

- Environment Monitoring

- Startup to Watch: Mineprism

- Use Cases:

- Augmented Reality & Virtual Reality

- Use Cases:

- Drilling Operation

- Blasting Training

- Team Communication

- Startup to Watch: GWPRO

- Use Cases:

- Big Data & Analytics

- Use Cases:

- Telematics Tracking

- Predictive Maintenance

- Market Demand Prediction

- Startup to Watch: SC Solutions

- Use Cases:

- Blockchain

- Use Cases:

- Sustainable Mining

- Fraud Management

- Conflict Resolution

- Startup to Watch: IotaOrigin

- Use Cases:

- CleanTech

- Use Cases:

- Carbon Capture, Storage, and Utilization

- Land Management

- Waste Management

- Startup to Watch: Travertine

- Use Cases:

- Cloud Computing

- Use Cases:

- Dynamic Market Adaptation

- Data Security

- Geological Modeling

- Startup to Watch: Genereso

- Use Cases:

- Connectivity Technologies

- Use Cases:

- Lower Earth Orbit

- Smart Mining

- Data Privacy

- Startup to Watch: Sensorz

- Use Cases:

- Internet of Things

- Use Cases:

- Geofence

- Worker Safety

- Autonomous and Continuous Monitoring

- Startup to Watch: HIXAA Technologies

- Use Cases:

- Advanced Robotics

- Use Cases:

- Drones

- Exploration Robots

- Explosive Handling

- Startup to Watch: Revolute Robotics

- Use Cases:

- Additive Manufacturing

Mining Industry FAQs

Is the mining industry growing?

The mining industry is projected to reach USD 2825.81 billion by 2028, growing at a compound annual growth rate (CAGR) of 5.5%. This growth is driven by increasing demand for essential minerals that support global energy transitions, urbanization, and infrastructure development.

What are the main challenges in the mining industry?

Environmental, social, and governance (ESG) concerns require companies to operate sustainably while maintaining their license to operate. The capital constraints and inflationary pressures have increased costs, making it harder to meet growing demands for critical minerals. Cybersecurity is also becoming a larger issue as mining companies accelerate their adoption of digital technologies.

How did technology change the mining industry?

Automation, AI, and the Internet of Things (IoT) reduce costs by optimizing operations and minimizing downtime. Digital twins allow for real-time monitoring and optimization of mining sites, while autonomous vehicles improve safety by reducing the need for human workers in hazardous environments. Predictive maintenance powered by AI also prevents equipment failures and reduces operational disruptions.

