Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

Industrial machinery is the backbone of manufacturing and production processes that support the economy. With the increased focus on climate change, there is growing pressure to facilitate higher efficiency and productivity. Further, aging infrastructure and machinery along with the need for sustainable and environmentally friendly solutions exacerbate these challenges. In this report, you will explore the top industrial machinery trends that drive innovation to solve these challenges.

Top 10 Industrial Machinery Trends (2024)

- Robotization

- Artificial Intelligence

- IIoT-enabled Equipment

- 3D Printing

- Clean Energy Machines

- AR/VR

- Supply Chain Traceability

- Cybersecurity

- Digital Twin

- Industrial Cloud Computing

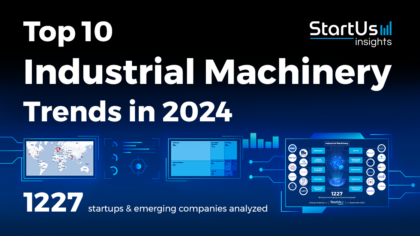

Innovation Map outlines the Top 10 Industrial Equipment Trends & 20 Promising Startups

For this in-depth research on the Top Industrial Machinery Trends and startups, we analyzed a sample of 1227 global startups & scaleups. This data-driven research provides innovation intelligence that helps you improve strategic decision-making by giving you an overview of emerging technologies in the manufacturing machinery industry. In the Industrial Machinery Innovation Map below, you get a comprehensive overview of the innovation trends & startups that impact your company.

These insights are derived by working with our Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 3 790 000+ startups & scaleups globally. As the world’s largest resource for data on emerging companies, the SaaS platform enables you to identify relevant technologies and industry trends quickly & exhaustively.

