Corporations worldwide are adopting AI in supply chain operations and AI in supply chain optimization to tackle challenges like transportation bottlenecks, labor shortages, and rising operational complexities. The AI market in the supply chain industry is expected to reach USD 157.6 billion by 2023 with a CAGR of 42.7%.

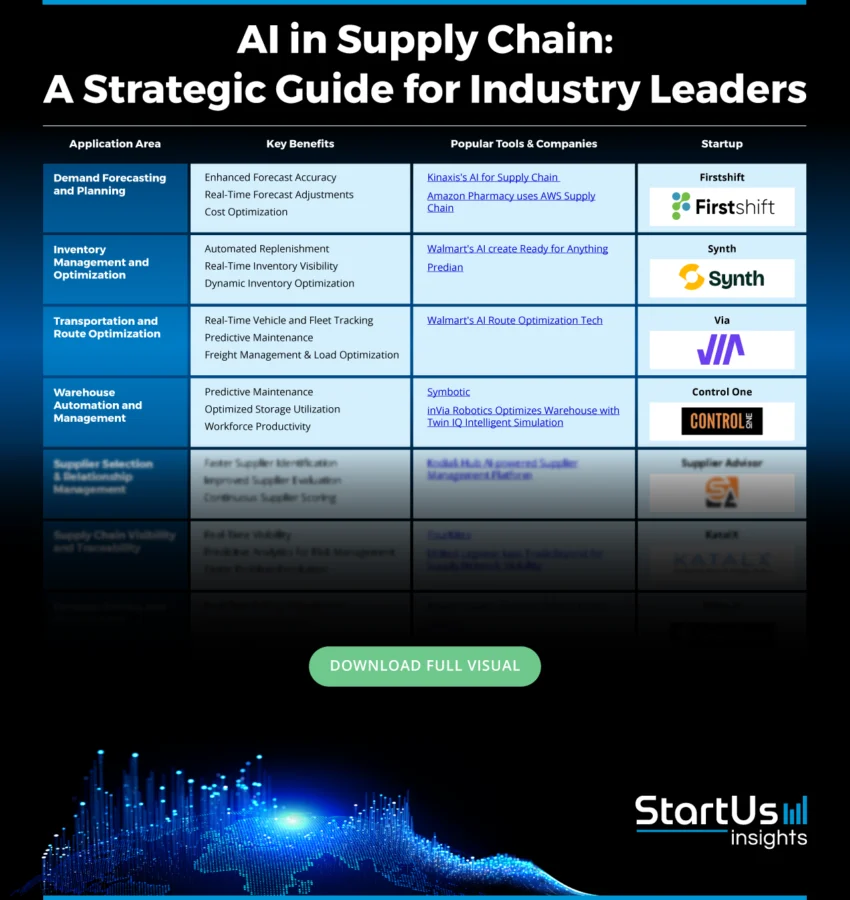

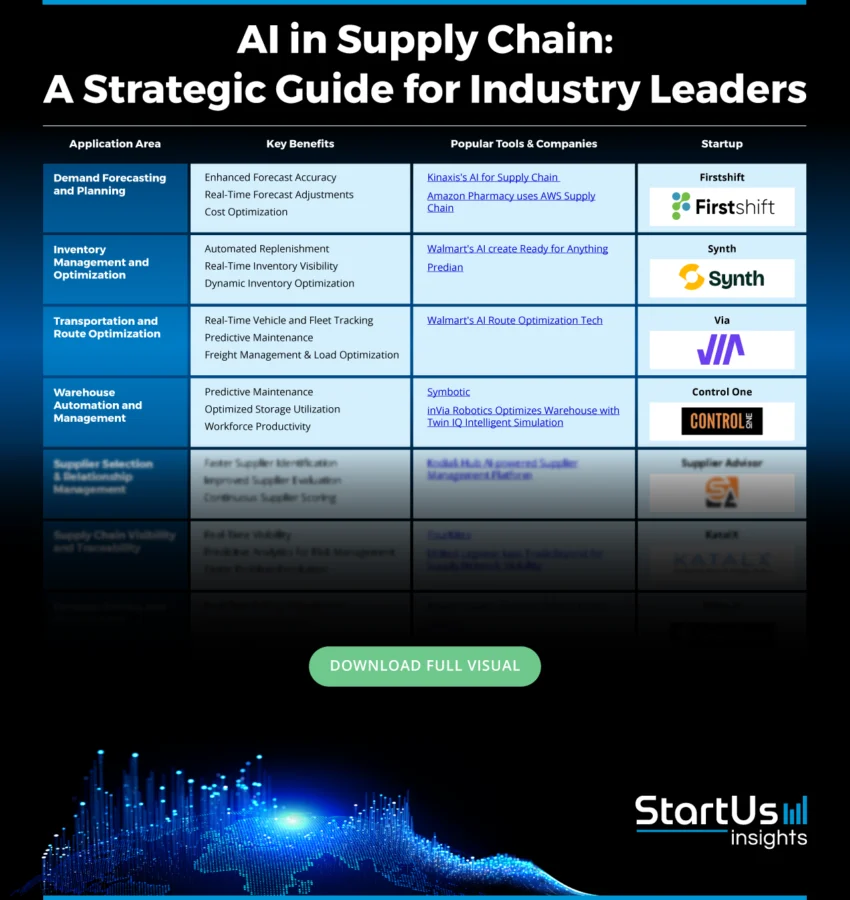

In this strategic guide, you will discover the top 10 implementation areas to improve your supply chain operations. You will also explore powerful AI tools to build more agile, resilient, and cost-effective supply chain networks.

Key Takeaways

- Outlook and Economic Impact of AI: AI adoption in supply chains is accelerating, with 46% of organizations already implementing it. Early adopters report a 15% reduction in logistics costs, a 35% improvement in inventory levels, and more.

