Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

Staying ahead of the technology curve means strengthening your competitive advantage. That is why we give you data-driven innovation insights into the materials industry. This time, you get to discover 5 hand-picked thermoset matrix composites.

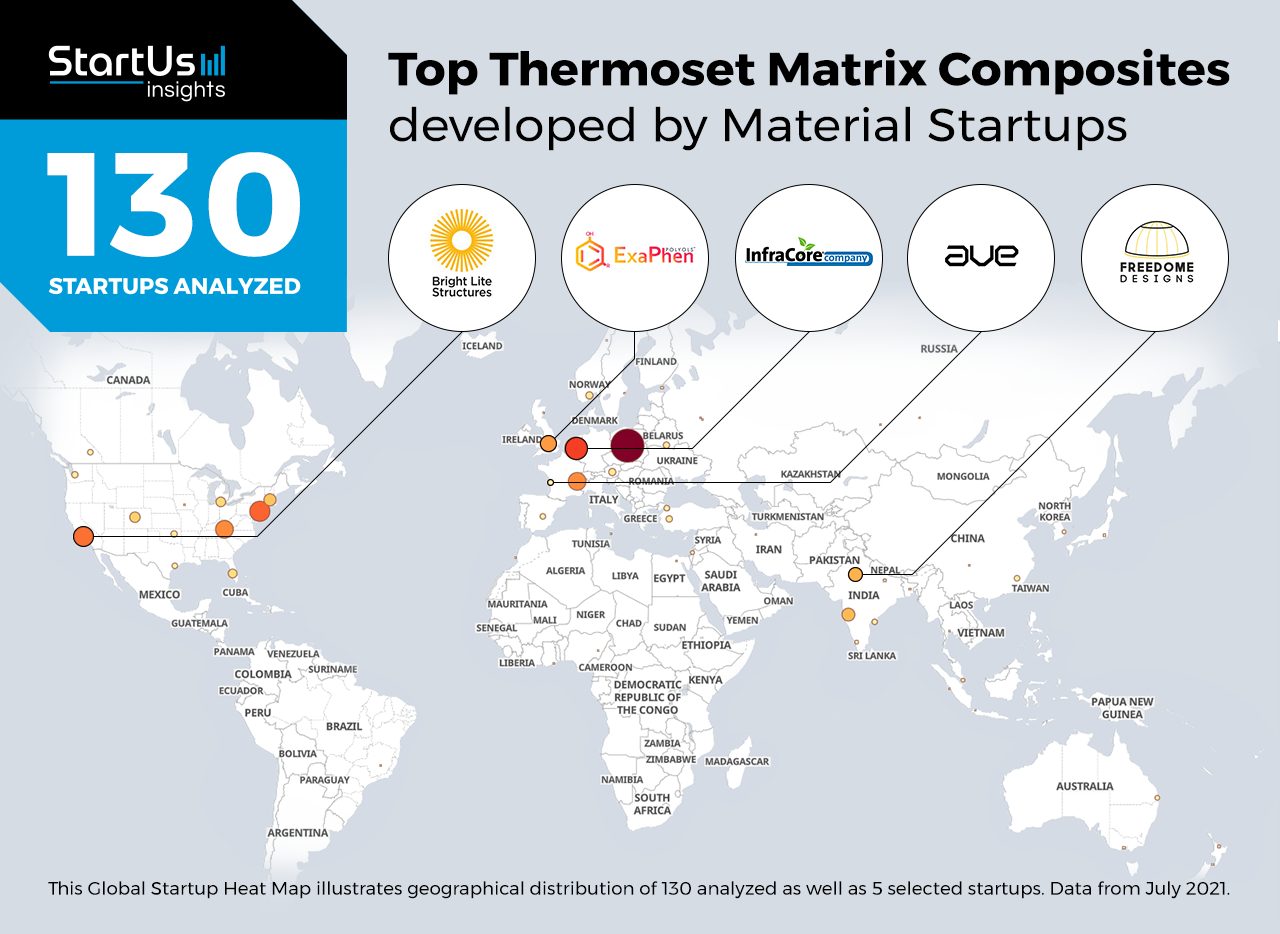

Global Startup Heat Map highlights 5 Top Thermoset Matrix Composites out of 130

The insights of this data-driven analysis are derived from the Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 2.093.000+ startups & scaleups globally. The platform gives you an exhaustive overview of emerging technologies & relevant startups within a specific field in just a few clicks.

The Global Startup Heat Map below reveals the distribution of the 130 exemplary startups & scaleups we analyzed for this research. Further, it highlights 5 materials startups that we hand-picked based on criteria such as founding year, location, funding raised, and more. You get to explore the solutions of these 5 startups & scaleups in this report. For insights on the other 125 thermoset matrix composite solutions, get in touch.

Freedome provides Fiberglass-Reinforced Plastics

Monolithic domes are a popular choice for roofs of buildings because of their extreme durability and strength against fire, water, and wind. Currently reinforced concrete is the widely used material for these structures. This offers a variety of challenges in the construction process both in the movement and processing of the constituent materials. Material startups are developing methods for constructing hemispherical structures using thermoset composites that are easier to handle.

