Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

Our Innovation Analysts recently looked into emerging technologies and up-and-coming startups working in on solutions for the energy sector. As there is a large number of startups working on a wide variety of solutions, we want to share our insights with you. This time, we are taking a look at 5 promising biodiesel startups.

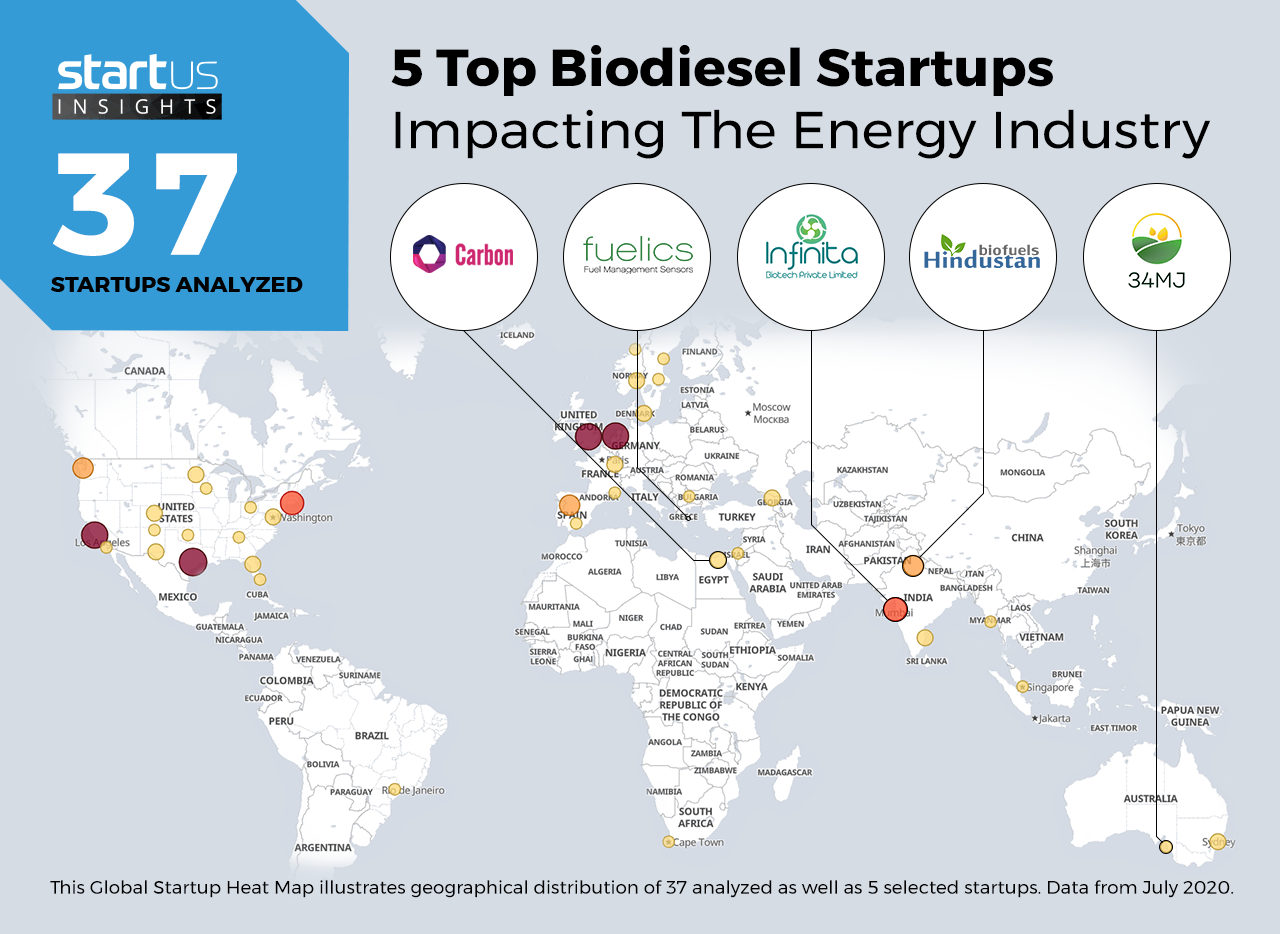

Heat Map: 5 Top Biodiesel Startups

Using our StartUs Insights Platform, covering 1.116.000+ startups & emerging companies, we looked at innovation in the field of energy. For this research, we identified 37 relevant solutions and picked 5 to showcase below. These companies were chosen based on a data-driven startup scouting approach, taking into account factors such as location, founding year, and technology among others. Depending on your specific criteria, the top picks might look entirely different.

