Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

In recent years, polymer industry trends have brought improvements to various sectors, providing lightweight, durable, and versatile materials. However, the growing concern over plastic waste and environmental pollution has prompted a need for innovative solutions in polymer technology.

This is why startups are developing biodegradable polymers, polymer recycling, and polymer composites, as these innovations aim to mitigate the environmental impact of polymer usage. The polymer industry trends further address plastic waste as well as its potential for industries like packaging, automotive, construction, and healthcare.

What are the Top 10 Polymer Industry Trends in 2025?

- Biopolymers

- Recyclability

- Smart Composites

- Nanopolymers

- 3D Printing

- Novel Specialty Additives

- Advanced Thermoplastics

- Conductive Polymers

- Lightweighting

- Material Simulations

Methodology: How We Created the Polymer Trend Report

For our trend reports, we leverage our proprietary StartUs Insights Discovery Platform, covering 5M+ global startups, 20K technologies & trends plus 150M+ patents, news articles, and market reports.

Creating a report involves approximately 40 hours of analysis. We evaluate our own startup data and complement these insights with external research, including industry reports, news articles, and market analyses. This process enables us to identify the most impactful and innovative trends in the polymer industry.

For each trend, we select two exemplary startups that meet the following criteria:

- Relevance: Their product, technology, or solution aligns with the trend.

- Founding Year: Established between 2020 and 2025.

- Company Size: A maximum of 200 employees.

- Location: Specific geographic considerations.

This approach ensures our reports provide reliable, actionable insights into the polymer innovation ecosystem while highlighting startups driving technological advancements in the industry.

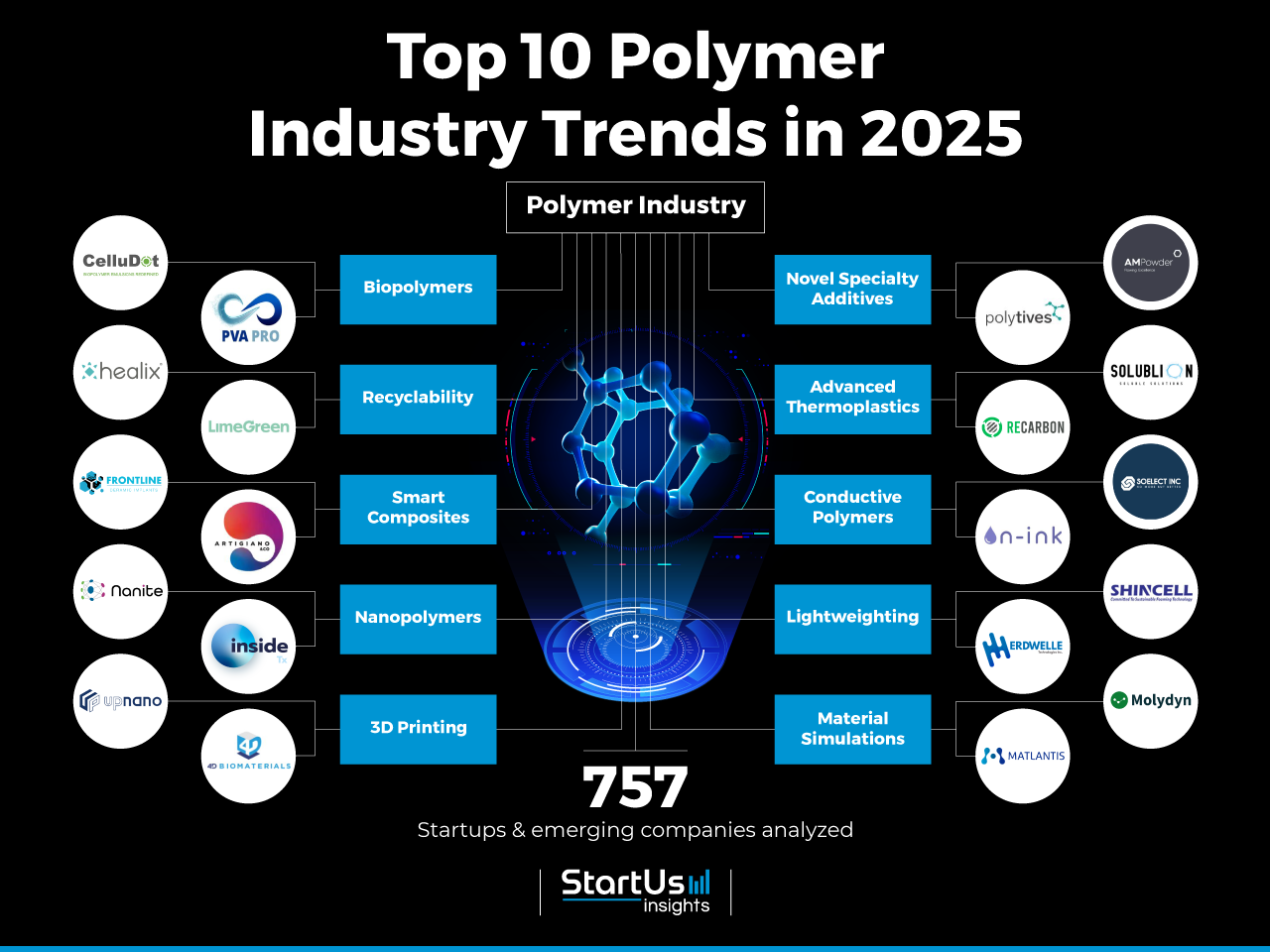

Innovation Map outlines the Top 10 Trends in Polymers & 20 Promising Startups

For this in-depth research on the Top Polymer Trends & Startups, we analyzed a sample of 750+ global startups & scaleups. The Polymer Innovation Map created from this data-driven research helps you improve strategic decision-making by giving you a comprehensive overview of the Polymer industry trends & startups that impact your company.

