Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

Our Innovation Analysts recently looked into emerging technologies and companies working on solutions for shipbuilding. As there is a large number of companies working on a wide variety of solutions, we want to share our insights with you. This time, we are taking a look at 4 promising robotics solutions.

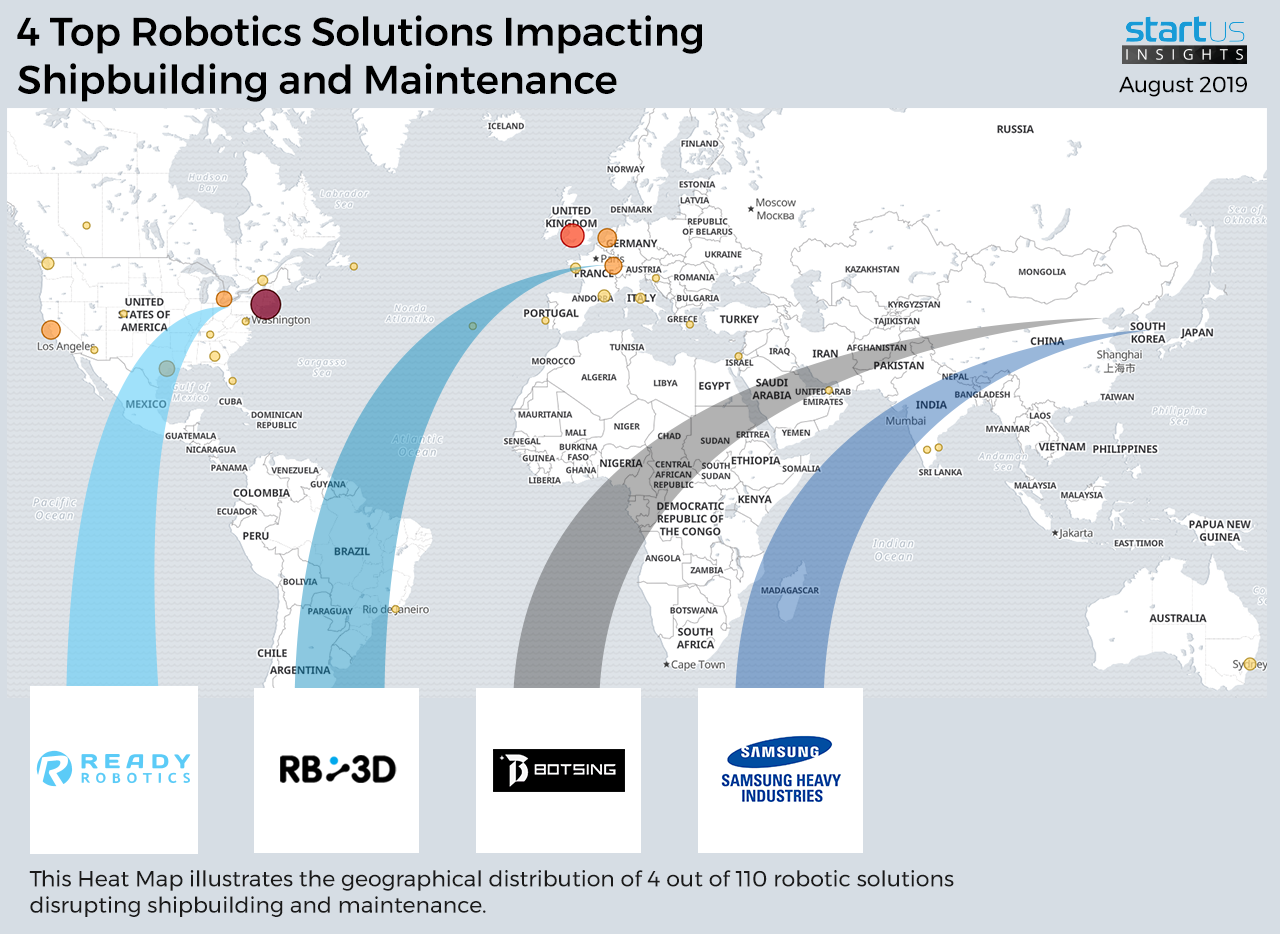

Heat Map: 4 Top Robotics Solutions

For our 4 top picks, we used a data-driven scouting approach to identify the most relevant solutions globally. The Global Heat Map below highlights 4 interesting examples out of 110 relevant solutions. Depending on your specific needs, your top picks might look entirely different.

