Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

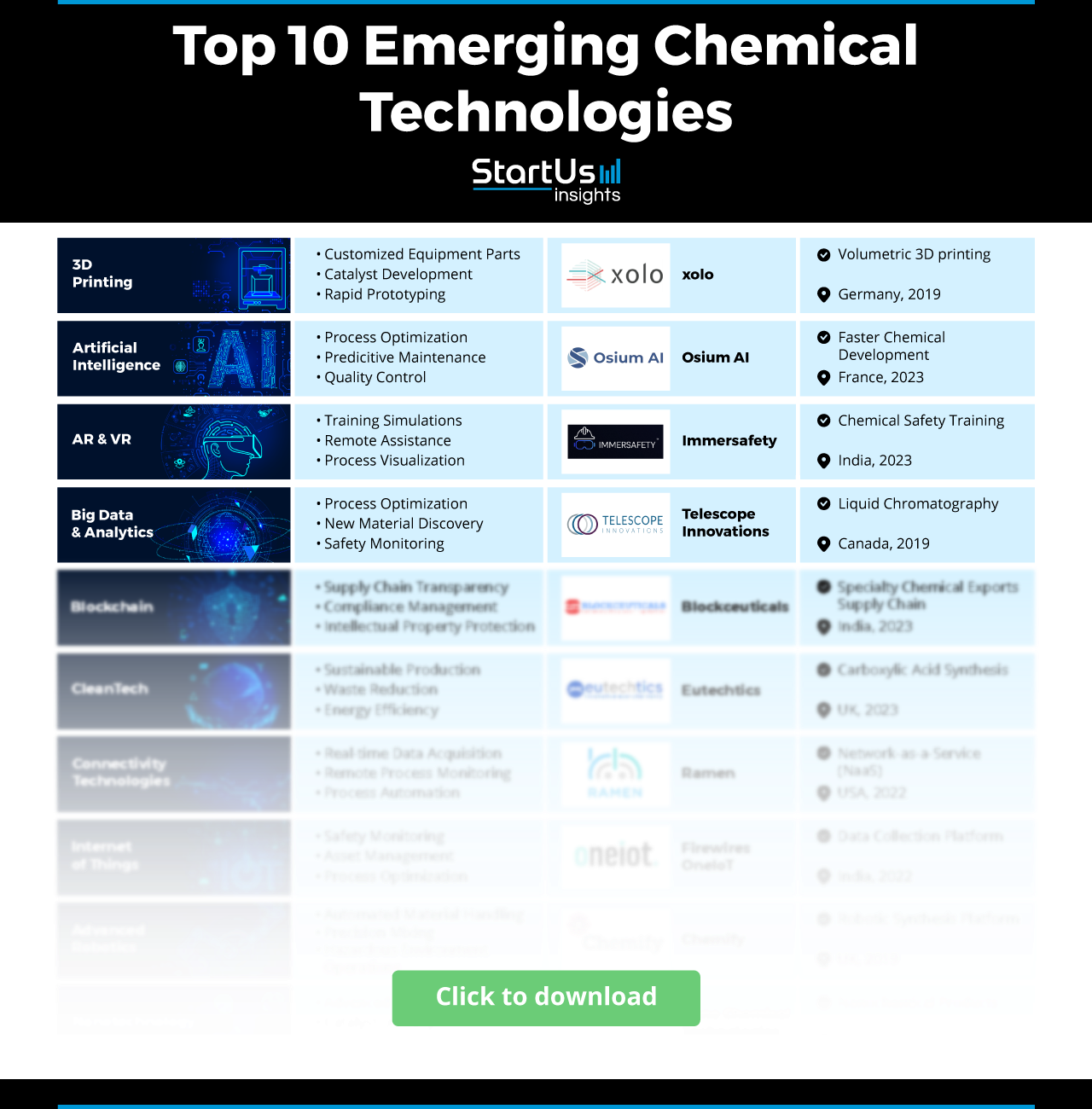

Advancements in chemical technology address challenges such as reducing environmental impact and improving process efficiency. Technologies like advanced process automation and AI-driven molecular design enhance the operational efficiency of chemical companies by minimizing waste and optimizing production. For instance, AI algorithms enable predictions in chemical reactions, while advanced sensors improve safety protocols across plants.