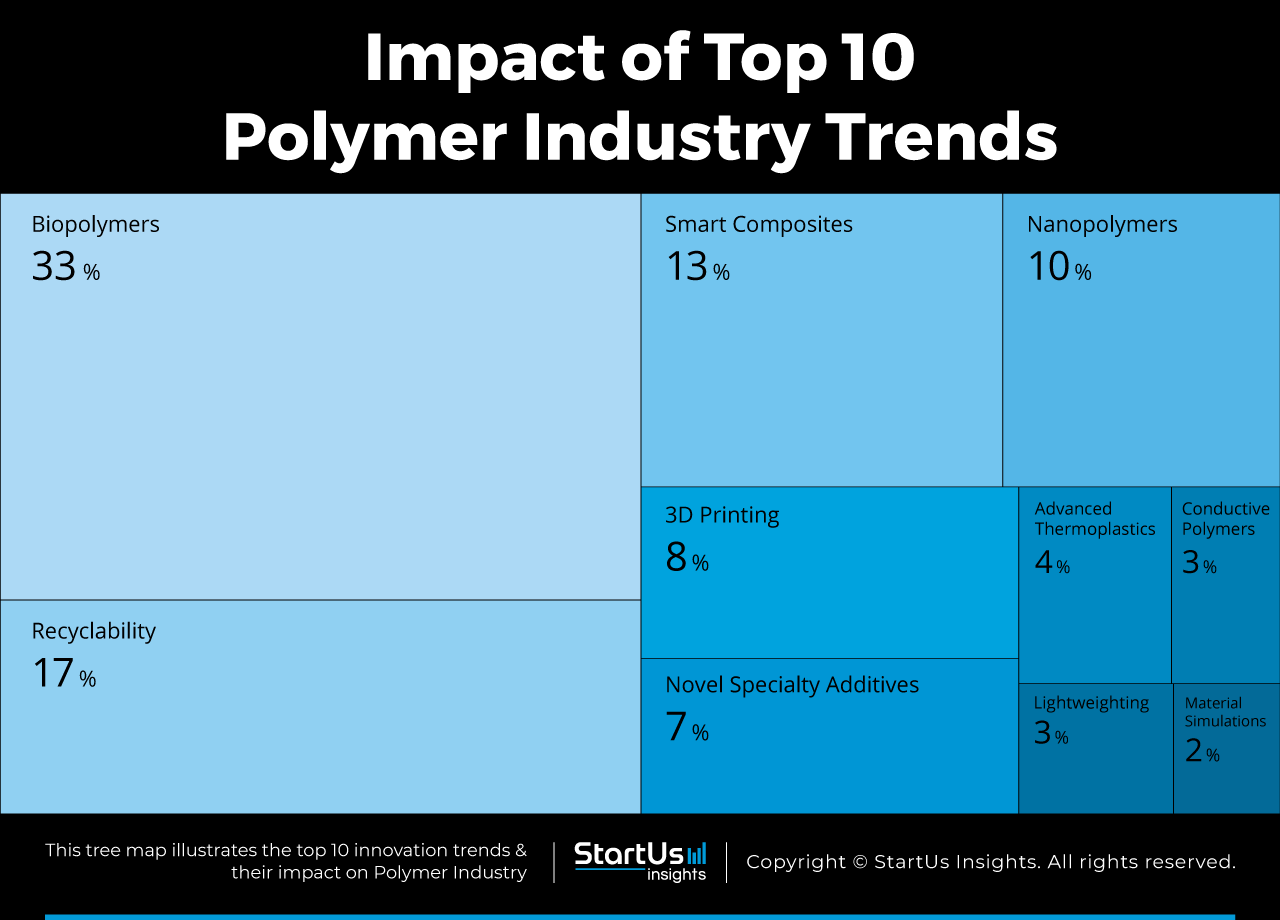

Tree Map reveals the Impact of the Top 10 Trends in the Polymer Industry

Based on the Polymers Innovation Map of 2025, biopolymers and recyclability are addressing the problem of growing polymeric waste promoting sustainability and reducing its environmental impact. Smart composites and nano polymers are creating materials with innovative properties and enabling high-performance and critical applications.

Meanwhile, 3D printing is transforming manufacturing processes by allowing complex geometries and customized designs.

