Accelerate Productivity in 2025

Reignite Growth Despite the Global Slowdown

Executive Summary: What are the Top 10 Printing Industry Trends in 2026 & Beyond?

- Custom & Personalized Printing: Demand surges with print-on-demand, AI-driven personalization, and eco-friendly materials. The market is expected to reach USD 68.5 billion by 2030, growing at a 10.3% compound annual growth rate (CAGR).

- Integration of AI in Printing Workflows: AI advances automation, predictive maintenance, and quality control. The market is expected to reach USD 34.8 billion by 2033.

- Digital Printing Expansion: Short-run, personalized, and packaging-driven printing pushes the digital printing market. It will grow to USD 59.9 billion by 2034.

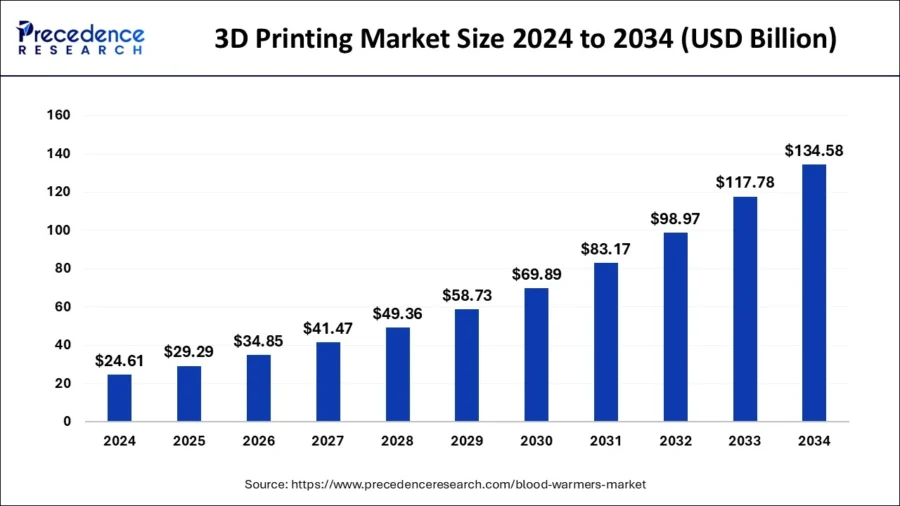

- Scaling 3D Printing: 3D printing or additive manufacturing expands beyond prototyping to mass production. The market is expected to reach USD 134.6 billion by 2034.

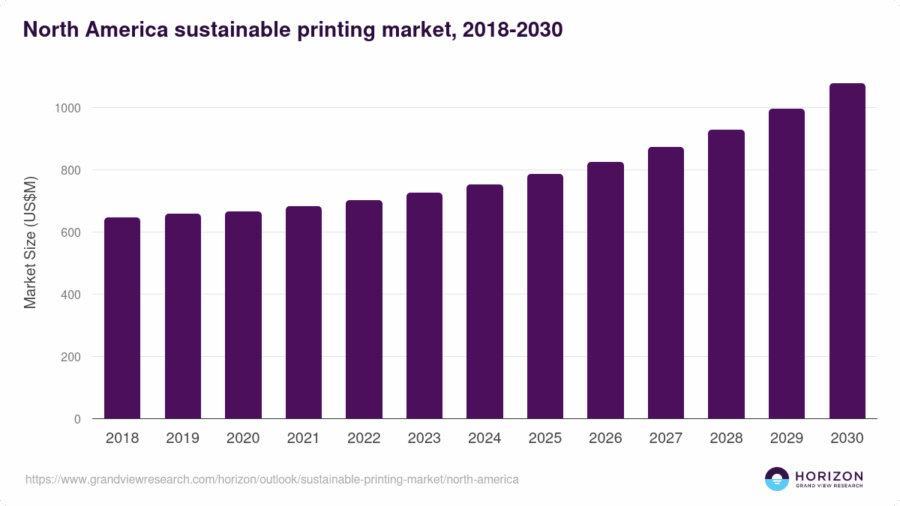

- Focus on Sustainable Printing: There is growing demand for bio-based inks, recyclable substrates, and energy-efficient technologies. Besides, the market is expected to reach USD 3.35 billion by 2030 at a 7.5% CAGR.

