Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

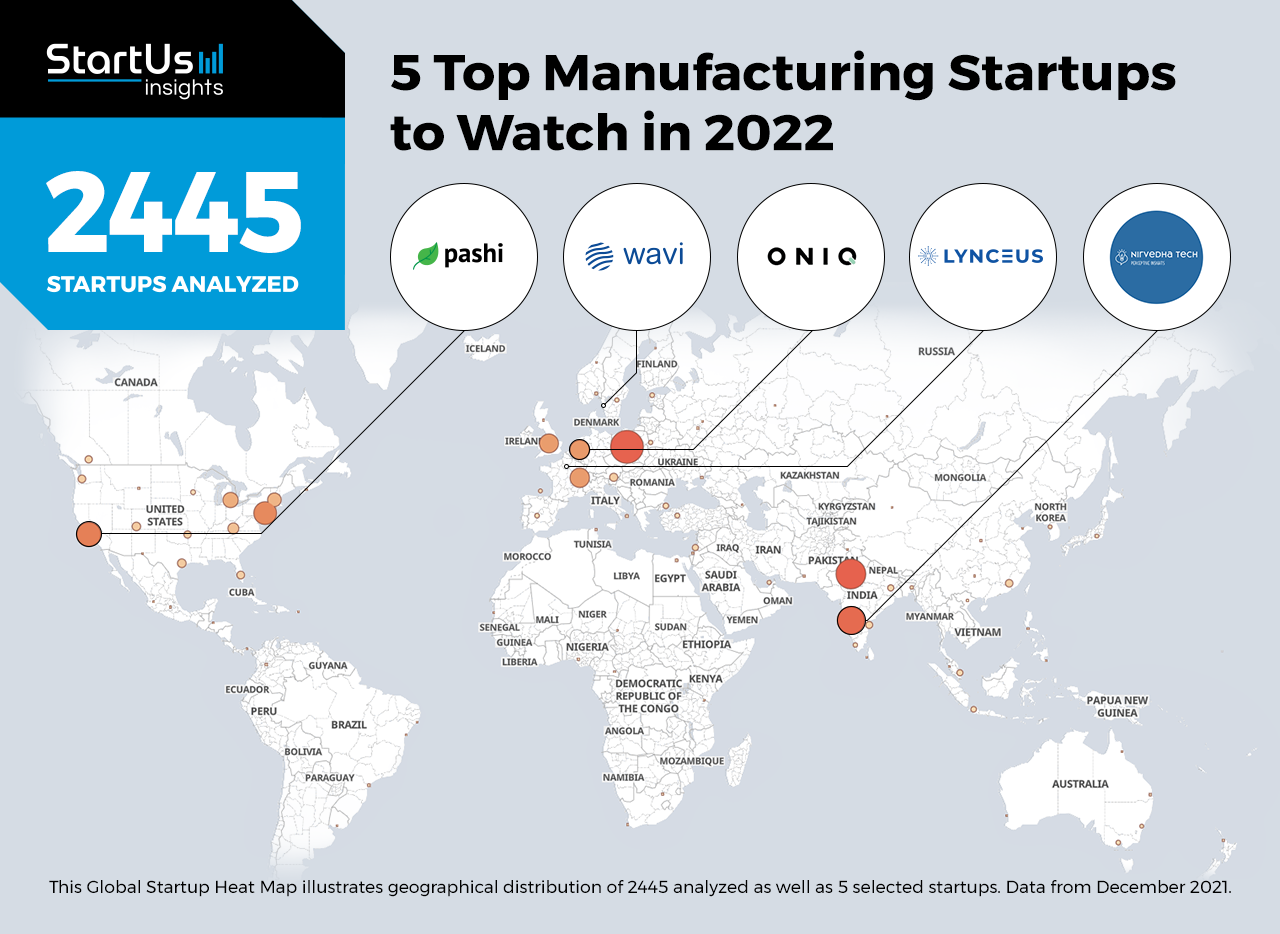

Thousands of new startups are founded every year – emerging companies with the potential to disrupt manufacturing. To give you a head-start on emerging technologies and startups that will impact the manufacturing sector in 2022, we analyzed a total of 2 445 global manufacturing startups & scaleups. Meet 5 of the most promising startups to watch!

Global Startup Heat Map highlights 5 Manufacturing Startups to Watch in 2022

Out of 2 445, the 5 manufacturing startups to watch are chosen through the Big Data & Artificial Intelligence (AI)-powered StartUs Insights Discovery Platform, covering over 2 093 000+ startups & scaleups globally. As the world’s largest resource for data on emerging companies, the SaaS platform enables you to identify relevant startups, emerging technologies & future industry trends quickly & exhaustively.