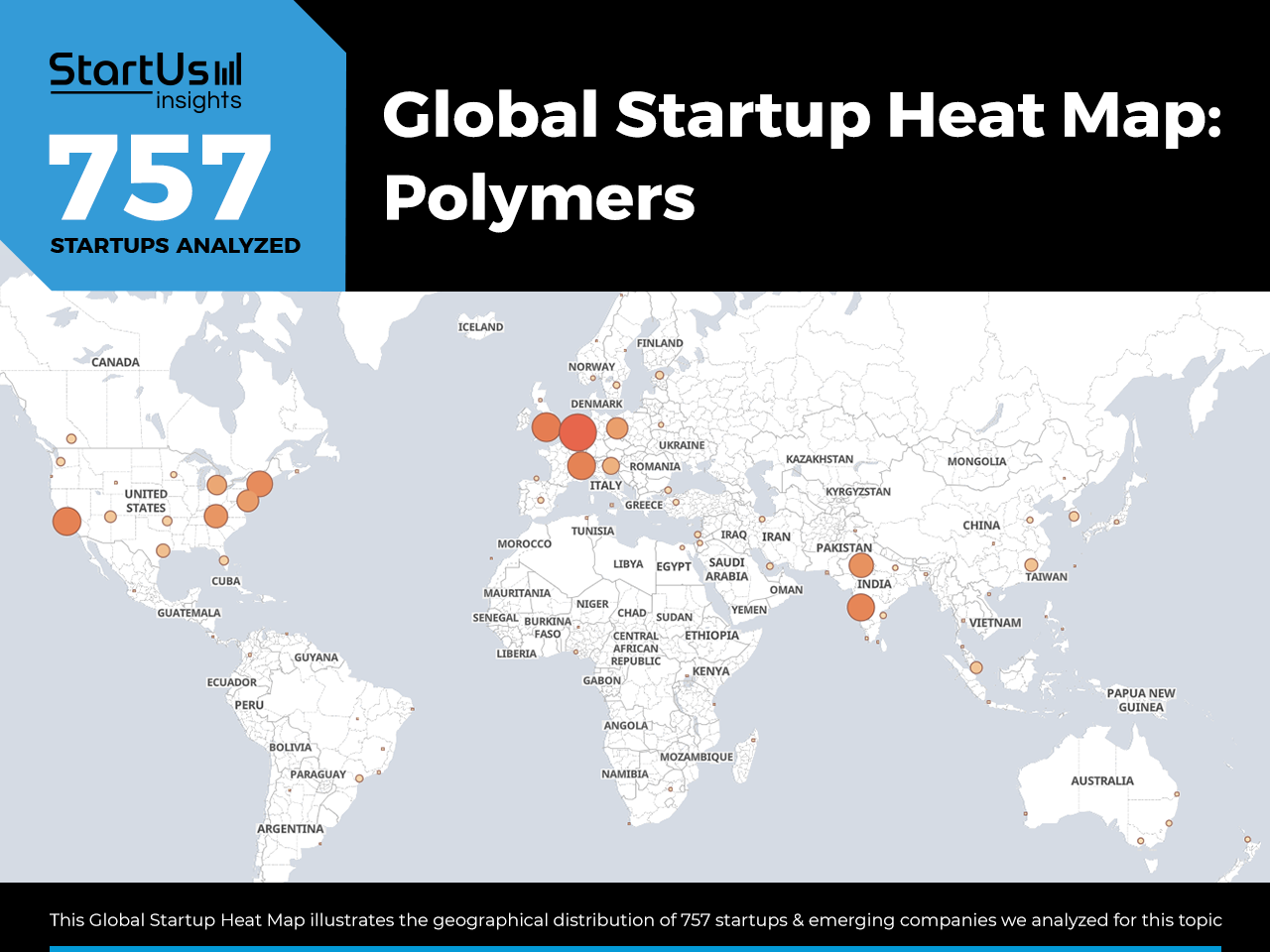

Global Startup Heat Map covers 750+ Polymer Startups & Scaleups

The Global Startup Heat Map showcases the distribution of 750+ exemplary startups and scaleups analyzed using the StartUs Insights Discovery Platform. It highlights high startup activity in Western Europe and the United States, followed by India. From these, 20 promising startups are featured below, selected based on factors like founding year, location, and funding.

Want to Explore Polymer Industry Innovations & Trends?

Top 10 Emerging Polymer Industry Trends [2025]

1. Biopolymers

Trends in polymer science currently tackle challenges with the need for sustainable alternatives to traditional petroleum-based polymers. As concerns about climate change and environmental degradation intensify, the demand for biopolymers has grown exponentially. Therefore, startups are developing biopolymers from renewable sources such as plants and microorganisms as a solution to this problem.

Innovations in the field of biopolymers include biodegradable, compostable, and renewable materials that effectively replace conventional plastics. Besides this, technological innovations in biopolymers, such as sustainable coatings and films offer improvements in biodegradability and barrier properties with benefits to industries like packaging, food preservation, and agriculture.

Additionally, electrospinning enables the production of nanofibers from biopolymers, offering valuable applications in tissue engineering, filtration, and energy storage.

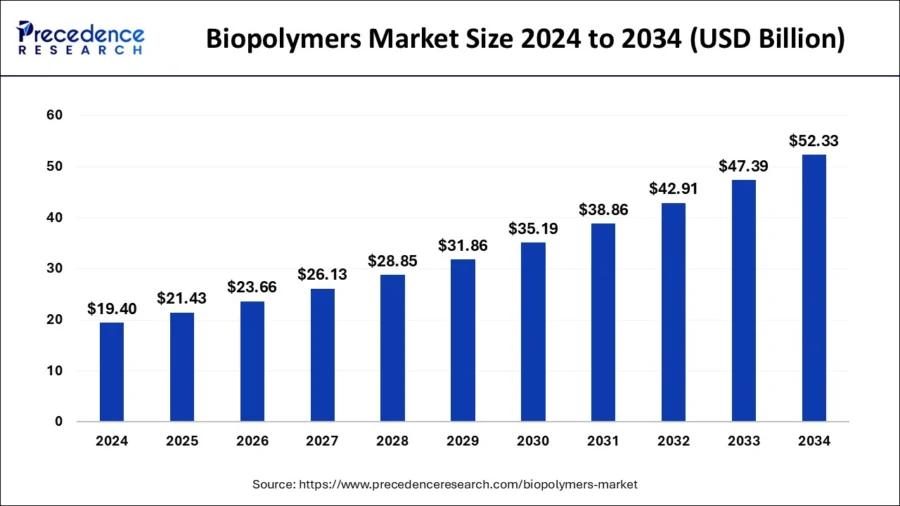

The global biopolymers market is set to reach USD 52.33 billion by 2034, growing at a compound annual growth rate (CAGR) of 10.43% from 2025 to 2034. One of the prevalent technologies improving biopolymers is artificial intelligence (AI).

Source: Precedence Research

CelluDot manages Agrochemical Drift Control

US-based startup CelluDot develops polymer technology to ensure agricultural chemicals remain at their intended use site to enhance safety and productivity.

The startup’s solution to herbicide drift involves a formulation called BioGrip which consists of nano cellulose-based networks that bind to the herbicide, reducing its vaporization and increasing its adherence to plants. CelluDot processes nano cellulose-based emulsions to create cost-effective agrochemical adjuvants, solving the problem of particle and vapor drift.

PVA PRO creates PVA-based Biopolymers

PVA PRO is a Vietnamese startup that develops AquaFlex, a PVA-based biopolymer that is water-soluble, biodegradable, compostable, recyclable, and safe for marine life. AquaFlex does not create micro-plastics and degrades safely once discarded which makes it an ideal replacement for traditional harmful plastics.

The startup also offers a range of AquaFlex products including dry packaging, garment packaging, gloves making, hot water soluble, cold water soluble, and paper extrusion coating. These products are strong, transparent, printable, heat-sealable, easy to use, and have a long shelf-life compared to other biopolymers.

Moreover, PVA PRO provides eco-friendly packaging solutions that are three times stronger than plastic, easy to use, and have a shelf-life of three to five years.

2. Recyclability

The current polymer industry struggles when it comes to recyclability, as conventional plastics often end up in landfills or pollute the environment. This is why startups are developing technological solutions to address this problem through the recycling of polymers.

Advancements such as chemical recycling, mechanical recycling, and novel sorting technologies enable the efficient and effective processing of plastic waste, leading to a more sustainable and circular approach.

Other innovations include the development of advanced sorting techniques, such as optical sorting and machine learning algorithms, to improve the efficiency and accuracy of plastic waste separation.

Additionally, chemical recycling methods, such as depolymerization and pyrolysis break down complex plastic waste into their molecular building blocks for the production of high-quality recycled polymers.