Meanwhile, 3D printing produces custom chemical components and catalysts to reduce lead times and meet fluctuating production demands. Also, blockchain ensures the integrity of raw material sourcing and product traceability across the supply chain, while big data analytics optimizes chemical formulations and streamlines operations. The integration of these innovations fosters a more connected and efficient chemical industry, driving progress in both production and sustainability efforts.

Why should you read this report?

- Gain insights into top 10 technologies impacting chemicals industry.

- Learn about three practical use cases for each technology.

- Meet 10 innovative startups advancing these technologies.

Key Takeaways

- Additive Manufacturing

- Use Cases:

- Customized Equipment Parts

- Catalyst Development

- Rapid Prototyping

- Startup to Watch: xolo

- Use Cases:

- Artificial Intelligence (AI)

- Use Cases:

- Process Optimization

- Predicitive Maintenance

- Quality Control

- Startup to Watch: Osium AI

- Use Cases:

- Augmented Reality (AR) & Virtual Reality (VR)

- Use Cases:

- Training Simulations

- Remote Assistance

- Process Visualization

- Startup to Watch: Immersafety

- Use Cases:

- Big Data & Analytics

- Use Cases:

- Process Optimization

- New Material Discovery

- Safety Monitoring

- Startup to Watch: Telescope Innovations

- Use Cases:

- Blockchain

- Use Cases:

- Supply Chain Transparency

- Compliance Management

- Intellectual Property Protection

- Startup to Watch: Blockceuticals

- Use Cases:

- CleanTech

- Use Cases:

- Sustainable Production

- Waste Reduction

- Energy Efficiency

- Startup to Watch: Eutechtics

- Use Cases:

- Connectivity Technologies

- Use Cases:

- Real-time Data Acquisition

- Remote Process Monitoring

- Process Automation

- Startup to Watch: Ramen

- Use Cases:

- Internet of Things (IoT)

- Use Cases:

- Safety Monitoring

- Asset Management

- Process Optimization

- Startup to Watch: Firewires OneIoT

- Use Cases:

- Advanced Robotics

- Use Cases:

- Automated Material Handling

- Precision Mixing

- Hazardous Environment Operations

- Startup to Watch: Chemify

- Use Cases:

- Nanotechnology

- Use Cases:

- Advanced Materials

- Catalyst Development

- Pollution Control

- Startup to Watch: Nano Chemical Technologies

- Use Cases:

Chemical Industry FAQs

What is the growth in the future of the chemical industry?

The integration of advanced technologies like AI, IoT, and blockchain drives the future growth of the chemical industry to enhance operational efficiency, sustainability, and supply chain resilience. Digitalization optimizes production processes and enables rapid innovation in product development, particularly in advanced materials.

Moreover, the industry’s shift towards decarbonization and bio-based chemicals aligns with global sustainability goals. Also, a few companies have moved into clean ammonia, battery manufacturing, and lithium processing. These chemical innovation developments position the chemical industry to adapt to evolving market demands and lead in the transition toward a more sustainable and technologically advanced future.

Read more: Top 8 Chemical Industry Trends in 2025

What are the challenges faced by the chemical industry?

- Sustainability Pressure: Reduce the environmental impact, especially carbon emissions, by adopting new, eco-friendly technologies.

- Supply Chain Instability: Difficult to get essential raw materials on time.

- Digital Integration: Bringing new digital technologies, like AI and IoT, into older systems requires careful planning and investment.

- Energy Efficiency: Rising energy costs to find ways to use energy more efficiently.

- Product Innovation: The need for constant innovation in products and processes while balancing cost and speed of development.

