Our Innovation Analysts recently looked into emerging technologies and up-and-coming startups in the manufacturing industry. As there is a large number of startups working on a wide variety of solutions, we decided to share our insights with you. This time, we are taking a look at 8 promising data analytics solutions.

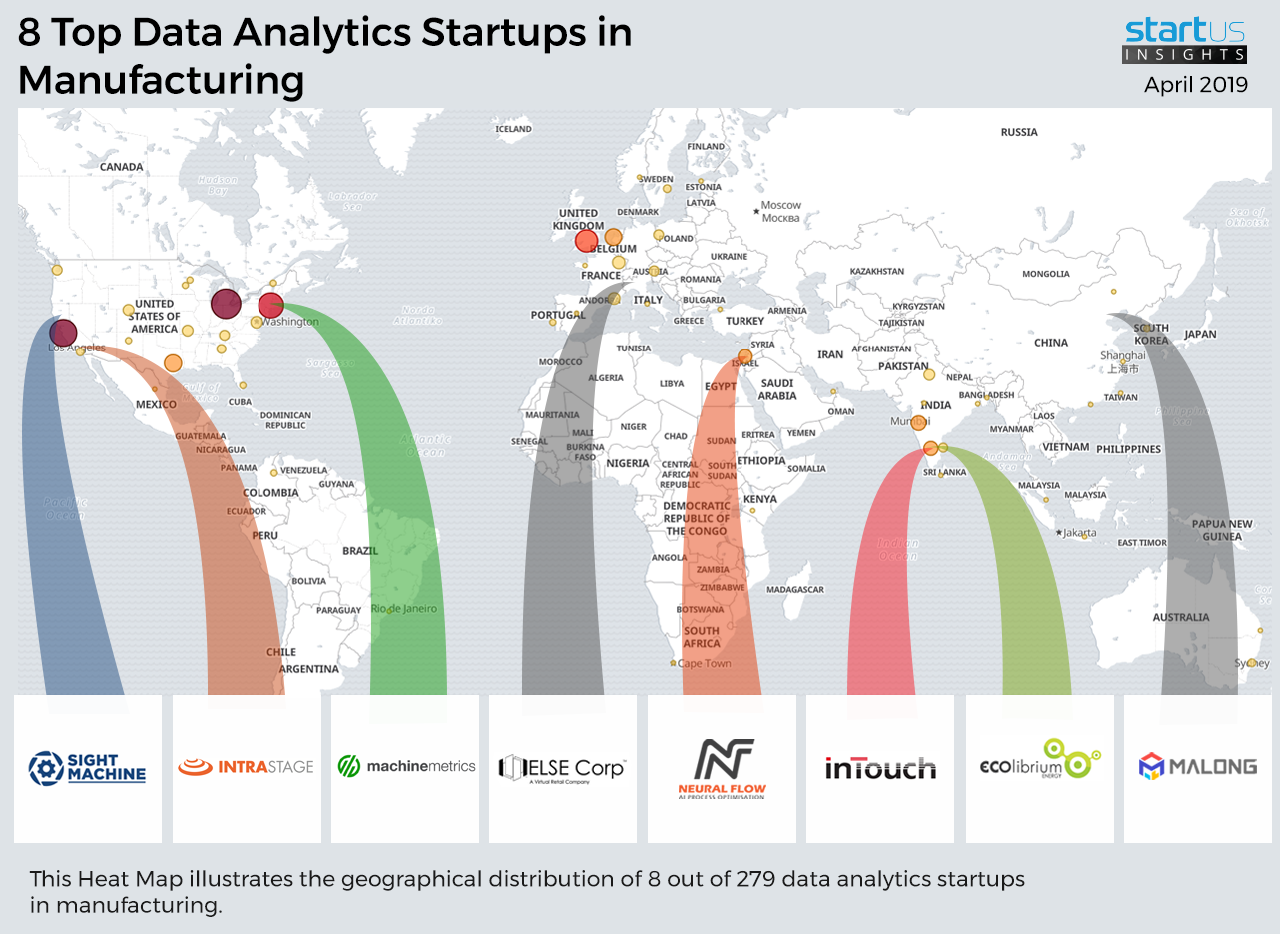

Heat Map: 8 Top Data Analytics Startups

For our 8 picks of data analytics startups in manufacturing, we used a data-driven startup scouting approach to identify relevant solutions globally. The Global Startup Heat Map below highlights 8 interesting examples out of 279 relevant solutions. Depending on your specific needs, your top picks might look entirely different.

PwC’s Annual Manufacturing Report shows that among manufacturers there is a significant movement towards the utilization of smarter technologies. The key factors for this are the increased implementation of the Internet of Things (IoT) and the digitalization of the industry. As products are usually at the heart of a manufacturing business, data and analytics are often aimed at refining product development rather than the end-to-end production process.

Due to constantly increasing expenses, companies in the sector are always looking to

- Reduce the cost of manufacturing

- Increase production efficiency

- Minimize waste, optimize the use of energy and other resources

The introduction of TPS (Toyota Production System), lean management, Six Sigma, and other manufacturing strategies brought substantial improvements to the sector. However, while these techniques were effective in certain areas, they have limitations in terms of complex production processes such as pharmaceuticals, mining, etc. Advanced Analytics is a hotspot that manufacturers are seeking to invest in as it does not have the limitations of earlier manufacturing strategies. Moreover, Big Data and related analytics technologies are constantly becoming more affordable.

Let’s take a look at 8 emerging data analytics solutions:

InTouch – Productivity/Yield Improvement

