Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

Staying ahead of the technology curve means strengthening your competitive advantage. That is why we give you data-driven innovation insights into industry 4.0. This time, you get to discover five hand-picked predictive maintenance startups impacting industry 4.0.

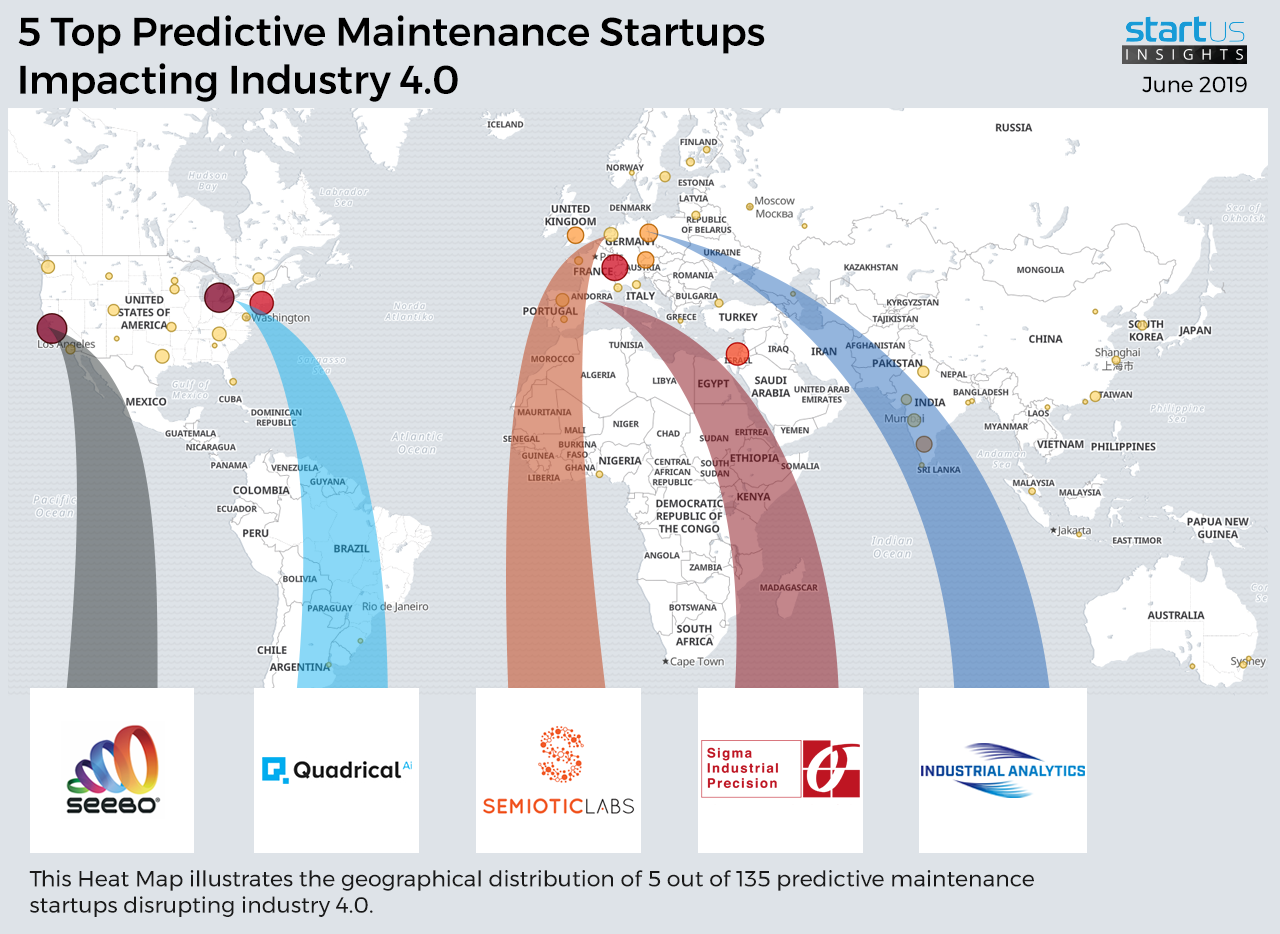

Out of 135, the Global Startup Heat Map highlights 5 Top Predictive Maintenance Startups impacting Industry 4.0

The insights of this data-driven analysis are derived from the Big Data and Artificial Intelligence (AI)-powered StartUs Insights Discovery Platform, covering 2 093 000+ startups and scaleups globally. The platform gives you an exhaustive overview of emerging technologies and relevant startups within a specific field in just a few clicks.

