Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

Innovations in additive manufacturing enable sophisticated medical parts and components like tissues, organs, prostheses, and more. Additive manufacturing also increases the speed and efficiency of healthcare and medical product development and production while reducing costs. Advances in 3D modeling, simulation, laser sintering, etc. enable hospitals and clinics to improve patient outcomes and overcome the rising cost of the medical industry. This article provides an overview of the top 10 global 3D printing trends in healthcare in 2023. Read more to explore the latest developments in additive manufacturing impacting the healthcare industry and how they impact care delivery.

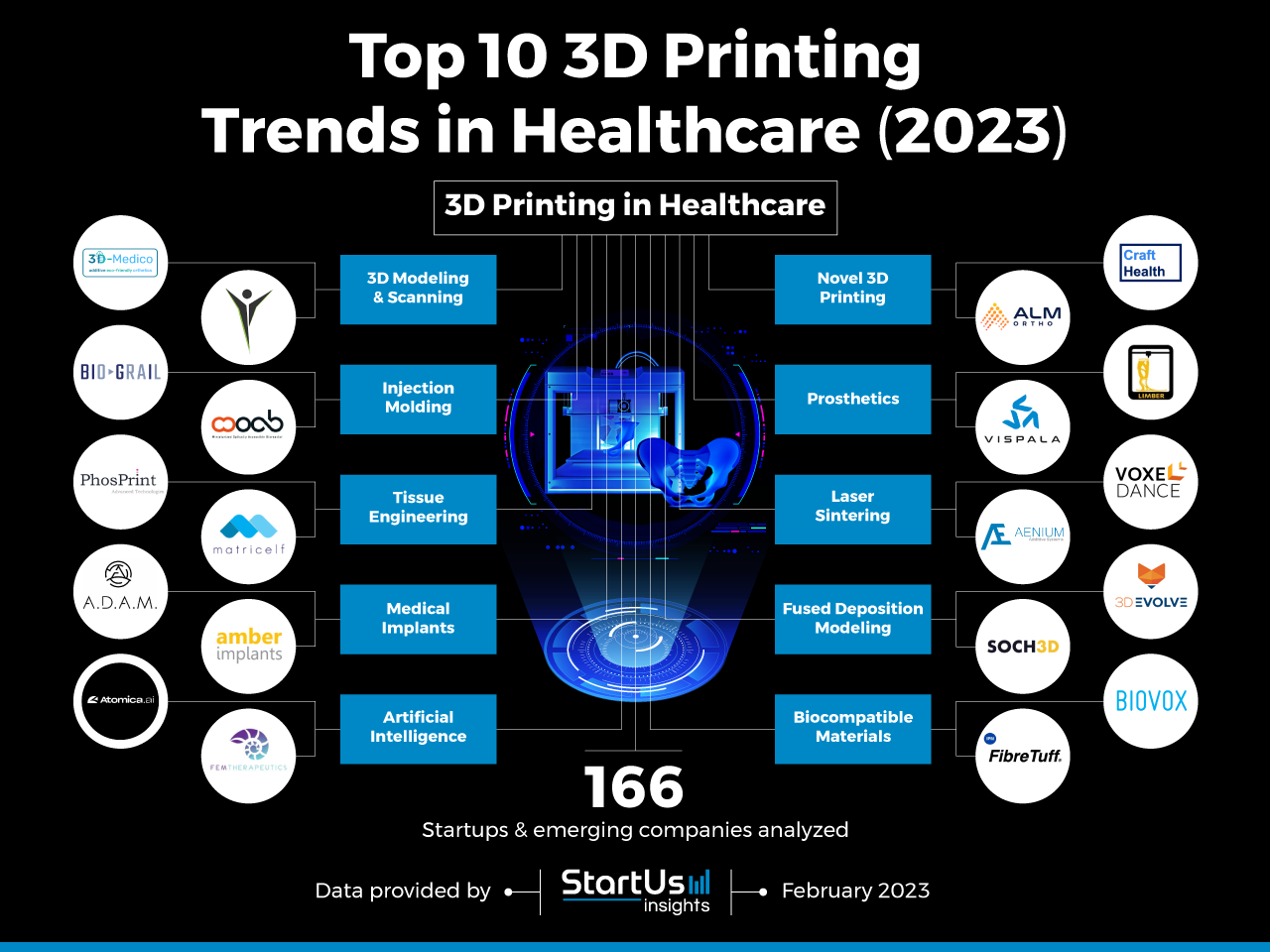

Innovation Map outlines the Top 10 3D Printing Trends in Healthcare & 20 Promising Startups

For this in-depth research on the Top 3D Printing Trends in Healthcare & Startups in the field, we analyzed a sample of 166 global startups & scaleups. The result of this research is data-driven innovation intelligence that improves strategic decision-making by giving you an overview of emerging technologies & startups in the healthcare industry. These insights are derived by working with our Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 3 790 000+ startups & scaleups globally. As the world’s largest resource for data on emerging companies, the SaaS platform enables you to identify relevant startups, emerging technologies & future industry trends quickly & exhaustively.

In the Innovation Map below, you get an overview of the Top 10 3D Printing Trends & Innovations in Healthcare that impact 166 companies worldwide. Moreover, the 3D Printing Trends in Healthcare Innovation Map reveals 20 hand-picked startups, all working on emerging technologies that advance their field.

Top 10 3D Printing Trends in Healthcare (2023)

