Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

Staying ahead of the technology curve means strengthening your competitive advantage. That is why we give you data-driven innovation insights into the materials industry. This time, you get to discover five hand-picked 3D printing materials startups.

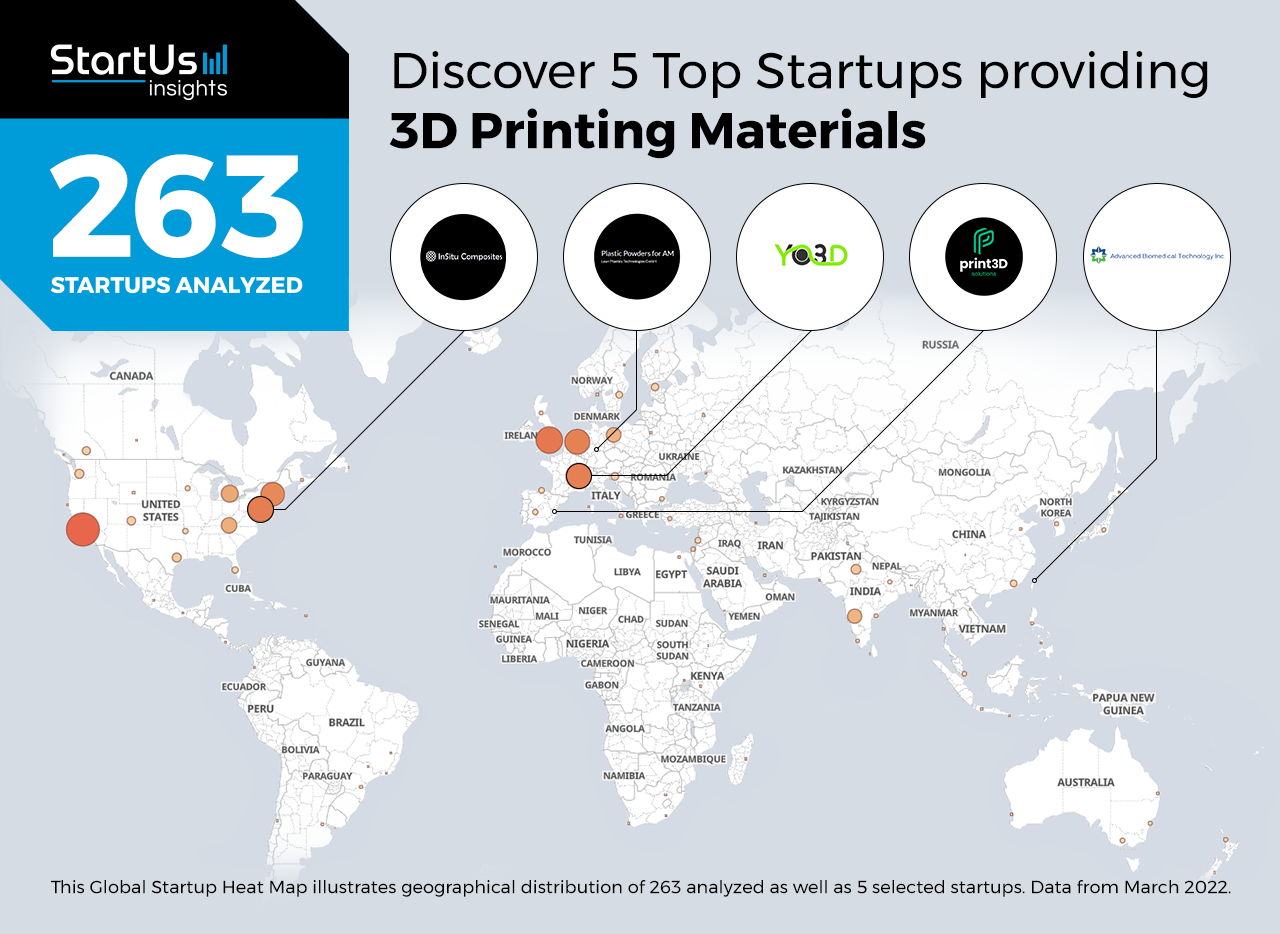

Out of 263, the Global Startup Heat Map highlights 5 Top 3D Printing Materials Startups

The insights of this data-driven analysis are derived from the Big Data & Artificial Intelligence (AI)-powered StartUs Insights Discovery Platform, covering 2 093 000+ startups & scaleups globally. The platform gives you an exhaustive overview of emerging technologies & relevant startups within a specific field in just a few clicks.

