Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

What does 3D printing do for companies worldwide? For starters, advancements in 3D Printing address important challenges like climate change and drive the shift toward sustainable production methods. 3D Printing for Companies benefits various industries with numerous applications by designing the production of complex geometries and rapid prototyping. Some of the prominent 3D Printing technologies include fused deposition modeling, selective laser sintering, directed energy deposition, and material jetting — where each technology contributes to different applications and unique advantages. 3D Printing focuses on less waste generation, on-demand part production, and custom tooling and fixtures. Startups like rrreefs develop artificial 3D-printed coral reefs that restore marine ecosystems, while Impessora offers affordable housing solutions using eco-friendly materials. Additionally, Biomedical 3D offers human organ models for better surgical planning using 3D printing techniques.

Why should you read this report?

- Gain insights into the top 3D prinitng innovations impacting businesses.

- Discover 30+ application areas of 3D printing.

- Learn about 10+ innovative startups offering breakthrough solutions.

Key Takeaways

- Tackling Climate Change

- Use Cases:

- Lightweight Components

- Tailored Prototyping Solutions

- Sustainable Construction

- Startup to Watch: rrreefs

- Use Cases:

- Navigating Demographic Shifts

- Use Cases:

- Custom Prosthetics

- Affordable Housing Solutions

- Assistive Devices for the Elderly

- Startup to Watch: Viortec

- Use Cases:

- Rapid Urbanization

- Use Cases:

- Affordable Housing Construction

- Customized Urban Infrastructure

- Emergency Disaster Relief

- Startup to Watch: Impressora

- Use Cases:

- The Energy Transition

- Use Cases:

- Custom Wind Turbine Components

- Solar Panel Manufacturing

- Hydrogen Storage Systems

- Startup to Watch: Material

- Use Cases:

- Future of Mobility

- Use Cases:

- Lightweight Vehicle Components

- Customization and Prototyping

- On-Demand Spare Parts

- Startup to Watch: Additive Drives GmbH

- Use Cases:

- Hyper-Connectivity

- Use Cases:

- Printed Electronics

- IoT Sensors

- Connected Medical Devices

- Startup to Watch: LPrint

- Use Cases:

- Rise of Technology & Industry 5.0

- Use Cases:

- Rapid Prototyping

- Tooling and Production

- On-Demand Production

- Startup to Watch: FreeD Printing GmbH

- Use Cases:

- Navigating the Shift in Global Economic Power

- Use Cases:

- Localized Production

- Customization

- Material Efficiency

- Startup to Watch: Biomedical 3D

- Use Cases:

- Innovating to Zero

- Use Cases:

- Zero Waste

- On-Demand Production

- Optimized Design

- Startup to Watch: Thrasos 3D

- Use Cases:

- Health and Wellness Evolution

- Use Cases:

- Patient-Specific Implants

- Bioprinting

- Drug Development

- Startup to Watch: Celldrive 3D

- Use Cases:

- Managing Social Instability

- Use Cases:

- Supply Chain Resilience

- On-Demand Manufacturing

- Customization and Adaptability

- Startup to Watch: Replique

- Use Cases:

- Navigating the Fracturing World

- Use Cases:

- Small Scale Manufacturing Hubs

- Infrastructure Repair

- Custom Medical Solutions

- Startup to Watch: Antonym

- Use Cases:

Overview: How do Companies Use 3D Printing?

Companies leverage 3D printing to streamline prototyping, allowing them to rapidly produce and test product designs, which accelerates the development process. They also use 3D printing to manufacture complex components that are difficult or costly to produce with traditional methods, enhancing efficiency in industries such as aerospace and automotive. Additionally, 3D printing enables on-demand production, reducing inventory costs and waste, which proves particularly useful in customized manufacturing sectors like healthcare, where personalized medical devices or implants are produced based on individual specifications.