- 10 Key Areas Where AI is Transforming Supply Chains

- Demand Forecasting & Planning

- Inventory Management & Optimization

- Transportation & Route Optimization

- Warehouse Automation & Management

- Supplier Selection & Relationship Management

- Supply Chain Visibility & Traceability

- Dynamic Pricing & Procurement

- Risk Management & Compliance

- Production Planning & Optimization

- AI-Driven Customer Interactions

- Key Drivers: Labor shortages, rising operational complexity, demand for real-time traceability, and pressure to reduce emissions.

- Future Outlook: The future of AI in supply chain involves self-healing networks, autonomous warehouse robots, hyper-personalization, and more.

How Do We Research and Where is This Data From?

We reviewed 3100+ industry innovation reports to extract key insights and construct a comprehensive guide for integrating AI in supply chain operations. To increase accuracy, we cross-validated this information with external industry sources.

Additionally, we leveraged the StartUs Insights Discovery Platform – an AI and Big Data-powered innovation intelligence tool covering over 7 million startups and more than 20K+ technologies & trends worldwide to:

- Confirm our findings using the Trend Intelligence feature.

- Gather market statistics for each technology.

- Identify startups for the “Spotlighting an Innovator” sections.

Current Outlook on the Adoption and Economic Impact of AI in Supply Chains

Adoption Rates and Technology Adoption Curve

- Adoption Rate: 46% of organizations are already using AI in their supply chains, and most implementations are still in the early stages.

- Strategic Implementation: 41% of professionals with innovation budgets make AI tools a prominent part of their approaches in supply chain innovation.

- Executive Buy-In: 70% of CEOs state that AI solutions are essential for stock management, logistical optimization, and supplier risk management.

- Application Distribution: Logistics and transportation emerged as the primary areas that benefit from AI. Almost 40% of respondents report improvements in these functions.

Financial Metrics and Cost Effectiveness

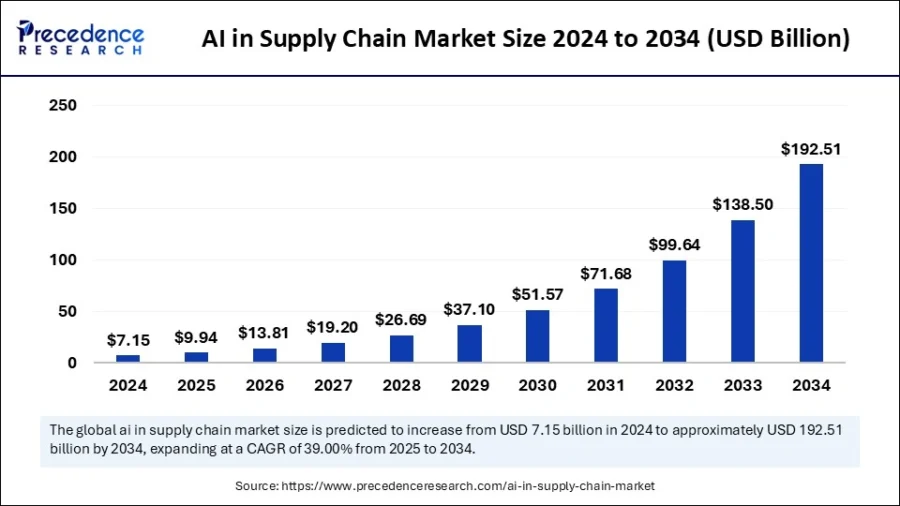

- Current Market Size: The global AI in supply chain management market is calculated at USD 9.94 billion in 2025.

Credit: Precedence Research

- ROI and Cost Savings: Early adopters of AI in the supply chain industry improve logistics costs by 15%, inventory levels by 35%, and service levels by 65%.

- Operational Outcome Metrics: AI enables preventive maintenance that reduces the time to predict mechanical failures by 75% at OYAK Cement.

10 Key Areas Where AI is Transforming Supply Chains

1. Demand Forecasting & Planning

AI in supply chain planning supports supply chains in tackling global complexities, shifting consumer behavior, and disruptions. McKinsey reports that AI-driven demand forecasting reduces forecast errors by 20% and 50%. This tool reduces lost sales by up to 65%.

An agribusiness uses C3 AI to convert weekly data into daily forecasts that process 72 million rows of data across 88 SKUs and 8 production lines. This resulted in an uplift in forecasting accuracy by 8% and gross margin by USD 30 million.

Further, neural networks handle complex forecasting scenarios, while generative AI optimizes logistics and production planning. Mars reduced 80% of its annual workload by using generative AI to consolidate truckloads through weather and shipment data analysis.

AI-driven demand forecasting also allows supply chain companies to gain actionable insights. Nike’s adoption of Celect reduces overstocks and markdowns by integrating historical data, market signals, and regional preferences.

Amazon Pharmacy used AWS Supply Chain to achieve 50% better forecast accuracy than the industry standard mean absolute percentage error (MAPE).

Additionally, AI improves new product forecasting by analyzing early market signals and comparable launches. This is especially useful in fast-paced sectors like FMCG, fashion, and tech.

Granular demand forecasting is critical to balancing inventory costs and service levels. Businesses that use AI for this purpose have reported up to a 35% improvement in inventory levels.

In retail, a hybrid long short-term memory (LSTM) model achieved 92.5% accuracy by analyzing historical sales, promotional activity, and macroeconomic data. This allows retailers to reduce inventory holding by 18% and increase order fulfillment rates by 22%.

Key Benefits

Enhanced Forecast Accuracy

Advanced predictive models analyze historical sales, market trends, and weather or economic indicators to deliver highly precise demand forecasts.

Real-Time Forecast Adjustments

Adaptive algorithms continuously process real-time data for supply chain businesses to quickly adjust to sudden market changes or disruptions. This agility maintains service levels during unforeseen events.

Cost Optimization

By leveraging intelligent forecasting, businesses reduce holding costs and minimize waste. It streamlines procurement and production across the supply chain.

Popular Companies and Tools

Kinaxis’ Demand.AI

Kinaxis’ Demand.AI is a demand forecasting platform that utilizes machine learning to analyze internal and external data sources. This enables the generation of highly accurate forecasts across various time horizons.