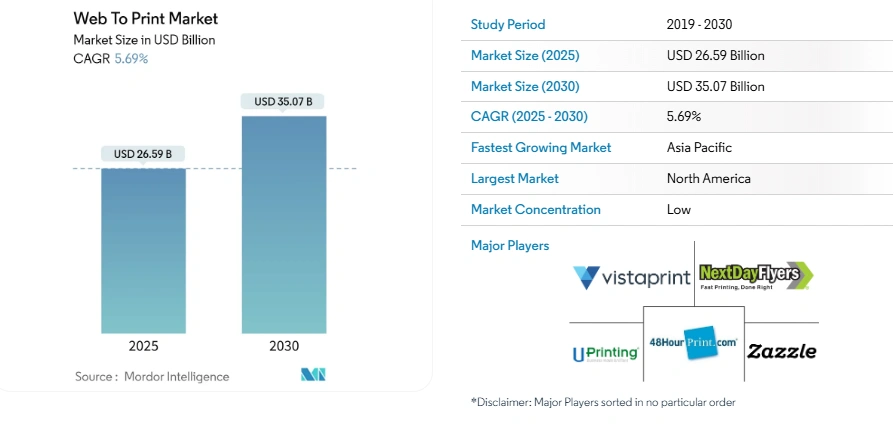

- Rise of Web to Print (W2P) Solutions: Online design, augmented reality (AR) previews, and personalized solutions propel the market to USD 35.1 billion by 2030. Additionally, 72% of companies are already adopting W2P.

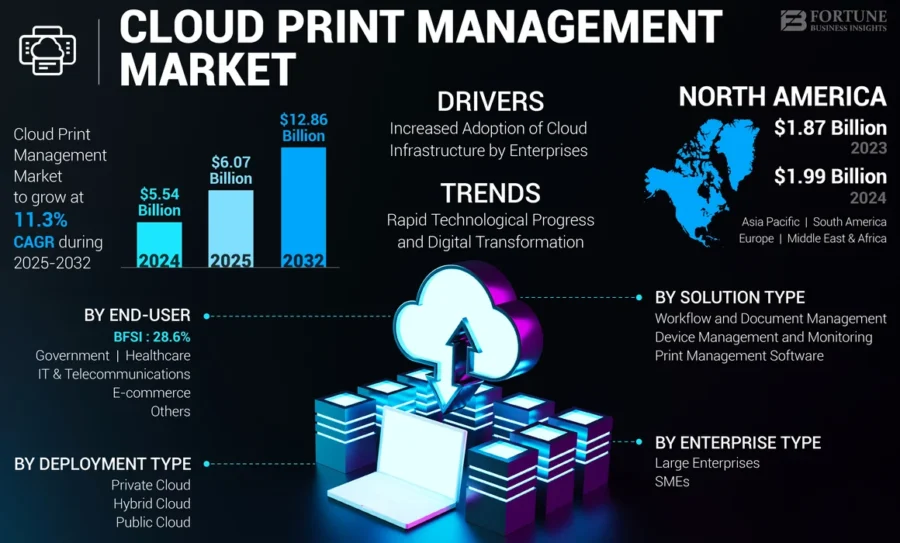

- Advanced Cloud Printing Technologies: Driven by hybrid work and secure workflows, the market is expected to grow from USD 6.07 billion in 2025 to USD 12.9 billion by 2032 with serverless, IoT-enabled solutions.

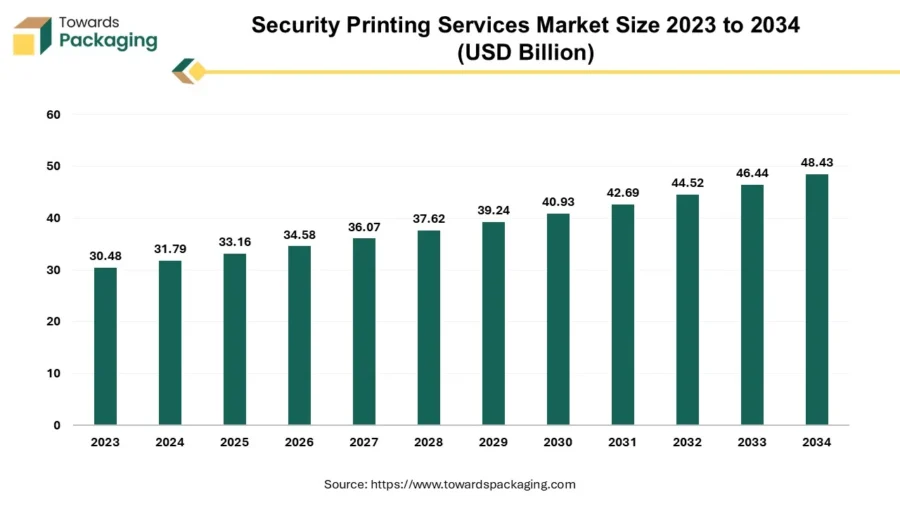

- Emphasis on Print Security: Rising cyber risks drive innovation with encrypted QR codes, luminescent inks, and blockchain. The market is expected to reach USD 62.6 billion by 2032.

