Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

Our Innovation Analysts recently looked into emerging technologies and up-and-coming startups working on solutions for the shipbuilding industry. As there is a large number of companies working on a wide variety of solutions, we decided to share our insights with you. This time, we are taking a look at 4 promising Digital Twin Solutions.

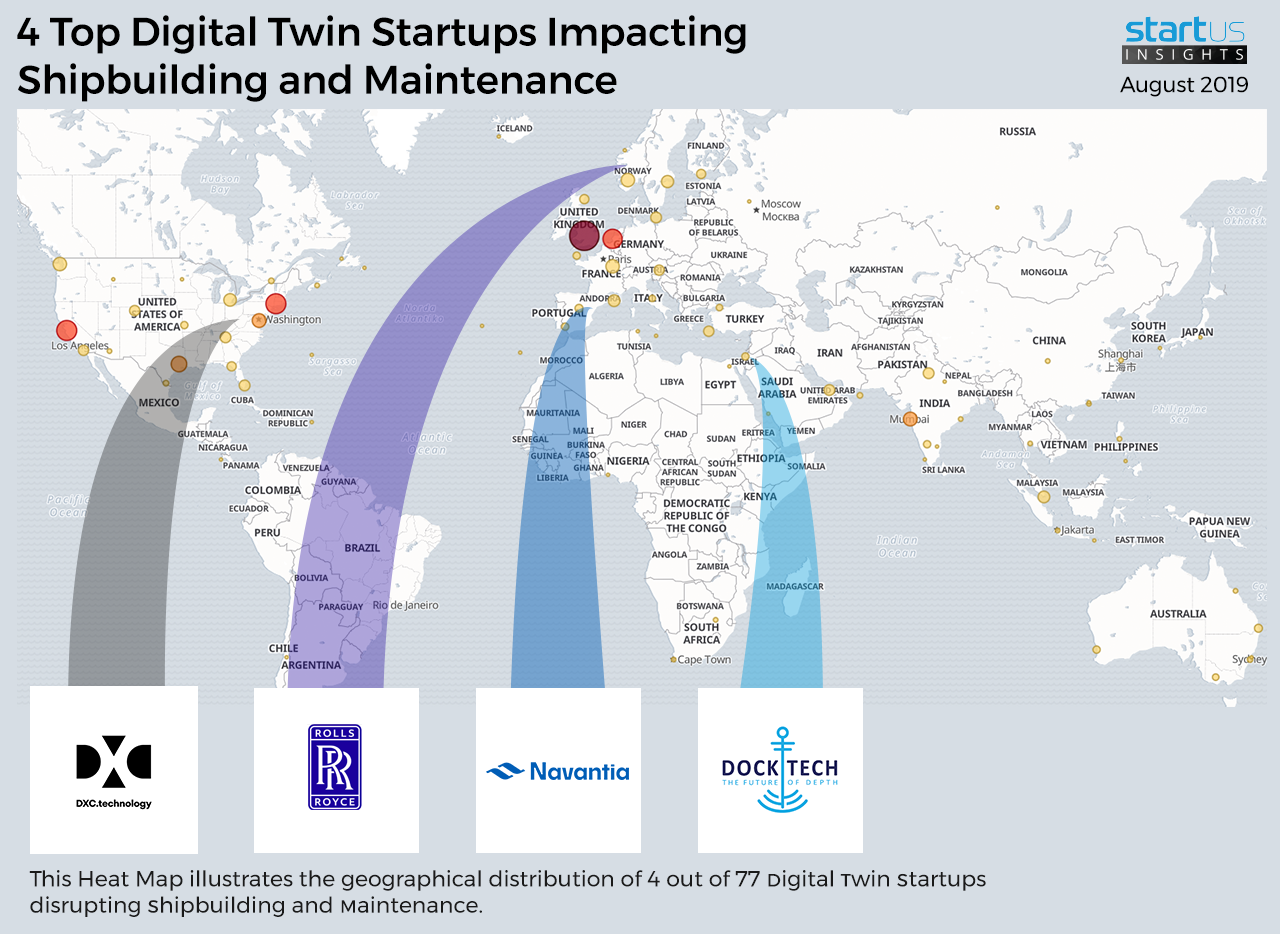

Heat Map: 4 Top Digital Twin Solutions

For our 4 top picks, we used a data-driven technology scouting approach to identify the most relevant solutions globally. The Global Startup Heat Map below highlights 4 interesting examples out of 77 relevant solutions. Depending on your specific needs, your top picks might look entirely different.

DockTech – Data-Driven Decision Making

Operating and managing a ship throughout its lifecycle is an enormous and complex task. With the current state of fragmentation in IT systems and databases, it is not feasible for ship operators to keep track of all of the ship’s components, its operational state, and manage their portfolio of ships, all under one roof. Digital Twins allow for integration across a ship’s components into one piece of software, constantly gathering data in real-time from sensors, Internet of Things (IoT) devices, and drones. Israeli startup DockTech provides digital twins of waterways for ports and rivers. The startup combines sensor data, such as water depth, location, and temperature, from vessels with AI and big data to better understand shipping route conditions. This allows ports and rivers to predict change patterns to improve navigational safety, cargo utilization, and resource optimization.

Navantia – Simulation Of Operation Scenarios

As the shipbuilding process is quite complex, it becomes vital to understand how a vessel behaves in various real-world scenarios, identify its shortcomings and deliver high-quality solutions to the stakeholder. As a ship evolves and is subject to regular maintenance procedures and testing, so is its digital twin. With data gathered from the lifecycle of a vessel, one can generate complex operational simulations and, when needed, adjust the ship’s design or layout using technologies like cloud computing, machine learning, and IoT. The 300-year-old Spanish shipbuilding company Navantia specializes in digital twin-based simulations for tracking a ship’s life cycle, from the design stage to its delivery to the customer and beyond.

DXC Technology – Predictive Malfunction Diagnostics

Accurately predicting the lifespan of a ship’s engine, hull, electrical systems, and other components is critical for shipbuilders. Due to a multitude of factors such as the purpose of the ship, the surrounding environment, weather conditions, and assembly process, digital twin technology is used to streamline data processing for predictive analytics. In combination with Artificial Intelligence (AI), digital twins can diagnose malfunctioning parts or systems and facilitate maintenance during the guarantee phase. The US-based IT provider DXC Technology uses AI on a digital twin setup to predict critical parts failures, simulate how a fire can spread during an emergency or during an attack, especially for navy and combat ships.

Open Simulation Platform – Improved Decision Making

During a ship’s lifespan, it might require changes to its software or hardware components, replacement of parts or other components that influence its operational performance. Digital twin technology allows for predicting the effect of a certain change or modification in the real world, taking into account the operational data from other vessels and simulating it onto a given ship’s digital copy. British giant Rolls-Royce Marine, in partnership with the Norwegian University of Technology Science (NTNU) and Hyundai Heavy Industries, develops an open-source platform called Open Simulation Platform (OSP) to standardize the creation of digital twin models. They use cloud computing and machine learning technologies to simulate changes to and identify aspects that affect the ship’s performance. These standards unify IT systems, help manage fleets of vessels, and compare their performances with ease.

What About The Other 73 Solutions?

While we believe data is key to creating insights it can be easy to be overwhelmed by it. Our ambition is to create a comprehensive overview and provide actionable innovation intelligence for your Proof of Concept (PoC), partnership, or investment targets. The 4 startups showcased above are promising examples out of 77 we analyzed for this article. To identify the most relevant solutions based on your specific criteria and collaboration strategy, get in touch.