- 3D Modeling & Scanning

- Injection Molding

- Tissue Engineering

- Medical Implants

- Artificial Intelligence

- Novel 3D Printing

- Prosthetics

- Laser Sintering

- Fused Deposition Modeling

- Biocompatible Materials

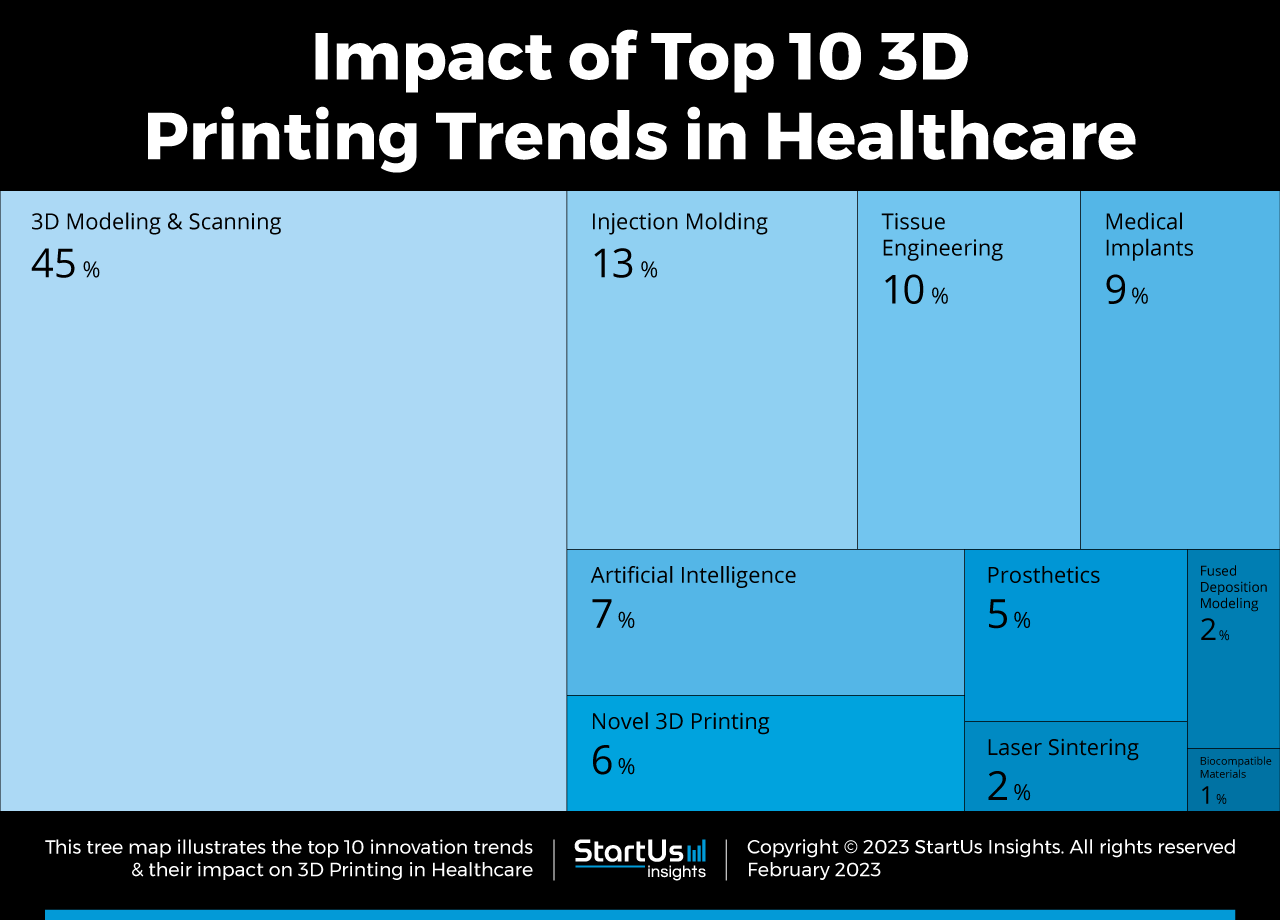

Tree Map reveals the Impact of the Top 3D Printing Trends in Healthcare

Based on the Innovation Map for 3D Printing in Healthcare, the Tree Map below illustrates the impact of the Top 10 3D Printing Trends in Healthcare in 2023. Advances in 3D scanning and modeling provide detailed images and models of body structures to enable precise diagnostics and treatments. Injection molding, fused deposition modeling, and laser sintering create custom and personalized medical products that also address patient-specific needs. Besides, prosthetics made with additive manufacturing are lower in cost and ensure faster production cycles. 3D-printed medical implants also improve patient mobility through the optimization of implant shapes and structures. AI assists medical professionals in assessment while biocompatible materials reduce side effects in patients. Lastly, tissue engineering powered by 3D bioprinting enables the creation of new tissues and organs for applications such as transplantation and regenerative medicine.