Beijing Bo Tsing Tech – Welding & Cutting Robotics

Building a ship encompasses a myriad of processes to be produced during the design and assembly stages of shipbuilding. Some of these tasks can be very demanding and sometimes, dangerous. Welding, cutting, and other steel-related activities are being slowly but steadily delegated to smart robots to increase workplace safety and make the assembly stage more efficient and effective.

Chinese startup Beijing Bo Tsing Tech trackless unguided welding robots for the shipbuilding sector. The startup’s solution combines AI, laser-based vision sensing, and multi-sensor integrated control to achieve high precision welding. This allows shipbuilders to automate the otherwise risky and time-intensive manual welding process, improving efficiency and worker safety.

Geoje Shipyard – Painting Robotics

Considering the size and complexity of painting large sea vessels during the shipbuilding process, it is vital to ensure that preparation for, and the painting process itself, is completed as efficiently as possible in order to avoid premature corrosion or other abrasive conditions. Using robots for this process reduces the likelihood of errors and significantly cuts down the assembly or maintenance time.

South Korean company Geoje Shipyard, owned by Samsung Heavy Industries, enables building ships with significantly higher dock turnover per year – about 10 ships. Their “spider robots”, used for blasting off the rust and other contaminants from the interior and exterior metal panels, automate the process of preparing a ship for painting. The robot uses a 3D camera sensor and a System-on-Chip (SoC) to navigate around the vessel and was originally used by the firm for automated welding purposes.

RB3D – Wearable Robotics & Exoskeletons

Shipbuilding always requires services for heavy lifting and assembly of large parts. While most powerlifting is done by heavy-duty machinery and transport, some still have to be performed manually by workers potentially putting them at risk of injury. Wearable robots, also known as exoskeletons, are capable of increased lifting capabilities and support the human body with external structures and mechanisms.

French company RB3D designs and develops ‘powered’ exoskeletons which provide workers with structural support using electrical motors to make objects feel much lighter than their actual weights, enabling easy lifting of large parts. Their Hercule exoskeleton allows human workers to carry up to 100 kilograms with minimal strain and effort.

Ready Robotics – Collaborative Robotics

The entire manufacturing industry is rapidly shifting towards collaborative robots, or cobots, for day-to-day operations. Their main goal is to collaborate with humans to make the production and assembly processes highly efficient. Lightweight and mobile cobots can move across factories and even between manufacturing plants by following and assisting employees. Hundreds of thousands of components – small and large, can be transported to the assembly points efficiently with the help of collaborative robots.

The USA-based company Ready Robotics produces various cobots that facilitate industrial and manufacturing automation services. The company offers Robotics-as-a-Service (RaaS) for manufacturers to pay a monthly ‘wage’ to such robots and cobots. Their Forge Station cobot is being used in Computer Numerical Control (CNC) and welding operations for picking up, transporting, attaching various elements, and to do the heavy lifting.

What About The Other 106 Solutions?

While we believe data is key to creating insights it can be easy to be overwhelmed by it. Our ambition is to create a comprehensive overview and provide actionable innovation intelligence for your Proof of Concept (PoC), partnership, or investment targets. The 4 solutions showcased above are promising examples out of 110 we analyzed for this article. To identify the most relevant solutions based on your specific criteria and collaboration strategy, get in touch.

![Future of Robotics: 12 Trends Powering the Next Wave [2025-2030]](https://www.startus-insights.com/wp-content/uploads/2025/06/Future-of-Robotics-SharedImg-StartUs-Insights-noresize-420x236.webp)