The Global Startup Heat Map below highlights 5 startups & emerging companies developing biodiesel solutions. Moreover, the Heat Map reveals regions that observe a high startup activity and illustrates the geographic distribution of all 37 companies we analyzed for this specific topic.

CARBON – Biodiesel Processing System

The benefit of substituting petrodiesel with biodiesel is a decrease in carbon emissions as biodiesel burns cleaner than petrodiesel. Even a blend of both as little as B2 (2% biodiesel and 98% petroleum diesel) results in a considerable decrease in greenhouse gasses. Nowadays, all diesel engines are capable of running on biodiesel and it is cost-effective compared to petrodiesel. This vast avenue for innovation enables startups to work on solutions to manufacture quality biodiesel efficiently.

Egyptian startup CARBON provides the fuel processing system FuelMax for managing biodiesel production. With the help of advanced process control and automation, the system bolsters the environmentally friendly manufacturing of biodiesel. Moreover, FuelMax enables better waste management and optimizes emissions. This technology does not require a traditional wet wash technique for biodiesel purification and enables faster processing of biodiesel by eliminating the separation time.

Hindustan Biofuels – Waterless Hydrogen Washing

Traditionally, manufacturers wash the biodiesel with water, a solvent, to remove impurities. This process is time-consuming as the biodiesel and water take a long duration to separate and residual water present in the biodiesel creates quality issues. Moreover, dry-washing and resin-based washing for biodiesel eliminates the use of water and does not require frequent changes. As a result, startups and emerging companies create resin-based solutions for washing biodiesel.

Indian startup Hindustan Biofuels manufactures adsorber resins for washing biodiesel. With the use of hydrogen bonding adsorbers, organizations wash the biodiesel and the resins regenerate for continued use. This resin enables minimizing downtime and increasing the quality of biodiesel. Moreover, the average lifetime of the resin is 5 years – a factor that decreases costs.

34MJ – Small-Scale Biodiesel Units For Localized Generation

There are also many regions in the world with limited access to energy – a disadvantage in many aspects. Being able to produce biodiesel locally enables remote villages to become self-sustainable. To achieve this, emerging companies create biodiesel self-generation units to help local communities reduce diesel consumption and their carbon footprint.

Australian startup 34MJ manufactures small-scale biodiesel units for farmers and mining operators. These container-sized units are built to be compact and mobile. The biodiesel produced is on a small scale and is 100% biodegradable as it breaks down in 20 days.

Infinita – Enzymes For Biodiesel

Traditionally, the esterification process involves methanol to process biodiesel. This process creates high energy electrons and makes the reaction mechanism difficult to control. Moreover, the esterification process requires vast energy to be efficient, which motivates startups to develop enzymes for the esterification process to improve energy consumption levels.

Indian startup Infinita creates enzymes for biodiesel manufacturing. These specialized enzymes enable the esterification of oils to produce biodiesel. The enzymatic process compared to the chemical process requires only one-tenth of the energy to produce biodiesel. An additional benefit of using the enzymes is operational flexibility as the processing of various cheap and high free fatty acid (FFA) feedstocks such as grease, acid oils, used cooking oil, and animal fat becomes operationally viable.

Fuelics – Fuel Management Sensors

The energy required to power and run factories and production facilities is a major cost component. Maintaining, controlling, and monitoring the fuel consumption with sensors enables organizations to be mindful of their costs. To provide a solution for this, startups manufacture sensors for fuel management that work with biofuels such as biodiesel.

Greek startup Fuelics produces Internet of Things (IoT) enabled sensors for biodiesel fuel management. With the help of edge computing, these sensors minimize data throughput. The sensors are battery operated and also have high-level fuel resolution for accurately monitoring fuel levels. Further, the battery lasts for more than 10 years and optimizes biodiesel production and inventory.

What About The Other 32 Solutions?

While we believe data is key to creating insights it can be easy to be overwhelmed by it. Our ambition is to create a comprehensive overview and provide actionable innovation intelligence so you can achieve your goals faster. The 5 biodiesel startups showcased above are promising examples out of 37 we analyzed for this article. To identify the most relevant solutions based on your specific criteria, get in touch.