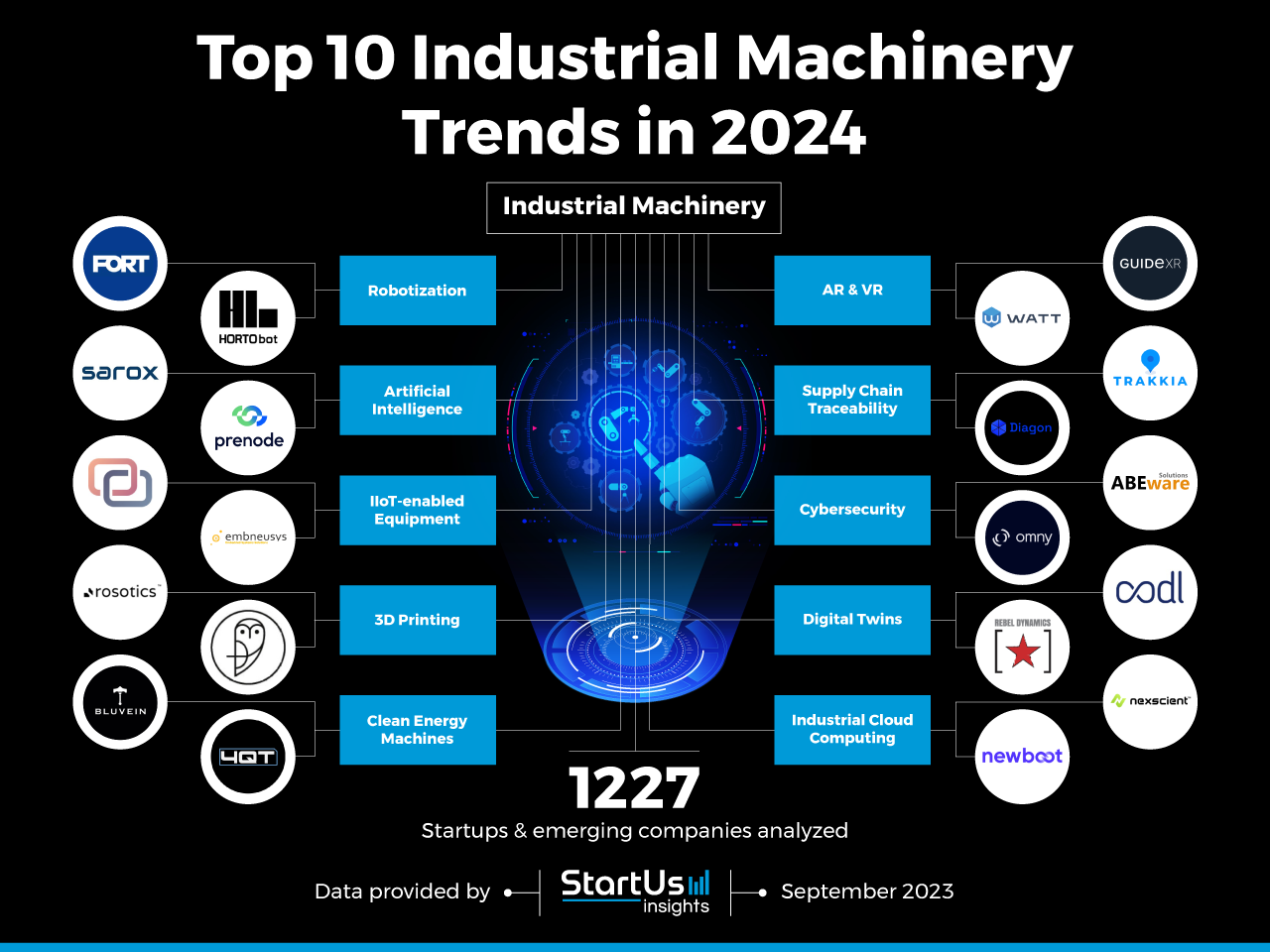

Tree Map reveals the Impact of the Top Industrial Machinery Industry Trends in 2024

Based on the Industrial Machinery Innovation Map, the Tree Map below illustrates the impact of the Top 10 Industrial Machinery Trends in 2024. Startups and scaleups utilize technologies like machine learning and big data analytics to analyze industrial equipment at every stage of its lifecycle to ensure maximum performance and efficiency. Improved visibility into the supply chain of industrial machines allows businesses to avoid bottlenecks or vulnerabilities and also improve asset handling in the industrial sector.

Further, innovations like 3D printing allow rapid prototyping, enabling engineers to test and iterate on designs quickly. By harnessing the power of the cloud, industries achieve seamless data integration across multiple machines and sites, enabling real-time monitoring and decision-making.