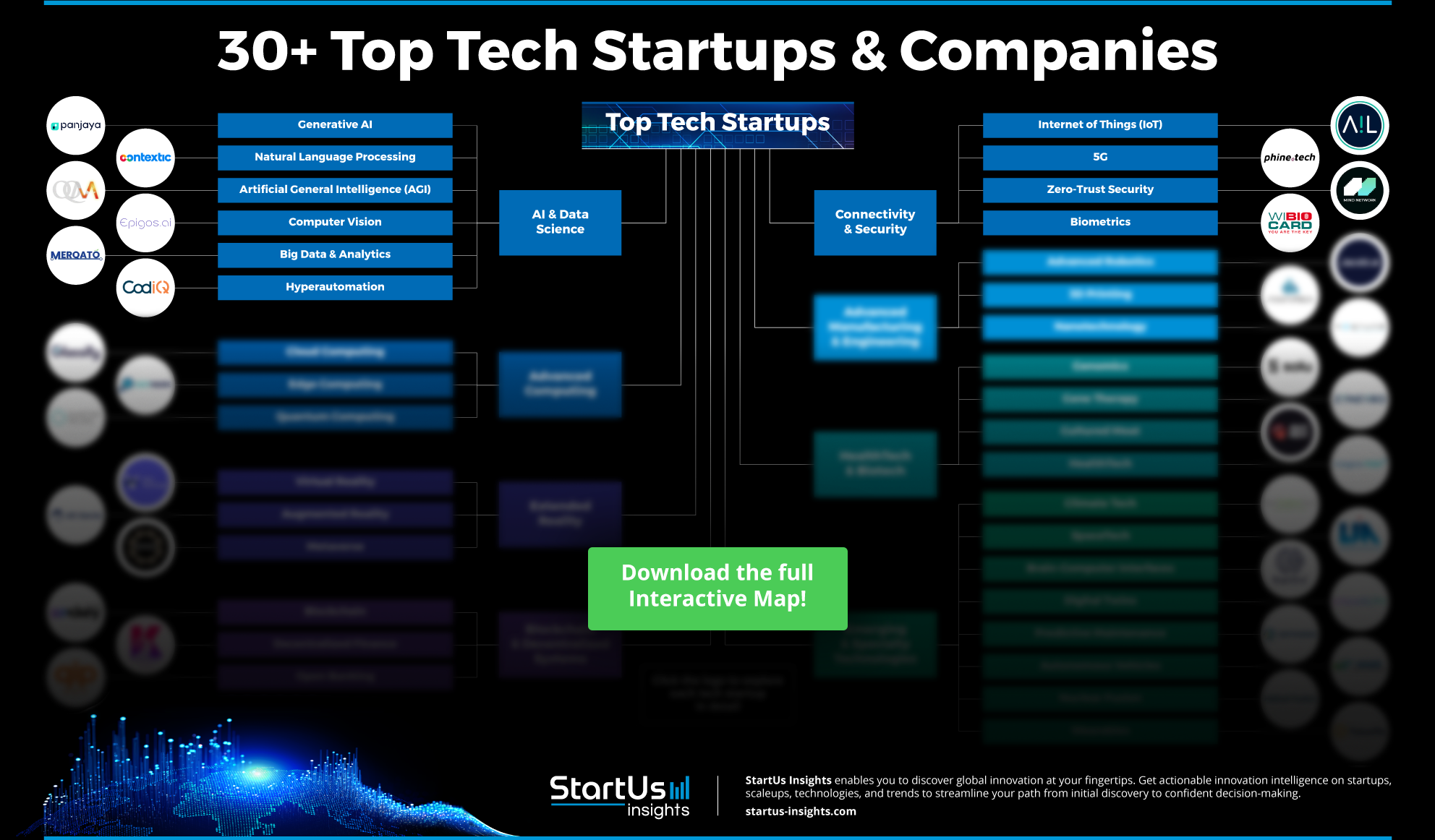

How We Identify Emerging Technologies & Startups

The data in this report originates from StartUs Insights’ Discovery Platform, covering 4.7 million global startups, scaleups, and technology companies, alongside 20,000 emerging technology trends. Our platform makes startup and technology scouting, trend intelligence, and patent searches more efficient by providing deep insights into the technological ecosystem. Utilizing the trend intelligence feature, we analyze industry-specific technologies for this report, detect patterns and trends, and identify use cases along with the startups advancing these areas. Further details and capabilities are accessible via the website.

10 Emerging Technologies Impacting the Future of Mining Industry [2025 & Beyond]

1. Additive Manufacturing

Technologies like metal 3D printing, laser cladding, and continuous fiber filament printing enable mining companies to fabricate strong, lightweight parts on demand at remote sites. This reduces reliance on traditional supply chains and minimizes downtime from equipment failures. 3D printing produces optimized designs for drilling rigs, crushers, and impellers to enhance energy efficiency and performance. These advancements in additive manufacturing support sustainability by reducing material waste and cutting transportation emissions, as spare parts is printed closer to mining operations.

3 Practical Use Cases of Additive Manufacturing in Mining

- Ore Body Modeling: Geological surveys, geochemical data, and geophysical data are used to 3D print ore bodies and improve spatial understanding and volumetric comparison of the mineral.

- Mine Layout Modeling: A mine layout provides insights into the limitations of mining operations and the terrain models of underground mine surfaces. 3D-printed models allow volume calculations, reserve estimation, pit design, and training.

- Personal Protective Equipment (PPE): 3D printing for PPE allows on-demand manufacturing and customization. It creates prototypes of protective gear like hard hats, eyewear, breathing apparatus, and monitoring equipment to estimate risk mitigation in subsurface areas.

