Staying ahead of the technology curve means strengthening your competitive advantage. That is why we give you data-driven innovation insights into Industry 4.0. This time, you get to discover 5 hand-picked lean manufacturing solutions.

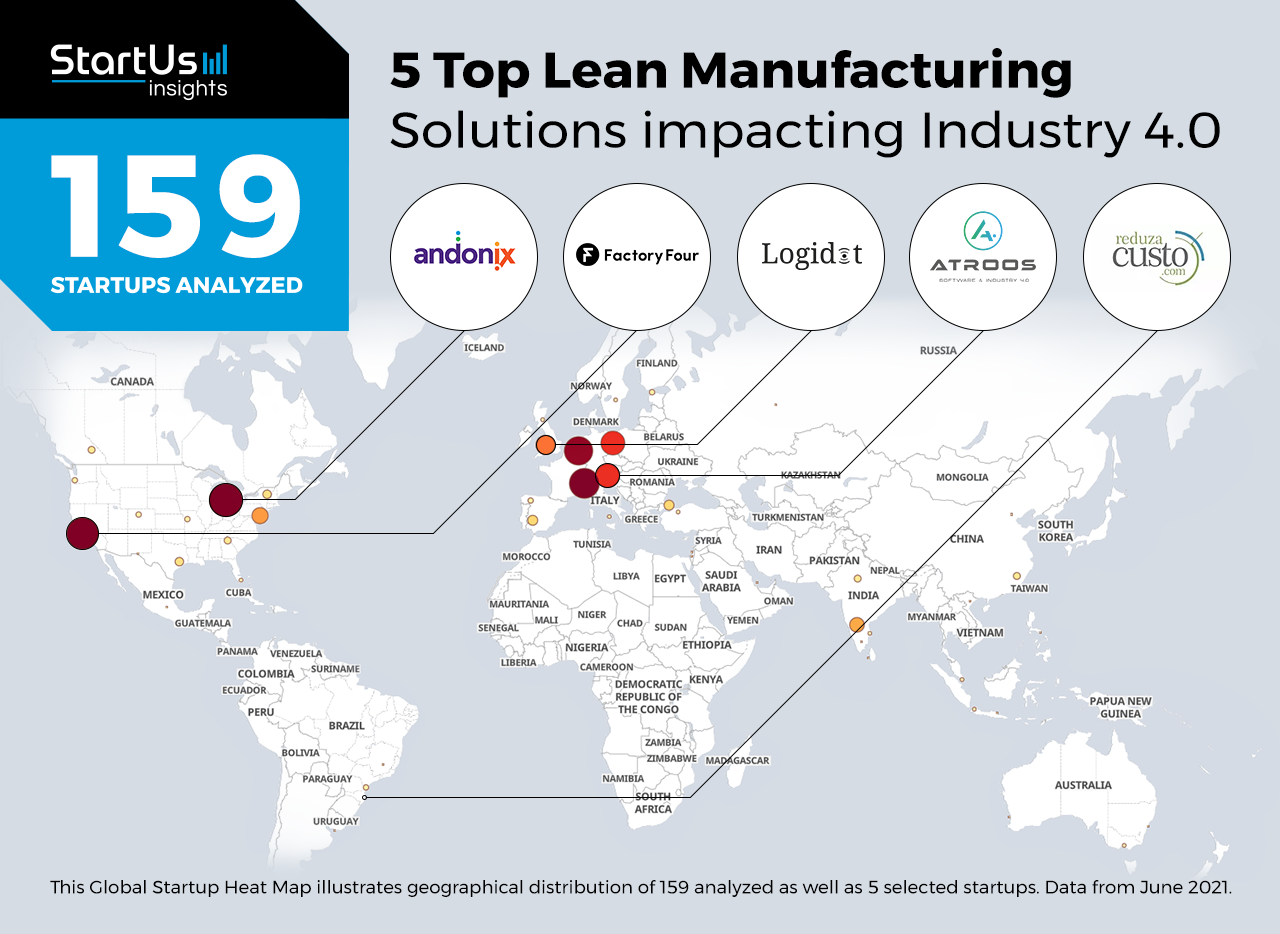

Global Startup Heat Map highlights 5 Top Lean Manufacturing Solutions out of 159

The insights of this data-driven analysis are derived from the Big Data & Artificial Intelligence-powered StartUs Insights Discovery Platform, covering 2.093.000+ startups & scaleups globally. The platform gives you an exhaustive overview of emerging technologies & relevant startups within a specific field in just a few clicks.