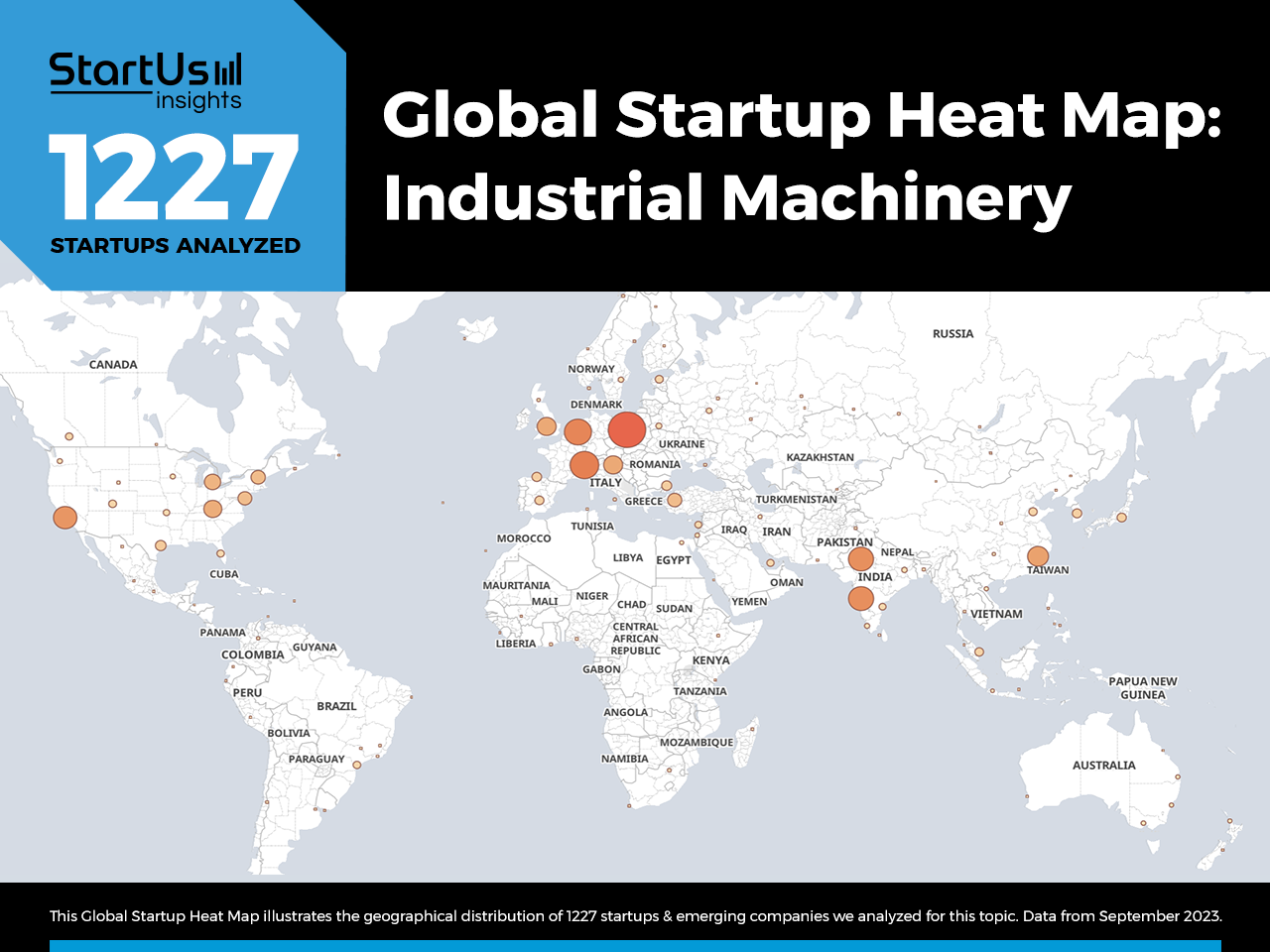

Global Startup Heat Map covers 1227 Industrial Machinery Startups

The Global Startup Heat Map below highlights the global distribution of the 1227 exemplary startups & scaleups that we analyzed for this research. Created through the StartUs Insights Discovery Platform, the Heat Map reveals high startup activity in Europe, India, and China, followed by the USA.

Below, you get to meet 20 out of these 1227 promising startups & scaleups as well as the solutions they develop. These 20 industrial equipment companies are hand-picked based on criteria such as founding year, location, funding raised & more. Depending on your specific needs, your top picks might look entirely different.

Interested to explore all 1200+ industrial machinery startups & scaleups?

Top 10 Industrial Machinery Trends in 2024

1. Robotization

Robotization provides innovative solutions to traditional challenges faced by industrial machines solving the issues of inefficiency, human error, and the limitations of manual labor. Robots with their precision and repeatability address these concerns by ensuring consistent quality and minimizing defects. Also, the ability of these robots to adapt to various tasks through programming and AI enables the quick reconfiguration of operations, saving both time and resources.

This adaptability is crucial in catering to dynamic market demands and short operation cycles. With sensors and cameras, robots enhance safety by detecting potential hazards and responding swiftly to avoid accidents. All of these allow robotized machinery to function around the clock, which is beneficial for meeting tight deadlines and handling large workloads with minimal human interaction.