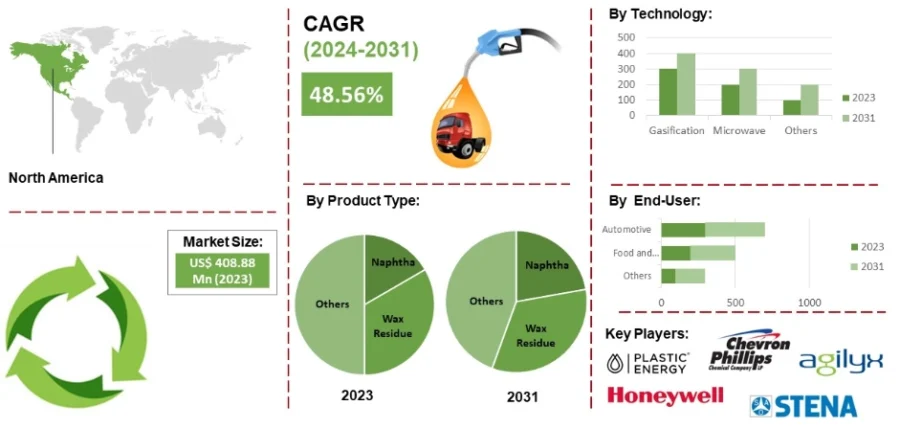

InsightAce Analytic predicts the global advanced recycling technology market size to reach USD 9.61 billion by 2031, at a CAGR of 48.56% during the forecast period for 2024-2031.

Advanced Recycling Technology Market Overview

Source: InsightAce Analytic

The main trends in the recyclability sector include an increase in chemical recycling, material reduction, expansion of rPET into fashion, textiles, and other sectors, and biodegradable alternatives to single-use plastics. In 2024, India allocated funds for 100 city plastic recycling infrastructures.

healix.eco innovates in Plastic Recycling

Dutch startup healix.eco creates a circular future for plastic fiber waste by transforming used ropes and nets from fishing and farming into virgin-like polymers for the global manufacturing supply chain. The recycling process involves reducing the size of the fibers, washing and drying the small particles, and then melting, filtering, and processing them into granules.

The startup’s extrusion process involves melting raw plastic and forming it into a continuous profile which is then cut into small pellets for optimal transport and processing. Helix’s technology also provides a solution to the plastic problem destroying marine life.

LimeGreen manufactures Artificial Grass

LimeGreen is a Dutch startup that focuses on the production of sustainable artificial grass using a single raw material for maximum recyclability and reduced energy consumption. The startup’s ONE-DNA artificial grass is fully recyclable and supports a circular economy through its transformation into new artificial grass after its lifespan.

Moreover, unlike other solutions, ONE-DNA does not require latex, PU, or PP dispersion coatings to achieve tuft lock. LimeGreen also offers various products that are ideal for playgrounds and sports fields and available in various colors and pile heights.

3. Smart Composites

Polymers offer various advantages such as versatility, lightweight properties, and cost-effectiveness, but they also come with their fair share of challenges. Issues like limited strength, poor durability, and environmental concerns hinder their widespread adoption in many applications.

However, innovations in smart composites are addressing these problems by integrating functional materials like shape memory alloys and advanced technologies such as 3D printing. These smart composites enhance the performance of polymers by providing added strength, self-healing capabilities, and resistance to degradation.

These composites leverage techniques like embedded sensors, nanotechnology, and responsive materials to create robust and sustainable solutions, enabling the development of more durable and eco-friendly polymer-based products for a wide range of industries.

The US composite market is set to grow by a CAGR of 5.6% from 2023 to 2030.

Source: Grand View Research

Frontline Ceramic Implants creates Dental Implants

US-based startup Frontline Ceramic Implants specializes in the use of smart composites like zirconia for implants and other autogenous bone graft materials. The startup’s product Zantex is a high-performance polymer matrix reinforced with a dense network of glass fibers in a three-dimensional arrangement.

Zantex enables dental technicians and dentists to fabricate substructures or frameworks that provide additional mechanical resistance for dental restorations. Despite its low density, Zantex exhibits high tensile strength as well as high flexural and compressive properties. It is also biocompatible, easily adjustable, requires no firing, and bonds well to most materials in current restorative dentistry.

Artigiano advances Polymeric Materials

Polish startup Artigiano specializes in the research and manufacturing of innovative polymeric materials, flame retardant compounds, and masterbatches.

The startup’s smart composite materials balance flame retardance and mechanical properties while meeting regulatory requirements for various applications and markets. Besides this, its flame retardant materials are highly effective offering low generation of toxic gases and black smoke during combustion with high thermal stability, and low volatility.

Artigiano’s other products include additive masterbatches, special effect masterbatches, and color masterbatches, all of which enhance the properties of end products.

4. Nanopolymers

Many polymers do not find direct use due to their limited mechanical strength, low thermal stability, and inadequate barrier properties which restrict their applications in various industries. This is why startups incorporate nanoscale additives and structures that make nanopolymers exhibit enhancements in their structural and functional properties.

The integration of nanoparticles, such as graphene, carbon nanotubes, or clay nanoparticles, into polymer matrices also significantly increases their strength and stiffness. Additionally, surface modifications and nanocoating techniques improve their thermal stability and barrier properties against moisture, gases, and UV radiation.

These innovations in nanopolymers offer enable the creation of high-performance materials with tailored properties, enabling their utilization in a wide range of applications, including electronics, automotive, packaging, and biomedical fields.

Source: Global Market Insights

The global polymer nanocomposites market was valued at USD 12.6 billion in 2024 and is estimated to grow at a CAGR of over 15.9% from 2025 to 2034.

Nanite Bio develops Programmable Polymer Nanoparticles

Nanite Bio is a US-based startup that develops a new class of programmable polymer nanoparticles for various modalities and indications. Its AI-driven platform SAYER combines high-throughput experimental and computational methods to design delivery vehicles that are fit for specific cargo and tissue.

Insights from billions of polymer representations and millions of polymer structures serve as the basis for predicting performance in diverse biological systems. Moreover, the AI models guide functional chemistry to design therapeutically relevant gene delivery vehicles with the generation of thousands of distinct polymer nanoparticles in a matter of days.

Nanite Bio also conducts high-throughput biological screening and in vivo multiplexing to test for trafficking, tropism, and expression.