Freedome is an Indian startup that designs and manufactures modular hemispherical units (MHU) from fiberglass-reinforced plastics. The startup offers the MHU as an assortment of lightweight, easy-to-transport segments of the thermoset composite. This allows for easy setup, and portability without compromising on structural strength. Freedome’s technology provides 5-layer insulation in between to increase resistance from harsh weather conditions and the composite also uses flame-retardant resin. These features make the solution useful for storage units, medical camps, and temporary shelters in natural disaster zones and checkpoints.

Bright Lite Structures develops Thermoset Sandwich Composites

Fiber-reinforced composites are used in a variety of applications thanks to their lightweight, highly functional nature. But these composites are usually weak against bending and torsional loads. Startups and scaleups are developing new materials and technologies that increase the bending and torsional performance of thermoset composites. Sandwich composites are one such solution that combines high functional fiber-reinforced composites with low strength material resulting in a material with high bending stiffness.

Bright Lite Structures is a US-based startup manufacturing sandwich composites using its patented technology. BLS’ products have high compression stiffness and torsional rigidity compared to conventional composites and are lighter than materials with the same mechanical strength. The outer thermoset fabrics are impregnated with BLS’ patented resin, the following process simultaneously thermo-forms the core and cures the resin reducing the manufacturing steps and lowering costs. The startup is also able to form complex shapes using this faster process that does not require pre-forming. Thus, it makes the technology suitable for manufacturing components for commercial vehicles, aircraft, rail transport, buses, and automobiles.

Ave produces Low-Density Thermoset Composites

The binder used in a composite generally contributes to the majority of its weight. Epoxy is the most commonly applied binder for thermoset composites thanks to its superior wettability. Reducing the binder quantity to decrease weight affects the integrity of the composite and will likely lead to failures. This is why material startups are developing low-density binders that replace epoxy with a lightweight alternative.

Ave is a French startup that develops and produces polymers for high-performance composites and smart materials. Xylium, the startup’s proprietary polymer binder, is nearly 3 times lighter than epoxy resin. The Xylium resin is applicable to a full range of fibers, such as glass, carbon, or kevlar, and has stronger adherence to fibers than epoxy resin. This allows it to transfer external forces efficiently to the composite fibers, making the composite more resistant to breakage. Ave also possesses capabilities to insert markers at a molecular level in the final product to help identify the authenticity. The startup thus provides high-performance materials for space, defense, and sports industries.

Infracore develops Durable Thermoset Composites

Delamination is the common failure mode for fiber-reinforced thermoset composites. This is due to the deterioration of the adhesive bonds between different layers of fibers, causing them to separate. Since thermoset composites are infusible, delaminated components stay non-repairable. Material startups and scaleups are developing maintenance-free and durable fiber-reinforced composites that are not prone to delamination in normal use.

InfraCore is a Dutch startup that develops and produces fiber-reinforced plastics (FRP). The startup‘s technology enables the development of strong, robust, damage-tolerant, and fail-safe FRP structures that are less expensive than conventional FRP solutions. InfraCore’s FRP also has high fatigue strength that helps to avoid delamination. This resistance to failure delivers a long service life combined with low maintenance components in the construction, shipbuilding, and aerospace sectors. This results in lower energy consumption throughout the product’s life.

Exaphen offers Polyol-based Thermosets

Polyurethane (PUR) is one of the most widely used thermosetting polymers derived from polyols. The ever-growing demand for PUR materials especially in the electronics industry has led startups to develop methods to produce PUR using low-cost natural raw materials. These technologies help in reducing the reliance of the polymer industry on petroleum-based feedstocks that are exhaustible and carbon-positive.

British startup Exaphen produces polyol products using cardonol, the main component of cashew nutshell liquid (CNSL). It manufactures PUR and polyisocyanurate (PIR) rigid foams in a manufacturing process that releases lower energy as compared to conventional counterparts. The final product provides long-lasting dimensional stability, increased temperature, and moisture resistance. The polymer compounds are also highly miscible with traditional polyols, isocyanates, surfactants, blowing agents, and catalysts that help in enhancing its performance. All these characteristics make ExaPhen products versatile for use in the construction and electrical devices sectors.

Discover more Materials Startups

Materials startups such as the examples highlighted in this report focus on nanocomposites, superalloys, and hybrid materials. While all of these technologies play a major role in advancing the materials industry, they only represent the tip of the iceberg. To explore more materials technologies, simply get in touch to let us look into your areas of interest. For a more general overview, you can download our free Materials Innovation Report to save your time and improve strategic decision-making.

![10 Top Startups Advancing Machine Learning for Materials Science [2025]](https://www.startus-insights.com/wp-content/uploads/2025/06/Machine-Learning-for-Materials-Science-SharedImg-StartUs-Insights-noresize-420x236.webp)

![10 Emerging AI Solutions for Material Science [2025]](https://www.startus-insights.com/wp-content/uploads/2025/06/AI-Solutions-for-Material-Science-SharedImg-StartUs-Insights-noresize-420x236.webp)