How We Identify Emerging Technologies & Startups

The data in this report originates from StartUs Insights’ Discovery Platform, covering 4.7 million global startups, scaleups, and technology companies, alongside 20,000 emerging technology trends. Our platform makes startup and technology scouting, trend intelligence, and patent searches more efficient by providing deep insights into the technological ecosystem. Utilizing the trend intelligence feature, we analyze industry-specific technologies for this report, detect patterns and trends, and identify use cases along with the startups advancing these areas. Further details and capabilities are accessible via the website.

10 Emerging Technologies Impacting the Future of Chemical Industry [2025 & Beyond]

1. Additive Manufacturing

Additive manufacturing, often referred to as 3D printing, advances the fabrication processes of materials and products. Technologies in this industry include selective laser sintering (SLS), fused deposition modeling (FDM), and stereolithography (SLA). These processes construct complex chemical components and devices layer-by-layer with precision. The use of high-performance thermoplastics, photopolymers, and metal powders produces highly customized, durable, and chemically resistant parts. This technology also reduces waste and improves efficiency by eliminating traditional subtractive methods, which involve cutting away excess material. As additive manufacturing evolves, the integration of advanced materials like metal alloys and the adoption of computer-aided design (CAD) and simulation software leads to faster prototyping, improved product customization, and more sustainable manufacturing processes.

3 Practical Use Cases of 3D Printing in Chemicals

- Customized Equipment Parts: Digital models produce tailored parts for chemical processing equipment to eliminate manufacturing delays. This reduces downtime during maintenance or upgrades and improves operational efficiency with quicker turnaround times for critical components.

- Catalyst Development: 3D printing fabricates advanced catalyst structures with features like hierarchical porosity or customized surface areas to enhance reaction kinetics and selectivity. This method allows chemical companies to iterate and refine catalyst designs rapidly.

- Rapid Prototyping: Additive manufacturing creates high-precision prototypes for equipment like reactors or mixers. This allows chemical companies to test and refine complex designs quickly, support agile development cycles, and reduce delays in scaling up processes.

Startup to Watch: xolo

German startup Xolo uses xolography, a volumetric 3D printing technology that employs dual-wavelength light to create high-resolution structures in photopolymer resins. This eliminates layer-based printing and produces chemical components and designs with increased speed and accuracy. Xolo’s dual-color photoinitiators (DCPIs) convert high-viscous materials into xolography formulations. These DCPIs ensure polymerization occurs at the intersection of two different light wavelengths for detailed, high-precision structures. The technology uses specialized resins with properties like transparency, mechanical strength, and chemical resistance for developing functional materials.

2. Artificial Intelligence

AI streamlines research, development, and production through advanced computational techniques. Deep learning models analyze complex chemical structures and predict reactions to enable faster and more accurate discoveries. Reinforcement learning optimizes chemical processes by improving decision-making based on real-time data to enhance efficiency and reduce waste. In chemoinformatics, natural language processing (NLP) extracts insights from vast scientific literature and databases by discovering new materials and formulations. Additionally, digital twins create virtual simulations of chemical plant operations for process optimization to minimize downtime and improve overall operational efficiency.

3 Practical Use Cases of AI in Chemicals

- Process Optimization: AI-driven algorithms continuously analyze real-time chemical process data to detect hidden patterns and inefficiencies. This advanced analysis allows chemical manufacturers to make dynamic adjustments to production parameters, optimize resource use, enhance yield, save cost, and minimize waste.

- Predictive Maintenance: AI tools monitor the performance of chemical processing equipment through continuous data collection for early detection of anomalies that indicate potential failures. By predicting maintenance needs before breakdowns occur, these tools prevent unplanned downtime, extend the operational lifespan of machinery, and reduce disruptions to production.

- Quality Control: AI-powered systems assess product quality by analyzing data from multiple stages of chemical production. This continuous monitoring ensures that each batch consistently meets the quality standards to reduce defects and rework, and enhance overall product reliability.

Startup to Watch: Osium AI

French startup Osium AI provides an AI-powered software platform to develop materials and chemicals. The platform predicts material and chemical properties quickly by eliminating trial-and-error approaches. Some features include advanced analytical capabilities for property prediction, optimized experiment design, process enhancement to reduce costs and emissions, and quality control at scale.