Fort Robotics offers a Robotics Control Platform

US-based startup Fort Robotics develops a robotics control platform (RCP) to maximize the safety, security, and productivity of robotic assets. The startup’s solution includes both software and hardware tools to reduce risk and ensure control of robotic systems.

The platform improves human-to-robot collaboration and enables enhanced machine-to-machine communications. It ensures reliable interaction with robots in unpredictable environments that change on the fly with built-in pathways and protections.

Hortobot develops Autonomous Agriculture Robots

Italian startup Hortobot designs and produces robotic solutions for use in the horticulture and agriculture industries. The HB700 All-in-One is the startup’s solution that incorporates multiple tool systems for various cultivation processes like sowing, weeding, and harvesting.

The machinery performs tasks with low added value while operators are free to plan production and assortments evaluating the economic yield from sales. This facilitates higher production yields on the same cultivation soil and reduces fatigue activities for the management of the soils.

2. Artificial Intelligence

With its self-learning algorithms, AI empowers machines to optimize their own operations, recognize patterns, and make predictive decisions. This ensures consistent and enhanced productivity. AI’s ability to identify patterns facilitates predictive maintenance that forecasts machine wear and tear. Consequently, it significantly reduces unplanned downtimes and ensures optimal utilization of resources.

This also improves human-machine collaboration, allowing workers to focus on tasks that require creativity, problem-solving, and decision-making while machines handle repetitive, physically demanding, or dangerous tasks. In this way, artificial intelligence forms an integral trend in industrial machinery to enhance productivity and reliability.

Sarox aids Machine Fault Identification

Canadian startup Sarox provides a machine-learning-powered condition monitoring and energy management solution to keep machines up and running. Sarox C-110T is the startup’s secure platform that continuously monitors, analyzes, and assesses machinery health parameters.

The platform identifies faults in industrial assets at a very early stage to avoid unplanned outages. This predictive maintenance tool streamlines maintenance management, asset integrity, and overhaul planning.

prenode enables Independently Optimized Machines

German startup prenode combines data and AI to optimize machine operations. The startup’s edge AI platform aids the deployment of AI on edge devices to facilitate predictive maintenance, anomaly detection, and process control.

It enables real-time data processing directly for individual machines allowing them to react to changes very fast. This direct processing also avoids the need for constant cloud connectivity, giving machines the ability to operate in offline or low-connectivity environments.

3. IIoT-enabled Equipment

Equipment with embedded sensors enables connectivity into machinery and industrial processes, facilitating real-time data collection and analysis across the entire operational ecosystem. This interconnectivity ensures instantaneous feedback, which allows optimized operations, reduces energy consumption, and improves overall equipment effectiveness (OEE).

Additionally, IIoT-enabled equipment fosters greater transparency, allowing for remote monitoring and control, which is especially valuable for industries with distributed operations. IIoT also aids industries in adhering to regulatory standards by automating data collection and reporting. This industrial machinery trend provides real-time machine insights that enhance the agility, efficiency, and responsiveness of machines.

Cohera offers a Modular Sensor Platform

US-based startup Cohera develops a modular sensor platform for efficient condition monitoring. The startup’s platform is sensor-agnostic, allowing it to work with a wide range of sensors and provide machine diagnostics locally, even in offline environments.

The platform’s customizable operations system allows for fast and seamless integration with existing systems. The solution by providing real-time data on machine performance improves machinery maintenance by allocating field technicians more efficiently.

embneusys enhances Real-time Asset Visibility

Greek startup embneusys offers an IoT platform for construction and mining industries to monitor their machinery and equipment regarding location and working conditions. The startup utilizes narrowband (NB) IoT devices mounted on equipment to monitor parameters like machine temperature, location, and working hours.

The solution allows asset owners to easily track and locate their equipment, avoiding theft and minimizing idling time. This increased visibility allows faster corrective actions and reduces operational costs.

4. 3D Printing

3D printing overcomes the long-standing production challenges of traditional methods that often involve subtractive processes. These conventional processes are time-consuming, resource-intensive, and restrictive in terms of design complexity. 3D printing overcomes these limitations by allowing for the direct fabrication of intricate parts layer by layer, eliminating the need for molds or extensive machining.