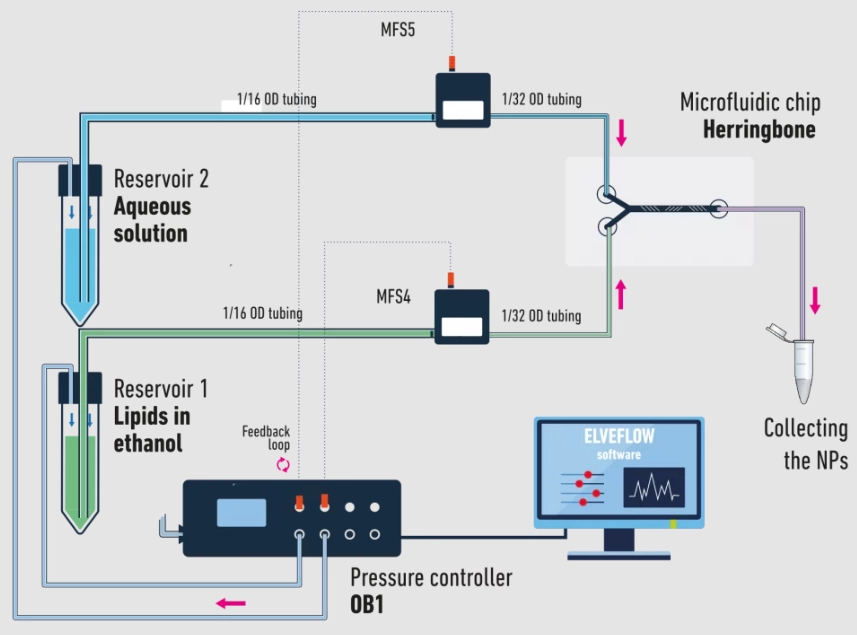

Inside Therapeutics synthesizes Lipid Nanoparticles

Inside Therapeutics is a US-based startup that performs the synthesis of lipid nanoparticles using a microfluidic-based platform. Its lipid nanoparticle synthesis pack allows for the synthesis of a wide range of lipidic and polymeric nanoparticles including Lipid nanoparticles (LNP), liposomes, lactic-co-glycolic acid (PLGA), and solid lipid nanoparticles (SLN).

The pack also features easy access to advanced microfluidics that offer optimal control of nanoparticle physicochemical parameters from size to encapsulation efficiency.

The platform is versatile, accommodates requirements in terms of automation, volumes, and flow rate, and encapsulates a range of compounds from mRNA and siRNA to small molecules and drugs. Inside Therapeutics’ solution is reusable, environmentally friendly, and offers a high degree of control over nanoparticle size making it a valuable tool for nanoparticle synthesis.

5. 3D Printing

Traditional polymer-based product manufacturing processes impose limitations such as design complexity, high production costs, and time-consuming tooling requirements. However, innovations in 3D printing are simplifying the creation of complex geometries and enabling the production of intricate designs that were previously challenging or impossible.

Additive manufacturing also eliminates the need for expensive tooling, making it cost-effective for low-volume or custom production. Further, advances in 3D printing materials, such as high-performance polymers and composite filaments, improve material strength, stability, and functional properties. These innovations find applications in rapid prototyping, customized production, and on-demand manufacturing.

Additionally, research claims there is an increase in the use of biopolymers for 3D printing.

UpNano facilitates Microfabrication

Austrian startup UpNano offers cutting-edge additive manufacturing solutions for microfabrication. Its 3D printing system, NanoOne, leverages multiphoton lithography and combines precise 2-photon polymerization with high throughput.

This system is ideal for batch and small series production of industrially applied microparts. Further, the startup’s process enables the printing of microscopic surface elements, microlenses, filter elements, microneedles, micro-mechanical components, and fluidic elements.

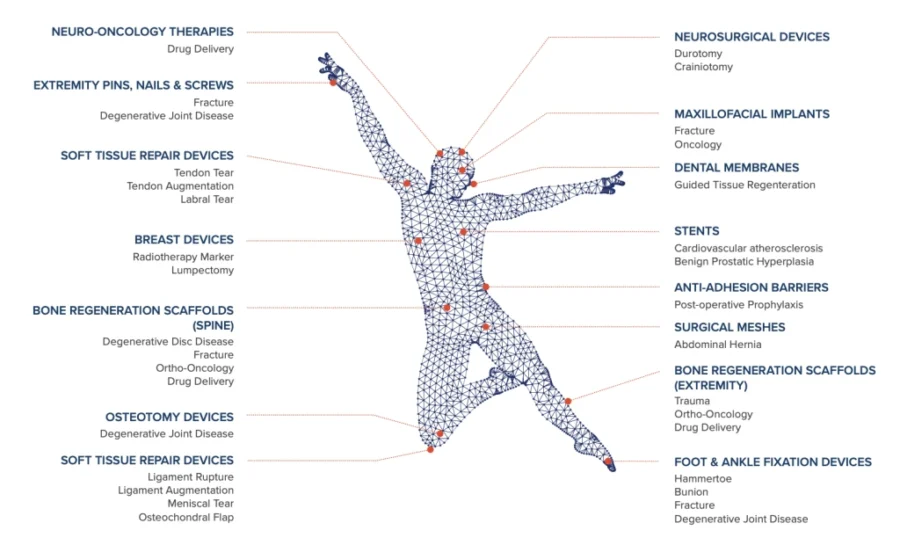

4D Biomaterials offers a Printable Bioresorbable Polymer

4D Biomaterials is a UK-based startup that creates 3D printable resorbable biomaterials for diverse medical applications. Its technology features polycarbonate-urethane chemistry called 4Degra which ranges from soft and flexible to strong and rigid. The material is suitable for a wide range of implantable medical device applications and promotes significantly faster tissue healing than established bioresorbable polymers.

Besides this, 4Degra resins are cast or 3D printed and also function as coatings. Further, 4D Biomaterial’s proprietary degradation-by-design simulation software determines the optimum geometry and resorption profile for a device, ensuring control over the degradation period.

6. Novel Specialty Additives

Innovations in novel specialty additives are addressing these issues and unlocking new potential for polymers. These additives enhance the properties and functionality of polymers by imparting unique characteristics. For example, additives like flame retardants improve the fire resistance of polymers, while plasticizers enhance flexibility and impact resistance.

Additionally, functional additives such as conductive fillers enable the development of electrically conductive polymers, opening doors to applications in electronics and energy storage.