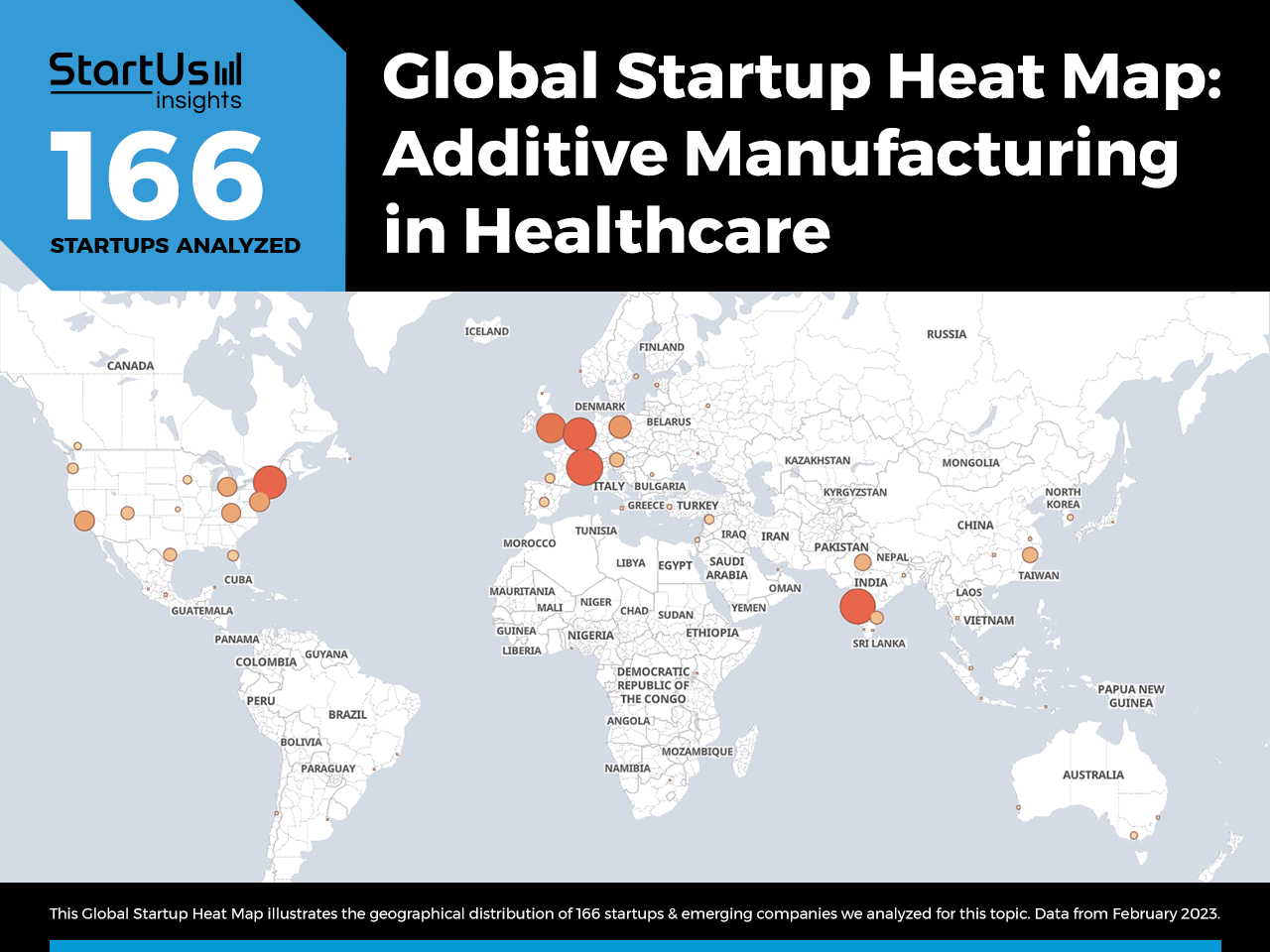

Global Startup Heat Map covers 166 3D Printing Startups & Scaleups in Healthcare

The Global Startup Heat Map below highlights the global distribution of the 166 exemplary startups & scaleups that we analyzed for this research. Created through the StartUs Insights Discovery Platform, the Heat Map reveals that Western Europe and the US see the most startup activity.

Below, you get to meet 20 out of these 166 promising startups & scaleups as well as the solutions they develop. These additive manufacturing startups are hand-picked based on criteria such as founding year, location, funding raised, & more. Depending on your specific needs, your top picks might look entirely different.

Top 10 3D Printing Trends in Healthcare in 2023

1. 3D Modeling & Scanning

Conventional patient-oriented medical solutions do not factor individual characteristics like body shape, size, and skin surface area. Additionally, replacing older implants and medical devices for patients requires remanufacturing to match the patient’s body. Rapid, high-precision 3D scanning and modeling accelerates product personalization and saves costs when combined with additive manufacturing workflows. Besides, portable scanners, 3d modeling software, and medical visualization tools avoid the need for invasive medical procedures. They allow medical professionals, like doctors and surgeons, to create custom components and detailed 3D medical models in a short time frame and without expensive equipment.

