Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

The wind power industry plays a critical role in the transition to a climate-positive and low-carbon future. The abundance of wind energy makes it an attractive option for countries to reduce their dependence on fossil fuels and cut down emissions. Advances in technology are improving efficiency, reducing expenses, and increasing the sustainability of wind energy operations. This article provides an overview of the top 10 global wind energy trends in 2023. They range from artificial intelligence (AI) and robotics to novel blade design and closed-loop recycling. Read more to explore the latest developments in the wind power industry and how they impact your business.

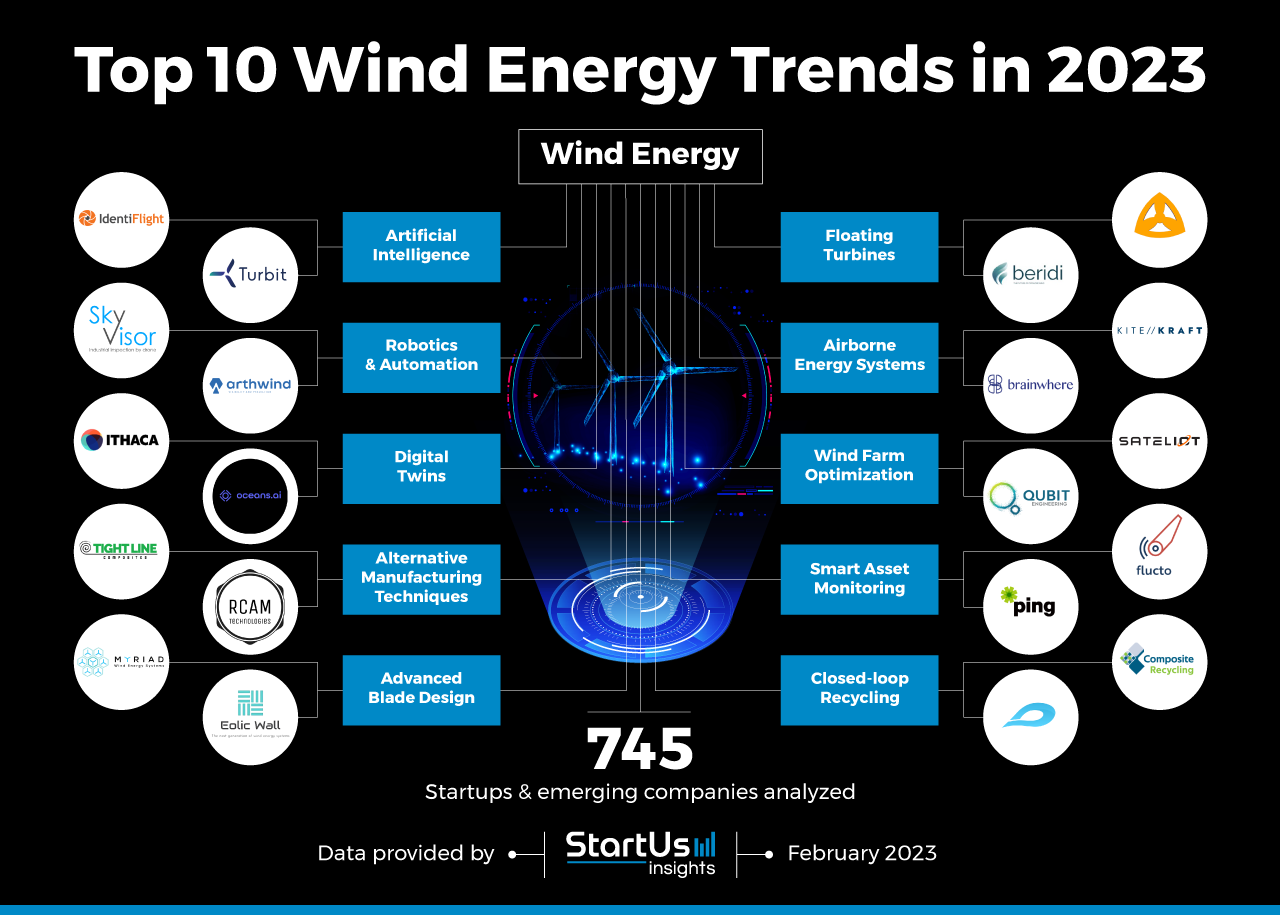

Innovation Map outlines the Top 10 Wind Energy Trends & 20 Promising Startups

For this in-depth research on the Top Wind Energy Trends & Startups, we analyzed a sample of 745 global startups & scaleups. The result of this research is data-driven innovation intelligence that improves strategic decision-making by giving you an overview of emerging technologies & startups in the energy industry. These insights are derived by working with our Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 3 790 000+ startups & scaleups globally. As the world’s largest resource for data on emerging companies, the SaaS platform enables you to identify relevant startups, emerging technologies & future industry trends quickly & exhaustively.

In the Innovation Map below, you get an overview of the Top 10 Wind Energy Trends & Innovations that impact 745 companies worldwide. Moreover, the Wind Energy Innovation Map reveals 20 hand-picked startups, all working on emerging technologies that advance their field.