The Global Startup Heat Map below reveals the distribution of the 135 exemplary startups and scaleups we analyzed for this research. Further, it highlights five predictive maintenance startups that we hand-picked based on criteria such as founding year, location, funding raised, and more. You get to explore the solutions of these five startups and scaleups in this report. For insights on the other 130 predictive maintenance solutions, get in touch.

Predictive-Sigma enables Smart Predictive Maintenance

Predictive maintenance is the analysis of a network of assets that enables to promptly predict potential outages. It ensures maximum machinery protection and minimum productivity impact, without necessarily increasing the overall system complexity. For this, startups utilize the industrial Internet of Things (IIoT), artificial intelligence, and machine learning.

Spanish startup Predictive-sigma offers a technological platform for predictive maintenance. The startup’s solution increases asset availability and improves the performance of industrial assets. This enables energy and telecom companies to detect machine failures in advance and follow countermeasures.

Semiotic Labs facilitates Asset Health Monitoring

Smart condition monitoring is used in the early detection and elimination of equipment defects that could lead to unplanned downtime or unnecessary expenditures. It takes into account sensor data, previous inspections, as well as the location and condition of the plant. This allows industrial plants to streamline operations and plan maintenance tasks with minimal downtimes.

Semiotic Labs is a Dutch startup that offers smart machine monitoring solutions for industry 4.0 applications. The startup’s solution, SAM4, combines machine learning and electrical signal analysis to monitor and detect machine failures with high accuracy. This allows manufacturing companies to eliminate unplanned downtime as well as optimize maintenance tasks and costs.

Quadrical Ai offers Predictive Maintenance Guidance

Predictive analytics is a subcategory of advanced analytics and big data that allows the prediction of future events and occurrences based on historic data sets. In an industrial setup, it describes the collection and analysis of data generated in operations and throughout the product lifecycle to predict future outcomes. Predictive analytics also enables the detection of abnormal machine behaviors without human input. This allows companies to optimize maintenance tasks and reduce labor costs.

Canadian startup Quadrical Ai develops a predictive operations and maintenance (O&M) guidance system for solar farms. The startup’s digital twin platform centralizes asset data and enables real-time monitoring. Its integrated maintenance management system leverages this data to prioritize maintenance tasks, allowing plant owners and managers to prevent anomalies and outages.

Seebo enables Predictive Quality Management

Root Cause Analysis (RCA) is the process of identifying factors that cause defects or quality deviations in the manufactured product. Startups provide RCA solutions using machine learning and data analytics. They utilize historical and real-time data from the production lines to offer unbiased insights into floor productivity.

US-based startup Seebo automates root cause analysis to predict production losses. The startup’s solution uses artificial intelligence to develop digital models of manufacturing processes and identify the suspected cause of losses. This allows food, cement, and steel manufacturers to gain increased visibility into manufacturing operations and avoid quality deviations.

Industrial Analytics offers Digital Twin-based Predictive Maintenance

Digital twins are continuous learning systems, powered by machine learning algorithms, which adapt to the changes in the state and configuration of a physical twin. Predictive maintenance solutions powered by digital twins precisely monitor equipment health and promptly recognize potential anomalies. This, in turn, allows manufacturers to significantly reduce downtimes and maintenance costs.

Industrial Analytics is a German startup that develops a digital twin-based predictive maintenance platform. The startup’s solution incorporates real-time asset and process data from digital twins to improve pattern recognition and anomaly detection. This enables manufacturers to minimize false alarms and improve productivity.

Discover more Industry 4.0 Startups

Industry 4.0 startups such as the examples highlighted in this report focus on digital twins, artificial intelligence, predictive analytics, and condition monitoring. While all of these technologies play a major role in advancing the industry, they only represent the tip of the iceberg. To explore industrial technologies in more detail, simply let us look into your areas of interest. For a more general overview, download our free Industry 4.0 Innovation Report to save your time and improve strategic decision-making.

![Future of Robotics: 12 Trends Powering the Next Wave [2025-2030]](https://www.startus-insights.com/wp-content/uploads/2025/06/Future-of-Robotics-SharedImg-StartUs-Insights-noresize-420x236.webp)