Staying ahead of the technology curve means strengthening your competitive advantage. That is why we give you data-driven innovation insights into the manufacturing industry. This time, you get to discover 5 hand-picked metal 3D printing solutions.

Out of 255, the Global Startup Heat Map highlights 5 Top Metal 3D Printing Solutions

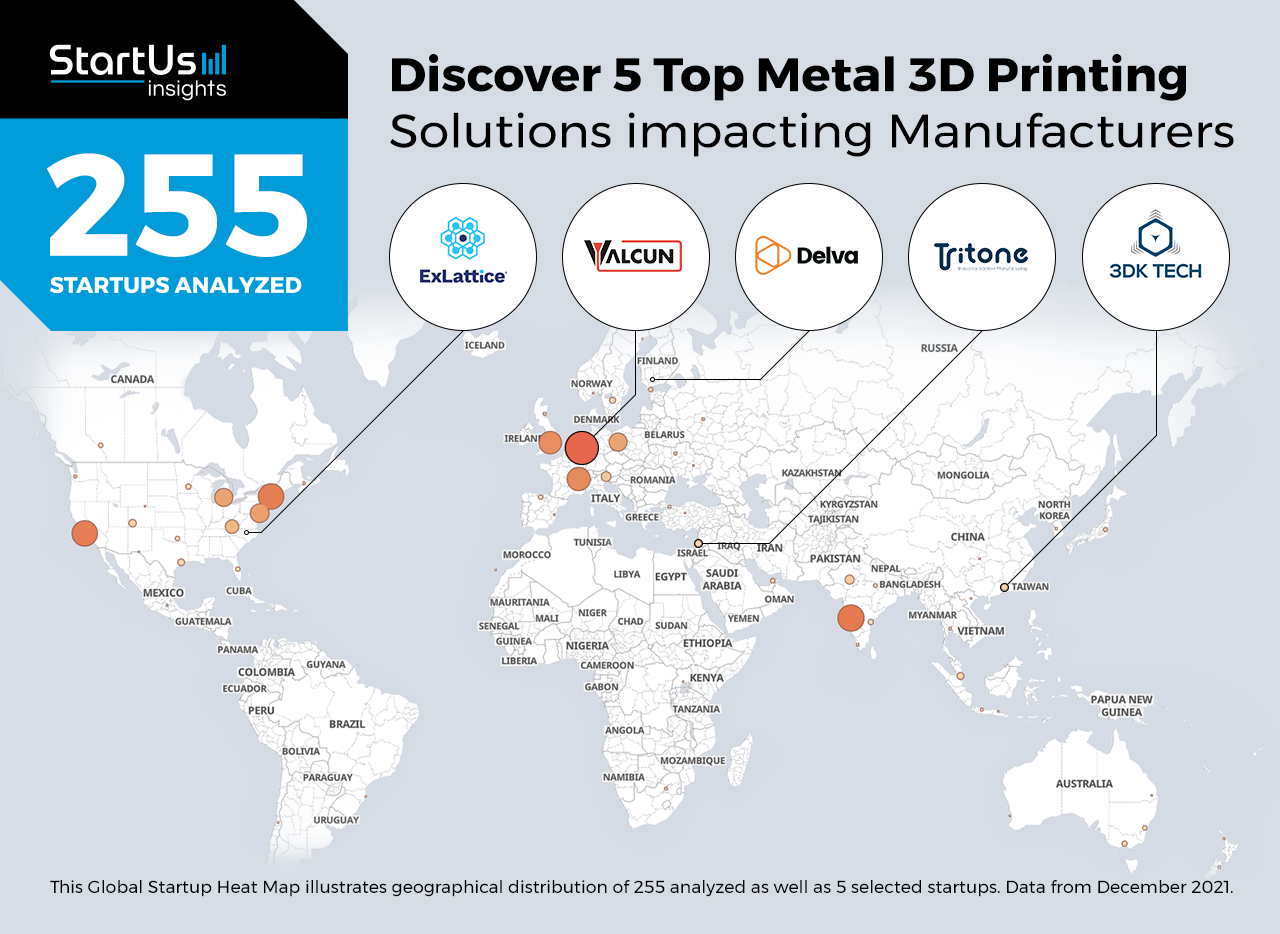

The insights of this data-driven analysis are derived from the Big Data & Artificial Intelligence (AI)-powered StartUs Insights Discovery Platform, covering 2 093 000+ startups & scaleups globally. The platform gives you an exhaustive overview of emerging technologies & relevant startups within a specific field in just a few clicks.