By incorporating dynamic signals such as market trends and consumer behavior, Demand.AI improves the responsiveness of supply chains to real-time changes. The platform’s ability to provide transparent insights into forecast drivers fosters trust and collaboration among stakeholders

Amazon Pharmacy & AWS Supply Chain

Amazon Pharmacy has implemented its platform, AWS supply chain solution, to improve demand forecasting. By utilizing machine learning, the platform analyzes historical sales data and current trends to produce accurate, daily forecasts.

This automation has led to a 50% improvement in forecasting accuracy compared to industry standards and has reduced manual planning time by approximately 13% weekly. The forecasting capabilities further support better staffing decisions and inventory management for the timely delivery of medications to customers.

Spotlighting an Innovator: Firstshift

Firstshift is a US-based startup that offers an AI-powered supply chain planning platform for the use of AI in supply chain. It integrates generative AI, machine learning, and automation to streamline demand forecasting, inventory optimization, and operational decision-making.

The platform features tools such as Pluto, a generative AI copilot, and AI-powered diagnostics that analyze structured data across enterprise systems. This enables planners to simulate scenarios, evaluate supplier performance, and adjust plans in real time.

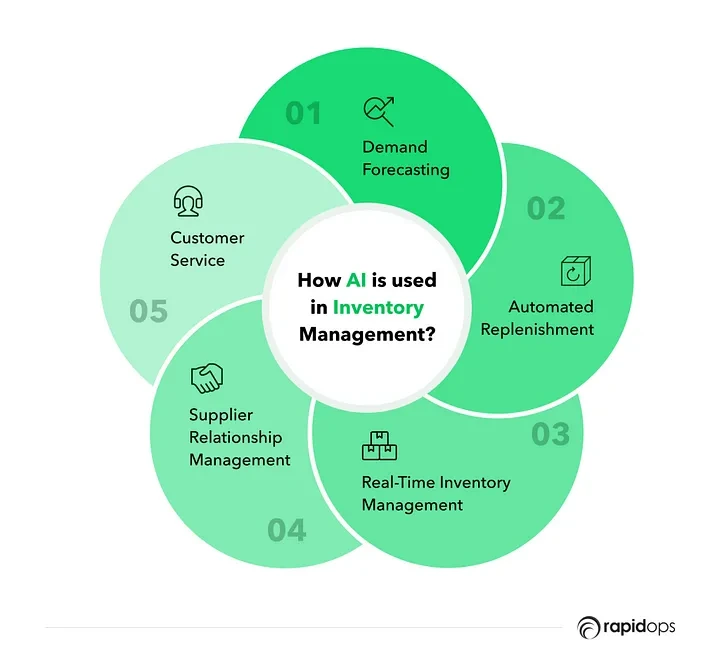

2. Inventory Management & Optimization

Suppliers that implement AI systems in combination with the Internet of Things (IoT) and radio frequency identification (RFID) offer real-time visibility of inventory across multiple locations. Tru Earth, for example, reports that AI-driven real-time inventory tracking led to better visibility and increased accuracy.

Smart algorithms automate reordering by setting dynamic reorder points based on real-time analytics. Amazon uses this kind of AI technology to efficiently turn over inventory, automate restocking, and respond to shifting demand.

AI reallocates inventory between warehouses and fulfillment centers to match regional demand. Nike, for instance, leverages AI to manage inventory globally and ensures popular products are available in the right regions.

Credit: Rapidops

Further, Siemens applies digital twins to model warehouse layouts and SKU velocity. In one automotive division, this reduced the excess stock of low-turnover items while improving access to high-demand components.

Its AI engine adjusts safety stock using real-time supplier risk scores sourced from geopolitical and financial data.

AI analytics also optimizes inventory by segmenting SKUs, automating rebalancing, and prioritizing high-margin items.

Companies using ThroughPut AI have released up to 62% of working capital and improved inventory availability by targeting bottlenecks.

Key Benefits

Automated Replenishment

Intelligent inventory systems monitor stock levels and predict demand patterns. These systems automatically generate restocking orders for timely replenishment.

Real-Time Inventory Visibility

Advanced analytics platforms integrate data from various sources for businesses to track inventory movements and detect discrepancies promptly to maintain optimal stock levels.

Dynamic Inventory Optimization

Predictive analytics tools adjust inventory strategies dynamically and allow businesses to respond swiftly to changing demand. This reduces holding costs and improves service levels.

Popular Companies and Tools

Walmart’s “Ready for Anything” Supply Chain

Walmart integrated its predictive analytics and machine learning to improve inventory management. By analyzing historical data alongside real-time inputs such as weather patterns, social media trends, and macroeconomic indicators, Walmart’s system anticipates demand fluctuations and adjusts inventory levels accordingly. This further ensures product availability, reduces overstock situations, and minimizes waste.

Predian’s ValueVision

Predian’s ValueVision platform supports automotive dealerships with advanced predictive analytics to optimize inventory decisions. By analyzing historical sales data, market trends, and customer behavior, the system forecasts demand and suggests optimal stocking levels and pricing strategies.

This data-driven approach reduces overstocking, minimizes carrying costs, and accelerates sales cycles. Additionally, Predian’s “Talk to My Inventory” feature leverages natural language processing to generate insightful reports.

Spotlighting an Innovator: Synth

Synth is a US-based startup that builds a unified inventory intelligence platform. It employs AI-powered agents to automate demand forecasting, production planning, and order management for consumer packaged goods (CPG) and e-commerce brands.

The platform integrates sales, marketing, and operations data and enables AI teammates, such as the email order analyst and marketing campaign assistant. This way, it processes orders, aligns promotions with inventory levels, and generates purchase orders in real time.

The platform also offers automated demand forecasting, production optimization, and real-time inventory tracking, which collectively enhance operational efficiency and reduce stockouts.

Synth further lean teams to scale effectively and ensure that inventory planning drives revenue growth rather than operational complexity.

3. Transportation & Route Optimization

AI integrates GPS tracking, vehicle sensors, and a delivery information acquisition device (DIAD) data to solve complex routing challenges. AI in supply chain examples include UPS’ on-road integrated optimization and navigation (ORION) system processes billions of daily data points to optimize multi-stop routes.