Novel specialty additives also address environmental concerns by offering sustainable alternatives, such as bio-based additives that reduce dependence on fossil fuels. Through these innovative additives, polymers are being transformed into high-performance materials, expanding their range of applications in diverse industries while addressing specific challenges and requirements.

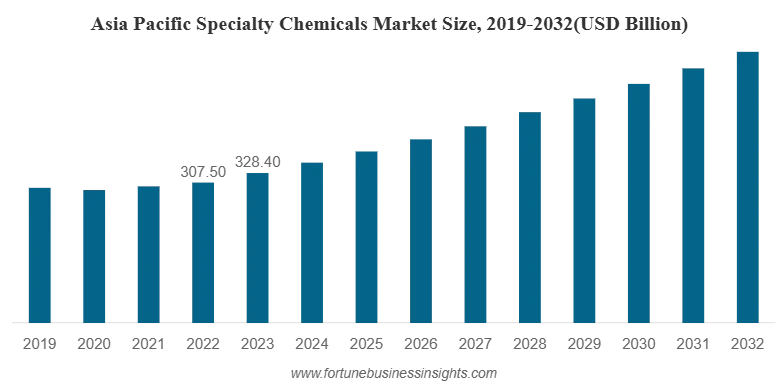

Additionally, the global specialty chemicals market size is set to reach USD 1063.4 billion in 2032 from USD 721.5 billion in 2024, growing at a rate of CAGR 5%.

Source: Fortune Business insights

amipm offers Additive Manufacturing Polymer Powders

amipm is a Switzerland-based startup that manufactures micro polymer powders for use in powder-based additive manufacturing processes. Its production process transforms a wide range of existing polymer granules into spherical, high-flowable micro powder.

This process produces spherical particles with a smooth surface that results in a higher density and flowability in comparison to existing techniques like milling. To maintain a constant quality of the powder, AMPowder uses continuous quality control in its process to precisely control particle size, shape, and distribution.

Polytives engineers Thermoplastics

Polytives is a Germany-based startup that specializes in creating tailor-made polymer additives for plastics. The startup offers solutions to enhance the mechanical properties of polymers based on specific requirements.

Additionally, its innovative flow improver bFI reduces melt viscosity, optimizes processing temperature, and increases the recyclability of plastics. Besides this, its additive is compatible with over 60% of available polymers.

Polytives’ polymer additives promote sustainability through lower energy consumption, fewer hazardous or toxic additives, and a greater proportion of recyclable components.

7. Advanced Thermoplastics

Polymer solutions commonly address the limited recyclability, poor dimensional stability, and low heat resistance but often neglect less-known issues such as poor chemical resistance, UV degradation, and low surface hardness. This is why startups create innovations in thermoplastics such as advanced formulations and additives incorporated into thermoplastic materials to enhance their chemical resistance, making them more resistant to aggressive environments and chemical substances.

The introduction of UV stabilizers and antioxidants protects against UV degradation and improves the durability of thermoplastics in outdoor applications. Additionally, modifications in the molecular structure of thermoplastics improve surface hardness and scratch resistance for applications in situations where abrasion resistance is crucial.

Through these innovations, thermoplastics are becoming more versatile, durable, and capable of withstanding a wide range of environmental conditions, making them suitable for numerous high-performance industrial applications.

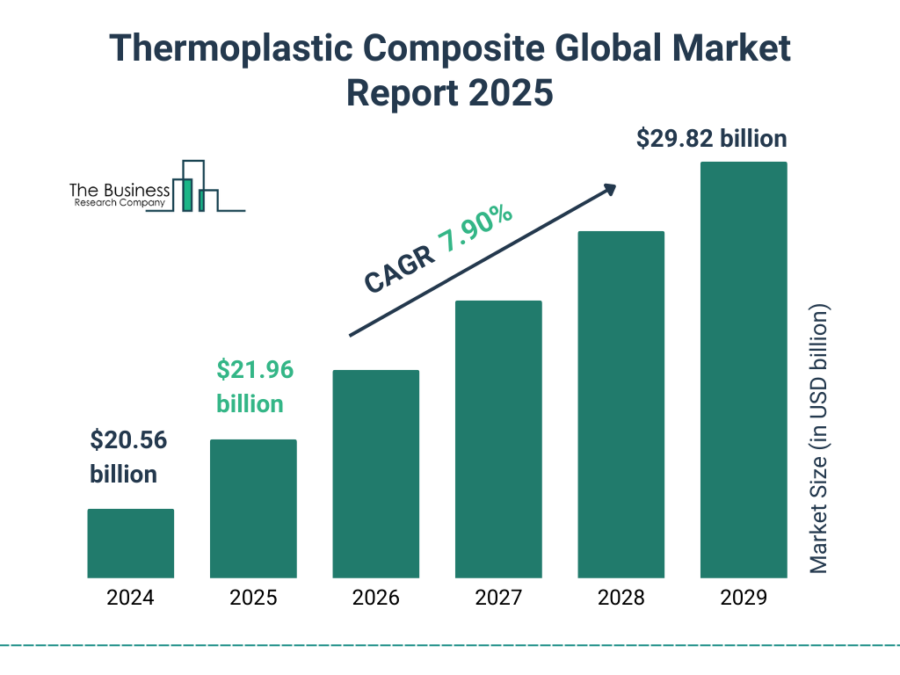

Source: The Business Research Company

The thermoplastics composite market is set to reach USD 29.82 billion by 2029, growing at a CAGR of 7.9%. Additionally, the high-temperature thermoplastics market size is set to grow at a rate of CAGR 9.3% from 2024 to 2031.

Solublion creates Biodegradable Thermoplastics

Solublion is a Spanish startup that offers advanced thermoplastic solutions that are biodegradable, compostable, and water-soluble. Solublion’s technology allows for a wide range of mechanical properties enabling the customization of products to meet specific customer needs.

Solublion provides specialty additives in a granule format which support reprocessing using conventional industrial machinery for the manufacture of end products. Moreover, its products use thermoplastic starch and provide the packaging industry with an environmentally friendly alternative to conventional packaging materials.

The startup also focuses on research and development to create new solutions and products that serve as an alternative to conventional polymers in a multitude of sectors.