3. Augmented Reality (AR) & Virtual Reality (VR)

Technologies like AR and VR enhance process visualization, operational control, and remote collaboration. AR utilizes holographic displays, and real-time data integration to improve process management and safety monitoring for visualizing chemical processes and interacting with live operational data. VR creates immersive simulation environments using advanced 3D modeling and spatial computing to enable virtual training platforms and simulations of complex chemical operations. ML algorithms further enhance AR and VR by supporting predictive modeling and improving real-time decision-making. Cloud-based solutions optimize chemical operations for greater efficiency and safety while reducing risks and enhancing worker training.

3 Practical Use Cases of AR & VR in Chemicals

- Training Simulations: AR and VR create immersive virtual chemical environments for employee training, allowing workers to gain hands-on experience without exposure to real-world hazards. This method enhances skill development, builds confidence, and efficiently prepares staff for managing complex chemical operations.

- Remote Assistance: AR enables remote experts to assist on-site technicians with tasks such as system diagnostics, calibration, or troubleshooting intricate chemical equipment. This real-time guidance improves accuracy, reduces errors, cuts downtime, and lowers travel-related costs by eliminating in-person support.

- Process Visualization: By using VR, chemical engineers visualize and interact with detailed 3D models of chemical processes and equipment. The technology identifies potential design flaws and optimizes production workflows before implementation. Also, it mitigates risks, improves process efficiency, and makes the new systems operational before they go live.

Startup to Watch: Immersafety

Indian startup Immersafety offers VR chemical safety training modules to enhance workplace safety for handling hazardous substances. The company’s VR technology immerses trainees in interactive simulations to practice handling chemical spills, understanding chemical properties, and responding to emergencies in a risk-free environment. The modules include emergency response drills, safe chemical storage and transport practices, and personal protective equipment (PPE) training for improving knowledge retention and compliance with safety regulations.

4. Big Data & Analytics

By leveraging datasets from chemical plants, big data optimizes operations and improves efficiency. With advanced analytics, ML, and cloud computing, chemical manufacturers process and analyze data from multiple sources, such as production systems, supply chains, and customer interactions. These technologies enable real-time insights to provide predictive maintenance, operational forecasting, and smarter decision-making across the entire value chain. By integrating with IoT devices and sensors, big data analytics continuously monitors equipment performance and plant conditions for controlling chemical processes and optimizing energy consumption.

3 Practical Use Cases of Big Data & Analytics in Chemicals

- Process Optimization: Big data and analytics analyze datasets from various stages of chemical production to identify patterns and inefficiencies in real time. This allows manufacturers to make precise adjustments to optimize resource utilization, reduce waste, and lower overall costs to ensure more efficient chemical processes.

- New Material Discovery: By leveraging complex chemical data, big data and analytics improve the discovery of new materials. They identify potential compounds and predict their properties before physical testing to reduce R&D time and costs. This approach allows for faster innovation and a quicker time-to-market for new chemical products.

- Safety Monitoring: Continuously monitoring sensor and equipment data streams across chemical plants detects anomalies that signal potential safety hazards. This proactive monitoring enhances workplace safety by enabling immediate corrective actions, reducing the risk of accidents, and ensuring compliance with safety regulations.

Startup to Watch: Telescope Innovations

Canadian startup Telescope Innovations builds the DIRECTINJECT-LC tool that converts offline high-performance liquid chromatography (HPLC) analysis for online real-time sampling and analysis of chemical reactions. The system continuously samples reaction vessels that provide aliquots directly to an external liquid chromatography instrument. This instrument further offers immediate concentration and composition profiles by automating sample capture, quenching, dilution, and analysis. Moreover, it handles complex chemical processes, including solid-liquid slurries, biphasic systems, and cryogenic transformations for detailed reaction profiling and optimization. The tool optimizes reactions by offering real-time insights into reaction mechanisms, side-product impacts, and catalytic activity.