ORION’s 1000-page algorithm framework solves the traveling salesman problem in seconds. Also, AI-driven route optimization directly reduces fuel consumption and emissions. For instance, UPS’ ORION system reduces CO2 emissions by 100 000 metric tons annually through route optimization and reduced idling.

Further, smart dynamic routing platforms address last-mile inefficiencies by optimizing delivery windows, vehicle capacity, and driver proximity.

For example, FarEye’s real-time dynamic routing reduced delivery times by 27% by automating order assignments and rerouting drivers around traffic bottlenecks. Similarly, the logistics partner achieved a 15% productivity improvement by minimizing idle time and empty-mile journeys.

Smart algorithms leverage computer vision and reinforcement learning to enable AI-driven robots to perform pick and stow inventory with greater accuracy. Amazon’s smaller bots, like the Sparrow, use AI and computer vision to recognize over 65% of Amazon’s product inventory.

AI optimizes routes through real-time vehicle tracking by integrating GPS and IoT for dynamic routing adjustments. Moreover, AI-driven predictive maintenance analyzes IoT sensor data to anticipate equipment failures and schedule timely interventions. Amazon also implements similar AI systems to maintain warehouse automated equipment.

Key Benefits

Real-Time Vehicle and Fleet Tracking

Advanced telematics systems, integrated with GPS and IoT sensors, provide continuous visibility into fleet movements. These technologies monitor vehicle locations, driver behaviors, and delivery statuses in real time.

Predictive Maintenance

Intelligent analytics platforms analyze data from vehicle sensors to forecast maintenance needs before issues arise. By anticipating potential failures, companies schedule timely interventions and extend the lifespan of their assets.

Freight Management and Load Optimization

Machine learning models assess variables such as shipment weight, delivery deadlines, and route constraints to optimize load distribution across fleets. This strategic allocation minimizes empty miles and ensures timely deliveries.

Popular Companies and Tools

Walmart’s Route Optimization

Walmart’s route optimization system utilizes advanced algorithms to improve its logistics operations. This system analyzes traffic conditions, delivery schedules, and vehicle capacities to determine the most efficient delivery routes. The system successfully reduces unnecessary mileage and, therefore, leads to major cost savings and a substantial decrease in carbon emissions.

Spotlighting an Innovator: Via

Via is a US-based startup that delivers an AI-powered transportation spend management platform. The platform centralizes freight and parcel invoice data to enhance supply chain cost visibility. It also employs real-time auditing algorithms to process transportation invoices, detect discrepancies, and streamline payment workflows. This reduces manual errors and administrative overhead.

By integrating data across carriers and logistics partners, Via enables businesses to identify cost-saving opportunities and optimize their transportation expenditures.

Further, the startup provides a unified solution that transforms fragmented logistics data into actionable insights, supporting more informed financial decisions and improved operational efficiency.

4. Warehouse Automation & Management

Warehouses are increasingly deploying AI to streamline inventory control, improve order fulfillment, and reduce operational risks. Further, predictive analytics enables companies to forecast demand and maintain optimal stock levels.

Amazon, for example, reduces forecasting errors and excess inventory using hybrid LSTM models while preserving a large amount of in-stock during peak seasons.

Warehouse automation is advancing with intelligent robotics. For example, the UWM-666 autonomous mobile robot uses LiDAR, depth sensors, and deep learning for real-time pallet detection and navigation.

It achieves 99% counting accuracy while reducing labor costs by 40% through minimized manual stock checks. Its path planning algorithm optimizes workflow by prioritizing high-demand zones during peak hours.

AI-powered robots use algorithms to optimize picking routes and accelerate order processing. Ocado’s robots currently process 15% of products and are expected to handle up to 70% within a few years.

Warehouse operators also use sensor data with AI to predict equipment failures. Amazon’s use of LiDAR and IoT sensors in warehouses leads to a reduction in near-miss incidents and improves automated guided vehicle (AGV) reliability.

Safety is improving through real-time hazard detection; LiDAR-enabled robots dynamically adjust paths to reduce collision risk by 80%.

Additionally, AI systems optimize lighting, HVAC, and equipment usage based on real-time activity. Robotics-driven automation also cuts labor needs, which lowers the warehouse’s carbon footprint.

Key Benefits

Predictive Maintenance

Intelligent maintenance systems analyze equipment data to forecast potential failures before they occur. By anticipating issues, warehouses schedule timely interventions and extend the lifespan of machinery.

Optimized Storage Utilization

Advanced analytics platforms assess inventory patterns and storage layouts to maximize space efficiency. By determining optimal product placements, these platforms improve storage capacity and streamline retrieval processes.

Workforce Productivity

Smart orchestration tools monitor employee performance and task allocations in real time. By identifying skill gaps and redistributing workloads dynamically, these platforms increase productivity.

Popular Companies and Tools

Symbotic’s Autonomous Warehouse Platform

Symbotic’s vision-enabled mobile robots navigate a high-density storage environment that executes tasks such as induction, storage, and retrieval of products with remarkable speed and precision.

These robots are orchestrated by software that optimizes the entire workflow and processes up to 1700 cases per hour per module.

The startup further creates mixed-SKU pallets tailored to specific store layouts or delivery routes. This customization reduces the time required for shelf stocking and improves inventory accuracy. The modular design of the system allows for scalability.

inVia Robotics’ Twin IQ

inVia Robotics offers Twin IQ, an intelligent warehouse simulation tool designed to optimize fulfillment operations. Twin IQ supports businesses in creating digital twins of their warehouse environments and testing scenarios virtually. This identifies optimal layouts, workflows, and automation strategies without disrupting actual operations.

Moreover, the tools pinpoint bottlenecks and areas for improvement to facilitate data-driven decisions that enhance productivity and reduce costs.

Twin IQ also integrates with inVia’s broader automation suite, including the inVia Logic warehouse execution system and autonomous mobile robots. This integration ensures that the insights gained from simulations translate into actionable strategies.