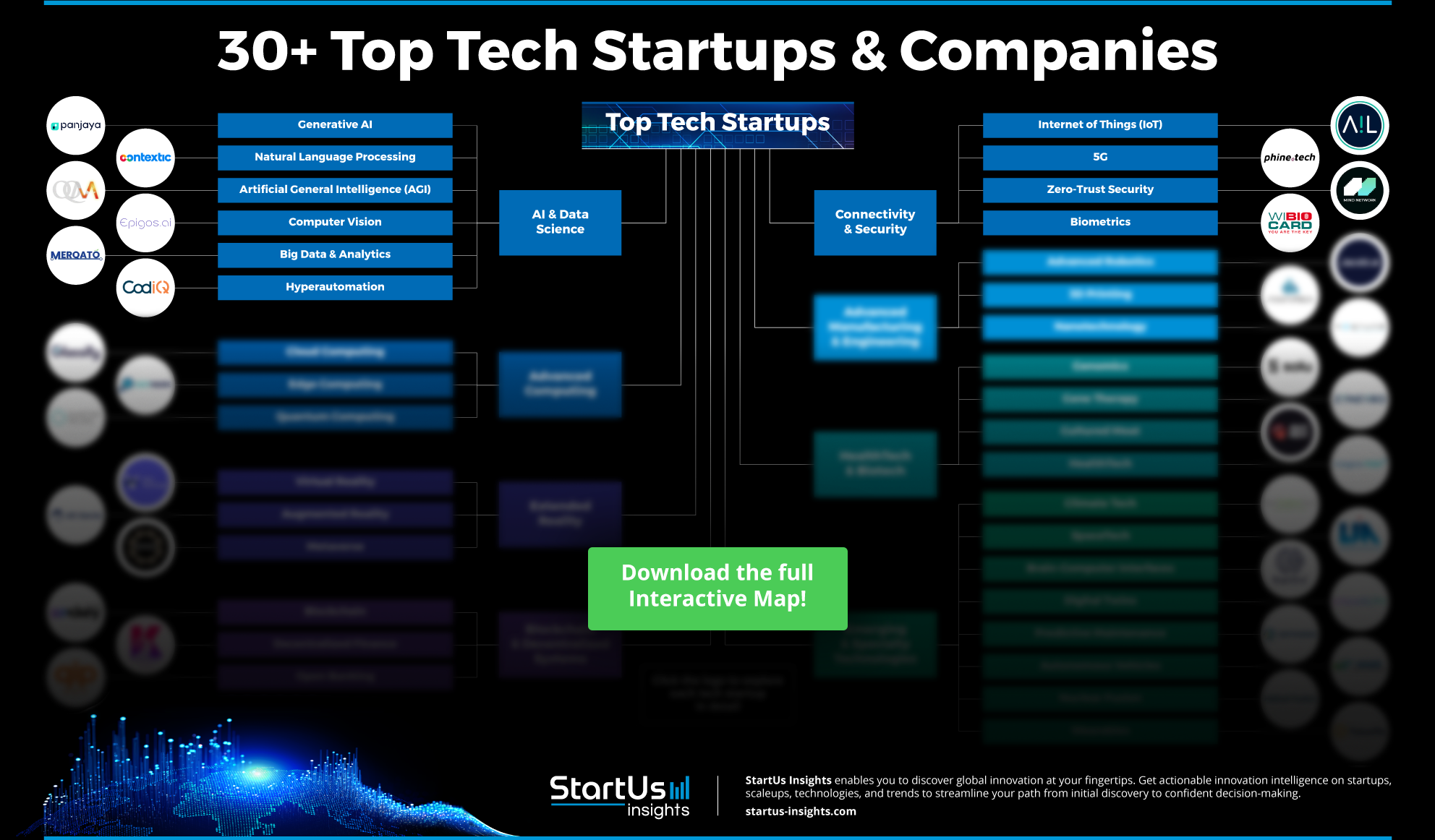

Where We Get Our Data From

StartUs Insights gathers data through its exhaustive Discovery Platform, covering information on 4.7 million startups, scaleups, and tech companies globally, alongside 20,000 emerging technologies and trends. The Discovery Platform accelerates startup and technology scouting, trend intelligence, and patent searches, offering thorough insights into technological advancements. By leveraging the trend intelligence feature for this report, we identified emerging technologies within specific industries. This process allows us to uncover patterns and trends, and pinpoint relevant use cases and the startups creating solutions for each scenario. Additional capabilities and information can be found at StartUs Insights Discovery Platform.