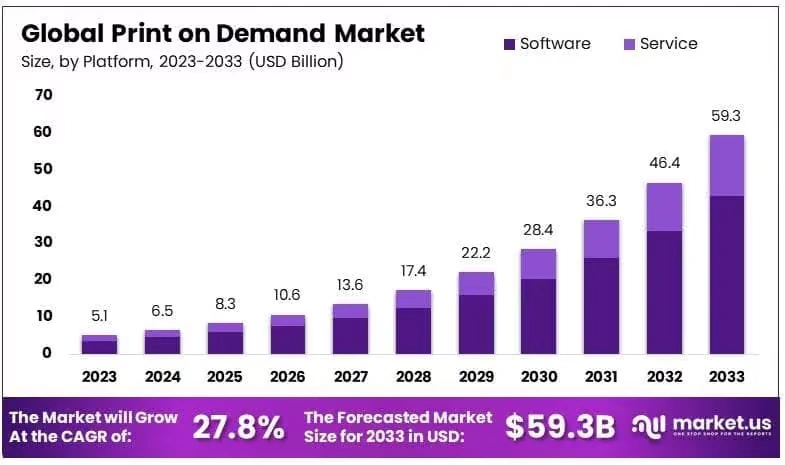

- Surge in Print-on-Demand (POD) Services: Rapid growth fueled by e-commerce and AI-powered automation pushes the market from USD 8.3 billion in 2025 to USD 59.3 billion by 2033 at a 27.8% CAGR.

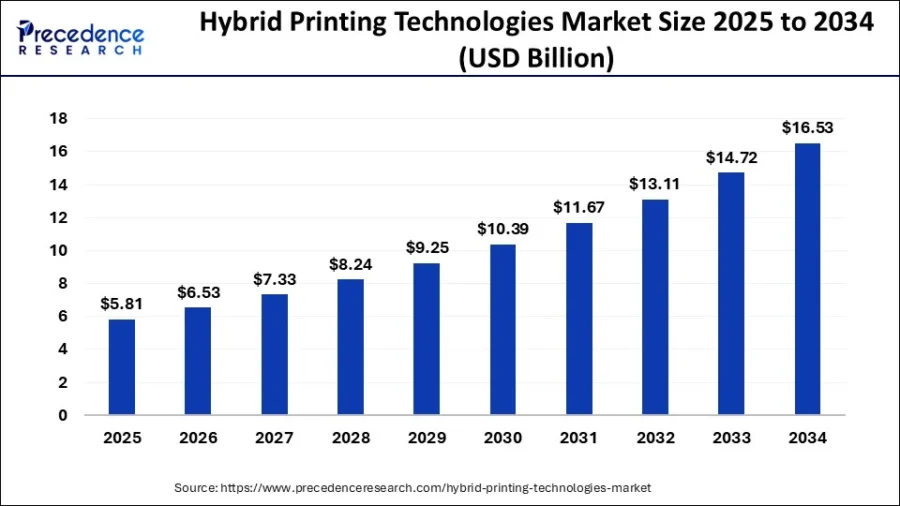

- Adoption of Hybrid Printing: Combining digital flexibility and analog quality, the market is expected to hit USD 16.5 billion by 2034, with demand for QR codes, variable data printing, and high-quality short runs.

Read on to explore each trend in depth – uncover key drivers, current market stats, cutting-edge innovations, and leading printing innovators shaping the future.

Frequently Asked Questions

1. What is 4D printing technology?

Incorporates time as a dimension, which enables printed objects to change shape or function in response to external stimuli such as heat, light, or moisture.

2. What is the future of the print industry?

The commercial printing market is projected to reach USD 598.06 billion by 2030. The print industry will be led by packaging, 3D/4D printing, and personalized print solutions.

Methodology: How We Created the Printing Industry Trend Report

For our trend reports, we leverage our proprietary StartUs Insights Discovery Platform, covering 7M+ global startups, 20K technologies & trends, plus 150M+ patents, news articles, and market reports.

Creating a report involves approximately 40 hours of analysis. We evaluate our own startup data and complement these insights with external research, including industry reports, news articles, and market analyses. This process enables us to identify the most impactful and innovative trends in the printing industry.