Spotlighting an Innovator: Control One

Control One is an Indian startup that develops physical AI agents by converting conventional warehouse equipment into autonomous, intelligent machines. Its proprietary operating system integrates vision-based navigation, digital twin modeling, and adaptive control to enable real-time decision-making in dynamic environments.

Its agents perceive their surroundings, process visual data, and execute tasks with human-like responsiveness. Control One introduces an autonomous forklift capable of interpreting voice commands and adapting to changes such as misaligned pallets.

Further, the “3-brain” architecture facilitates human-AI collaboration that allows operators to oversee multiple machines remotely with minimal training.

5. Supplier Selection & Relationship Management

Supply chain leaders are turning to AI for supplier selection and relationship management by accelerating discovery, improving resilience, and ensuring ethical sourcing.

AI platforms leverage machine learning and natural language processing (NLP) to scan millions of online sources, like social media and news sites, to build dynamic supplier profiles. These smart algorithms evaluate suppliers based on financial stability, compliance history, and production capacity.

Veridion’s AI updates supplier data weekly to support procurement teams in generating shortlists in hours instead of weeks. Siemens leverages Scoutbee’s AI-powered platform to identify 6893 potential suppliers for 94 projects across 18 business units. This reduces discovery time by 90%.

At the same time, Unilever employs AI to scan customer records, patent databases, and customer reviews to generate supplier risk scores. AI is also used in dynamic risk scoring. Akira AI’s Piper agent analyzes vast data points per supplier to predict bankruptcy risks.

Further, suppliers leverage NLP in contract management and compliance to support relationship management. For example, GEP SMART uses NLP to extract key terms from multiple contracts that flag non-compliance risks and auto-generates renewal reminders. GEP’s tools reduce contract review times by up to 80%.

Companies like Coupa and SAP Ariba use prescriptive analytics to suggest renegotiation strategies and automate invoice workflows. As technologies like blockchain and generative AI mature, they enable traceability and dynamic contract updates.

Key Benefits

Faster Supplier Identification

Machine learning platforms rapidly analyze extensive supplier databases and evaluate capabilities, certifications, and performance metrics. This results in the accurate identification of suitable suppliers.

Improved Supplier Evaluation

Advanced analytics tools assess suppliers across multiple dimensions, including financial health, compliance records, and sustainability practices. This enables businesses to align supplier choices with strategic goals.

Continuous Supplier Scoring

Predictive analytics continuously monitor supplier performance, which provides real-time risk assessments and performance scores. This enables organizations to proactively manage supplier relationships and mitigate potential disruptions.

Popular Companies and Tools

Kodiak Hub’s Cloud-based SRM

Kodiak Hub‘s cloud-based supplier relationship management (SRM) platform integrates automation and data analytics to improve supplier selection and collaboration.

The platform offers a modular suite of solutions that streamline supplier onboarding, performance monitoring, and risk assessment. This platform consolidates supplier data into a single source of truth, enriched with visual insights and real-time analytics.

Further, the centralization facilitates transparent and traceable supply chains for organizations to proactively manage supplier performance and compliance.

Spotlighting an Innovator: Supplier Advisor

SupplierAdvisor, a South African company that develops an AI-enabled supplier discovery and relationship management platform that leverages RegTech and blockchain technologies to improve trust and compliance in procurement processes.

The platform further utilizes advanced algorithms to assess supplier data against regulatory requirements that connect with vetted and reliable partners. By integrating blockchain, SupplierAdvisor provides an immutable record of supplier credentials and transactions.

This combination of AI-driven analysis and secure data management streamlines supplier onboarding and monitoring.

6. Supply-Chain-Visibility-&-Traceability

Suppliers leverage artificial intelligence systems to collect and analyze data from sensors, IoT devices, RFID tags, and GPS trackers to receive real-time insights on location and status.

Smart algorithms also forecast demand, anticipate disruption, and identify anomalies to optimize production and distribution plans. When combined with blockchain, AI improves traceability by offering a secure, tamper-proof record of every transaction. This improves the authenticity and provenance of products.

For example, Walmart partnered with IBM to create a blockchain system using Hyperledger Fabric that reduces the time to trace mango shipments from 7 days to 2.2 seconds. This blockchain system also identified contaminated lettuce, which prevented USD 120 million in losses by pinpointing affected suppliers instantly.

Key Benefits

Real-Time Visibility

Advanced monitoring systems provide continuous, real-time insights into raw material sourcing to final product delivery. By integrating data from various sources, businesses track inventory movements and detect discrepancies promptly.

Predictive Analytics for Risk Management

Machine learning models analyze historical and real-time data to forecast potential disruptions like supplier delays or transportation issues. This proactive method enables companies to implement contingency plans and mitigate risks.

Faster Problem Resolution

Intelligent analytics platforms swiftly identify anomalies and bottlenecks within the supply chain by pinpointing issues in real time.

Popular Companies and Tools

FourKites’ Real-Time Visibility Platform

FourKites delivers real-time, end-to-end visibility across multimodal supply chains by analyzing data from GPS, electronic logging device (ELD) telematics, mobile devices, and automatic identification system (AIS) tracking systems.

Its platform leverages predictive analytics to generate dynamic ETAs for companies to proactively manage delays and disruptions.

Its Intelligent Control Tower integrates digital twins and autonomous workflows to automate manual logistics tasks. The platform also includes Dynamic Yard®, which streamlines yard operations by integrating live data for better dock scheduling and reduced dwell times.

Further, the Order Intelligence Suite unifies order, shipment, and inventory information to support agile decision-making.

TradeBeyond’s Supply Network Visibility Platform

TradeBeyond offers an AI-powered solution that allows companies like United Legwear & Apparel Co. to gain deeper control over their supplier networks. The platform automates the verification of compliance documents and helps identify discrepancies and mitigate risks in real time.

Its chain of custody track feature provides full visibility into product movement from raw material sourcing to final delivery and ensures compliance with regulations such as the Uyghur Forced Labor Prevention Act (UFLPA).

TradeBeyond also supports sustainability initiatives by collecting data needed for recyclability assessments and carbon reporting. TradeBeyond further allows businesses to enforce ethical sourcing practices, streamline supplier collaboration, and maintain compliance with global ESG standards.