The Global Startup Heat Map below reveals the distribution of the 255 exemplary startups & scaleups we analyzed for this research. Further, it highlights 5 manufacturing startups that we hand-picked based on criteria such as founding year, location, funding raised, and more. You get to explore the solutions of these 5 startups & scaleups in this report. For insights on the other 250 metal 3D printing solutions, get in touch.

Delva provides Complete Metal 3D Printing

Founding Year: 2017

Location: Hämeenlinna, Finland

Reach out for Metal 3D Printing-as-a-Service

Delva is a Finnish startup that provides comprehensive metal 3D printing solutions for manufacturing companies. With metal additive manufacturing (AM), it creates manufacturing components that are cost-effective and efficient. Its metal 3D printing services are scalable from single pieces to full-scale serial production and work with a wide range of materials. In addition to optimizing material selection, it also offers post-processing to supply clients with ready-to-use parts with the desired finish.

ExLattice enables 3D Printing Simulations

Founding Year: 2018

Location: Raleigh, US

Partner for AM Simulations

US-based startup ExLattice develops real-time simulation software for additive manufacturing. The startup’s software uses parallel computing technology to provide real-time simulation insights faster than traditional simulation tools. It evaluates the potential risks of common metal 3D printing issues and predicts distortions in the component without the requirement of simulation expertise. This reduces defects in printed parts thus saving on cost and time on the production line. ExLattice’s simulation software also provides automatic design tools that optimize pre-processing setups for part designs. These tools hone the printing quality, time, and cost with optimized performance.

ValCUN develops 3D Feedstock Material

Founding Year: 2016

Location: Ghent, Belgium

Partner for Mass 3D Production

Belgian startup ValCUN offers ecological metal 3D printing technology. The startup’s patented technology uses a safe to handle feedstock material instead of metal powders and operates without high-energy lasers. This facilitates metal 3D printing for medium-scale production units dealing in automotive, manufacturing, robotics, and artistic products. ValCUN’s technology, thus, allows a higher degree of customization in mass production outside capital-intensive industries.

Tritone allow Industrial-scale Metal 3D Printing

Founding Year: 2017

Location: Petah Tikva, Israel

Collaborate with Tritone for Metal Parts Production

Israeli startup Tritone provides additive manufacturing solutions that enable the mass production of accurate parts with a range of metals and ceramic materials. Moldjet, the startup’s technology, allows high printing resolution for complex parts at an industrial throughput. It delivers materials through sealed cartridges suitable for clean industrial environments. The startup’s industrial AM machine, Dominant, prints metal components in a variety of materials such as stainless steel, tool steel, titanium, and copper-based alloys. The startup’s system also includes a software platform that controls the full production cycle from job set up to the manufacturing process with the provision for real-time monitoring and control.

3DK Tech enables Selective Laser Melting (SLM)

Founding Year: 2017

Location: Hong Kong, China

Innovate with 3DK Tech for Faster AM

3DK Tech is a Hong Kong-based startup that develops ultrasonic SLM technology. It avoids the post-processing heat treatment by using ultrasonic waves to alter materials on a molecular level. This results in a material structure that achieves a built-in fatigue strength without additional heat treatment procedures. 3DK Tech’s process offers high repeatability and consistency with zero possibilities of errors and deformities. The lack of extra processes and defects reduces energy consumption and lowers the emission of greenhouse gases, providing manufacturing companies with an eco-efficient process.

Discover more Manufacturing Startups

Manufacturing startups such as the examples highlighted in this report focus on stereolithography, polymer 3D printing, and circular 3D printing. While all of these technologies play a major role in advancing the manufacturing industry, they only represent the tip of the iceberg. To explore more manufacturing technologies, simply get in touch to let us look into your areas of interest. For a more general overview, you can download our free Manufacturing Innovation Report to save your time and improve strategic decision-making.