Top 10 Wind Energy Trends in 2023

- Artificial Intelligence

- Robotics & Automation

- Digital Twins

- Alternative Manufacturing Techniques

- Advanced Blade Design

- Floating Turbines

- Airborne Energy Systems

- Wind Farm Optimization

- Smart Asset Monitoring

- Closed-loop Recycling

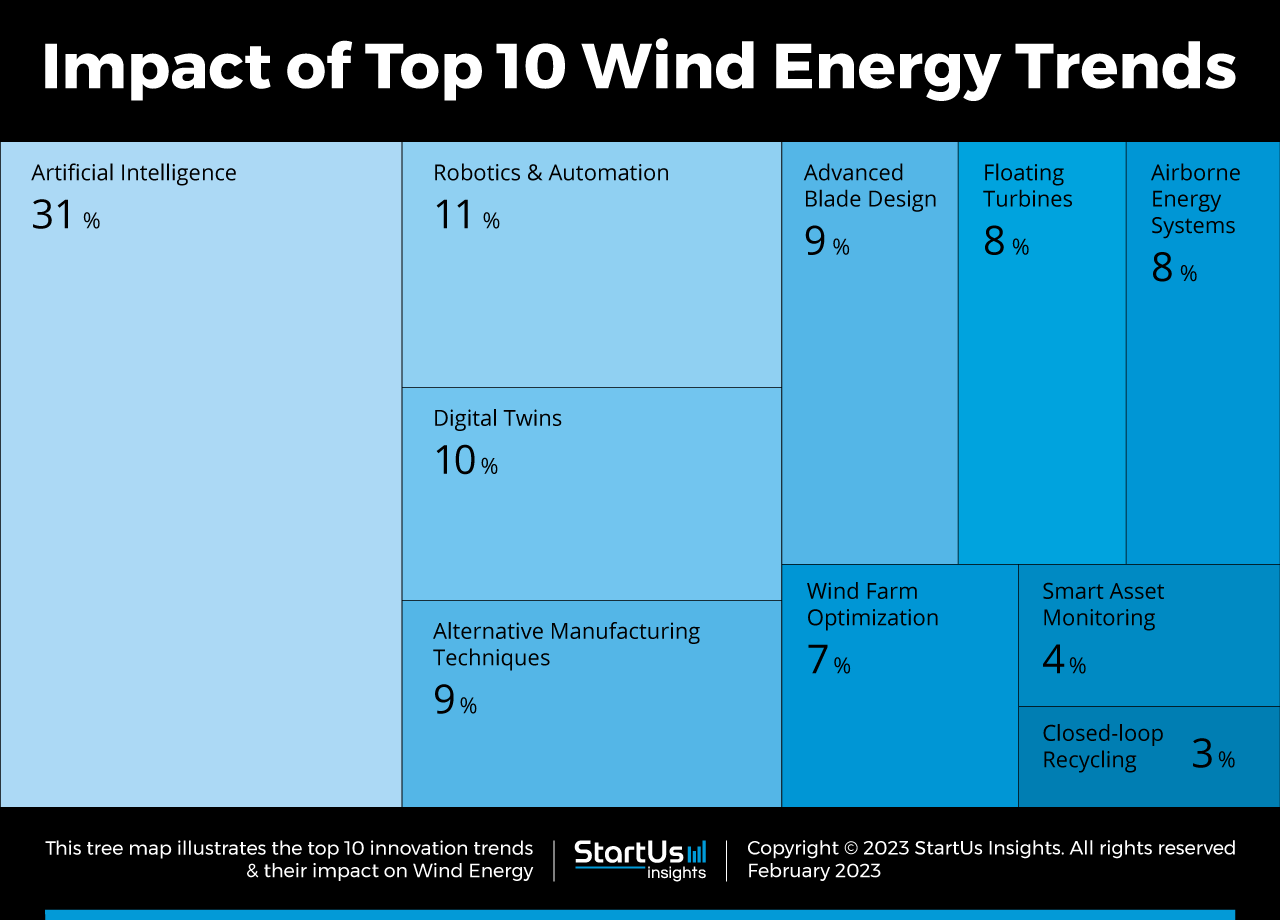

Tree Map reveals the Impact of the Top 10 Wind Energy Trends

Based on the Wind Energy Innovation Map, the Tree Map below illustrates the impact of the Top 10 Wind Energy Trends in 2023. AI and digital twins optimize wind turbine performance and enable predictive maintenance. At the same time, robotics and process automation improves worker safety in turbine manufacturing and inspection. Alternative manufacturing utilizes 3D printing and advanced materials to simplify production and transportation. Novel blade designs also offer more opportunities to increase wind turbine efficiency. Meanwhile, alternative means of wind energy harvesting, like floating turbines and airborne energy systems, are gaining traction. Wind farms are further leveraging the internet of things (IoT), satellites, 5G, and more to prolong equipment lifespan, streamline operations, and improve asset monitoring. Lastly, closed-loop recycling ensures high-value material recovery from decommissioned wind turbines, reducing the need for virgin raw materials.