The Global Startup Heat Map below reveals the distribution of the 159 exemplary startups & scaleups we analyzed for this research. Further, it highlights 5 startups that we hand-picked based on criteria such as founding year, location, funding raised, and more. You get to explore the solutions of these 5 startups & scaleups in this report. For insights on the other 154 lean manufacturing solutions, get in touch.

Atroos develops an Internet of Things (IoT) Platform

Lean manufacturing practices reduce the time during each manufacturing step, thereby increasing the productivity of the factory floor. Real-time monitoring solutions react rapidly to any changes, subsequently lowering downtimes. Startups use IoT-based sensors and other devices to achieve this outcome. Moreover, since the devices are connected to each other as well, it allows operators to optimize all steps so that the waiting time between processes is as low as possible.

Italian startup Atroos builds an IoT platform for industrial automation. The startup’s cloud-based platform utilizes data communication protocols and data processing to enable communication between heterogeneous devices. It also features a web portal that allows operators to manage the park of connected devices and collect data from them. The platform enables continuous monitoring of the work cycle and makes the manufacturing process leaner.

FactoryFour builds a Manufacturing Execution System (MES)

Another major time sink in manufacturing facilities is the distance between the management and the factory floor. This is where manufacturing execution systems come in, providing real-time data on factory productivity and material movement. In recent years, businesses have realized their value for making manufacturing leaner as well. Manufacturing startups are developing solutions that integrate MES and advance lean manufacturing to reduce waste and identify unproductive behavior.

FactoryFour is a US-based startup offering a manufacturing execution system for scaling production. It ensures lean manufacturing with responsive digital dashboards. The startup’s MES monitors production in real-time, maximizes first pass yield, and improves the productivity of operators. FactoryFour also offers solutions for production planning and process control to simplify production and enable process adherence, respectively.

Andonix offers Smart Work Stations

In any manufacturing facility, connecting people is often the fastest and least expensive way to increase savings. This is why many lean manufacturing startups focus on solutions that save time in communication between different sets of employees. By automating reports, process standardization, and quality compliance & management, such solutions save time on employee training and manual checks.

Andonix is a US-based startup that develops smart work stations for Industry 4.0 applications. It creates digital solutions to automate layered and process audits (LPA), monitor business KPIs, and perform root-cause quality analysis. It uses data analytics to improve productivity while reducing training time and waste. Moreover, by performing frequent quality and compliance checks, the startup’s solution enables continuous improvement in lean manufacturing.

ReduzaCusto provides Lean Cost Management

Some manufacturing processes contribute more disproportionately than others to product price changes. Consequently, solutions that identify these processes help managers implement measures that lower or maintain product prices while improving productivity. Moreover, many enterprise resource management (ERP) systems do not track waste properly. By accounting for waste in final costs, comprehensive cost management solutions further enable lean manufacturing.

Brazilian startup ReduzaCusto offers lean cost management Software-as-a-Service (SaaS). The startup’s solution tracks waste across the manufacturing chain and detects inefficiencies across processes. It also simulates resource usage maximization to quantify the cost per activity of the value stream. ReduzaCusto enables Industry 4.0 companies to stay lean by providing insights on how each cost affects the price of products.

Logidot advances Just-in-Time (JIT) Production

Lean manufacturing enables a new paradigm in the industry, JIT production. It allows manufacturers to produce the exact quantities that a customer wants when they want it. Manufacturing startups deploy lean principles to reduce lead times significantly. Additionally, JIT production reduces inventory costs, planning complexity, equipment handling costs, as well as the order to payment timelines.

British startup Logidot provides solutions for warehouse and factory automation. The startup’s real-time location system (RTLS) enables managers to track mobile assets in real-time both indoors and outdoors. This improves equipment and resource utilization while reducing idle and throughput times. With detailed insights on asset activity, capacity metric, order frequency, and fulfillment, Logidot drives just-in-time production for Industry 4.0 startups and scaleups.

Discover more Industry 4.0 Startups

Industry 4.0 startups such as the examples highlighted in this report focus on advanced robotics, digital twins, edge computing as well as 3d printing. While all of these technologies play a major role in advancing Industry 4.0, they only represent the tip of the iceberg. To explore more technologies, simply get in touch to let us look into your areas of interest. For a more general overview, you can download our free Industry 4.0 Innovation Report to save your time and improve strategic decision-making.