12 Ways 3D Printing is Advancing Business [2025 & Beyond]

1. Tackling Climate Change

3D printing reduces carbon emissions by consuming only 50% of the energy consumed by traditional manufacturing. It minimizes material waste by utilizing only the necessary materials from the CAD model, promoting sustainable manufacturing and material efficiency. 3D printing creates lightweight structures, used in aerospace which contributes to lower energy consumption in their end applications. Recycled materials, Biodegradable plastics, and other sustainable alternatives are increasingly used in 3D printing, that minimize reliance on fossil fuels and reduce environmental impact.

3 Practical Use Cases of 3D Printing in Tackling Climate Change

- Lightweight Components: Lightweight components through new material combinations are possible through 3D Printing. For instance, it produces parts for renewable energy systems, such as wind turbine blades and solar panel mounts. Consuming less time 3D printing generates complex geometries production, minimizing the lead time and increasing the production efficiency.

- Tailored Prototyping Solutions: It enables rapid prototyping and tailored solutions for climate-risk challenges. This includes components for environmental monitoring equipment, specialized parts for waste management systems, or solutions for improving energy efficiency in various applications.

- Sustainable Construction: 3D printing fosters construction with techniques like printing buildings and infrastructure using eco-friendly materials. It lowers carbon emissions, minimizes waste, and enables the use of recycled or locally sourced materials.

Startup to Watch: rrreefs

Swiss startup rrreefs designs and implements human-made reef structures to combat climate change and restore marine ecosystems. The company utilizes 3D printing technology to create modular reef systems that mimic the three-dimensional structure of natural coral reefs. These artificial structures over time allows natural corals to settle and grow, thus creating habitats for marine ecosystems. Within months, rrreefs’ structures modifies into resilient, self-sufficient coral reefs which accelerates the regeneration of marine ecosystems and addresses the challenges of marine biodiversity and reef restoration.

2. Navigating Demographic Shifts

3D Printing for Companies addresses demographic shifts for aging populations through personalized medical solutions and improved medical procedures. The technology enables the production of medical devices such as hearing aids and custom implants for various body parts. The technology enables affordable housing solutions using unique material combinations in less time for printing.

3 Practical Use Cases of 3D Printing in Navigating Demographic Shifts

- Custom Prosthetics: For the aging population or individuals with specific needs, 3D printing enables the creation of personalized prosthetics and implants. These prosthetics improve comfort and functionality for elderly people and assist in effective surgical planning.

- Affordable Housing Solutions: In response to the demographic shifts, 3D printing offers the construction of affordable and durable housing. The technology creates low-cost housing in areas with high population density, addressing housing shortages and providing scalable solutions for growing urban populations.

- Assistive Devices for Elderly: 3D printing creates customized assistive devices for elderly individuals, such as ergonomic tools and mobility aids. These devices enhance the quality of life by providing support and improving daily functionality for older adults.

Startup to Watch: Viortec

Australian startup Viortec develops orthopedic technology products aimed at improving surgical outcomes of joint replacements. The company produces implants and surgical tools utilizing proprietary 3D printing and computer-aided design to manufacture personalized implants tailored to each patient’s anatomy. Viortec’s solutions use smart sensors and data analytics to provide real-time feedback during surgery and monitor post-operative recovery. The company’s product supports minimally invasive procedures and ensures a high success rate in joint replacements.

3. Rapid Urbanization

By using advanced materials and techniques, 3D printing can produce structural components or even entire buildings faster than traditional methods, reducing construction time and labor costs. With the ability to quickly produce customizable building components, 3D printing helps address the housing shortage by enabling the creation of affordable and modular housing solutions. This is particularly useful in urban areas experiencing rapid population growth.

3 Practical Use Cases of 3D Printing in Rapid Urbanization

- Affordable Housing Construction: In cities experiencing rapid population growth, 3D printing builds affordable housing This method significantly reduces construction time and costs, allowing for the rapid deployment of housing units in areas where traditional building methods would be too slow or expensive.