For each trend, we select two exemplary startups that meet the following criteria:

- Relevance: Their product, technology, or solution aligns with the trend.

- Founding Year: Established between 2020 and 2025.

- Company Size: A maximum of 200 employees.

- Location: Specific geographic considerations.

This approach ensures our reports provide reliable, actionable insights into the printing innovation ecosystem while highlighting startups driving technological advancements in the industry.

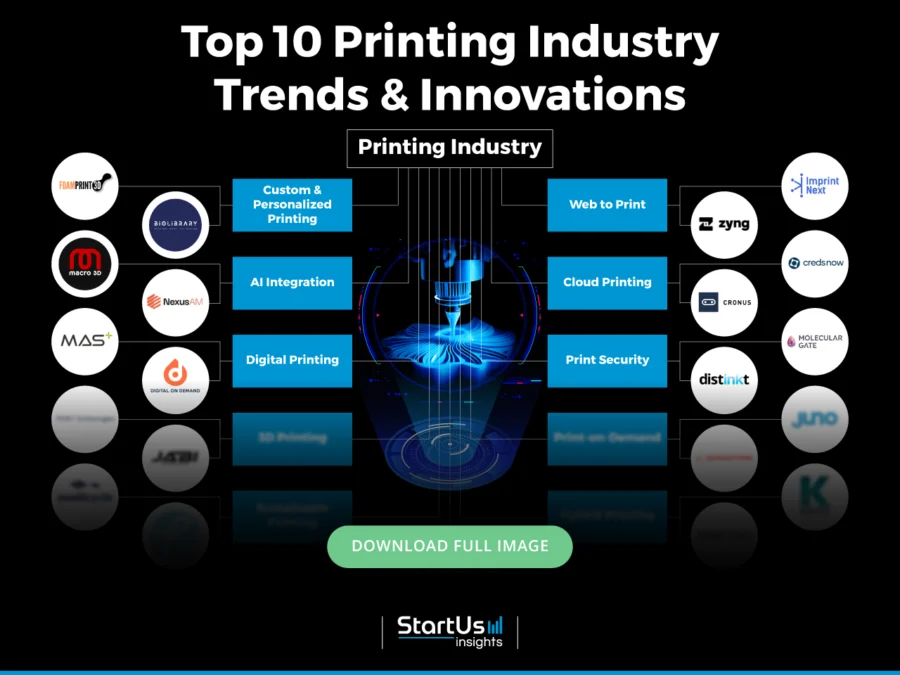

Innovation Map outlines the Top 10 Printing Industry Trends & 20 Promising Startups

For this in-depth research on the Top Printing Industry Trends & Startups, we analyzed a sample of 9200+ global startups & scaleups. The Printing Industry Innovation Map created from this data-driven research helps you improve strategic decision-making by giving you a comprehensive overview of the printing industry trends & startups that impact your company.