Startup to Watch: Arcobo

Kazakh startup Arcobo manufactures large-scale metal products using steel, stainless steel, aluminum alloys, titanium alloys, and bronze. The process starts with uploading a 3D model in STL format. Arcobo then creates a specialized blank using high-tech equipment, followed by precise machining with four and five-axis CNC machines. This approach allows mining companies to receive custom-manufactured parts within a few days.

2. Artificial Intelligence

Machine learning algorithms analyze geological and geophysical data to identify mining sites and optimize resource extraction. Deep neural networks improve ore sorting by recognizing valuable minerals more accurately. Also, smart robotics, integrated with AI, handle tasks like autonomous drilling, hauling, and processing to enhance safety and productivity. Further, AI-powered predictive maintenance systems monitor equipment in real time to reduce downtime by predicting failures before they occur.

3 Practical Use Cases of Artificial Intelligence in Mining

- Exploration and Detection: AI analyzes geological data to provide information about mineral deposits to reduce resource overuse and waste. Machine learning algorithms process satellite imagery, historical data, and geological surveys to suggest precise mining sites with higher mineral concentrations.

- Worker Safety: Autonomous operations reduce human intervention in hazardous locations. AI predicts slope failure in open-pit mines and identifies dangerous areas in surface mining activities. Machines and drones equipped with AI assist in autonomous operations.

- Environmental Monitoring: AI integration in mining optimizes operations, reduces waste, and allocates resources to manage environmental risks. It also monitors the surrounding ecosystem’s health.

Startup to Watch: Mineprism

US-based startup Mineprism builds RockyAI, an AI-powered rock fragmentation analysis system that integrates with other tools in the mining industry. RockyAI analyzes rock formations by segmenting them and providing insights into their volumes and characteristics. This is done using smartphone photos or a dedicated hardware device for real-time AI analysis. The platform also offers automated calculation of P80 and AI-led blast design.

3. Augmented Reality & Virtual Reality

AR overlays digital information onto physical environments that allow miners to access real-time data on equipment and surroundings through devices like smart glasses. It enables workers to visualize machinery status, improve maintenance accuracy, and reduce downtime. VR creates fully immersive simulated environments where miners practice complex tasks, like blasting, in a risk-free setting. VR platforms are also used for maintenance planning, safety training, and operational optimization.

3 Practical Use Cases of AR & VR in Mining

- Drilling Operation: AR-based mining solutions overlay real-time data on the stress in the drill bit to reduce the risk of sudden drill rupture during mining operations.

- Blast training: Immersive technology solutions produce a virtual setup customized to the mine’s specifications. Trainees practice igniting the blast points with explosives. Subsequent weathering of rocks and the aftershock are also present in the virtual reality to give them a glimpse of the actual operation.

- Team Communication: VR creates an immersive experience of the mining sites, which is seen and maintained remotely by several team members, regardless of their physical locations. This collaboration allows access to and monitoring of remote areas and confined locations.

Startup to Watch: GWPRO

UAE-based startup GWPro provides VR-based training for excavation safety that simulates the role of a safety inspector at a trench site. The platform guides workers through assessing their readiness, evaluating trench conditions, and inspecting the performance of excavation equipment and shielding systems. It has three training modes: study, training, and exams. It engages in step-by-step activities that improve their understanding of trench safety risks, including traffic accidents, electric shock, wall collapse, and equipment hazards. The training is also available in multiple languages.

4. Big Data & Analytics

Mining companies leverage vast amounts of data generated across operations — from exploration to processing. This allows them to predict equipment failures, optimize resource extraction, and improve safety. Big data platforms integrate data from sensors, devices, and business systems to provide insights for productivity and risk management. The predictive models and algorithms identify operational anomalies, enabling mining firms to minimize downtime and enhance efficiency.

3 Practical Use Cases of Big Data & Analytics in Mining

- Telematics Tracking: Addresses vehicle underutilization due to a lack of visibility into asset availability and performance. Continuous data acquisition, monitoring, and analysis lead to better fleet management and efficient mining operation.