- Customized Urban Infrastructure: Urban areas require infrastructure solutions tailored to local needs. 3D printing creates customized components such as modular street furniture, unique architectural features, and intricate public art installations. For instance, the City of Dubai has used 3D printing to create innovative and bespoke street furniture and public amenities, enhancing the city’s aesthetic appeal and functionality.

- Emergency Disaster Relief: In the aftermath of natural disasters or other emergencies, 3D printing produces essential materials and structures for disaster relief. 3D printing creates temporary shelters and essential infrastructure components. This rapid production capability helps in providing immediate support and rebuilding efforts in affected areas.

Startup to Watch: Impressora

Spanish startup Impressora builds homes by integrating 3D printing techniques with eco-friendly materials, addressing the needs of rapid urbanization. This approach reduces construction time and minimizes environmental impact. Impressora’s key benefit lies in its use of local resources, which decreases logistical costs and enhances the sustainability of its projects. The company also develops new material mixes for three-dimensional printing considering environmental and construction limitations.

4. The Energy Transition

Advancements in energy-efficient 3D printers, which integrate renewable energy sources and low-power consumption technologies support the energy transition. In the aerospace and automotive industries, 3D-printed components can be designed with intricate geometries that reduce weight and enhance fuel efficiency, thereby decreasing overall energy consumption.

3 Practical Use Cases of 3D Printing in The Energy Transition

- Custom Wind Turbine Components: 3D printing allows the creation of custom parts for wind turbines, such as turbine blades or internal components. This reduces production lead times and costs while improving energy efficiency through optimized designs.

- Solar Panel Manufacturing: 3D printing produces more efficient solar panels by designing intricate structures at the micro-level. This helps increase the surface area for light absorption, boosting the energy output.

- Hydrogen Storage Systems: 3D printing can produce complex hydrogen storage tanks that are lightweight and durable. These tanks play a critical role in hydrogen fuel applications for clean energy systems.

Startup to Watch: Material

US-based startup Material develops 3D-printed battery systems using its proprietary Hybrid3D technology. Material utilizes power optimization solutions addressing the need for extended runtime in mobile electronics by leveraging computing and 3D printing. HYBRID3D printing integrates multiple additive manufacturing technologies, enabling the creation of energy storage devices with complexities and superior material properties. The company’s technology utilizes less space, ensures high energy capacity with fewer fabrication steps, and optimizes power consumption at the chip level.

5. Future of Mobility

3D printing allows for the production of lightweight components, reducing vehicle weight and improving energy efficiency, which is crucial for electric vehicles (EVs) and other sustainable transportation modes. It enhances supply chain efficiency by enabling decentralized production, reducing the need for large inventories of spare parts. 3D printing impacts autonomous vehicles and urban mobility systems, producing modular designs that are easily adaptable to changing urban environments and new mobility concepts like flying cars or hyperloop technologies.

3 Practical Use Cases of 3D Printing in the Future of Mobility

- Lightweight Vehicle Components: These lightweight components improve fuel efficiency and extend the electric vehicle range through reduced overall weight. Lattice patterns that lower vehicle weight without lowering strength allow customization based on specific vehicle requirements.

- Customization and Prototyping: 3D printing allows for quick and cost-effective prototyping of new vehicle designs, components, and systems. This speed accelerates the innovation cycle, enabling manufacturers to test and iterate on designs before mass production, significantly reducing time-to-market for new mobility solutions.

- On-Demand Spare Parts: 3D printing enables the rapid production of spare parts, reducing lead times compared to traditional manufacturing methods. This agility is vital in the mobility sector, where downtime can lead to substantial operational losses.

Startup to Watch: Additive Drives GmbH

German startup Additive Drives develops customized electric motor technology addressing higher power density needs through its patented 3D printing techniques. This approach enables the creation of lightweight motors by optimizing material use and facilitates complex geometry creation. The motors feature enhanced copper content and optimized winding structures, resulting in improved efficiency and performance. The company’s product enhances thermal management by integrating cooling channels directly into the motor components, addressing the needs of demanding applications in aerospace and motorsports.