The Global Startup Heat Map below highlights the 5 manufacturing startups you should watch in 2022 as well as the geo-distribution of the other 2 440 startups & scaleups we analyzed for this research. We hand-picked the 5 highlighted manufacturing startups based on our data-driven startup scouting approach, taking into account factors such as location, founding year, the relevance of technology, and funding, among others.

ONIQ facilitates Value Stream Management

Founding Year: 2020

Location: Cologne, Germany

Partner for: Lean Manufacturing, Just-in-Time Manufacturing, Process Improvement

German startup ONIQ develops IQ/A, a digital tool for value stream management. IQ/A uses process mining and AI-based production-specific analytics to create digital twins of manufacturing operations. While there are numerous options for industries to automate their workflows, very few of them offer insights and visibility into granular-level operational data. IQ/A mitigates this issue by providing guided workflows that let users identify inefficiencies and deviations from target processes. This data includes lead times, process performance, quality, carbon footprint, and production costs, among others. As a result, IQ/A allows manufacturing plants to identify bottlenecks, reduce downtimes, improve resource efficiency, and manage market volatility.

Lynceus provides AI-based Quality Control

Founding Year: 2020

Location: Paris, France

Funding: USD 99 000

Partner for: Semiconductor Manufacturing, Wafer Quality Management

Lynceus is a French startup that develops a non-invasive, machine-agnostic, AI-based quality control solution. Current quality control methods detect excursions only after wafer fabrication and require frequent measurements, reducing yield and throughput. The startup’s solution, on the other hand, integrates into existing production lines without the need for extra hardware and offers real-time predictions. This enables semiconductor manufacturers to predict the results of both in-line metrology and end-of-line electrical tests for every wafer. Consequently, they reduce wafer scrap as well as the time to detect and resolve faults.

Wavi Analytics enables Continuous Monitoring

Founding Year: 2020

Location: Gothenburg, Sweden

Funding: USD 42 200

Partner for: Coolant & Fluid Condition Monitoring

Wavi Analytics is a Swedish startup that provides a continuous monitoring system for metalworking fluids and industrial coolants. The startup’s sensors measure the composition of the fluids and inform the results to machine operators. Unlike existing testing patterns and lengthy lab analyses, Wavi Analytics monitors fluid conditions in real-time. This results in minimal and precise operator interventions as well as prolongs fluid life and decreases wastage. It also offers an automatic top-up system and data logging solution to facilitate fluid management. This reduces downtime due to fluctuating fluid conditions, improves traceability, and enables autonomous production.

Nirvedha Technology Solutions accelerates Factory 4.0 Implementation

Founding Year: 2020

Location: Pune, India

Partner for: Asset Management, Equipment Monitoring, Predictive Maintenance

Indian startup Nirvedha Technology Solutions facilitates factory 4.0 integration. To achieve this, the startup provides analytics and internet of things (IoT) management platforms along with edge gateway devices. These solutions enable manufacturers to collect data from individual machines and create digital twins for the entire factory. The analytics platforms provide actionable insights and alerts based on rule chains as well as allow users to visualize key performance indicators (KPIs). The startup’s solutions also enable equipment condition monitoring, intelligent asset management, and predictive maintenance, among others. Unlike conventional manufacturing lines where faults and inconsistencies are only visible after the incident, Nirvedha Technology Solutions facilitates real-time production monitoring to improve operational efficiency.

Pashi develops a Manufacturing Operating System (OS)

Founding Year: 2020

Location: San Francisco, USA

Funding: USD 150 000

Partner for: Production Flow Control

Pashi is a US-based startup that makes the Pashi Program, an operating system for the manufacturing industry. The OS unifies all operations in production to closely monitor and analyze involved processes, such as quality control and product assembling. Even if companies use solutions like robotics and IoT from different service providers, the Pashi Program interfaces with all hardware and software. This breaks data silos and improves transparency into end-to-end operations. Besides, users are able to modify the logic of production within a few minutes, which is usually spread across different systems. These include supervisory control and data acquisition (SCADA) and manufacturing execution systems (MES). Due to this flexibility, manufacturing companies gain access to improved flow control, data logging, and metrics tracking. This, in turn, accelerates time-to-market, reduces production line downtimes, and optimizes quality control for manufacturing companies.

Discover All Emerging Manufacturing Startups

The manufacturing startups showcased in this report are only a small sample of all startups we identified through our data-driven startup scouting approach. Download our free Manufacturing Innovation Report for a broad overview of the industry or get in touch for quick & exhaustive research on the latest technologies and emerging solutions that will impact your company in 2022!