- Predictive Modeling: Uses statistical techniques, machine learning, and data mining to identify areas needing optimized resource allocation. This data network allows mining companies to save on operational costs, improve production scheduling, and reduce downtime.

- Market Demand Prediction: Time series analysis forecasts future demands based on records, while machine learning algorithms identify complex patterns and correlations. Mining companies use these data models to understand potential demands under various conditions by simulating scenarios based on different requirements, such as changes in economic growth, technological advancements, or policy shifts.

Startup to Watch: SC Solutions

US-based startup SC Solutions develops I-Sat, a platform that transforms raw Earth observation data into actionable intelligence. It leverages machine learning techniques, deep learning, neural networks, and a distributed infrastructure for analysis. The platform offers comprehensive data sets and an NLP-enhanced query tool, that allows businesses to process queries with precision. I-Sat integrates AI and edge computation to analyze vast amounts of data accurately. The hyperspectral insights pinpoint potential mining sites, identify mineral composites, and improve excavation strategies and delivers valuable insights for resource exploration.

5. Blockchain

Blockchain platforms streamline supply chain processes by digitizing trade, tracking minerals from extraction to delivery, and automating transactions with smart contracts. Decentralized ledgers provide tamper-proof transaction records to ensure traceability of commodities like cobalt and diamonds. Blockchain also supports sustainability by verifying responsible sourcing and reducing manual, paper-based systems.

3 Practical Use Cases of Blockchain in Mining

- Sustainable mining: Blockchain securely stores all blast operation data, including geological data, ore body characteristics, drilling parameters, and explosive usage. This tamper-proof audit trail aids blasting engineers in data and simulations.

- Fraud management: Blockchain validates mining certificates and product quality documents to prevent counterfeit products from entering the market. It also secures financial documents and confidential transactions.

- Conflict resolution: The transparent and immutable nature of blockchain provides a clear record of transactions and agreements to address conflicts. It speeds up mining settlements by optimizing insurance claims with a tamper-proof, time-stamped record of events.

Startup to Watch: IotaOrigin

German startup IotaOrigin develops a distributed ledger platform for mineral supply chain management. It uses blockchain to record and track conflict-free commodities throughout the supply chain. The platform allows parties to verify compliance with the OECD Due Diligence Guidance without disclosing sensitive trade information. IotaOrigin’s technology includes digital traceability, maintaining trade secrets, and potential data monetization within supply chains.

6. CleanTech

Innovations like battery-powered mining equipment, methane capture, and carbon dioxide storage allow mining companies to lower greenhouse gas emissions and improve operational efficiency. Companies invest in water management and recycling technologies, such as membrane-based filtration and sulfide precipitation, to recover valuable metals and minimize water waste. Further, carbon capture and biological remediation techniques reduce the environmental footprint of mining operations.

3 Practical Use Cases of CleanTech in Mining

- Carbon Capture, Storage, and Utilization: Reduces GHG production and ensures compliance with ESG guidelines. Methane captured at mining sites is converted to CO2, which is then stored or utilized. Captured CO2 is combined with hydrogen to produce synthetic fuels, reducing fossil fuel dependency. It is also stored in geological formations, used to improve oil recovery, or as a feedstock for chemical production.

- Land management: Geospatial technology aids in mapping and estimating mineral concentration, reducing land resource wastage, enabling environmental monitoring, and reclaiming mining areas.

- Waste Management: Techniques like geopolymerization create water and oxygen-tight covers for mine back-fill, and thermal digestion recycles nutrients into nature.

Startup to Watch: Travertine

US-based startup Travertine upcycles sulfate byproducts from mining and fertilizer operations into carbon-negative sulfuric acid and green hydrogen. This process permanently sequesters CO2 from the atmosphere into carbonate minerals. The startup’s process involves electrolysis, which splits aqueous sulfate into sulfuric acid and caustic solutions; direct air capture (DAC), which uses caustic solution to remove CO2 from the air; and mineralization, which reacts the resulting carbonate solution with sulfate byproducts to produce carbonate minerals and regenerate sulfate. Travertine also partners with mining companies to produce carbon-negative and zero-waste lithium, nickel, and phosphate fertilizers.