3D-Medico develops a Phone-based 3D scanner

German startup 3D-Medico makes 3D scanning software for smartphones. The scanner captures all-around videos of body parts to create adjustable and changeable orthosis. 3D-Medico’s smartphone-based scanning solution also renders images on its server and does not require a separate computer-aided design (CAD) device. This enables medical professionals and institutions to improve patient care by providing accurate and precise 3D representations of anatomic structures for 3D printing.

BeyondShape offers Photogrammetry-based 3D Reconstruction

Italian startup BeyondShape creates a scanning device that enables non-invasive disease diagnosis and monitoring. The startup’s instant body scanner, inbody, accurately recreates 3D human body shapes with support for multiple acquisition postures. Its companion data analysis software, beyondshape toolbox 3D, allows medical professionals to then extract and monitor a series of measures and indices from human body models. It also provides downloadable medical reports that contain information from the scan data. The startup’s device supports a wide range of applications, including prostheses and orthoses, while enabling the fast production of custom biomedical equipment.

2. Injection Molding

High cost of device and equipment production as well as complex manufacturing processes are critical issues in the healthcare and medical industries. Injection molding, on the other hand, provides a scalable and cost-effective method for the mass production of implants, beakers, surgical equipment, orthopedics, and more. Further, the use of advanced engineering and medical-grade plastics in the molding process results in better-finished products that also comply with medical guidelines. Injection molding improves patient treatment and safety by enabling production using biocompatible materials and making medical devices more affordable.

Biograil creates Injection Molded Pharmaceuticals

Biograil is a Danish startup that manufactures pharmaceutical products using injection molding. Its technology, BIONDD, directs the biological drug molecules inside the stomach wall for safe and effective release to the body. This circumvents issues, such as degradation and poor gut absorption, commonly found in traditional oral medication. Moreover, the technology meets FDA approval and supports low-cost, high-volume commercial manufacturing by injection molding.

MOAB makes a Miniaturized Optically Accessible Bioreactor

MOAB is an Italian startup that fabricates in-vitro models to observe 3D tissues in transparent polycarbonate using injection molding. The startup’s miniaturized optically accessible bioreactor (MOAB) enables medical researchers to observe the behavior of multiple stem cell lines in 3D organoids. This prevents unwanted outcomes and assists in best candidate discovery for clinical applications. Moreover, the design of the platform is optimized for mass production and uses affordable injection molding processes. MOAB significantly reduces the time to market and cost of newly developed drugs and biopharmaceuticals.

3. Tissue Engineering

Conventional pharmaceutical treatments do not work on tissues or organs that are severely damaged and thus require transplant or reconstruction. This is where additive manufacturing benefits healthcare providers and patients by creating personalized new tissues and organs in a laboratory setting. Leveraging printable bio-inks and biomaterials, startups are growing tissues, bones, cartilage, and organs to improve patient care. Moreover, such innovations enable hospitals to overcome the shortage of organ donors and reduce the risk of rejection in transplant patients.

PhosPrint Skin provides Laser Bioprinting

Greek startup PhosPrint develops PhosDB. I, a high-resolution laser bioprinter for precise and rapid delivery of cells on planar and curved substrates. It features a dual-wavelength module to print and post-process bio-inks on demand. The bioprinter also prints bio-inks for tissue constructs with a resolution of 10 μm and precisely places cells at predefined positions in 3-dimensional spaces to build complex structures. It thus finds applications in demanding cell-printing applications like tissue regeneration and biosensing.

Matricelf 3D makes 3D-Printed Hearts

Israeli startup Matricef develops an autologous tissue regeneration platform that creates hydrogels composed of a matrix and cells derived from patient biopsies. The startup’s extracellular matrix (ECM)-based hydrogel 3D printed biocompatible vascularized cardiac patches deliver vascularized tissue by injection of the autologous omental hydrogel. This technology utilizes personalized hydrogel as a bio-ink for tissue and organ 3D printing. By incorporating patient cells into the hydrogel, the resulting tissues and organs feature an exact match with the patient immunological, biochemical, and anatomical properties. Matricelf’s regenerative medicine thus heals spinal cord injuries (SCI), age-related macular degeneration (AMD), Parkinson’s disease, and myocardial infarction.

