Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

Staying ahead of the technology curve means strengthening your competitive advantage. That is why we give you data-driven innovation insights into the materials industry. This time, you get to discover 5 hand-picked startups developing photopolymer resins.

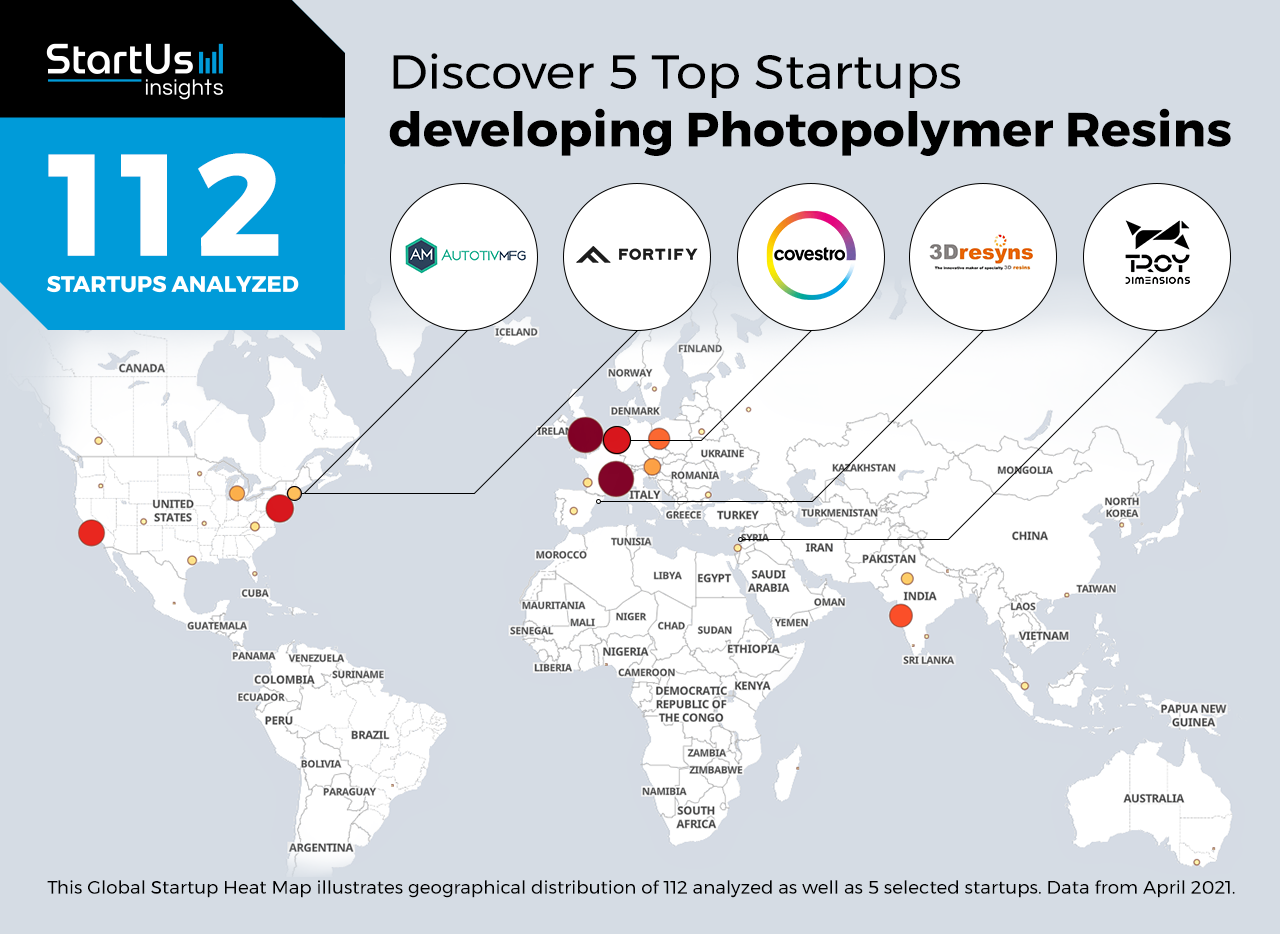

Global Startup Heat Map highlights 5 Top Startups developing Photopolymer Resins out of 112

The insights of this data-driven analysis are derived from the Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 1.379.000+ startups & scaleups globally. The platform gives you an exhaustive overview of emerging technologies & relevant startups within a specific field in just a few clicks.