6. Hyper-Connectivity

Integration of 3D Printing with the Internet of Things (IoT) and cloud-based platforms facilitates real-time collaboration, allowing designers, engineers, and manufacturers to work together globally, improving efficiency. 3D printers connected to digital networks enable on-demand manufacturing, reducing lead times and eliminating the need for large inventories.

3 Practical Use Cases of 3D Printing in Enabling Hyper-Connectivity

- Printed Electronics: 3D printing enables the creation of customized, flexible wearable electronics embedded directly into clothing or accessories. These devices can include health monitoring sensors, fitness trackers, and smart textiles, providing seamless connectivity without bulky external components.

- IoT Sensors: 3D-printed electronics allow for customized sensor arrays used in smart environments, such as homes or industrial facilities. These sensors can monitor conditions like temperature, humidity, or pressure and communicate with IoT networks to provide real-time data for improved automation and control.

- Connected Medical Devices: Personalized medical implants, prosthetics, and diagnostic devices benefit from 3D-printed electronics. These printed circuits are embedded into devices like hearing aids or heart monitors, allowing for precise monitoring and data transmission to healthcare providers.

Startup to Watch: LPrint

French startup LPrint develops PCB printing technology that enables the production of complete circuits in a single process including both the substrate and the conductive traces. This modified approach reduced the time and materials required for circuit board production. This process allows rapid iteration and testing of electronic designs and integrates into the existing workflows. The company’s 3D printer allows to use high viscosity materials for printing while maintaining high conductivity of traces. It generates less waste and uses less production time to print PCBs where metal is used for printing conductive layers and polymer is used for printing insulation layers.

7. Rise of Technology & Industry 5.0

3D printing enables workers to focus on creative and complex tasks while machines handle repetitive and precise manufacturing. By minimizing material waste and enabling on-demand production, 3D printing aligns with Industry 5.0 focus on sustainable practices. It also supports local production, reducing the carbon footprint associated with global supply chains.

3 Practical Use Cases of 3D Printing in Advancing the Rise of Technology & Industry 5.0

- Rapid Prototyping: 3D printing accelerates the prototyping process, allowing designers and engineers to quickly iterate and test new product designs. This speeds up the development cycle and reduces time to market.

- Tooling and Production Aids: In manufacturing, 3D printing is used to create custom tooling, jigs, and fixtures. This can improve production efficiency and accuracy by providing tailored solutions that enhance the performance of manufacturing processes.

- On-Demand Production: It supports just-in-time manufacturing by enabling on-demand production of components. This reduces the need for large inventories and allows for rapid response to market changes or specific customer requirements, optimizing supply chain efficiency.

Startup to Watch: FreeD Printing GmbH

German startup FreeD Printing employs a six-axis robot in the modeling process, enabling multidirectional model construction that breaks free from traditional manufacturing. The company’s process allows variable modeling directions, thus helping in the production of complex geometry components and fostering new possibilities for industrial processes. It combines different layer orientations and optimizes surface quality and part strength. It offers benefits such as lower processing time, saving of manufacturing materials, and needs no post-processing.

8. Navigating the Shift in Global Economic Power

With 3D printing, manufacturing can be localized, allowing businesses to produce goods closer to their markets. This decentralization reduces transportation costs, lowers carbon footprints, and can lead to more resilient supply chains. 3D printing can lower production costs by reducing waste and allowing for the use of less expensive materials. The shift towards on-demand production reduces the need for large inventories and can lower production costs, impacting supply chain dynamics and inventory management.

3 Practical Use Cases of 3D Printing in Navigating the Shift in Global Economic Power

- Localized Production: With rising concerns over global supply chain disruptions and shipping delays, 3D printing allows for localized production. This trend is especially beneficial for producing goods close to the end consumer, reducing shipping costs and lead times, and supporting local economies.

- Customization: The shift towards personalized products across various industries such as consumer goods, healthcare, and fashion benefits from 3D printing’s ability to create bespoke items efficiently. This trend aligns with the growing consumer preference for unique, tailored products.