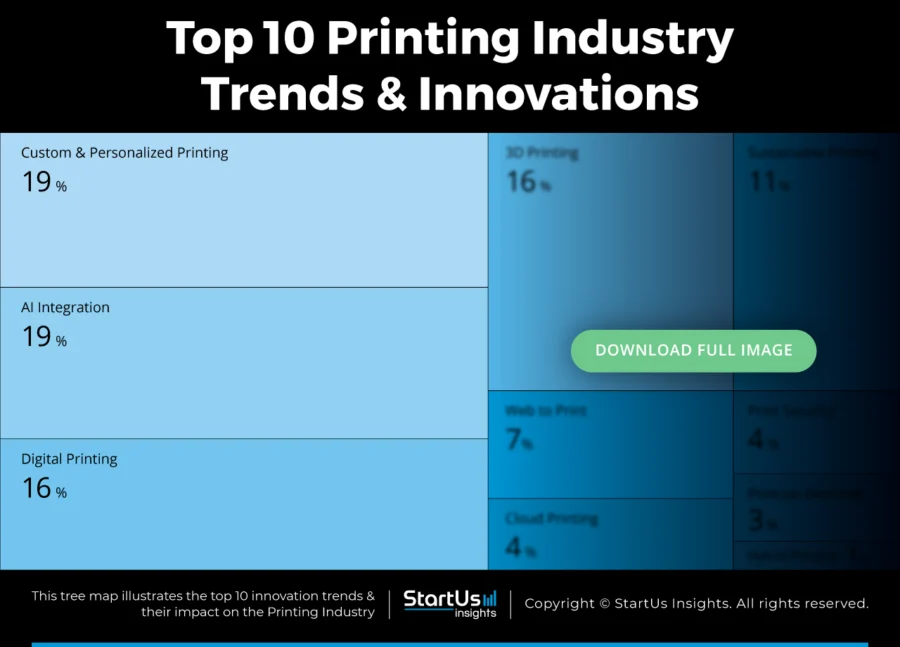

Tree Map reveals the Impact of the Top 10 Printing Industry Trends

Based on the Printing Industry Innovation Map, the Tree Map below shows the Top Printing Industry Trends. Custom printing grows with on-demand production, AI-driven personalization, and eco-friendly materials. AI in printing advances automation, predictive maintenance, and quality control. Digital printing expands short-run packaging and label production with connected workflows. 3D printing enables mass customization using advanced materials and AI designs.

Further, sustainable printing drives bio-based inks, recyclable substrates, and energy-efficient processes. Web-to-print supports online customization, AR previews, and real-time tracking. Cloud printing improves security, predictive analytics, and centralized control. Print security strengthens with encrypted codes, luminescent inks, and blockchain authentication. Besides, hybrid printing merges digital and analog systems for efficient, high-quality production.

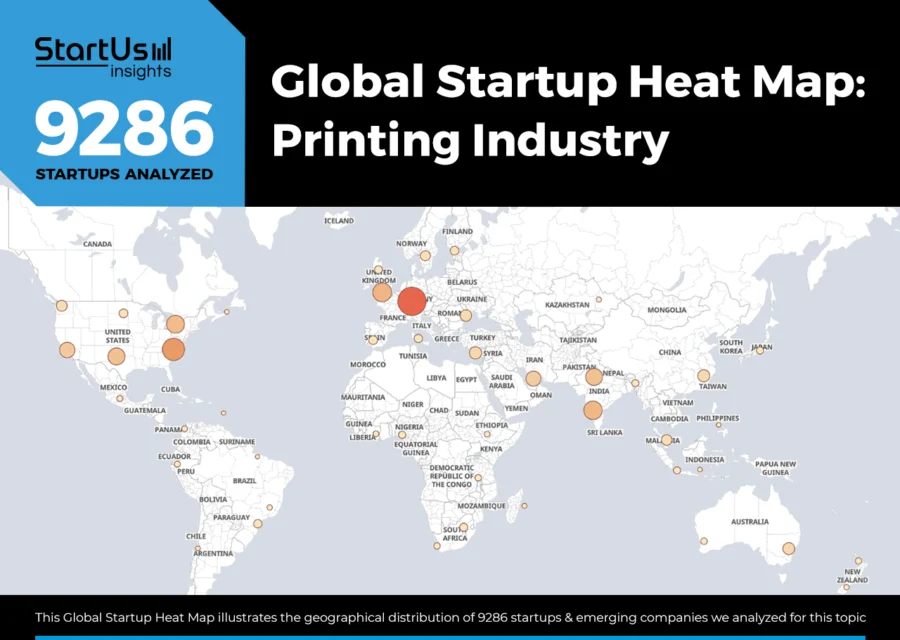

Global Startup Heat Map covers 9200+ Printing Startups & Scaleups

The Global Startup Heat Map showcases the distribution of 9200+ exemplary startups and scaleups analyzed using the StartUs Insights Discovery Platform. It highlights high startup activity in Western Europe and the United States, followed by India. From these, 20 promising startups are featured below, selected based on factors like founding year, location, and funding.

Want to Explore Printing Industry Innovations & Trends?

Top 10 Emerging Printing Industry Trends [2026]

1. Custom and Personalized Printing: USD 68.5 B Market by 2030

Custom and personalized printing is driven by new technology and changing customer expectations. The industry’s expansion depends on a few main forces, like the demand for hyper-personalized products, the shift toward eco-friendly solutions, and the use of AI-powered processes. These changes reshape how products get designed, produced, and delivered.

Print-on-demand has become a key trend as it aids businesses in cutting costs and avoiding waste by producing exactly what customers order. Digital printing supports faster and more flexible fulfillment.

Moreover, sustainability plays a central role. Companies use biodegradable paper, water-based inks, and carbon-neutral operations to appeal to eco-conscious buyers. Technologies such as augmented reality (AR), 3D printing, and AI-supported scheduling make custom printing smarter and cheaper.

The industry still faces higher production costs, volatile material prices, and pressure from mass-produced goods. To overcome this, companies use AI to optimize resources, adopt sustainable practices to cut long-term expenses, and rely on automation and smart data to lower waste.