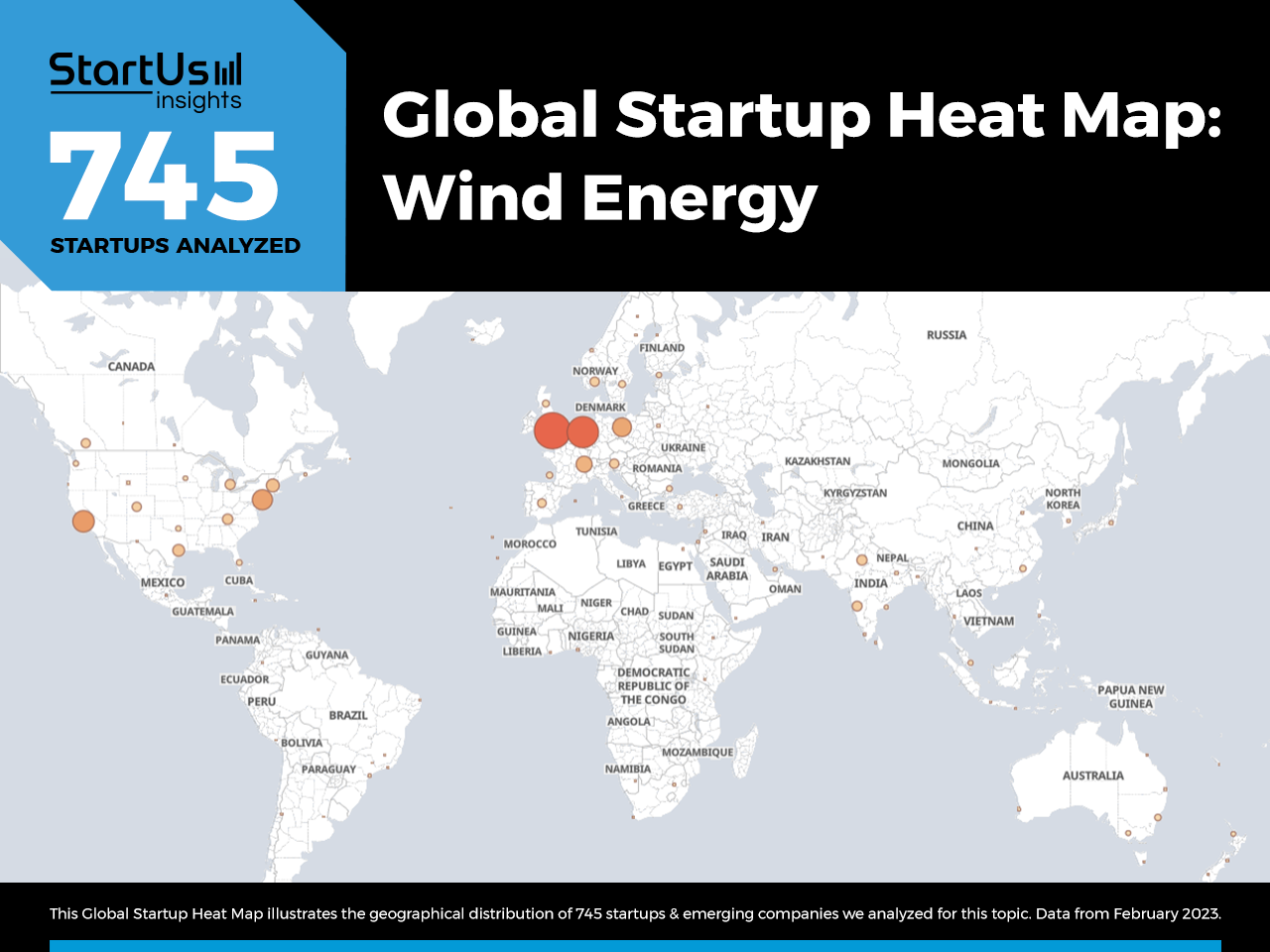

Global Startup Heat Map covers 745 Wind Energy Startups & Scaleups

The Global Startup Heat Map below highlights the global distribution of the 745 exemplary startups & scaleups that we analyzed for this research. Created through the StartUs Insights Discovery Platform, the Heat Map reveals that Western Europe sees the most startup activity.

Below, you get to meet 20 out of these 745 promising startups & scaleups as well as the solutions they develop. These wind energy startups are hand-picked based on criteria such as founding year, location, funding raised, & more. Depending on your specific needs, your top picks might look entirely different.

Top 10 Wind Energy Trends in 2023

1. Artificial Intelligence

Startups are developing various solutions using AI, machine learning (ML), computer vision, neural networks, and deep learning for the wind energy industry. They speed up data processing workflows and deliver insights into critical operations to increase efficiency and reduce costs. For instance, AI algorithms optimize the performance of wind turbines by predicting wind patterns and adjusting blade positions. Improved weather forecasting and real-time analytics aid wind farm operators in making better decisions. Additionally. computer vision-powered inspection platforms remotely analyze wind turbines for damage. This allows inspectors to promptly identify asset problems and also enables predictive maintenance.

Turbit Systems advances Predictive Wind Turbine Maintenance

German company Turbit Systems uses AI to improve wind turbine operations and maintenance. The startup’s AI-based predictive maintenance solution detects and resolves underperformance issues early on. Using ML algorithms and advanced analytics, it identifies abnormal behavior patterns in wind turbine component data. The startup’s companion smart dashboard provides automatic reports, statistical visualizations, and benchmark comparisons. Turbit Systems thus reduces costs and maintenance efforts, benefiting operators and asset managers.