4. Medical Implants

Medical implants may lead to multiple risks from implant failure, such as infection, tissue damage, and the need for revision surgery. Therefore, startups are developing digital platforms in combination with additive manufacturing to design and build personalized implants within days rather than weeks or months. These solutions also enable the rapid prototyping of implants while supporting complex shapes and reducing material waste. Moreover, 3D-printed spinal, cranial, dental, and orthopedic implants provide customized products and solutions that enable hospitals and clinics to treat unmet medical issues.

A.D.A.M. creates Personalized Implants

A.D.A.M. is a US-based startup that provides on-demand 3D bioprinting for bone implants. The startup’s digital platform lets patients upload magnetic resonance imaging (MRI) and computerized tomography (CAT) scans to create personalized and precise 3D models of implants. Its proprietary 3D printers then print the 3D models within a production time of up to 24 hours. Moreover, the resulting implants are functional bones with no toxic, allergic, or teratogenic effects. This provides medical professionals with sterilized 3D-printed bone implants that are ready for use in surgery.

Amber Implants makes a Vertebral Body Augmentation System

Amber Implants is a Dutch startup that develops solutions to tackle vertebral compression fractures (VCFs) and burst fractures. Its vertebral body augmentation system, VCFix Spinal System, features a 3D-printed perforated structure and consists of preparation, implantation, and an optional supplementary fixation kit. The system stimulates bone ingrowth as a more natural healing process. Additionally, the system avoids the use of bone cement for maintaining bone fractures and eliminates the dangers associated with cement injections. This way, Amber Implant’s solution enables medical professionals to improve patient outcomes for spinal fractures.

5. Artificial Intelligence

Current additive manufacturing methods involve printing multiple prototypes due to the presence of defects and errors. Additionally, 3d printers are prone to breakdown in large-volume production, causing delays. At the same time, AI-driven additive manufacturing workflows, like assisted maintenance and quality management, improve production throughput. This approach also cuts down production time and cost as well as delivers large amounts of data that aid medical device development. This way, artificial intelligence in additive manufacturing enables hospitals and clinics to provide their patients with more efficient, accurate, and customizable solutions.

Atomica offers an AI-powered Dentistry Platform

US-based startup Atomica provides Atomica Scanner, implant planning software that provides guided digital workflows for accurate and predictable implant treatments. It digitally scans patients and replaces manual dental impressions. Atomica’s software suite then lets dentists plan, design, and 3d print surgical guides for accurate and precise implant surgeries. The platform also features orthodontic and smile design simulation apps that boost patient engagement by showing them the expected treatment outcomes. Atomica’s solutions provide dentists with the tools to deliver complete or temporary prosthetic solutions to their patients on the day of surgery.

Fem Therapeutics simplifies Pelvic Floor Modelling

Canadian startup Fem Therapeutics creates FemPessos, an AI-based platform that uses proprietary gynecological data to design and customize medical devices. Its AI analyzes pelvic floor data to design patient-specific pessary. Healthcare providers are then able to 3d print the pessary with medical-grade silicone. Furthermore, patients receive a reusable pessary equipped with an applicator and withdraw tab to ease insertion and removal. By doing so, the platform improves wearer comfort and reduces the discontinuation rate.

6. Novel 3D Printing

While additive manufacturing opens the possibilities of custom medical device production, many conventional 3D printing methods are not biocompatible. That is why startups are providing biocompatible 3D printing technologies like electron beam melting (EBM), stereolithography, and binder jetting. They overcome such problems by printing with medically approved biocompatible materials. Innovations in 3D printing also allow the pharmaceutical, biotechnology, and medical industries to make unique formulations and reduce product turn-around times.