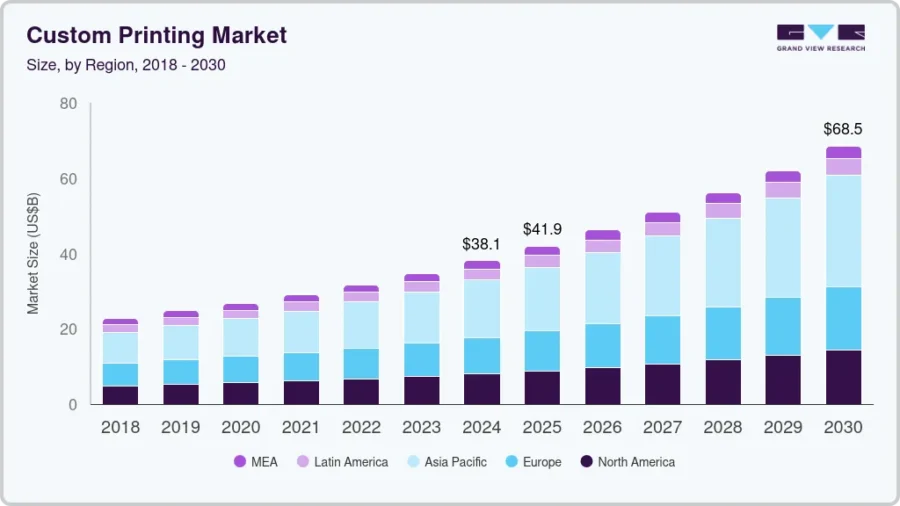

Credit: Grand View Research

The global custom printing market is projected to reach USD 68.5 billion by 2030 at a 10.3% CAGR. In custom T-shirts alone, the market is expected to grow from USD 4.67 billion in 2025 to USD 11.37 billion in 2035. This is supported by e-commerce growth and better direct-to-garment and screen printing methods.

Several companies contribute significant advancements in custom and personalized printing. For instance, Canva introduced new AI-powered design tools like Magic Studio and Visual Suite 2.0 to make design and printing easier and faster. Carbon provides high-speed digital manufacturing for mass customization, using its Carbon Digital Light Synthesis process.

FoamPrint3D offers 3D Printed Foam Manufacturing

Dutch startup FoamPrint3D develops a 3D printing technology that leverages additive manufacturing to create foams with precise control at the cell level to enable open-cell, closed-cell, mixed, or graded designs based on performance needs.

The technology supports bio-sourced, biodegradable, and solvent-free materials to reduce waste and eliminate processes like cutting, gluing, and molding. Additionally, it also uses polyurethane and hydrogels to create the foam. Thus, the startup’s technology finds applications in footwear, orthopedics, medical devices, aerospace, and tires

Biolibrary provides Automated Prosthetic Modeling

Italian startup Biolibrary builds an online platform that generates custom, ready-to-print 3D models of prostheses and musculoskeletal devices for orthopaedists and doctors. It utilizes a patented algorithm to automatically convert patient data from radiographs and mobile phone images into digital models without requiring 3D modelling skills.

Further, the platform operates in the cloud, matches patient parameters with customized digital models, and prepares these models for additive manufacturing. It also provides automated digital simulations to ensure proper fit and functionality while removing the need for manual measurements. Moreover, using hemp-based, recyclable materials, the printed devices are lightweight, breathable, and maintain shape under different conditions.

2. Integration of AI in Printing Workflows: AI Usage Reaching 15% by 2025

AI drives advances in automation, efficiency, personalization, and sustainability. In 2025, up to 15% of printers will use AI to optimize print quality and reduce waste. Meanwhile, global spending on AI in print technology increases, as over 84% of organizations invest in smarter hardware, predictive maintenance, and workflow automation.