IdentiFlight offers a Bird Detection System

US-based startup IdentiFlight combines AI, ML, and high-precision optics to protect birds. Unlike traditional solutions, the startup’s proprietary machine vision technology detects birds a kilometer afar in real-time. It also utilizes a convolutional neural network to gather data and train its bird detection system. This optical technology features a wide field of view (WFOV) and high-resolution stereoscopic (HRSC) cameras. As a result, the startup’s bird detection system curtails the blades to protect them from collisions. This way, IdentiFlight minimizes unnecessary and costly interruptions during turbine operations.

2. Robotics & Automation

Process automation in wind farms employs a combination of software and hardware solutions. This includes supervisory control and data acquisition (SCADA) systems and programmable logic controllers (PLCs) to automate turbine pitch, power output, alarms, etc. Startups are also integrating machine learning and cloud computing to make such systems more accessible and accurate. Moreover, autonomous inspection robots and unmanned surface vehicles (USVs) minimize manual labor requirements. For example, climbing robots reduce the associated risks of working at heights. Additionally, sensor-integrated drones for aerial surveys significantly save inspection time. Wind farm managers and workers benefit from the use of robots and drones as they reduce maintenance costs and downtime while improving workplace safety and farm performance.

SkyVisor provides Autonomous Turbine Inspection

French startup SkyVisor develops SkyVisor Wind, an autonomous drone for wind turbine inspection. It features AI-based asset performance data acquisition and processing. The drone also features centimetric positioning and collects 120 standardized high-resolution images per blade. Additionally, the startup’s software optimizes inspection frameworks based on the weather, technician planning, and local drone regulations. This enables the detection of erosion, lightning impacts, voids, and clogged drain holes, allowing wind farms to reduce downtime and follow cost-effective maintenance strategies.

ArthWind develops Robotic Crawlers

Brazilian startup ArthWind provides robotic crawlers and drones for wind turbine internal and external inspections. The startup’s robotic crawler, Arthbot, explores dangerous and hard-to-reach areas and enables repeatable data collection, ensuring greater visibility and reliability. Besides, ArthWind’s drone makes high-quality image maps for the detailed analysis of damage levels. Consequently, the startup’s solutions eliminate the need for manual inspections, reducing time and costs for wind turbine owners.

3. Digital Twins

By using data collected from sensors on wind turbines, startups create virtual replicas, or digital twins, of wind farm assets. Digital twins find applications in turbine performance optimization, wind farm design and planning, failure diagnosis, safety analysis, and more. By simulating and analyzing the performance of wind power projects, they deliver valuable data to enhance decision-making. Digital twins also maximize energy production by simplifying energy modeling while reducing costs and improving safety. This is especially important for wind energy equipment manufacturers, maintenance teams, and regulators.

ITHACA provides Offshore Wind Project Digital Twins

US-based startup ITHACA makes ODISY, a digital twin platform for offshore wind projects. It generates a digital replica of various stages in wind farm projects, such as construction, maintenance, and decommissioning. The platform also features cloud-based data storage, weather-based project timeline creation, digital record keeping, and dynamic monitoring. 3D asset visualization through ODISY thus allows offshore wind developers to leverage data-driven decision-making.

oceans.ai delivers Wind Turbine Simulations

Singaporean startup oceans.ai develops cognitive digital twin solutions by combining IoT sensors, robotics, and drones. The startup’s digital twin system, INSYD, simulates turbine performance. Its AI-powered time-series analysis then helps prevent failures and unexpected disruptions. For instance, the AI tracks degradation and changes in wind turbines and visually predicts which parts are wearing out the most. This results in improved operational efficiency, preventing wind turbine downtimes.