Spotlighting an Innovator: KatalX

KatalX is a French company that offers an AI-driven supply chain visibility and compliance platform. It integrates advanced analytics, real-time collaboration, and process intelligence to support high-stakes industries such as life sciences.

The platform captures both process and product data to track chain of custody, temperature, humidity, and shock, while leveraging digital twin modeling and intelligent automation to monitor deviations, predict risks, and guide corrective actions.

It enables secure, role-based document sharing with tamper-proof audit trails and facilitates real-time communication among stakeholders through embedded chat and video tools.

Further, KatalX unifies visibility, collaboration, and trusted analytics to build resilient, sustainable supply chains.

7. Dynamic Pricing & Procurement

AI-based dynamic pricing adjusts prices in real time based on demand, competition, customer behavior, and market conditions. This enables companies to monitor and respond to competitors’ prices quickly.

Amazon, for example, implements AI systems that continuously adjust prices for millions of products while considering competitor activities, inventory levels, and customer demand.

Dynamic pricing also balances supply and demand through price adjustments. Walmart employs AI to predict demand spikes or dips across its extensive retail network. This enables it to remain competitive while optimizing profit margins across thousands of products.

A study reveals that 47% of businesses have adopted AI for dynamic pricing and demand shifts. IBM, for example, integrates its Watson AI system to improve demand forecasting, supplier management, and risk assessment. This integration led to a 30% improvement in demand forecasting accuracy and a 15% reduction in procurement costs.

Key Benefits

Real-Time Pricing Adjustments

Machine learning models analyze real-time market demand, competitor pricing, and inventory levels to dynamically adjust prices.

Revenue Maximization

Advanced pricing algorithms identify optimal price points by evaluating customer behavior, purchasing patterns, and market trends. By tailoring prices to these insights, companies maximize revenue without compromising customer satisfaction.

Personalized Pricing

Intelligent pricing engines segment customers based on factors like purchase history and browsing behavior for personalized pricing strategies. This enhances customer engagement and loyalty and increases sales.

Popular Companies and Tools

Imaginnovate’s Dynamic Pricing Engine

Imaginnovate’s pricing engine automates pricing practices in the transportation and logistics industry. This tool leverages AI to analyze historical buying and selling patterns, aggregated market data, and personalized pricing rules.

This enables companies to establish pricing ranges for logistics services based on variables such as demand, competition, lanes, equipment, and types of transportation. The pricing ranges serve as a basis for final contract negotiations and more accurate and competitive pricing strategies.

Werner Enterprises’ AI-Powered Dynamic Pricing Engine

Werner Enterprises’ AI-powered pricing engine optimizes transportation costs, improving pricing accuracy and streamlining pricing processes.

The pricing engine generates buy rates for each shipment and moves beyond simple automation to provide a more robust and adaptable solution that aligns with Werner’s evolving business needs. The implementation of this pricing engine leads to more efficiency, better customer satisfaction, faster response times, and streamlined workflows.

Spotlighting an Innovator: Solvo.AI

Solvo.ai, a UK-based startup that develops an AI-powered freight pricing and revenue optimization platform. It enables freight forwarders to make data-driven pricing decisions aligned with strategic objectives. The platform integrates real-time market feedback, historical data, and customer behavior analytics to generate tailored pricing recommendations.

Solvo.ai also offers price suggestions, KPI management at trade lane or port pair levels, and continuous learning from market trends to improve yield performance. Its static pricing models convert into responsive strategies that optimize margins, react swiftly to market fluctuations, and enhance overall profitability.

8. Risk Management & Compliance

Organizations in the global supply chain market face a multitude of risks such as supplier disruption, regulatory noncompliance, geopolitical tensions, and environmental challenges.

Businesses are adopting AI to improve supplier selection and relationship management to enhance resilience and compliance across global networks. Predictive analytics allows procurement teams to identify risks and optimize supplier portfolios before disruptions occur.

For instance, Unilever utilizes AI to scan supplier financials, sustainability metrics, and customs data. This enables rapid switches during crises and reduces downtime.

Additionally, Koch Industries applies AI at the SKU level to streamline sourcing and reduce dependency on manual requests for quotations (RFQs).

Real-time compliance monitoring further automates oversight. Zycus’ AI platform evaluates supplier reports and social sentiment to detect fraud and regulatory red flags, while companies like Landsec save time in invoice validation through AI.

Automated supplier management tools, like Certa.ai and WNS, enhance contract compliance, reduce manual errors, and consolidate vendor bases.

A Fortune 200 frozen foods firm used WNS’ AI solution to eliminate USD 14 M in inactive inventory and save USD 500K annually through better supplier consolidation.

Key Benefits

Real-Time Risk Monitoring

Advanced analytics platforms continuously scan global events, supplier performance, and market conditions to provide up-to-the-minute risk assessments.

Enhanced Supplier Risk Assessment

Machine learning models evaluate suppliers based on financial stability, compliance records, and geopolitical factors. By aggregating data from diverse sources, these systems offer a comprehensive view of supplier risk profiles.

Scenario Simulations

Generative AI tools simulate “what-if” scenarios for businesses to anticipate the impact of potential disruptions like natural disasters or regulatory changes. These simulations enable companies to develop effective contingency plans.

Popular Companies and Tools

Marsh McLennan’s Sentrisk

Marsh McLennan’s Sentrisk is an AI-powered platform that manages global supply chain risks. Developed through the collaboration of Marsh and Oliver Wyman, Sentrisk employs technologies such as supply chain mapping, AI, and geospatial satellite imaging to provide visibility into supply chains.

This enables organizations to identify vulnerabilities at granular levels such as specific sites, suppliers, or components. By analyzing factors like natural hazards, geopolitical tensions, climate-related events, and structural risks, Sentrisk offers actionable insights that help businesses develop tailored risk mitigation strategies.

Certa’s Generative AI-Powered Third-Party Management

Certa launches a generative AI-powered platform that automates the conversion of unstructured data from contracts, SOC reports, and ESG disclosures into structured, actionable insights. This capability allows organizations to gain a clearer understanding of their third-party ecosystems and make informed decisions.

