Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

Staying ahead of the technology curve means strengthening your competitive advantage. That is why we give you data-driven innovation insights into the engineering industry. This time, you get to discover 5 hand-picked startups working on lean manufacturing solutions.

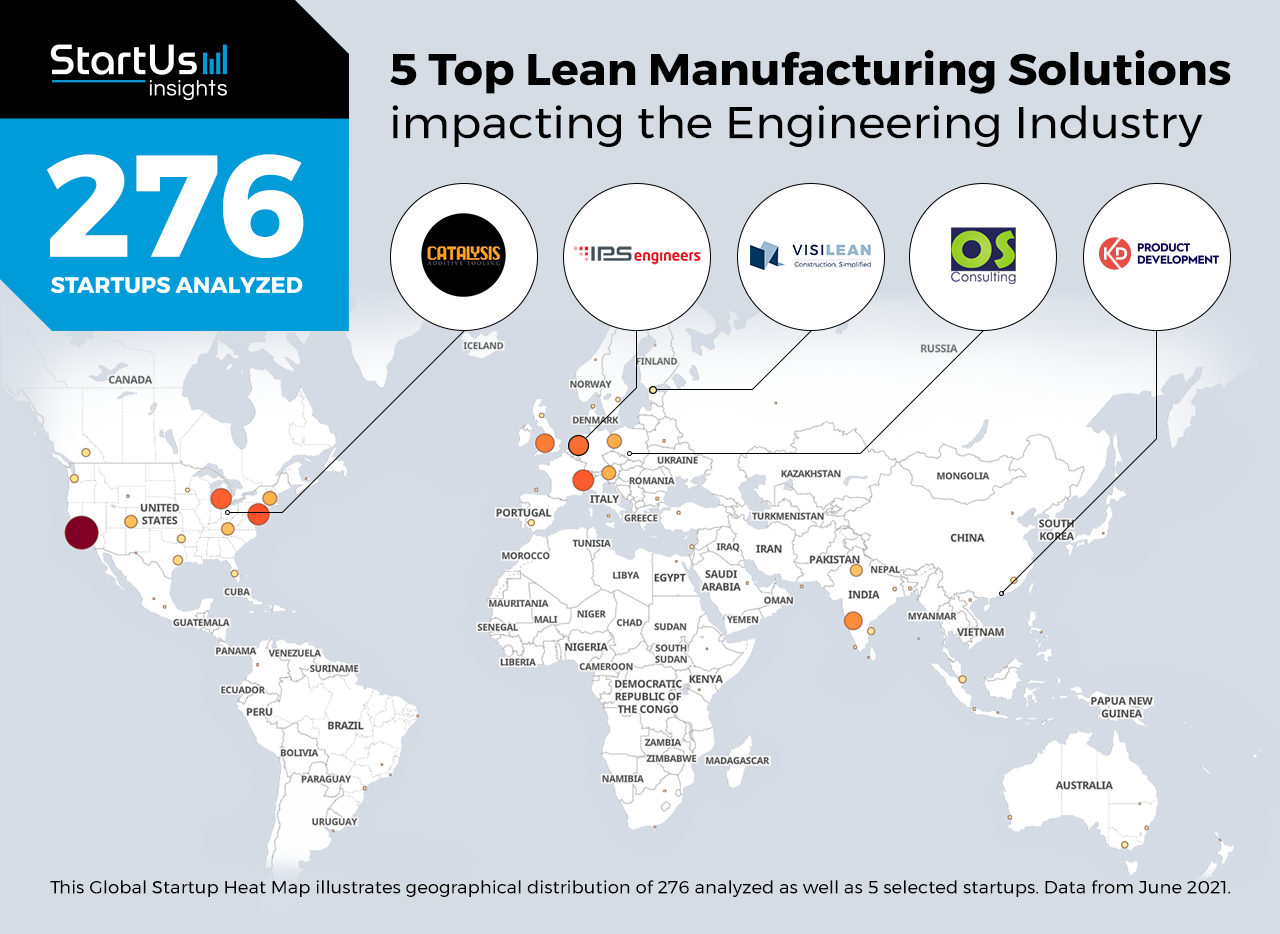

Global Startup Heat Map highlights 5 Top Lean Manufacturing Solutions out of 276

The insights of this data-driven analysis are derived from the Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 2.093.000+ startups & scaleups globally. The platform gives you an exhaustive overview of emerging technologies & relevant startups within a specific field in just a few clicks.