4. Alternative Manufacturing Techniques

The wind power industry is leveraging innovative manufacturing techniques to increase operational efficiency, safety, and sustainability. For instance, part manufacturers use advanced materials, such as carbon fiber and fiberglass, to create wind turbine blades and components. They are lighter and stronger, resulting in improved performance. Besides, 3D printing enables rapid prototyping, allowing engineers to quickly finalize their designs for mass production. It enables quick production of replacement parts as well as simplifies repair and maintenance processes. Lastly, automated assembly lines ensure efficient and seamless integration of wind turbine components like blades, nacelle, and towers. This way, alternative manufacturing techniques deliver time and cost-effective solutions while ensuring sustainable manufacturing.

Tight Line Composites offers Pultruded Material

US-based startup Tight Line Composites manufactures carbon fiber-reinforced plastic (CFRP) profiles for wind energy applications. Its pultruded products portfolio contains flat laminates, solid round rods, round tubes, square tubes, and custom shapes. These reinforced plastic products feature lightweight, high strength, corrosion resistance, high durability, and increased efficiency. This way, the startup provides wind turbine producers with high-performance and energy-efficient materials that improve structural integrity while reducing costs.

RCAM Technologies provides 3D Concrete Printing

US-based startup RCAM Technologies utilizes 3D concrete printing for use in the wind industry. Since current wind turbine towers are difficult to transport, the startup develops on-site 3D-printed towers to reduce material and transportation costs. The startup’s locally 3D-printed suction anchors for floating wind farms use domestic materials to reduce the carbon footprint. RCAM Technologies also makes a modular concrete tripod structure that mitigates the need for heavy lift vessels. This approach reduces costs and installation noise while optimizing coastal supply chains for offshore and onshore wind turbine owners.

5. Advanced Blade Design

Existing wind turbines are bulky and loud, and they do not operate in changing weather conditions. To meet growing energy demands and address technical challenges, startups are developing innovative blade designs. This includes twisted, variable-pitch, airfoil, adaptive, and bionic blades. Twisted blades reduce noise and vibrations while airfoil blades have a curved shape to maximize drift. On the other hand, variable-pitch and adaptive blades change the angle and shape under changing wind conditions. Startups also take inspiration from bird wings to design bionic blades with self-cleaning materials. These innovations help wind turbine manufacturers to improve efficiency, performance, and cost-effectiveness.

Myriad Wind Energy Systems designs High-Performance Wind Turbines

UK-based startup Myriad Wind Energy Systems produces high-performance, multi-rotor wind turbines. Conventional bulky turbines are difficult to transport, install, and maintain, whereas the startup’s multi-rotor systems are more cost-effective and energy efficient. Moreover, they incorporate multiple small units with built-in inherent redundancy. This ensures continuous energy production and increased reliability even if one unit fails. Therefore, the altered blade design generates more energy, increasing revenue for wind farms.

Eolic Wall makes At-home Wind Turbines

Eolic Wall is a Peru-based startup that provides an at-home wind energy system utilizing its proprietary technology, Eolic Cells. Its aerodynamic structures increase wind speed to extract more energy from wind resources. To minimize mechanical losses, Eolic Cells features a peripherally supported magnetic levitation turbine. The blades of the turbine also widen towards the tip to maximize energy production to better utilize high wind velocity. Further, its modular design allows for customized solutions to meet specific energy needs while the enclosure protects the rotors. This results in a compact at-home wind solution that provides residents with more energy.

6. Floating Turbines

Floating wind turbines are placed in deeper waters where wind speeds are stronger and more consistent, This results in increased energy generation compared to land-based wind turbines. By not being limited by land availability, floating turbines reduce project costs, visual impacts, and potential land conflicts. Innovations in the field include concrete and steel foundations, advanced mooring systems with dynamic positioning, sensor-based automation, and remote monitoring. This reduces the environmental impact of wind energy projects. For the energy industry, floating wind turbines offer a way to diversify energy-sourcing portfolios and reduce reliance on fossil fuels.