Moreover, 3D printing makes customization economically feasible, enabling industries to tailor products to specific client needs without significant cost escalations. The technology also promotes sustainable practices by utilizing materials more efficiently and offering the potential to use recyclable or bio-based materials. Additionally, 3D printing rejuvenates aging machinery by producing replacement components on demand, mitigating issues related to obsolete or hard-to-find parts.

Rosotics develops Induction-based Additive Manufacturing

US-based startup Rosotics provides a metal additive manufacturing (AM) platform to eliminate the manufacturing challenges in the heavy industry. The startup’s solution involves rapid induction printing that utilizes induction to liquefy metal feedstock rather than a laser-based approach.

This process is significantly more energy efficient than the usual metal additive manufacturing methods. The solution offers a highly efficient AM solution that offers modularity and eliminates bottlenecks in production and implementation.

OWL enables Powder-based Additive Manufacturing

German startup Owl Additive Manufacturing specializes in hot isostatic pressing (HIP) and powder metallurgy. The HIP process involves treating components with elevated heat and pressure in an inert gas atmosphere. This eliminates internal cavities and micro-porosities through plastic deformation, flow, and diffusion bonding.

The method facilitates the manufacturing of tungsten-based components, where powder metallurgy followed by HIP makes it easier to achieve complex designs. The startup serves various sectors, including aerospace, motorsport, mechanical engineering, and medical technology, ensuring efficient processes.

5. Clean Energy Machines

Clean energy machines directly address the mounting environmental and efficiency challenges that plague traditional systems. Transitioning to electric machines powered by renewable energy sources like wind, solar, and hydropower drastically reduces the carbon footprint of industrial operations. Apart from the environmental benefits, these machines are more energy-efficient, leading to lower operational costs and reduced resource consumption.

They also offer quieter and more sustainable alternatives, reducing noise pollution in industrial settings. Moreover, electric machines provide precise control and faster response times, which improves manufacturing accuracy and efficiency of processes. Further, their modularity and adaptability enable seamless integration with emerging technologies.

BlueVein enables Dynamic Heavy Equipment Charging

Australian startup BluVein offers a dynamic charging technology for heavy-duty battery electric mining vehicles. The startup’s BlueVein1 and BluVeinXL system electrifies underground mining, enabling the decarbonization of industrial equipment. The charging system is OEM-agnostic supporting underground mines with diverse heavy-haulage fleets.

The solution is capable of dynamically feeding power to mixed-OEM fleets. This enables the onboarding of smaller battery packs, faster vehicle haulage speeds up the ramp, grid load balancing, and maximum fleet availability.

4QT manufactures Heavy Equipment Electric Drives

Swiss startup 4QT develops high-power electric drives for heavy equipment. The startup’s axial-flux magnet-free motor has a stackable and power-dense architecture that offers modular torque output. The motor also consists of two rotors with differential torque, facilitating regenerative braking.

The drive system does not use rare-earth permanent magnets making it cheaper and recyclable by design. 4QT’s modular electric drive system aids heavy equipment manufacturers in electrifying their diesel fleets.

6. Immersive Tech (AR/VR)

AR and VR are tools that overcome the traditional limitations of industrial machinery in training, troubleshooting, and maintenance. AR enhances worker training and maintenance by providing real-time, interactive information overlays on machinery. This makes it easier for operators to diagnose issues, perform repairs, and follow complex assembly procedures.

VR, on the other hand, enables immersive training experiences by exposing workers to simulated machinery operation and maintenance tasks in a safe and controlled virtual environment. This avoids the risks associated with hands-on training.

Both AR and VR enhance remote assistance by enabling experts to guide field technicians or operators in real-time, irrespective of location. In this way, AR and VR technologies enhance training, maintenance, and remote support capabilities, ultimately improving efficiency, safety, and productivity in industrial settings.