RECARBON offers Recycled Carbon-fiber-based Products

RECARBON is an Italian startup that creates sustainable solutions for the industrial reuse of carbon fibers and other advanced materials. The startup manufactures both prepregs and thermoplastic intermediate products from recycled carbon fibers (rCFs).

RECARBON’s Organosheets consist of rCF nonwoven mats co-mingled with thermoplastic fibers to produce flat panels of various thicknesses and widths. Besides this, its prepregs make use of rCF mats and chopped rCF fibers to offer a wide range of epoxy-based thermosetting matrices.

These products are storable at room temperature, have an almost unlimited shelf life, and feature a short process time while being cost-efficient.

8. Conductive Polymers

Traditionally, polymers have low suitability in electronic devices and applications due to their low electrical conductivity, lack of tunability, and limited processability. However, startups are addressing these problems by developing conductive additives or designing polymer structures with inherently conductive properties.

Moreover, the development of dopants and functionalized polymers allows for enhancements in the tunability of electrical properties, enabling precise control over conductivity levels. Additionally, breakthroughs in processing techniques, such as solution-based methods and printing technologies improve the processability and manufacturability of conductive polymers.

This facilitates their integration into flexible electronics, sensors, energy storage devices, and other emerging technologies. These innovations in conductive polymers enable the creation of lightweight, flexible, and cost-effective electronic devices with tailored electrical properties.

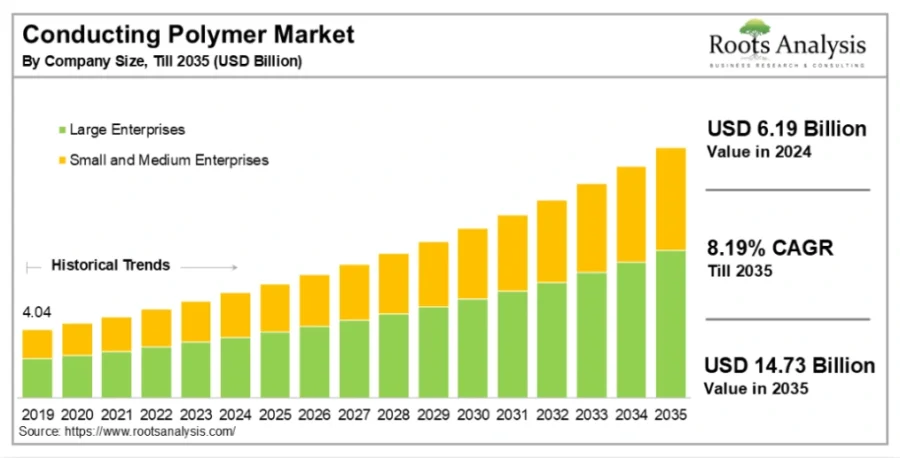

The conducting polymer market is set to reach USD 14.73 billion by 2035, growing at a CAGR of 8.19%.

Source: Root Analysis

Soelect develops a Polymer Electrolyte Membrane

US-based startup Soelect develops dendrite-resistant LiX battery (Lithium-X) anode technology and solid-state electrolyte material. The startup’s LiX technology allows for a full battery charge in just 15 minutes, significantly reducing charge time for electric vehicles.

The batteries using this technology retain over 80% of their capacity for 400 cycles, ensuring longer battery life. Its non-PEO-based polymer membranes feature high ionic conductivity with a wider operating temperature range and apply to any electrode material. This ensures higher safety of batteries while minimizing the risk of overheating.

Moreover, Soelect’s manufacturing process is easily scalable for mass production at a low cost, making it a suitable solution within the wider battery ecosystem.”

n-ink creates Polymer E-Inks

Swedish startup n-Ink provides ink formulations that are highly conductive, easy to handle, stable, and printable. Its patented n-Inks are on par with commercial p-type inks and are compatible with existing solution-deposition processes for printed electronics, IoT, and bioelectronics.

n-Ink products are also eco-friendly, thermally stable up to 350°C, resistant to long exposure to air, and orthogonal to most organic solvents. The startup’s inks enable the development of high-performing printed electronic devices where efficient p-type and n-type materials are required like organic solar cells, organic supercapacitors, and more.

9. Lightweighting

Polymers typically have high density, low strength-to-weight ratio, and limited load-bearing capacity, which hinder their widespread adoption in lightweight applications. Therefore advanced polymer composites with lightweight fiber reinforcement such as carbon fibers or glass fibers significantly improve the strength-to-weight ratio of polymers.

Additionally, the integration of microcellular or nano-cellular structures within polymers reduces their density while maintaining mechanical integrity. Further, advancements in additive manufacturing and design optimization techniques are enabling the creation of intricate lightweight structures with optimization for load distribution and reduction in material consumption.

Through these innovative lightweight solutions, polymers find applications in high-performance materials that offer both strength and lightness.

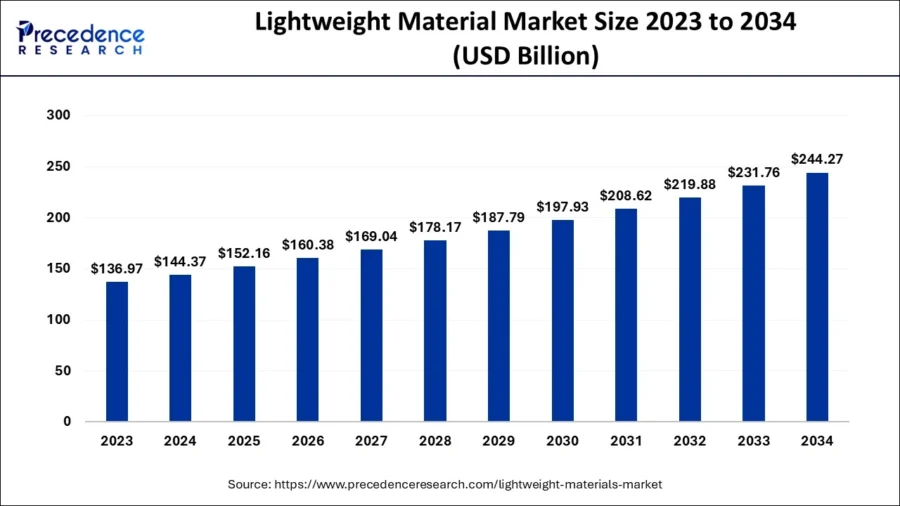

Automotive and aerospace are two of the industries with the highest demands for lightweight materials. Additionally, the lightweight material market size is set to reach USD 244.27 billion by 2034, growing at a CAGR of 5.4% from 2024 to 2034.