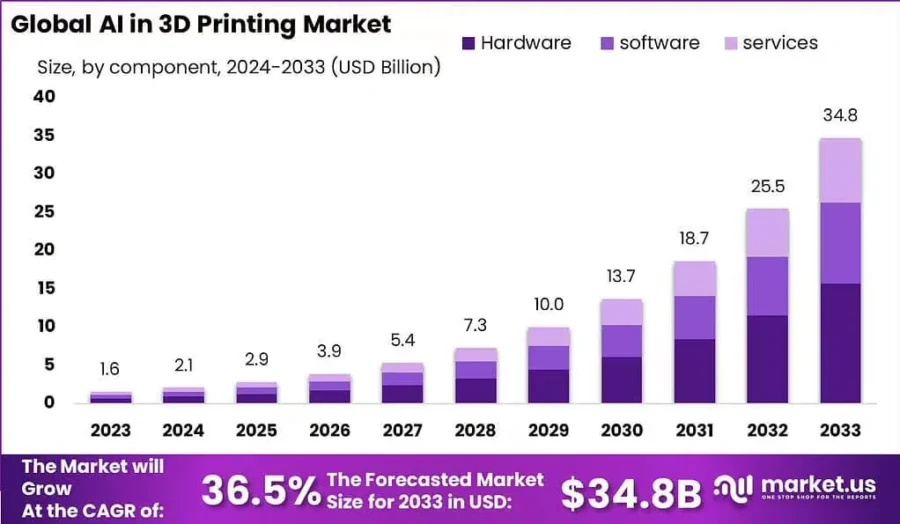

Credit: market.us

With this, the AI in the 3D printing segment expects to reach USD 34.8 billion by 2033. The entire printing sector will reach nearly USD 960 billion globally by 2025, with AI and digital technologies replacing manual interventions and driving efficiency.

The shift toward AI encounters challenges like legacy equipment, inconsistent workflow integration, skills gaps, and cybersecurity risks from greater digitization. Companies overcome these issues by deploying modular software platforms, educating staff on AI and digital skills, and investing in secure cloud and hybrid infrastructures.

Automation enables resource optimization and error reduction, while predictive maintenance cuts machine downtime and lowers operational costs. AI also aids in achieving sustainability goals by reducing waste. It enables eco-friendly ink and substrate selection and optimizes runs for minimal resource use.

Likewise, many companies innovate with AI in printing. HP released HP Print AI for large-format printing. It simplifies setup to support while enabling personalized, secure, and efficient printing for homes, offices, and large-format workflows.

Picsart deploys tools for AI-driven image processing and generative design. The platforms automate cleanup, asset generation, resizing, and ensure quality at scale for print-ready files. Siemens applies AI and 3D printing in manufacturing to reduce component design times by 90% and increase production efficiency by 80%.

Macro3D offers AI-Powered Concrete 3D Printing

Australian startup Macro3D makes MacroPrint, a 3D printing software that integrates its AdaptivePrintAI technology to optimize concrete printing processes. It offers cloud-based access, real-time monitoring, and control of print paths from anywhere. The software includes parametric design tools that allow users to customize models and automatically generate optimized print paths.

At the same time, its robot-agnostic compatibility supports printers with custom-built robot arms. Further, AdaptivePrintAI technology uses real-time data on variables like water flow and pump speed. This aids in automatically adjusting to printing parameters and learning from past prints to improve quality and efficiency.

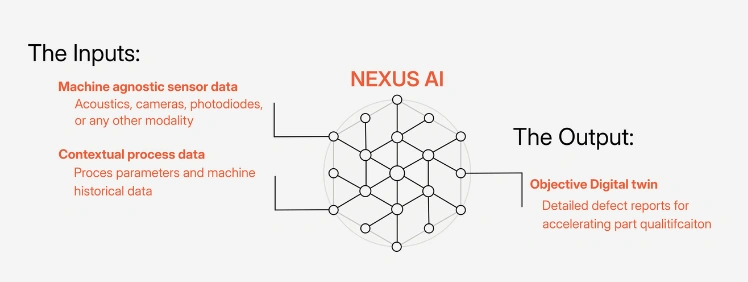

Nexus Additive provides Metal 3D Printing QA

UK-based startup Nexus Additive offers an AI-powered quality assurance platform for metal 3D printing to reduce part qualification costs and improve production reliability. The platform connects directly to machine sensors to capture real-time acoustic, optical, and process data. Thus, it creates an objective digital twin of each component without requiring additional hardware.

Credit: Nexus Additive

Further, the platform uses predictive intelligence to detect defects early, generate detailed quality reports, and accelerate part certification by over 50%. Thus, the startup enables aerospace, medical, and energy sectors to achieve consistent, traceable, and scalable additive manufacturing at lower costs.