Certa’s platform features natural language workflow design, automated risk assessments, and plug-and-play ESG modules that facilitate compliance with global standards such as the Corporate Sustainability Reporting Directive (CSRD) and the EU Deforestation Regulation (EUDR).

Further, Certa proactively navigates regulatory complexities and maintains compliant and sustainable third-party relationships.

Spotlighting an Innovator: Lyric

Lyric is a US-based startup that offers Lyric Studio, an AI-driven platform designed to enhance risk management and compliance within supply chain operations. The platform integrates a four-layer architecture, i.e., data, algorithms, workflows, and user interfaces, to convert raw data into actionable insights. This is done through native integrations, no-code configurations, and customized algorithms.

Its GPU-accelerated computing, including NVIDIA cuOpt, enables rapid scenario testing and optimization. Its composable modeling environment allows users to tailor workflows and applications to specific business needs.

Moreover, Lyric allows organizations to proactively manage risks and ensure compliance by providing scalable, adaptable tools that support intelligence across the supply chain landscape.

9. Production Planning & Optimization

The smart algorithm also optimizes production schedules by evaluating machine capabilities, labor availability, and order priorities. Lenovo’s AI-powered advanced production scheduling (APS) system increases production capacity by 24%.

Similarly, predictive maintenance powered by AI and the IoT prevents equipment failures by analyzing vibration, temperature, and performance data. BMW, for example, achieves a 20% increase in efficiency and minimizes unplanned downtime by using predictive maintenance in its production lines.

AI plays a role in quality control and yield enhancement. For instance, Intel employed machine learning to boost semiconductor yield by 30%. AI plays a pivotal role in assembly lines.

Toyota deployed AI-driven robotics and computer vision to inspect thousands of components daily, which reduced defects by 30%. This led to a simultaneous 20% reduction in inventory costs.

AI improves accuracy in demand forecasting by 50% higher accuracy. For instance, Unilever’s smart AI system integrates supplier data, customs records, and sustainability metrics into demand forecasts. AI-powered tools reduce supply chain downtime by 30% during disruption.

Also, recurrent neural networks (RNNs) generate dynamic forecasts. Koch Industries, for example, employs AI to optimize SKU-level supplier bases.

Key Benefits

Dynamic Production Scheduling

Advanced scheduling systems harness machine learning to analyze real-time data, enabling manufacturers to adapt production schedules swiftly in response to demand fluctuations, equipment availability, and supply chain disruptions. This agility ensures optimal resource utilization and minimizes downtime.

Inventory Optimization

Predictive analytics tools assess historical sales data, market trends, and external factors to forecast demand accurately. By aligning inventory levels with these forecasts, businesses reduce holding costs, prevent stockouts, and improve customer satisfaction.

Capacity Planning

Intelligent capacity planning solutions evaluate production capabilities, workforce availability, and equipment constraints to determine optimal production levels. By simulating various scenarios, these systems support manufacturers to make informed decisions and balance supply with demand.

Popular Companies and Tools

RELEX Solutions

RELEX Solutions’ unified platform integrates demand forecasting, supply optimization, and production scheduling. RELEX’s platform enables businesses to anticipate market changes and align production with real-time demand. Leveraging advanced analytics, the system helps manufacturers reduce waste and improve availability.

Eurocell’s Transformation with Peak’s Inventory AI

Eurocell, a UK-based manufacturer and distributor of UPVC products, deploys Peak’s Inventory AI solution. Facing the challenge of balancing inventory across over 220 branches, Eurocell utilized Peak’s AI to use real-time inventory tracking and demand forecasting.

The implementation led to a GBP 1.86 million release in inventory, a 6.7% increase in product availability, and a GBP 50 higher average order value.

Further, by integrating restocking targets into its enterprise resource planning (ERP) system, Eurocell achieves optimized stock levels and better visibility for branch managers. This process ensures products are available when and where customers need them.

Spotlighting an Innovator: SupplyET

SupplyET, a German company, offers a visual AI-powered supply chain planning platform. It enables manufacturers to optimize production capacity and adapt swiftly to market changes.

Its plug-and-play software combines a no-code interface with advanced optimization algorithms for planners to model complex production scenarios and identify optimal machine allocations within seconds.

The platform integrates with existing IT systems that facilitate rapid deployment and minimize the need for extensive training. Its accelerated planning processes reduce capital expenditures by avoiding unnecessary equipment investments and enhance resilience in production networks.

Further, SupplyET’s intuitive, data-driven process empowers manufacturers to build agile and future-proof operations.

10. AI-Driven Customer Interactions

AI-powered chatbots allow customers and logistics staff to access real-time order and shipment information via natural language. This reduces response times and increases satisfaction. AI-powered bots also assist in warehouse management and customer support.

Further, chatbots handle tasks like order placement and returns processing. BotCore’s chatbots, for example, enable customers to retrieve order details using tracking numbers, check delivery statuses, and manage amendments autonomously.

Businesses also integrate ERP systems with chatbots to receive real-time updates on inventory levels, production schedules, and supplier lead times. AI synchronizes data across supply chain nodes to anticipate disruptions and communicate proactively with customers.

Unilever’s AI-driven customer connectivity model integrates real-time sales data with supplier networks to synchronize inventory replenishment the moment a product is purchased. This reduces supply chain downtime during disruptions.

Similarly, Deposco’s AI platform reduces logistics costs by 15% and improves delivery reliability by 20% through predictive route optimization.

AI-powered voice and visual search optimization further allows customers to interact using their preferred methods. NICE’s AI-driven systems employ NLP and robotic process automation to update shipment statuses automatically and generate invoices.

Key Benefits

24/7 Customer Support

Conversational agents provide round-the-clock assistance by handling routine logistics inquiries like shipment tracking and delivery estimates. This continuous availability ensures customers receive immediate responses.

Real-Time Shipment Tracking

Advanced tracking systems integrate with GPS and IoT devices to offer customers real-time updates on their shipments. This transparency allows customers to monitor their orders from dispatch to delivery.