5. Blockchain

3 Practical Use Cases of Blockchain in Chemicals

- Supply Chain Transparency: By leveraging blockchain, chemical companies trace and verify the origin and journey of raw materials to ensure ethical sourcing and compliance with industry regulations and build trust among stakeholders.

- Compliance Management: Secure and tamper-proof record-keeping through blockchain simplifies the handling of compliance data, such as environmental reports and safety audits. Chemical manufacturers reduce the risk of non-compliance and adhere to regulatory standards to make the audit process more efficient.

- Intellectual Property Protection: A decentralized ledger ensures the security of intellectual property by registering and timestamping proprietary formulations and innovations. This approach prevents unauthorized use or duplication by safeguarding the technological advancement of the chemical companies.

Startup to Watch: Blockceuticals

Indian startup Blockceuticals develops a blockchain-powered supply chain management system to provide end-to-end transparency, security, and efficiency. The system collects and monitors data in real-time to record it on an immutable blockchain ledger. Further, it tracks data points such as location, environmental conditions, and handling for providing the product’s journey record. The company’s system leverages data analytics and machine learning to identify anomalies and trigger alerts to ensure optimal product integrity and reduce wastage. Also, it simplifies regulatory compliance by automating verification processes and securing sensitive data, accessible only to authorized individuals.

6. CleanTech

Cleantech focuses on sustainability, reduces environmental impact, and improves energy efficiency. Technologies like carbon capture, utilization, and storage (CCUS) address emissions by capturing carbon dioxide from industrial processes and either storing it or converting it into useful products. Another emerging area includes the use of bio-based feedstocks, which replace fossil fuels with renewable sources to lower the industry’s carbon footprint. Green hydrogen production that leverages low-carbon energy to split water into hydrogen and oxygen decarbonizes industrial processes. Additionally, advancement in recycling technologies, particularly chemical recycling of polymers, enable the recovery of raw materials from waste to promote a circular economy.

3 Practical Use Cases of CleanTech in Chemicals

- Sustainable Production: By utilizing renewable energy sources like solar and wind power, chemical manufacturers reduce reliance on fossil fuels and lower carbon emissions. This supports sustainable production practices while minimizing its environmental impact.

- Waste Reduction: CleanTech solutions enable chemical companies to incorporate renewable raw materials and adopt processes such as bio-based feedstock conversion for reducing waste generation at the source. This cuts down on hazardous waste disposal costs and advances the industry’s move toward a circular economy.

- Energy Efficiency: The integration of renewable energy systems, along with advanced energy management practices like smart grids and energy storage, optimizes energy consumption in chemical plants. These innovations reduce operational costs while enhancing the overall sustainability and efficiency of production processes.

Startup to Watch: Eutechtics

UK-based startup Eutechtics offers EvoCarbon, a process technology that utilizes carbon dioxide emissions to produce carboxylic acids. It converts CO2 emissions into a feedstock by running reactions at specific temperatures and atmospheric pressure. The process recycles waste chemicals to resynthesize reagents, enhances atom economy, and separates carboxylic acids from reaction mixtures. It reduces the carbon footprint of carboxylic acid production to benefit industries that use chemicals including food additives, pharmaceuticals, fertilizers, textiles, polymers, and paints.

7. Connectivity Technologies

Technologies like advanced wireless sensors and real-time data analytics monitor and control the production environments of chemical companies with precision. By connecting equipment, assets, and personnel, these tools provide real-time insights that enhance predictive maintenance, improve safety protocols, and ensure higher quality control in material production. The instant collection and analysis of data assist chemical plants to optimize their operations, reduce downtime, and increase productivity. When integrated with big data analytics, these connectivity technologies streamline supply chains and enhance process efficiency.

3 Practical Use Cases of Connectivity Technologies in Chemicals

- Real-time Data Acquisition: The integration of sensors and equipment across chemical plants provides real-time data on operational metrics. This instantaneous insight enables quick decision-making, improves process control, optimizes production efficiency through immediate adjustments, and minimizes waste.

- Remote Process Monitoring: Connectivity allows continuous monitoring of chemical processes from remote locations by reducing on-site personnel and improving safety. This approach ensures faster response times to potential issues, allows for proactive intervention, and minimizes operational disruptions.