Source: Precedence Research

Suzhou Shincell New Material manufactures Supercritical Foam Materials

ShinCell Foam is a Chinese startup that focuses on the production of supercritical foam materials. These materials feature a low product density of 0.036g/cm3, which supports the demand for lightweight materials.

The foam materials, including FR-MPP, M-TPU, and M-TPEE foam sheets, offer UL-94V0 level flame retardant properties and emit no smoke toxicity during combustion, enhancing the safety performance of batteries, airliners, and high-speed railways.

The startup’s materials also provide heat insulation, shock absorption, waterproofing, and sound insulation properties with applications in a wide range of industries.

Erdwelle Technologies innovates in Stealth Technology Polymers

US-based startup Erdwelle Technologies develops a polymer technology called Rynomer that is harder than carbon fiber, lightweight, and both non-flammable and waterproof.

The polymer’s unique attributes extend to being invisible to X-ray machines and radar which results in significant potential for military technologies. The stealth capabilities of Rynomer enhance the undetectability of military vehicles and aircraft with its X-ray invisibility assisting in covert operations.

Besides this, the polymer protects communication and electronic warfare technologies by absorbing electromagnetic radiation. Further, its radar-defiant nature finds applications in surveillance, intelligence gathering, electronic warfare, and defense.

10. Material Simulations

Innovations in material simulation are addressing problems like complex material behavior, unpredictable mechanical properties, and difficulty in predicting long-term durability by providing a deeper understanding of polymer behavior and enabling more accurate predictions of their performance.

Through computational modeling and simulation techniques, researchers simulate the behavior of polymers under different conditions, allowing for the identification of key parameters and material properties. This further enables the optimization of polymer formulations, predicts mechanical properties, and assesses long-term durability.

Additionally, advanced simulation tools enable virtual prototyping and design optimization, reducing the need for physical prototyping and testing.

With material simulation, the development and selection of polymers can be accelerated, leading to improved material performance, reduced costs, and faster time-to-market for a wide range of applications, including aerospace, automotive, and consumer goods.

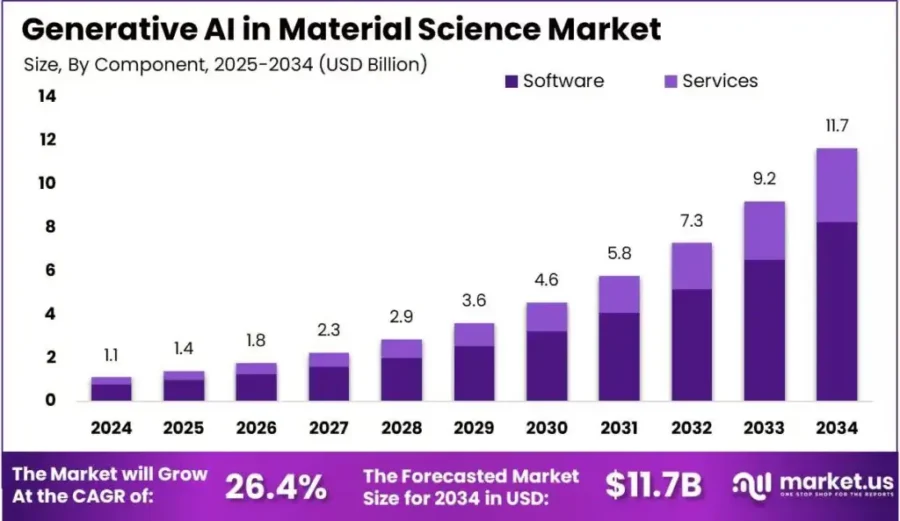

Source: Market.Us

For instance, the generative AI-driven material science market is predicted to reach USD 11.7 billion by 2034, at a CAGR of 26.4%.

FULLRMC Stochastic provides an Advanced Material Research Platform

Fullrmc Stochastic is a Lebanon-based startup that provides a platform for advanced material research. The platform specializes in cloud and AI-based modeling and simulations of materials including polymers and composite materials. The platform is also suitable for crystalline and amorphous materials, metal-organic frameworks (MOF), nanoparticles, nanoclusters, glass, ceramics, and more.

The startup offers an API for atomic stochastic modeling and optimization, supported by reinforcement machine learning. The platform further utilizes RMC, theoretical optimization, DFT, structure building, and more. Researchers use the platform for material research and synthesis in battery, energy storage, pharmaceuticals, drug delivery, etc.

Preferred Computational Chemistry advances Atomic Simulation

Preferred Computational Chemistry is a Japanese startup that develops atomic simulations for innovative materials discovery. Its product uses proprietary neural network potential (NNP) which allows for high-speed and versatile atomistic simulations.

Matlantis simulates the properties of molecules and crystal systems including unknown materials with any combination of 72 elements. The platform is significantly faster than conventional methods, completing tasks that take hours to months using density functional theory (DFT) in just a few seconds.

The user-friendly interface requires no hardware or software installations, and the pre-trained deep learning model eliminates the need for user data collection or training. This allows researchers to quickly simulate a massive number of realistic, complex systems with relatively low calculation costs without compromising versatility.

Discover all Polymers Trends, Technologies & Startups

Smart composite materials like self-healing polymers offer improvements in strength and durability while nanopolymers enhance mechanical and barrier properties in specialized applications. 3D printing enables complex designs and custom polymeric material production with novel specialty additives imparting unique functionalities.

Moreover, conductive polymers open up new possibilities in electronics and batteries with material simulation platforms allowing for accurate prediction of material behavior.

The polymer trends & startups outlined in this report only scratch the surface of trends that we identified during our data-driven innovation & startup scouting process. Identifying new opportunities & emerging technologies to implement into your business goes a long way in gaining a competitive advantage.

![10 Top Startups Advancing Machine Learning for Materials Science [2025]](https://www.startus-insights.com/wp-content/uploads/2025/06/Machine-Learning-for-Materials-Science-SharedImg-StartUs-Insights-noresize-420x236.webp)

![10 Emerging AI Solutions for Material Science [2025]](https://www.startus-insights.com/wp-content/uploads/2025/06/AI-Solutions-for-Material-Science-SharedImg-StartUs-Insights-noresize-420x236.webp)