The ideal manufacturing plant is one that runs its machinery at its full capacity and efficiency. Modern production plants and their equipment have an abundance of data with various parameters available. Data Analytics allow manufacturers to apply Machine Learning and Big Data tools to monitor equipment in real-time and build predictive models in order to provide production and plant managers with a better understanding and insight into their equipment. This supports them to utilize their equipment to the fullest. Indian company InTouch develops a data analytics platform for manufacturing industries. Their system improves productivity and profitability, identifies trends and patterns. The range of their production data analytics is only limited by the available data and how it is used.

Machine Metrics – Smarter Use Of Resources

Manufacturing waste is becoming an environmental issue especially in the industries dealing with hazardous waste. Previously, manufacturers applied green initiatives and lean methods which offered them a large number of benefits. With the advent of data-driven analytics and tools, manufacturers use statistical and mathematical techniques to create models and identify more efficient manufacturing methods. This results in better use of resources and identifying better energy utilization techniques for production processes. US-based startup Machine Metrics creates a platform that increases productivity through real-time visibility, deep analytics, and Artificial Intelligence-driven predictive notifications. By using their platform to closely monitor equipment, the amount of waste being created due to inefficiencies is reduced significantly while it also helps reduce energy being wasted.

Else Corp – Mass Personalization/Product Customization

Personalization in the current market is a process where multiple vendors create custom prototypes and manufacture products with specifically designed or acquired parts, which has made it a cumbersome process for a manufacturer with higher costs involved. With today’s data analytics and modeling tools manufacturers virtually build models with customized details prior to needing any physical materials. With the application of these digital analytics solutions, brands use insights about their customers to create better products and meet their customers’ expectations. Italy-based Else Corp transforms the field of personalized/customized retail products by implementing their Virtual Reality (VR) technology, allowing customers to view a virtual collection of products from brands, retailers, and manufacturers. Customers then get their virtual products customized. This entire process requires no physical stock during the customization phase and allows manufacturers to be more flexible in their production process.