- Process Automation: Connectivity technologies allow for automated responses to changing conditions based on predefined parameters. It streamlines production workflows, reduces human error, and improves overall throughput by enhancing efficiency in chemical manufacturing.

Startup to Watch: Ramen

US-based startup Ramen provides a network-as-a-service (NaaS) solution for chemical plants. It integrates smart devices and IoT systems across hazardous sites using citizens broadband radio service (CBRS) and WiFi frequency bands. This creates private cellular networks that offer operational control. Ramen’s solution enables real-time monitoring of environmental conditions and secure data transmission in chemically intensive areas. Also, it integrates with existing security architectures to ensure compliance and safety.

8. Internet of Things

With the integration of IoT technologies like real-time sensors, edge computing, and AI-driven analytics, chemical companies enable more intelligent, data-driven decision-making. Sensors embedded throughout chemical plants gather data from production processes to process it in real time via cloud platforms or edge devices. This interconnected network continuously monitors equipment performance and operational conditions for better-informed decisions that enhance both efficiency and safety. IoT also enables more responsive environmental monitoring to ensure compliance with industry regulations and allows chemical companies to reduce energy consumption by optimizing resource utilization.

3 Practical Use Cases of IoT in Chemicals

- Safety Monitoring: IoT devices embedded in critical equipment and hazardous environments continuously collect and transmit data for monitoring safety conditions in real time. This ensures immediate detection of anomalies such as gas leaks or temperature spikes for prompt corrective action and enhanced workplace safety.

- Asset Management: By integrating IoT sensors with facility equipment, chemical manufacturers track the location, condition, and performance of machinery. This real-time visibility supports predictive maintenance strategies, reduces downtime, and extends the lifespan of critical assets by lowering operational costs and improving overall efficiency.

- Process Optimization: IoT systems integrate data from various stages of chemical production to view the process performance. It enables manufacturers to make any changes to the processes in real time, optimize resource use, improve product quality, and minimize waste for increasing process efficiency.

Startup to Watch: Firewires OneIoT

Indian startup Firewires OneIoT develops an IoT platform that uses IoT devices across chemical plants. It ensures real-time monitoring and control of processes through secure transport layer security (TLS) authentication and support for multiple communication protocols like message queuing telemetry transport (MQTT), hypertext transfer protocol (HTTP), and hypertext transfer protocol secure (HTTPS). Firewires OneIoT’s rule-based engine automates data collection and analysis from sensors monitoring temperature, pressure, and chemical compositions for maintaining safety and efficiency in chemical operations. The platform also features a dashboard for managing devices and performing over-the-air updates. Further, it monitors system performance and transmits and stores data.

9. Advanced Robotics

Advanced robotics combines technologies like AI-driven automation, machine learning algorithms, and integrated sensors to optimize plant operations. These systems, including collaborative robots (cobots) and delta robots, exhibit high-level perception and adaptability, allowing them to self-learn and make real-time adjustments during operations. Innovations such as haptic feedback for precision handling and enhanced mobility enable these robots to function in challenging environments with hazardous chemicals, extreme temperatures, or confined spaces. Moreover, the integration of AI-powered predictive algorithms with robotics provides real-time data analysis and dynamic decision-making based on sensor inputs. By incorporating cloud computing, 5G networks, and edge computing, chemical facilities achieve operational autonomy to optimize safety, efficiency, and productivity with minimal human intervention.

3 Practical Use Cases of Robotics in Chemicals

- Automated Material Handling: Robotic systems streamline the transport of raw materials and finished products, including bulk substances and sensitive compounds, throughout chemical facilities. This automation reduces human error, enhances safety, and increases throughput to ensure efficient and consistent material management during production.

- Precision Mixing: Advanced sensors and controls with robots mix chemical ingredients with precision. This level of accuracy improves product consistency, reduces waste from errors, and creates complex formulations.