The Global Startup Heat Map below reveals the distribution of the 276 exemplary startups & scaleups we analyzed for this research. Further, it highlights 5 engineering startups that we hand-picked based on criteria such as founding year, location, funding raised, and more. You get to explore the solutions of these 5 startups & scaleups in this report. For insights on the other 271 lean manufacturing solutions, get in touch.

KD Product Development offers Design for Manufacturing (DFM) as a Service

Lean product development (LPD) is an integral part of lean manufacturing. From defining customer requirements to managing an efficient cross-team workflow, LPD constitutes all the lean principles that optimize new product development. This allows engineers and designers to reduce development cycles and wastage, thereby reducing production costs. That is why startups develop lean engineering solutions to improve product design and time to production.

Chinese startup KD Product Development offers end-to-end product development and design for manufacturing solutions. The startup initiates its projects with product requirement documents (PRD) and takes product development through design and prototyping to design reiteration and finalization. KD Product Development allows manufacturing companies to speed up new production runs without disrupting the production flow, thereby saving time and overall operational costs.

IPS Engineers specializes in Industrial Engineering

Conventional production runs focus on product functions and manufacturing costs. On the other hand, lean manufacturing measures a product’s success across its value chain and life cycle. While waste reduction is one outcome, lean principles in engineering improve design quality and facilitate production runs. Startups devise numerous solutions that allow manufacturers to integrate lean engineering into their production workflows without disturbing existing development systems.

IPS Engineers is a German startup that offers industrial engineering with lean principles. The startup’s solution includes conventional lean tools such as value stream analysis and workplace design to advanced methods like ergonomics evaluation and line clocks. Additionally, IPS Engineers’ solution uses motion capture, sensor-based data acquisition, and time-management tools for target costing, resource sizing, order scheduling, and more. In effect, the startup enables manufacturers to engineer their production units for maximum efficiency and minimal resource wastage.

Catalysis Additive Tooling 3D-prints Production Level Tools

All production runs quite often produce waste such as overproduction parts, transportation wastage, inventory wastage, defects, and more. While lean production reduces this wastage, lean engineering focuses on reducing product development cycles and improving product design. For example, additive manufacturing, a solution that enables rapid prototyping and production, significantly reduces prototype development periods and eliminates tooling costs. Plus, it allows engineers to revise their designs without cost constraints.

Catalysis Additive Tooling is a US-based additive manufacturing startup that develops 3D printed tools to make mass production-level parts. The startup uses vacuum forming, plastic injection, and foam tooling to manufacture low to medium volume parts as well. In addition, the startup supports custom development and engineering needs of its customers, thereby facilitating tooling and product development. Overall, the startup’s additive manufacturing solution cuts down tooling costs and development time.

VisiLean offers Lean Construction Management with BIM

In civil engineering, poor project planning and unexpected circumstances lead to delayed construction projects and increased expenses. However, adopting lean principles on-site reduces execution costs, accidents, and variability, among others. Startups develop lean construction solutions to help civil engineers and construction companies optimize construction planning and operations. For example, the last planner system (LPS) improves project planning and execution, thereby enabling engineers to minimize impacts due to uncertain events.

Finnish startup VisiLean develops a lean construction management solution integrated with building information modeling (BIM). The startup’s solution also enables dynamic planning, team collaboration, real-time visualization, performance review, and dynamic reporting. Plus, their smartphone app allows on-site staff to report in real-time, thereby offering real-time visibility into construction operations enhancing data-driven decision making.

OSConsulting develops Welding Jigs

Lean engineering tools and solutions allow manufacturers to improve process efficiency and production performance. These include optimizing the design process to minimize waste as well as the use of part and product development processes that reduce wastage in mass production runs. In addition, using computer simulation solutions such as computational fluid dynamics (CFD) and computer-aided design (CAD) in the product development stage significantly reduces development cycles.

OSConsulting is a Polish startup that designs tooling and equipment as well as allows for production optimization. The startup develops universal welding jigs for assembly to shorten the manufacturing process. Plus, it offers production optimization using lean management, production planning, conscious management, and methods time of production process. OSConsulting also offers consulting and process optimization services for manufacturing companies. The startup’s solutions improve the quality and ergonomics of production lines.

Discover more Engineering Startups

Engineering startups such as the examples highlighted in this report focus on design services, optical trigger distribution modules, telemetry solutions as well as new materials. While all of these technologies play a major role in advancing the engineering industry, they only represent the tip of the iceberg. To explore more technologies, simply get in touch to let us look into your areas of interest. For a more general overview, you can download one of our free Industry Innovation Reports to save your time and improve strategic decision-making.