7. Cloud Computing

Cloud infrastructure allows mining companies to store, process, and analyze data from remote operations to improve decision-making and operational efficiency. Cloud-based platforms integrate various digital tools, including predictive maintenance, AI, and machine learning, which optimize production, enhance safety, and reduce costs. Cloud computing also supports real-time monitoring and remote management of mining activities for improving resource allocation and productivity.

3 Practical Use Cases of Cloud Computing in Mining

- Dynamic Market Adaptation: The tech enables the mining industry to respond to changing commodity prices, regulations, and customer demands by enabling scalable data analytics and financial modeling that allows rapid testing of new business models and optimization of operations.

- Data Security: Cloud computing provides encrypted storage and real-time threat detection across distributed networks. This protects sensitive data, such as geological and operational information, from unauthorized access or breaches.

- Geological Modeling: Companies use cloud computing to process complex geological surveys to assess mining sites and optimize extraction plans. It powers applications that analyze regulatory and environmental data, identifying risks and minimizing pollution through informed decision-making.

Startup to Watch: Genereso

Swiss startup Genereso offers a SaaS platform with geospatial data for the mining industries in Argentina, Chile, Peru, Colombia, and Ecuador. The platform combines mining, cadastral, geological, and environmental data into web maps for informed decision-making. It synchronizes real-time data from governmental portals to provide up-to-date information on mining cadastral databases and exploration projects. Genereso allows access to exclusive mining projects, advanced data search capabilities, and historical satellite data for time-based insights.

8. Connectivity Technologies

5G networks provide high-speed, low-latency connections for operating autonomous vehicles and machinery in surface and underground mines. Low Earth Orbit (LEO) satellite networks offer reliable communication in remote mining locations to ensure continuous connectivity where traditional networks may fail. This allows miners to remotely control operations, optimize workflows, and perform predictive maintenance to avoid downtime. Companies use LEO satellite technology to support equipment like autonomous haulage systems and integrate real-time data from sensors into broader mining operations.

3 Practical Use Cases of Connectivity Technologies in Mining

- Lower Earth Orbit: LEO addresses poor connectivity issues with low-latency networks and faster download speeds. Combining LEO with SD-WAN provides a network solution for mining sites and corporate locations.

- Smart Mining: Private 5G enables secure wireless connections for devices within the mining site. It connects edge networks around the mine, converting job site data into intelligence and speeding up data transmission and processing.

- Data Privacy: Private cellular networks encrypt traffic and keeps it within the mine’s local area networks. Devices are authenticated using device identity and perimeter or network access levels. This gives mining operators full control over their network resources, making information available to everyone on the mine site while keeping it secure.

Startup to Watch: Sensorz

Israeli startup Sensorz develops SWORD, a wireless observability platform (WOP) for Private 5G/LTE network spectrum visibility. It features a flexible orchestration engine that enables real-time loop closure. This allows the creation and management of complex response flow in real-time across various third-party systems. The startup’s platform ensures constant network availability in hazardous and remote areas to support uninterrupted communication during emergencies and safety protocols. It provides real-time monitoring of the 5G spectrum, identifying network performance issues caused by mining equipment interference. The platform also improves network security by detecting threats and anomalies through instant alerts and protects critical data and communications.

9. Internet of Things

Integrating IoT sensors and devices allows mining operations to gather real-time data on equipment, environmental conditions, and workforce safety. Technologies like Wi-Fi 6, 5G networks, and edge computing support the connectivity needed to process and analyze this data on-site and optimize operations. IoT-enabled systems allow remote control of machinery, predictive maintenance through continuous monitoring of equipment health, and environmental oversight by tracking variables like air quality and gas concentrations.

3 Practical Use Cases of Internet of Things in Mining

- Geofence: It is a virtual boundary used in a mining site to track assets and resources and ensure safety. It uses data from satellite images, remote sensing, and lidar technologies. IoT devices along the geofence perimeter ensure continuous monitoring and timely warnings for any asset nearing the danger zone.

- Worker safety: Mine site workers wear IoT wearables that continuously provide location information. IoT-enabled helmets identify toxic gases, temperature, humidity, and fire, sending timely warnings.