The Global Startup Heat Map below reveals the distribution of the 263 exemplary startups & scaleups we analyzed for this research. Further, it highlights five materials startups that we hand-picked based on criteria such as founding year, location, funding raised, and more. You get to explore the solutions of these five startups & scaleups in this report. For insights on the other 258 3D printing materials solutions, get in touch with us.

InSitu Composites offers Thermoplastic Composites

Founding Year: 2018

Location: New York, USA

Use this solution for Continuous Fiber Composites

US-based startup InSitu Composites manufactures continuous-reinforced thermoplastic composites for 3D printing. It mixes plastic with carbon fibers to create composites. InSitu’s processes reduce the cost of material production and offer a short lead time. This provides an efficient alternative to the automated fiber placement (AFP) technique for the manufacturing of composite parts.

Lean Plastics Technologies produces Plastic Powders

Founding Year: 2018

Location: Ilmenau, Germany

Partner for Powder-based 3D Printing

Lean Plastics Technologies is a German startup that provides plastic powders for 3D printing. It processes thermoplastics into powders for selective laser sintering (SLS), binder jetting, and multi-jet fusion. The startup’s proprietary pulverization technology enables the usage of a wider range of plastics for additive manufacturing. This addresses the issue of the limited availability of the traditional specialized plastics for powder-based 3D printing. Moreover, 3D printing requires specific particle sizes and shapes to print effectively. Lean Plastics also solves this problem utilizing its printer-agnostic proprietary pulverization technology.

Print3D Solutions provides Biocompatible Ceramics

Founding Year: 2016

Location: Valencia, Spain

Funding: USD 960 000

Innovate for Fused Deposition Modeling

Spanish startup Print3D Solutions makes ceramic filaments and pellets for additive manufacturing. It develops advanced ceramic materials resistant to high temperatures, chemicals, compression, corrosion, and thermal shocks. The ceramics are biocompatible and are useful for making personalized implants, pre-surgical tools, and dental devices. They also provide a lighter alternative to metals. Due to their ability to withstand vibrations, these ceramics find applications in engines or structures for the aerospace and automotive sector. These also find applications in the energy industry for turbine manufacturing, solar thermal energy conversion, rotors, and more.

Yo3D creates Customized 3D Printing Filaments

Founding Year: 2018

Location: Oyonnax, France

Reach out for Fused Filament Fabrication

Yo3D is a French startup that manufactures customized 3D printing filaments. It creates filament prototypes using polymers such as acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), and polycarbonate (PC). The process involves pushing the filaments through heated nozzles to create 3D printed objects layer by layer using fused filament fabrication (FFF). Yo3D’s filaments having tight dimensional tolerances find applications in the manufacturing of functional and large dimension parts.

Advanced Biomedical Technology makes Medical Filaments

Founding Year: 2016

Location: Hsinchu, Taiwan

Collaborate for Medical-grade Biomaterials

Taiwanese startup Advanced Biomedical Technology makes medical-grade filaments for 3D printing. It designs a biodegradable filament, MeDFila, using polymers or ceramics. MeDFila produces biocompatible implants, dental fillers, and bone graft substitutes through fused deposition modeling. It also finds use in plastic surgery, neurosurgery, and drug delivery. Moreover, by utilizing 3D printing, Advanced Biomdeical ensures a custom and more precise fit over the conventional one-size-fits-all approach.

Discover more Materials Startups

Materials startups such as the examples highlighted in this report focus on biocompatible ceramics, thermoplastic composites, customized filaments as well as medical-grade biomaterials. While all of these technologies play a major role in advancing the materials industry, they only represent the tip of the iceberg. To explore materials technologies in more detail, simply let us look into your areas of interest. For a more general overview, download our free Materials Innovation Report to save your time and improve strategic decision-making.

![10 Top Startups Advancing Machine Learning for Materials Science [2025]](https://www.startus-insights.com/wp-content/uploads/2025/06/Machine-Learning-for-Materials-Science-SharedImg-StartUs-Insights-noresize-420x236.webp)

![10 Emerging AI Solutions for Material Science [2025]](https://www.startus-insights.com/wp-content/uploads/2025/06/AI-Solutions-for-Material-Science-SharedImg-StartUs-Insights-noresize-420x236.webp)