Spatial Guide offers AR Instruction Manuals

US-based startup Spatial Guide offers an AR instruction manual that improves workforce productivity. GuideXR is the startup’s AR platform that enhances training, skill adoption, and familiarity with the work environment.

The platform educates operators about the equipment and environment using intuitive instructions. This allows technicians to work faster, minimizing machinery downtime and maximizing first-pass yield.

Watt enables Virtual Note-making

South Korean startup Watt offers an AR-based smart glass solution that makes hands-free field work more efficient and workers’ work environments safer. AR Post-it is one of the functions of the smart glass that facilitates AR data history management system using AI.

The smart glass creates notes and takes photos through voice commands. It also records these documents in the system as if pasting a post-it. The startup’s interactive user interface makes these easier to read and edit, unlike reports or drawings.

7. Supply Chain Traceability

With the increasing complexity and globalization of supply chains, there is an amplified risk of quality inconsistencies, fraud, counterfeiting, and delays. These risks compromise the performance, safety, and reliability of machinery. Implementing a comprehensive traceability mechanism allows equipment manufacturers to gain a clear and unbroken view of the entire supply chain. Smart devices like RFID tags and low-power IoT devices are useful in recording product information at every stage of the supply chain.

This improved visibility allows stakeholders at each level to verify the authenticity of components, ensure quality control, and optimize logistics and inventory management. Further, AI-based analysis of data collected from the supply chain allows manufacturers to identify vital trends and patterns. This information is crucial for meeting sustainability goals and reducing waste. Supply chain traceability, in this way, enhances efficiency, minimizes downtime, and fosters trust among stakeholders in the industrial machinery sector.

Trakkia enhances Real-time Supply Chain Tracking

Indian startup Trakkia provides IoT and AI-powered cloud software that tracks, manages, and optimizes the utilization of supply chain assets and inventories. The software’s plug-and-play enterprise resource planning (ERP) workflows digitize supply operations by leveraging IoT for real-time visibility on supply chain items and AI to automate tasks.

These features allow asset managers to make data-driven decisions about their assets, maximizing their value and improving their bottom line. The streamlined processes also improve inventory accuracy, reduce fulfillment time, and optimize operations.

Diagon enables Automated Equipment Procurement

US-based startup Diagon offers a sourcing platform that automates sourcing for automation equipment. The platform enables procurement teams to source equipment based on product requirements and equipment specifications.

Diagon also ensures data privacy and transaction security by encrypting all purchase-related communications. The solution enables manufacturers to procure and deploy equipment quickly and efficiently

8. Cybersecurity

As industrial systems become increasingly connected through the IIoT and Industry 4.0 initiatives, they become more vulnerable to cyber threats. Effective cybersecurity measures, encompassing both hardware and software solutions, act as shields against these threats. These measures include employing advanced encryption, multi-factor authentication (MFA), intrusion detection systems, and regular patching. This allows manufacturers and operators to protect sensitive data, guard against unauthorized access, and ensure the consistent and safe performance of machinery.

Cybersecurity services like backup and disaster recovery plans further enable industrial machinery companies to recover quickly from attacks and minimize financial losses. Moreover, these solutions aid organizations in maintaining regulatory compliance by safeguarding sensitive data and ensuring proper reporting. Cybersecurity solutions preserve the functionality of machinery and also instill trust and confidence among stakeholders, from clients to regulatory bodies.

ABEware makes Accessible Operational Technology Cybersecurity

US-based startup ABEware offers a centralized cybersecurity and inventory management solution for the operational technology (OT) environment without the complexity of IT tools. The software prevents, detects, and remediates cyber threats, reducing process safety risks and optimizing profitability.

Its credential management tool tracks user activities, logons, and failed attempts to completely understand the activities on the system. Further, the vulnerability management tool monitors the latest common vulnerabilities and exposures (CVE), making sure the system is not exposed to dangerous threats.