Faster Response Times

Intelligent customer service platforms analyze data to provide quick and accurate responses to customer queries. By automating information retrieval and response generation, these systems significantly reduce wait times.

Popular Companies and Tools

DHL Parcel Benelux’s Chatbot Tracy

DHL Parcel Benelux has implemented Chatbot Tracy, developed in collaboration with CM.com. Tracy utilizes conversational AI to provide real-time, personalized responses to both business and consumer inquiries across multiple digital channels.

Its integration with DHL‘s core systems enables it to access real-time data and deliver context-aware assistance. The chatbot handles a broader range of queries and reduces the need for human intervention in routine inquiries.

By automating common customer service tasks, Tracy improves operational efficiency and allows human agents to focus on more complex issues.

DTDC’s DIVA 2.0

DTDC Express launches DIVA 2.0, which offers real-time assistance in 17 regional Indian languages. This multilingual support ensures that a diverse customer base can interact with the virtual assistant in their preferred language.

DIVA 2.0 leverages advanced natural language understanding (NLU) and machine learning algorithms to interpret customer queries and provide accurate, human-like responses. With each interaction, the system learns and adapts, continually improving its performance and the quality of assistance provided.

By automating routine inquiries and providing instant support, DIVA 2.0 reduces the workload on human customer service agents, allowing them to focus on more complex tasks.

Spotlighting an Innovator: MakTek

MakTek, a UAE-based company, delivers an AI-powered platform that integrates predictive maintenance and supply chain optimization to enhance operational efficiency.

The platform employs advanced machine learning algorithms and real-time analytics to monitor equipment health, forecast maintenance needs, and streamline supply chain processes.

MakTek’s platform further analyzes sensor data and historical performance metrics to identify potential equipment failures before they occur.

Simultaneously, it optimizes supply chain operations by predicting demand fluctuations and adjusting inventory levels accordingly.

Key Drivers Leading to the Adoption of AI in the Supply Chain Industry

Growing Demand for Real-Time Visibility and Traceability

The need for complete, real-time visibility across supply chains has accelerated AI adoption. Companies now prioritize real-time tracking of goods, faster issue resolution, and better transparency to stay agile.

A recent study found that approximately 68% of supply chain organizations have integrated AI-driven visibility tools.

For example, Amazon employs AI-powered inventory systems that enable routing and inventory placement, which improves delivery reliability and customer satisfaction.

Predictive Analytics for Demand Forecasting and Inventory Optimization

Accurate demand forecasting is critical to minimize excess inventory and stockouts. AI analyzes historical sales data, external market conditions, and seasonal trends to provide actionable forecasts.

Zara utilizes AI-driven predictive analytics to adjust production and distribution dynamically, ensuring a fast response to rapidly changing fashion trends.

Operational Efficiency and Cost Reduction

Operational inefficiencies, such as manual warehouse management and route planning, contribute to major cost burdens. AI solutions address these by automating repetitive tasks and optimizing processes.

Early adopters reported up to a 15% reduction in logistics costs and a 35% decrease in inventory levels through AI adoption.

For instance, Tesla integrates AI into its production lines and supply chain operations to monitor performance metrics, optimize material flow, and reduce operational delays.

Improved Quality Control

Ensuring product quality is critical for brand reputation and customer loyalty. AI-based quality control systems detect defects early in the manufacturing process using machine learning and computer vision.

Around 82% of supply chain organizations have implemented AI for quality control, achieving an 18% reduction in product defects.

Industry-wide, companies now rely on AI to automate defect detection, minimizing returns and enhancing customer satisfaction.

Competitive Pressures

The rise of AI-powered supply chain models among leading enterprises has created competitive pressure across industries. Companies that delay adoption risk losing market share and operational advantages.

In the retail sector alone, AI-driven supply chain optimization commands a 24.1% market share, underscoring the competitive necessity of AI implementation.

Amazon and Walmart’s aggressive use of AI in logistics and fulfillment serves as a benchmark for the industry.

Future of AI in the Supply Chain Industry

Self-Healing Supply Chains

AI will drive the evolution of self-healing supply chains, where disruptions like natural disasters or geopolitical conflicts are autonomously detected and resolved. AI systems will reroute shipments, switch suppliers, and adjust production schedules without human intervention, ensuring business continuity.

Impact: Autonomous disruption mitigation will significantly reduce downtime and operational losses.

Ethical AI Auditing Systems

The future supply chain will integrate ethical AI auditing systems to ensure transparency and compliance. AI will monitor suppliers for labor practices, environmental standards, and resource usage using NLP and satellite imagery analysis.

Impact: Real-time ESG compliance will become the standard, enabling companies to meet evolving regulatory demands dynamically.

Hyper-Personalized Last-Mile Delivery

AI will improve last-mile delivery by predicting optimal delivery windows based on customer behavior and enabling in-transit customization through 3D printing.

Impact: Failed delivery attempts could drop by 40%, and customer satisfaction will significantly increase.

Quantum AI for Ultra-Complex Optimization

Quantum machine learning will solve complex optimization problems such as multi-tier global routing and tariff minimization across massive networks.

Impact: Supply chains will achieve new levels of efficiency and transparency.

Bio-Inspired Swarm Intelligence

Drawing inspiration from natural ecosystems, AI swarms will self-organize warehouse robots and develop adaptive packaging materials.

Impact: Shipping costs could fall while warehouse workflows become more efficient and responsive to real-time demand.

Finding the Best AI Solutions for Your Business

With thousands of emerging AI technologies and startups, navigating the right investment and partnership opportunities is challenging.

With access to over 7 million emerging companies and 20K+ technologies & trends globally, our AI and Big Data-powered Discovery Platform equips you with the actionable insights you need to stay ahead of the curve.

Leverage this powerful tool to spot the next big thing in AI before it goes mainstream. Stay relevant, resilient, and ready for what is next.

![AI in Supply Chain: A Strategic Guide for Industry Leaders [2025-2030]](https://www.startus-insights.com/wp-content/uploads/2025/05/AI-in-Supply-Chain-SharedImg-StartUs-Insights-noresize-420x236.webp)