Craft Health integrates Multi-material Printing

Singaporean startup Craft Health specializes in pharmaceutical drug delivery using 3D printing. CraftBlends are the startup’s 3D printable proprietary formulations for varied controlled releases. The formulations include immediate, delayed, enteric, and sustained release and oral disintegrating tablet (ODT) formulations. Moreover, the tables are printable in various shapes and geometries with necessary active ingredients mixed with formulations in the desired controlled release profile. Craft Health thus enables the pharmaceutical industry to create personalized supplements and medicines with short manufacturing cycles.

ALM Ortho offers Electron Beam Melting

US-based startup ALM Ortho creates orthopedic implants for the spine using electron beam melting. The startup’s manufacturing process uses a 3D printer capable of printing with biocompatible titanium materials. Further, its anatomic designs conserve bones and make surgeries more efficient. The startup also optimizes implants for bone growth with porous metal and lattice structures. Moreover, ALM Ortho’s printing technology provides physicians with a high-quality, patient-centric implant solution with a short time to market.

7. Prosthetics

Prosthetics generally cause discomfort, are high in cost, and have limited functionality. Additive manufacturing enables healthcare and medical industries to create orthotics, knee braces, bionic limbs, and assistive devices tailored for specific patients. Moreover, 3D printing processes produce prosthetics with innovative materials, such as metal composites and polymers, that provide improved strength, lightweight, and durability, reducing the need for replacements.

LIMBER Prosthetics & Orthotics manufactures Affordable Prosthetic Devices

LIMBER Prosthetics & Orthotics is a US-based startup that creates affordable prosthetic devices. The startup’s process scans amputee limbs and converts them into personalized prostheses. Its manufacturing process integrates imaging, modeling, simulation, testing, digital design, and 3D printing to reduce production costs significantly. Apart from lower costs, the startup also accommodates each user’s needs to better assist amputees and disabled patients.

Vispala Technologies provides Wearable Assistive Technology

Vispala Technologies is an Indian startup that creates custom 3D-printed prosthetics and orthotics that improves wearer grip. Its solution, iGrip, is a voluntary-closing, body-powered, below-elbow prosthetic system that equals or exceeds the user’s normal capabilities. The lightweight prosthetic offers high-force transmission and features a position control switch that allows for constant gripping with position locking. This way, the startup’s 3D-printed prosthetics restore amputees’ mobility and improve their quality of life.

8. Laser Sintering

By using a laser to bind together powder particles from a powder bed, selective laser sintering (SLS) improves product accuracy, reproducibility, and biocompatibility. This enables the production of medical devices and implants with consistent and repeatable results. SLS also supports a wide range of shapes and geometries, which enables the production of complex and intricate medical devices. This enables hospitals and clinics to reduce the risk of reactions from prosthetics and improve patient outcomes cost-effectively.

Aenium develops Multi-Volume Variable Laser Energy Density

Spanish startup Aenium specializes in end-to-end industrial additive manufacturing of components. The startup’s patented multivolume variable laser energy density manufacturing method creates components with complex specifications. Aenium also manufactures components that require different mechanical properties or thermal/electrical behavior over the same part. Moreover, Aenium’s laser-based additive manufacturing uses advanced materials and powders to create medical devices and prosthetics that are fully biocompatible. By doing so, the startup accelerates the industrial processes of original equipment manufacturers cost-effectively.

VoxelDance offers 3D Printing Data Preparation Software

Chinese startup VoxelDance develops 3D printing software solutions compatible with selective laser melting (SLM), stereolithography (SLA), digital light processing (DLP), and selective laser sintering (SLS) printing technologies. The startup’s software, Voxeldance Additive, supports a wide range of file formats, rapid 2D and 3D nesting placement, and advanced orientation tools to manipulate objects. It also includes 3D laser sintering solutions such as 3D model import, repair, orientation optimization, 3D nesting, slicing, hatching, etc. Further, designers quickly prepare 3d print builds, improve production efficiency, and significantly increase printing success rates through its geometry engine and streamlined workflow.