Ægir Harvest builds a Floating Wind Turbine Foundation

Norwegian startup Ægir Harvest develops a floating wind turbine foundation. It is based on a tension leg platform (TLP) and reduces the cost of assembly, installation, and maintenance. Additionally, the foundation enables multiple deployments in deeper waters with stronger and more consistent wind resources. This results in a reduced levelized cost of electricity (LCOE), wider accessibility, and scalability for offshore wind energy projects.

Beridi Maritime constructs a Concrete Floating Platform

Spanish startup Beridi Maritime delivers a concrete-based platform to ensure the safe installation of offshore wind turbines. It is a single, hollow, and sturdy concrete structure that features extra resistance to dynamic sea pressures. The platform also stays stable during transport, installation, and operation with minimal oscillations. The technology is compatible with common fabrication methods used in the port industry, which allows for fast construction without specialized facilities. As a result, Beridi’s low-cost floating platforms reduce the environmental impacts of offshore installations, benefiting energy producers and coastal communities.

7. Airborne Energy Systems

Airborne energy systems harness consistent and stronger winds at higher altitudes. They typically consist of a kite, a tether, and a generator on the ground. Several improvements in the field revolve around automatic control of the energy systems’ position and orientation, integration of hydro and solar power, usage of composites, and novel tethered systems like kytoons. Consequently, airborne wind systems enhance energy accessibility in remote locations and improve energy security.

Kitekraft offers Airborne Electric Aircraft

German startup Kitekraft generates airborne wind energy using tethered electric aircraft. The startup’s aircraft, kite, features eight onboard wind turbines, which allows it to autonomously fly in figure-eight patterns and generate electrical energy from the wind. Its box plane structure, truss-like airframe, and aluminum body maximize rigidity while keeping weight to a minimum.

Brainwhere makes a Vertical Airborne System

Swiss startup Brainwhere converts high-altitude wind energy into electricity using its vertical airborne system, Brainwhere Airborne. It features a vertical multi-component system that reaches and functions at the jet stream level. Rather than waiting for wind, the startup deploys turbines based on weather predictions. Further, the generator acts as a motor during takeoff, landing, or during weak wind periods. Moreover, real-time adjustments of each wing’s pitch angle ensure the system’s stability and control. Brainwhere’s sustainable technology aids off-grid and offshore wind parks.

8. Wind Farm Optimization

Wind farm optimization focuses on improving the efficiency, safety, and profitability of wind power operations. Startups are utilizing satellites, IoT, 5G, high-performance computing (HPC), and advanced control systems to achieve this. For instance, satellites gather information on wind patterns and weather conditions, allowing wind farm operators to predict energy output and adjust turbines. Wind parks equipped with IoT sensors monitor equipment performance to improve accuracy and reliability. Further, quantum computers process large amounts of data to run complex simulations and find the optimal positions for turbine deployment. Rather than controlling individual turbines, farm optimization maximizes the energy output of existing farm infrastructure without additional investments in new equipment.

Sateliot delivers Wind Power Forecasts

Spanish startup Sateliot develops nanosatellites powered by narrowband (NB)-IoT and 5G. The startup’s compact nanosatellites weigh around 12 kilos and circulate in a low-altitude orbit. They provide global connectivity using 5G, where the nanosatellites act as mobile towers connecting wind turbine sensors. By providing real-time data and enabling more informed decision-making, Sateliot optimizes wind farms with automated production, energy prediction, and predictive maintenance.

Qubit Engineering aids Wind Farm Layout Optimization

US-based startup Qubit Engineering implements quantum computing for wind farm layout optimization. The startup’s quantum software for micro-siting wind turbines delivers a comprehensive view of the project site. Its optimization algorithms gather data including potential construction sites, wind data, and land features. Further, the quantum software quickly selects the best locations for wind farm turbines and provides real-time estimation of energy production. This approach significantly improves wind power generation and minimizes asset failure from wake turbulence. By efficiently distributing loads, Qubit Engineering boosts wind farm performance and extends turbine longevity for wind farm developers and operators.