The Global Startup Heat Map below reveals the distribution of the 112 exemplary startups & scaleups we analyzed for this research. Further, it highlights 5 material startups that we hand-picked based on criteria such as founding year, location, funding raised, and more. You get to explore the solutions of these 5 startups & scaleups in this report. For insights on the other 107 photopolymer resin solutions, get in touch.

Autotiv offers 3D Printing with Photopolymer Resins

The utilization of photopolymer resins in additive manufacturing (AM) increases the accuracy and speed of printing while also reducing the costs. Light sensitivity of photopolymers allows for their application in processes such as stereolithography (SLA) and material jetting. Startups offer these 3D printing services for product prototyping and ready-to-use production parts.

US-based startup Autotiv offers SLA and PolyJet 3D printing services with photopolymer resins. The startup’s polyjetting technique produces detailed prototypes and allows for the utilization of multiple materials for one print. Moreover, Autotiv’s SLA 3D printing enables the production of both prototypes and end products with large build volumes.

Troy Dimensions works on Photopolymer Resin Production

The standard photopolymer resins utilized in processes such as SLA display fragility and are prone to breaking and cracking. As a result, such resins are commonly used for the development of prototypes and models. By advancing the mechanical properties of resins, startups adapt photopolymers to practical applications in engineering, BioTech, and healthcare.

Lebanese startup Troy Dimensions works on photopolymer resin production for engineering, ceramics, medical, and jewelry applications. The startup alters material properties and develops resins for use-cases that require component precision, flexibility, or biocompatibility. Additionally, the startup manufactures 3D printing hardware and proprietary software for the setup, management, and monitoring of 3D printing processes.

3Dresyns creates Custom Photopolymer Resins

The manufacturing of 3D models and prototypes usually does not require extra hard or flexible materials. However, the functionality of high-performance components and objects often depends on the enhanced mechanical properties of the material. Consequently, startups provide custom photopolymer resin manufacturing solutions.

Spanish startup 3Dresyns develops custom photopolymer resins with increased flexibility, toughness, and foldability. The startup offers a range of functional resins and additives to customers in sectors such as defense, security, engineering, and biomedicine. Additionally, 3Dresyns develops a resin color kit to increase resolution and add detailed finishes to the materials.

Fortify specializes in Digital Composite Manufacturing (DCM)

Photopolymer property reinforcement requires the application of functional additives such as fibers. The introduction of such materials to photopolymer resins during the printing process allows for increased control over the mixing and dispersion of additives. Therefore, startups develop dynamic polymer reinforcement processes, which enable photopolymer resin enhancement with such properties as thermal and wear resistance.

US-based startup Fortify develops a DCM platform for photopolymer property reinforcement. The startup’s Continuous Kinetic Mixing (CKM) technology enables the introduction of functional additives during the printing process. The startup uses magnets to properly align and disperse fibers throughout the component. Fortify’s technology enhances a range of material properties, including temperature resistance, toughness, and durability.

Covestro develops Photopolymer Films for Holography

Photopolymer materials generate a chemical response when they come into contact with light. This property enables the use of photopolymer interference patterns for the creation of optical components. Leveraging the photopolymers’ chemical responses to light, startups develop thermoplastic films for applications in industrial holography.

German startup Covestro develops photopolymer films for holography. The startup produces a range of proprietary Bayfol films that contain photopolymers for volume holographic optical elements (VHOE) recording. These properties enable the films’ application for 3D glasses and head-mounted displays, as well as for laser strike protection and counterfeit resistance of products and banknotes.

Discover more Materials Startups

Materials startups such as the examples highlighted in this report focus on lightweighting, additive manufacturing, smart materials as well as nanotechnology. While all of these technologies play a major role in advancing the materials, they only represent the tip of the iceberg. To explore more technologies, simply get in touch to let us look into your areas of interest. For a more general overview, you can download our free Materials Innovation Report to save your time and improve strategic decision-making.

![10 Top Startups Advancing Machine Learning for Materials Science [2025]](https://www.startus-insights.com/wp-content/uploads/2025/06/Machine-Learning-for-Materials-Science-SharedImg-StartUs-Insights-noresize-420x236.webp)

![10 Emerging AI Solutions for Material Science [2025]](https://www.startus-insights.com/wp-content/uploads/2025/06/AI-Solutions-for-Material-Science-SharedImg-StartUs-Insights-noresize-420x236.webp)