- Material Efficiency: As economic trends increasingly focus on sustainability, 3D printing contributes by using materials more efficiently and reducing waste. Additive manufacturing builds objects layer by layer, which often results in less material consumption compared to subtractive methods.

Startup to Watch: Biomedical 3D

Spanish startup Biomedical 3D enhances surgical interventions and medical treatment planning by offering 3D printing solutions for the medical sector. It employs a collaborative process with doctors and engineers to create surgical guides, custom implants, and prosthetics. This approach addresses shifting economic trends in healthcare by providing improved, cost-effective surgical outcomes. The company’s services extend to orthopedics, maxillofacial surgery, neurosurgery, medical image segmentation and models for surgical planning.

9. Innovating to Zero

3D printing can be more energy-efficient compared to traditional manufacturing methods. By producing parts with fewer processes and eliminating the need for molds or excessive material handling, 3D printing can lower the overall energy consumption. The technology enables the creation of highly customized products tailored to specific needs, which can lead to more efficient use of materials. Additionally, 3D printing facilitates the production of complex geometries that optimize material usage and performance.

3 Practical Use Cases of 3D Printing in Innovating to Zero

- Zero Waste: 3D printing can facilitate the recycling of used plastics and other materials into new products. This closed-loop approach reduces waste and supports a circular economy by extending the lifecycle of materials.

- On-Demand Production: 3D printing supports on-demand manufacturing, which reduces the need for large inventories and associated waste. Products are manufactured as needed, decreasing the risk of overproduction and unsold goods.

- Optimized Design: 3D printing allows for advanced design optimization techniques, such as lattice structures and topology optimization. These designs minimize material use while maintaining structural integrity, leading to lighter components.

Startup to Watch: Thrasos 3D

Mexico-based startup Thrasos 3D develops carbon-negative 3D-printed coral reef structures using terracotta materials. The company utilizes energy-efficient hardening methods that reduce carbon emissions and produce sustainable, custom-made coral reefs. These artificial systems biomimic marine ecosystem and acts as the shelter for sea animals, accelerating ecosystem restoration. By utilizing ceramic and clay-based products for printing, the reefs offer carbon sequestration and promote sustainable artificial reefs.

10. Health and Wellness Evolution

3D printing supports the creation of patient-specific surgical models for preoperative planning, enhancing surgical accuracy and outcomes. The ability to rapidly prototype and test new medical devices also accelerates innovation in treatment options. Overall, 3D printing enhances personalized care and drives advancements in medical technology. 3D printing enables the production of customized medical devices, prosthetics, and implants tailored to individual patient needs.

3 Practical Use Cases of 3D Printing in the Health and Wellness Evolution

- Patient-Specific Implants: Surgeons use 3D printing to produce implants tailored to the exact specifications of a patient’s anatomy, improving the integration and effectiveness of devices such as bone replacements and dental implants.

- Bioprinting: Emerging bioprinting technologies are being developed to print tissues and organs, potentially leading to breakthroughs in regenerative medicine and organ transplantation.

- Drug Development: Researchers use 3D printing to create customized drug delivery systems, including personalized dosage forms and complex drug-release mechanisms, improving treatment efficacy.

Startup to Watch: Celldrive 3D

Spanish startup Celldrive3D develops a modular bioink technology for 3D bioprinting that enables the creation of living tissues on demand. The company’s bioink which is engineered using genetic techniques mimics the extracellular matrix and is free from animal components. This ensures high cell viability and precise 3D structure resolution. It remains stable post-printing without crosslinkers or photoinitiators and assists in developing biofunctional protein polymers. These polymers interact with human cells at the micro level and promote tissue regeneration and the bioprinting process.

11. Managing Social Instability

3D printing enables decentralized, localized production, reducing reliance on centralized manufacturing hubs and global supply chains. This technology adapts to disruptions by shifting production to unaffected areas and minimizes dependence on a single country or region for manufacturing. 3D Printing boosts the possibility of establishing production facilities worldwide, strategically located to serve local markets. It also reduces the need to transport physical goods across borders overcoming the trade barriers.