- Hazardous Environment Operations: High-risk areas such as high-temperature zones, toxic atmospheres, or regions with explosive materials use robots to safeguard human health. By operating continuously in restricted environments, these robotic systems improve productivity and ensure operational reliability in conditions unsafe for human workers.

Startup to Watch: Chemify

UK-startup Chemify develops a chemical programming language that converts meta-representations of molecules into tangible chemical products. This language assists Chemify’s robotic synthesis platform, which automates the chemical synthesis process. It aids in high-throughput discovery, parallel optimization, execution of optimized reactions, and purification of final products. Further, it leverages computer science, chemical engineering, and cheminformatics to execute fully automated design-make-test-analyze cycles. This enables rapid discovery and production of novel molecules.

10. Nanotechnology

Nanotechnology manipulates matter at the nanoscale. This emerging technology leverages materials like carbon nanotubes, nanocomposites, and quantum dots to offer enhanced chemical reactions, and superior material properties, and create specialized nanomaterials. For example, nanocomposites like carbon fiber-reinforced polymers (CFRP) and metal-organic frameworks (MOFs) are developed for their lightweight and high-strength characteristics. Quantum dots, with their semiconductor properties, enable advanced applications in optoelectronics and imaging technologies. Additionally, the integration of AI in the development of nanomaterials creates customizable nanostructures with precision for improving efficiency across chemical processes.

3 Practical Use Cases of Nanotechnology in Chemicals

- Advanced Materials: Nanotechnology creates materials with enhanced properties such as increased strength, lighter weight, and improved thermal resistance. These innovations develop durable and efficient chemical products to enhance performance in applications like coatings and structural materials.

- Catalyst Development: By creating catalysts with larger surface areas and greater activity, nanotechnology enhances the efficiency of chemical reactions. These advancement speed up reactions, increase selectivity, reduce energy consumption, and lower production costs in various chemical processes.

- Pollution Control: Nanotechnology develops filtration and adsorption materials for targeting and removing pollutants at the nanoscale. This allows for more effective pollution control by capturing the smallest contaminants to improve environmental protection efforts across the chemical industry.

Startup to Watch: Nano Chemical Technologies

Colombian startup Nano Chemical Technologies develops nanometric chemical products that convert the mobility and quality of heavy and extra-heavy crude oils. The company’s NCT Series, comprising inorganic and organic nanofluids, reduces viscosity, increases fluidity, and increases the American Petroleum Institute (API) gravity of hydrocarbons through a cold chemical reaction at the nano level. This process promotes stable and irreversible improvements in crude oil to enhance efficiency during transport and refining without causing corrosion or catalyst poisoning. NCT’s technology also addresses challenges in hydrocarbon production by mitigating acid gases and improving the demulsification of water-in-oil emulsions.

Don’t Miss Out on the Latest Chemical Technologies

Ready to leverage the latest chemical technologies shaping the future? With StartUs Insights, you gain quick and easy access to over 4.7 million startups, scaleups, and tech companies, along with 20,000 emerging technologies and trends. Our AI-powered search and real-time database provide exclusive solutions that set you apart from the competition.

Industry giants like Samsung, Nestlé, and Magna trust our innovation intelligence tools to lead trends, optimize operations, and uncover new market opportunities. This is what DIC Corporation says about our platform & service, “StartUs Insights is our most efficient, data-driven scouting partner and one of the best sources for in-depth overviews on startups, technologies, and industry trends.”

Like them, you can also benefit from our unmatched data, comprehensive industry views, and reliable insights to drive strategic decision-making. Get in touch to learn how our tailored discovery options can accelerate your innovation journey.

Discover All Chemical Technologies & Startups!

![10 Top Startups Advancing Machine Learning for Materials Science [2025]](https://www.startus-insights.com/wp-content/uploads/2025/06/Machine-Learning-for-Materials-Science-SharedImg-StartUs-Insights-noresize-420x236.webp)

![10 Emerging AI Solutions for Material Science [2025]](https://www.startus-insights.com/wp-content/uploads/2025/06/AI-Solutions-for-Material-Science-SharedImg-StartUs-Insights-noresize-420x236.webp)