Intrastage – Supplier Quality Control

Industries that manufacture products in large (or sometimes even small) quantities receive their materials from various suppliers, which makes it more difficult to maintain a standard quality and a steady production schedule from end-to-end of the production process. By using sensor data and data analytics techniques manufacturers are able to better track the quality of the products being supplied. US company Intrastage uses a real-time data capture and monitoring platform suitable for both simple components and complex assemblies. Their platform detects any deviation in the components’ parameters before they arrive for production, and their failure analyses allow manufacturers to investigate and resolve issues as they occur.

Malong – Internal Quality Control

Product quality is a top priority for manufacturers. Most of them already have the data needed to significantly improve quality levels and reduce quality-related costs, but very few of them can connect their data sources in a way they provide actionable insights. Great savings can be made when using predictive analytics in areas such as product testing as one single product might require thousands of different quality tests. The number of tests required can be hugely reduced if pattern recognition and predictive analytics are used to determine the number and type of tests that are really needed, instead of performing all tests on all items. Sensor data analysis detects manufacturing defects early, which reduces the time and cost related to adjusting the production processes. Beijing-based Malong creates a platform called ProductAI. Their platform provides state-of-the-art APIs and embedded systems for visual product recognition based on artificial intelligence or artificial neural networks. This technology enables a machine to “see” products like a person can – recognizing them holistically. The application of this system in manufacturing quality analytics allows manufacturers to locate defects in their processes much faster than any conventional system. Moreover, since the system is self-learning, its accuracy increases with time.

Sight Machine – Meta-Production Plant-Level Analysis

Big data allows companies to quickly compare the performance of different production plants and accurately determine the exact reasons for the differences. Utilizing big data helps manufacturers to look beyond their own internal comparative analyses and compare the entire market along with building what-if scenarios with predictive modeling. Collecting and analyzing data makes decisions such as locating a good area for a new plant or introducing new products easy, straightforward, and based on factual data. Sight Machine a startup from the USA creates a platform that collects all the sensor data from equipment in real-time, then analyzes the data and creates benchmarks for comparison among not just the enterprise but also across different plants. This allows for optimal maintenance, yield, etc. to be monitored from a centralized platform.

Neural-Flow – Automotive Painting Process & Optimization

The painting process in an automotive painting system can consist of 15 or 20 different painting subprocesses. During a regular painting cycle, there are hundreds of sensors collecting data and checking for errors, which makes optimization tedious using current methods. Manufacturers understand that the very first and the most valuable aspect for a customer is the finish on their product. Therefore, by collecting various data points such as temperature, humidity, air flow of application robots, energy consumption, state of filters, etc. and by applying big data analytics manufacturers look to create a better and more optimized automotive painting process.US-based Neural-Flow aspires to optimize industrial manufacturing processes and operational efficiency by combining Process Engineering with Artificial Intelligence tools. They have developed in-depth engineering know-how in mixing and process engineering analytics, and their capabilities to identify the areas of improvement in the quality of Ink&Paints are highly beneficial to automotive painting processes.

Ecolibrium – Digital Twin-Based Simulations For Process Optimization

As the capabilities of high-performance computers and supercomputers increase, so do connected technologies. Earlier simulations were limited to small scale or single machines. They were also limited by their technology. However, with today’s computers, whole buildings, factories, and even cities can be simulated and have thousands of tests running in hundreds of virtual environments. This allows manufacturers to build, test and optimize a new factory or a production process before they even decide to begin the physical construction process. Indian startup Ecolibrium develops a system that helps enterprises improve their asset efficiency with IoT-powered predictive analytics. Their Digital Twin Plant and Creation platform take a multitude of sensor and data inputs, which allows companies to perform automated fault detection and diagnostics all within a virtual environment with factual data.

What About The Other 271 Data Analytics Solutions?

While we believe data is key to creating insights it can be easy to be overwhelmed by it. Our ambition is to create a comprehensive overview and provide actionable innovation intelligence for your Proof of Concept (PoC), partnership, or investment targets. The 8 data analytics startups showcased above are promising examples out of 279 we analyzed for this article. To identify the most relevant solutions based on your specific criteria and collaboration strategy, get in touch.