3 Practical Use Cases of 3D Printing in Managing Social Instability

- Supply Chain Resilience: By enabling local production of parts and components, 3D printing can help overcome supply chain disruptions caused by geopolitical events, natural disasters, or pandemics.

- On-Demand Manufacturing: 3D printing supports just-in-time production, reducing the need for large inventories and minimizing risks associated with stockpiling goods in uncertain times.

- Customization and Adaptability: The ability to easily customize products allows companies to cater to specific local preferences and regulations, facilitating market entry and adaptation in different geopolitical contexts

Startup to Watch: Replique

German startup Replique develops a 3D printing platform that allows businesses to produce high-quality products on demand. It accommodates materials like polymers, metals, and ceramics allowing for the production of versatile parts. It addresses the challenges of uncertain geopolitical nature by offering on-demand manufacturing facilities and building supply chain resilience. The company’s technology saves cost, reduces time for production, and assures parts produced meet sustainability standards. It supports a digital inventory system to support businesses of all sizes to produce the right quantity at good quality and right place.

12. Navigating the Fracturing World

3D printing improves the production and distribution of medical devices, particularly in areas with limited resources or during a crisis. It offers low-cost, quick manufacturing facilities that use standard 3D desktop printers, solving a wider range of healthcare problems. By enabling production close to the point of use and supporting the use of diverse, locally sourced materials, 3D printing mitigates the impact of global fragmentation and enhances the ability to respond to regional and local challenges effectively.

3 Practical Use Cases of 3D Printing in Navigating the Fracturing World

- Small-Scale Manufacturing Hubs: 3D printing enables small-scale manufacturing hubs across different regions that reduces the need for centralized manufacturing systems and minimizes the impact of trade conflicts, and regional disruptions. Further, this approach ensures more resilient and adaptable production capabilities in a fracturing global landscape.

- Infrastructure Repair: Implementation of 3D printing reduces the time and cost associated with infrastructure repairs. It offers design flexibility and eliminates the need for large part inventories.

- Custom Medical Solutions: It enables precise customization based on individual anatomy, allowing for better fit and comfort. 3D printing facilitates the use of biocompatible materials, resulting in solutions that adapt well to the human body, improving healing and overall outcomes.

Startup to Watch: Antonym

UK-based startup Antonym develops localized micro-factories using cloud and additive manufacturing technologies. The company’s turnkey plug-and-play micro-factory system integrates metal 3D printing, robotics, and a digital supply chain to produce spare parts on demand, directly at the point of need. It increases access to critical parts on-site by deploying these micro-factories globally as alternatives to traditional mega-factories. This approach enables real-time monitoring and control of production which facilitates seamless collaboration between distributed manufacturing sites.

Outlook for the 3D Printing Industry

Patents & Grants

Additive manufacturing drives innovation with over 15,000 patents, demonstrating rapid technological growth. Supported by more than 1,000 grants, this strong backing reflects a substantial investment in new technologies.

Investment Landscape

Key investors include Techstars, MassChallenge, AM Ventures, and EIC Fund. The top funding types are seed, accelerator/incubator, early-stage VC/series A, pre-seed, and angel, with an average funding amount of USD 4.5 million per round.

Global Footprint

The industry’s global influence is evident through its major country hubs: the USA, Germany, India, the UK, and Italy. Key city hubs include New York City, London, Shenzhen, Melbourne, and San Francisco, highlighting the sector’s broad reach and influence.

Don’t Miss Out on the Latest 3D Printing Innovations

Ready to leverage the latest 3D Printing technologies shaping the future? With StartUs Insights, you gain quick and easy access to over 4.7 million startups, scaleups, and tech companies, along with 20,000 emerging technologies and trends. Our AI-powered search and real-time database provide exclusive solutions that set you apart from the competition.

Industry giants like Samsung, Nestlé, and Magna trust our innovation intelligence tools to lead trends, optimize operations, and uncover new market opportunities. Benefit from our unmatched data, comprehensive industry views, and reliable insights to drive strategic decision-making. Get in touch to learn how our tailored discovery options can accelerate your innovation journey.

Discover All 3D Printing Technologies & Startups!