9. Fused Deposition Modeling

FDM constructs three-dimensional objects with a temperature-controlled head that extrudes thermoplastic material layer by layer. This approach increases material selection choices, including thermoplastics, metals, and ceramics, and production accuracy. Its production process is relatively low-cost, removes the need for clinics to have sophisticated equipment, and produces larger parts compared to methods like SLS.

3D Evolve manufactures FDM Printers

3D Evolve is an Italian startup that manufactures fused deposition modeling printers for high-precision medical applications like dentistry. The startup’s printers feature patented high-precision movement with axis positioning repeatability of 0.001 mm. It also contains a high-temperature copper heated bed that provides thermal stability and a flexible spring steel printing surface. 3D Evolve’s printers create study samples based on the real measurements carried out with instruments such as CT scans, MRIs, and digital scans. Besides, the large availability of filaments for medical use enables healthcare professionals to quickly print parts and components for a wide range of needs.

Soch3D offers FDM-printed Medical Models

Soch3D is an Indian startup specializing in FDM-powered cloud-based manufacturing. The startup provides an online platform that allows clients to upload 3D design stereolithography (STL) files and process them to deliver pricing quotations. The clients then select from a range of printing techniques such as SLS, SLA, and FDM. The startup’s FDM printers use various materials to print low-cost and customizable anatomically correct models for medical education and training. Soch3D’s solution allows healthcare clients to 3D print braces, joint replacements, and printing replacements for large sections of lost bone structure to improve patient outcomes.

10. Biocompatible Materials

The biocompatibility of materials is highly important in implants and devices due to the potential dangers of rejection by the immune system. Therefore, startups are developing biocompatible materials like polyamide 12, silicon 30, and cyanate ester. They do not trigger reactions when in contact with living tissue. Moreover, advanced materials mimic the characteristics of tissues and bones to enhance regeneration and improve patient outcomes.

BIOVOX makes Medical-Grade Bioplastics

German startup BIOVOX develops bioplastic compounds made from renewable raw materials to reduce dependency on fossil fuels. The startup’s medical-grade 3d printable bioplastics include MedEco Rigid for rigid components, MedEco Soft for medium-stiff components, and a high-performance plastic, MedEco Perform. Additionally, MedEco’s compounds are available with a broadband antimicrobial effect that are metal-free and biocompatible. These compounds support use in injection molding, film extrusion, and blow molding to make a range of medical products. BIOVOX’s bioplastics promote energy efficiency and reduce the carbon footprint in pharmaceutical packaging, medical devices, and more.

Fibre Tuff develops Silicon Microfluidic Cooling

US-based startup Fibre Tuff creates materials that are biocompatible and possess bone-like radiopacity properties. The startup’s material features a highly conducive surface texture and cell and tissue adhesion, resembling the texture of real bones. Unlike highly-engineered nylon resins, it is easy to print and does not require extensive drying processes. By developing these unique qualities, medical anatomical models produced with Fiber Tuff’s material is more accurate and are sterilized through standard methods such as autoclaving.

Discover all 3D Printing Trends, Technologies & Startups in Healthcare

AI-based additive manufacturing solutions are reducing wastage and initial design time for medical products and devices. FDM and SLS are providing a wider range of printable materials. Additionally, 3D printing-powered tissue engineering mitigates the risk of organ rejection. Further developments such as poly jet printing and metal-polymer hybrid materials are increasing the capabilities of additive manufacturing within healthcare.

The 3D Printing Trends & Startups in Healthcare outlined in this report only scratch the surface of trends that we identified during our data-driven innovation & startup scouting process. Among others, biocompatible materials, automated 3D printing, and intricate additive manufacturing techniques will transform the sector as we know it today. Identifying new opportunities & emerging technologies to implement into your business goes a long way in gaining a competitive advantage. Get in touch to easily & exhaustively scout startups, technologies & trends that matter to you!