- Autonomous and Continuous Monitoring: IoT devices in the subsurface mining area work 24/7, sensing even slight deviations from the suitable environment. Parameters like temperature, gas, humidity, and crowd density are monitored and a timely warning is triggered when the anomaly is detected.

Startup to Watch: HIXAA Technologies

Indian startup HIXAA Technologies develops Raksha IoT, an automated worker safety monitoring system for industries involving confined spaces like mining pits. The system tracks and logs worker entry and exit statuses through a web portal-based dashboard to reduce reliance on error-prone manual ledgers. The startup’s system manages bulk employee registration, generates smart reports, and produces irregularity alerts using real-time employee tracking and management.

10. Advanced Robotics

Autonomous vehicles with advanced sensors and computer vision systems transport materials and navigate hazardous mining environments with minimal human intervention. Robotic drilling systems use sensors and imaging technologies, like LiDAR and inertial navigation, to extract resources precisely, even in complex underground conditions. Further, machine learning and AI enhance decision-making and optimize control systems that allow mining robots to operate accurately and with reduced risk in challenging environments.

3 Practical Use Cases of Advanced Robotics in Mining

- Drones: Equipped with cameras, LIDAR technology, or photogrammetry software explore, survey, and map mining sites. They produce 3D and 4D images and maps of surface models, terrains, and contour lines before and after mining operations. These images and maps generate geospatial data to better understand the mining site. Aerial surveying also predict the volume and placement of stockpiles.

- Exploration Robots: Collect geological samples at new mining sites and map underground deposits to provide data on the site’s mineral concentration. This approach speeds up the exploration process, reduces costs, and prevents human intervention in remote or harsh environments.

- Explosive Handling: Robots handle and deploy explosives in surface and underground mining operations to improve operation control without compromising safety. These robots are built to withstand the aftershock of explosions and are reusable, reducing operational costs over time.

Startup to Watch: Revolute Robotics

US-based startup Revolute Robotics builds H.M.R., a hybrid mobility robot that ensures worker safety in shafts and excavation sites. These robots navigate challenging underground environments to perform safety inspections for leaks, cracking, corrosion, warping, and hot spots. Using sensors and real-time data processing, they track the health of mining assets and provide detailed reports on equipment status to optimize maintenance schedules and predict end-of-life timing. Further, these robots monitor and measure stockpiles to offer accurate assessments of material quantities and locations as sites develop.

Outlook for the Mining Industry

Patents & Grants

The mining sector is experiencing advancements driven by innovation and technological progress, as demonstrated by over 52000 patents and the receipt of more than 3700 grants. These figures highlight the sector’s commitment to research and development.

Read more on this: Explore the Mining Industry Outlook

Investment Landscape

Investors such as Techstars, QuantumTX, Y Combinator, the Grantham Foundation, and Polychain play a critical role in propelling this innovation forward. The funding occurs across various stages, including seed rounds, early-stage VC/series A, post-IPO equity, pre-seed, and angel investments, which are essential in driving the technological growth of startups within the sector.

Global Footprint

Globally, major hubs like the US, Australia, Canada, India, and China lead the industry’s innovation efforts, with key cities such as Perth, Vancouver, Sydney, Brisbane, and Melbourne acting as centers of activity.

Don’t Miss Out on the Latest Innovations in Mining

Ready to leverage advanced mining technologies shaping the future? With StartUs Insights, you gain quick and easy access to over 4.7 million startups, scaleups, and tech companies, along with 20000 emerging technologies and trends. Our AI-powered search and real-time database provide exclusive solutions that set you apart from the competition.

Industry giants like Samsung, Nestlé, and Magna trust our innovation intelligence tools to lead trends, optimize operations, and uncover new market opportunities. Harald Angerer, Business Development & Managing Director at Imerys says, “StartUs Insights’ Scouting approach opens up different business opportunities for us as we discover new companies and solutions”. Benefit from our unmatched data, comprehensive industry views, and reliable insights to drive strategic decision-making. Get in touch to learn how our tailored discovery options can accelerate your innovation journey.

Discover All Mining Technologies & Startups!