Omny ensures Cyber-Physical Security

Norwegian startup Omny provides cybersecurity software that enables precise and timely actions, linking cyber and physical through its industrial security graph. The software uses advanced data capabilities to protect critical infrastructure for seamless operations to create business continuity.

It offers immediate visibility into OT assets, providing equipment owners with the tools to proactively manage risks, boost resilience, and ensure seamless business operations.

9. Digital Twin

Digital twin technology mirrors real-world machines in a virtual space, capturing their performance, wear and tear, and dynamic responses to different operating conditions. Through simulation and analytics, digital twin systems predict machinery failures, optimize performance, and design improvements without invasive or expensive prototyping.

The valuable insights into machine behavior enable data-driven decisions and design improvements for enhanced product quality and efficiency. Further, by integrating real-time data from sensors on the machinery, digital twins continuously update and evolve, offering a dynamic tool for troubleshooting, training, and innovation.

Oodl offers an Industrial Digital Twin Ecosystem

UK-based startup Oodl provides a digital twin ecosystem utilizing IoT and machine learning to create a live, digital representation of industrial assets. The startup takes in information from multiple sensors to get a full and rich representation of the digital twin.

Further, the AI-powered platform uses the collected data to make decisions and forecast the state of the digital twin. Oodl also provides smart asset tags that allow assets to be tracked, traced, and managed through a dashboard. This provides all stakeholders with an accessible portal to understand the present and future of a facility.

Rebel Dynamics optimizes Robotic Designs

Italian startup Rebel Dynamics provides a dynamic servo platform that allows designers to optimize heavy robotic systems through simulations. The startup utilizes the human-in-the-loop technique to simulate sensors, actuators, and mechanical components of a system before they are integrated.

The digital twin solution thereby understands all the possible parameters that comes into action and optimizes them for maximum performance and efficiency.

10. Industrial Cloud Computing

Data siloing is one of the perennial challenges faced by the voluminous data generated by modern industrial machinery. Industrial cloud computing provides a centralized platform for collecting, storing, and analyzing this data in real-time, enabling insightful analytics, predictive maintenance, and optimized performance.

Further, cloud platforms offer scalable computing resources which are customizable to the evolving needs of the industry, without the hefty upfront costs associated with traditional IT infrastructure. By implementing robust security measures, industrial cloud computing also offers a secure environment for sensitive operational data, thus safeguarding against potential cyber threats.

Nexscient enables Secure Data Streaming

US-based startup Nexscient provides a cloud platform that utilizes a robust, secure, and scalable IIoT architecture to monitor factory floors. The solution avoids the need to purchase equipment and build and operate a data center.

This eliminates the cost of hardware, facilities, utilities, and other aspects of maintaining software. At the same time, it improves the ease of sharing data and allows employees to access data in a centralized location while offsite at any time.

Newboot offers Multi-protocol Industrial Gateways

French startup Newboot offers multi-protocol industrial gateways that connect facilities simply and quickly to cloud infrastructure. The solution allows organizations to extract data from machines and programmable logic controllers (PLC) to monitor their processes.

Without the need for an extensive IT infrastructure, Newboot collects and shares machine data that aids in real-time utilization analysis to facilitate monitoring of operational efficiency.

Discover all Industrial Machinery Trends, Technologies & Startups

With the world moving towards clean energy and autonomy, innovations improving the accessibility and cost of electrified and autonomous equipment are poised to transform the industry. The green initiative also calls for advanced material solutions that reduce the carbon footprint of machines while ensuring longevity.

The Industrial Machinery Trends and startups outlined in this report only scratch the surface of trends we identified during our data-driven innovation & startup scouting process. Identifying new opportunities & emerging technologies to implement into your business goes a long way in gaining a competitive advantage.

![Future of Robotics: 12 Trends Powering the Next Wave [2025-2030]](https://www.startus-insights.com/wp-content/uploads/2025/06/Future-of-Robotics-SharedImg-StartUs-Insights-noresize-420x236.webp)