9. Smart Asset Monitoring

Continuous asset monitoring is crucial to identify potential turbine issues, reduce downtime, and extend their lifespan. Startups leverage advanced analytics, IoT, wireless connectivity as well as remote and condition-based monitoring to achieve this. Sensors integrated into wind turbines collect data on wind speed, blade angle, temperature, and more to detect failures. This helps to maximize turbine performance and schedule maintenance in advance. Besides, remote monitoring allows project managers to track equipment health and performance in real-time. By doing so, smart asset monitoring solutions increase transparency for better-informed decision-making, aiding operators and managers in lowering maintenance costs.

Flucto provides Digital Wind Farm Monitoring

German startup Flucto integrates digital monitoring technologies in offshore wind farm installations. The startup utilizes a motion sensor box with a single-board computer, navigation system, wireless connection, and cameras. It allows farm operators to measure accelerations, location, and time, as well as estimate weather conditions. For instance, the motion sensor box tracks collisions and wind properties to provide precise measurements for dynamic installations. As a result, Flucto helps wind farm owners assess asset performance for fast and cost-effective development.

Ping Services enables Continuous Wind Energy Generation

Australian startup Ping Services monitors wind turbine blade conditions for continuous wind energy generation. The startup’s device, Ping Monitor, tracks the acoustic signature of turbine blades to identify changes and damages. It monitors internal structural damage, external surface damage, and ice and lightning detection systems. This way, Ping Services improves the performance and efficiency of wind assets by allowing wind farm managers to mitigate asset failures and downtime.

10. Closed-loop Recycling

The construction of wind turbines generates waste, including scrap materials from the manufacturing process and waste from decommissioned turbines. Wind energy companies utilize closed-loop recycling to reduce the environmental impact of wind energy operations and reduce their carbon footprint. Since composite materials are difficult to recycle mechanically, startups offer chemical, mechanical, and hybrid recycling methods to reclaim valuable components. Additionally, upcycling, reusing, and refurbishing improve material and value recovery. For instance, some startups repurpose old blades for energy storage or water pumping. By recycling materials and components used in wind turbines, the industry reduces the need for virgin materials.

Composite Recycling aids Wind Turbine Composite Reclamation

Swiss startup Composite Recycling develops a closed-loop system for recycling glass fiber-reinforced polymer (GFRP) composites in wind turbines. The startup’s pyrolysis method extracts the fibers from the resin to convert them into pyrolysis oil. Then, its post-treatment process brings the recycled fibers back to their original appearance and functionality. As a result, this enables the wind industry to use the recovered fibers and pyrolysis oil to source raw materials resource-efficiently.

Wings for Living advances End-of-Life Turbine Blade Upcycling

German startup Wings for Living converts wind turbine rotor blades into outdoor furniture. Conventional saws are not able to cut the rotor blade due to the epoxy resin coating. Therefore, the startup applies a complex wire sawing process. Further, the startup creates seats and backrests from lacquered larch wood, handcrafted to fit each blade piece. This way, Wings for Living recycles nonfunctional wind turbine blades into delicate furniture pieces for urban planners and architects. Consequently, the startup reduces material wastage and advances the circular economy.

Discover all Wind Energy Trends, Technologies & Startups

The wind power trends advance clean energy transition and combat the climate crisis. Technological advances such as floating wind turbines, AI-powered predictive maintenance, modular wind systems, and offshore wind energy are driving the future of the industry. This way, wind power companies are able to move towards a greener future.

The Wind Energy Trends & Startups outlined in this report only scratch the surface of trends that we identified during our data-driven innovation & startup scouting process. Among others, floating wind plants, predictive maintenance, and continuous asset monitoring will transform the sector as we know it today. Identifying new opportunities & emerging technologies to implement into your business goes a long way in gaining a competitive advantage. Get in touch to easily & exhaustively scout startups, technologies & trends that matter to you!