3. Digital Printing Expansion: USD 59.93 B Market by 2034

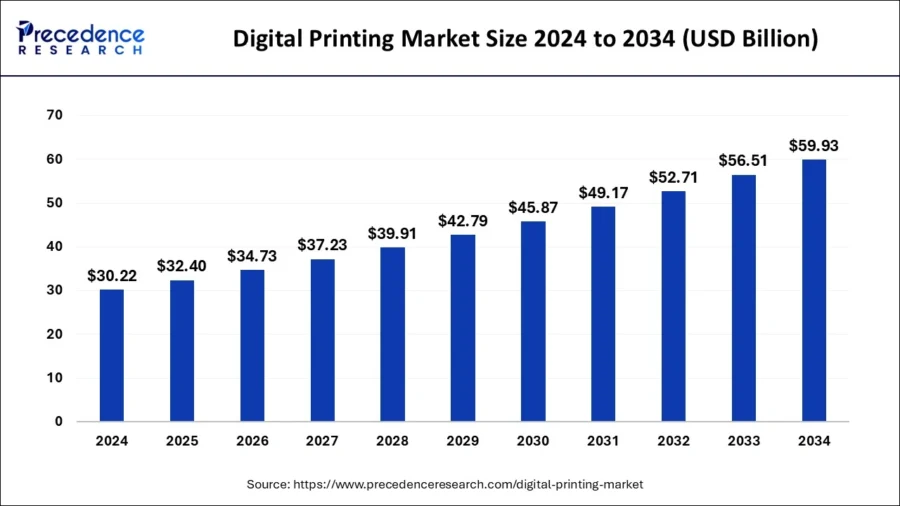

The digital printing market is projected to reach USD 59.93 billion by 2034 and is driven by demand for short-run and customized printed products.

Credit: Precedence Research

Some of the dominant trends in digital printing include print-on-demand, sustainability solutions, product personalization, automation, and integration of AI in production workflows. Specialty segments like packaging and large-format experience fast growth.

Packaging alone is expected to account for 30% of total print market sales in 2025 due to high demand from e-commerce and consumer innovations. The digital label printing market is valued at USD 12.3 billion in 2025 and expected to hit USD 20.6 billion by 2035.

Despite strong growth, digital printing faces challenges such as high printing costs for large runs, limited color matching accuracy, paper size constraints, and capital expenditure barriers for small converters. Emerging solutions offer web-to-print (W2P) software for automation, cost transparency, precise resource management, and workflow optimization.

Further, AI integration and smart automation assist companies in addressing manual inefficiencies, reducing material wastage, and enabling predictive maintenance for devices. Advances in substrate flexibility and simplified order management reduce barriers for small businesses and enable rapid job change capability. It caters to short-run orders and customized printing demand.

For instance, Midjourney uses generative algorithms to create print-ready visuals for banners, posters, and merchandise. It enables small shops to compete in seasonal and trending campaigns without in-house design talent. Similarly, Replique builds digital spare part inventories for industrial supply chains. It offers rapid prototyping through digital printing. This allows businesses to create and test multiple design iterations quickly.

MAS makes Textile Digital Printers

Italian startup MAS provides digital textile printers, MAS Vertical, MAS Twelve, and MAS Extreme that connect directly with enterprise resource planning (ERP) platforms. It enables real-time data export, automated process control, and intuitive software interfaces that simplify machine operations and reduce training time. The startup focuses on eco-friendly production by optimizing energy and material use while supporting water reduction and environmentally friendly inks.

MAS Vertical prints on both sides of textiles simultaneously using up to eight colors for high-speed, precise results. MAS Twelve provides printing up to twelve color channels and compatibility with various inks and raster image processor (RIP) software for diverse design needs. Further, MAS Extreme is designed for high-volume production with multipass technology, wide color coverage, and speeds that compete with traditional rotary and single-pass printers.

Digital On Demand provides Custom Product Printing

US-based startup Digital On Demand offers digital printing and fulfillment solutions that simplify custom product personalization for e-commerce businesses. The startup leverages Helix digital printing technology. It enables full-color, high-quality customization on products to create designs without size or color limitations.

Moreover, the startup’s order management system (OMS) integrates directly with platforms like Shopify, OrderDesk, and WooCommerce through a simple application programming interface (API). Thus, it automates order processing and ensures accuracy.

Also, the startup simplifies artwork preparation by automatically generating cyan, magenta, yellow, black (CMYK), white, and varnish layers for precise printing. Simultaneously, its barcode-based artwork retrieval minimizes operator errors and improves quality control.

4. Scaling 3D Printing: 77% Revenue from Industrial 3D Printers

Additive manufacturing (AM) is no longer just for prototyping. It has become a mainstream solution for mass production, particularly in aerospace, automotive, defense, and healthcare applications. With a projected global market size of USD 29.29 billion in 2025, it is expected to reach USD 134.58 billion by 2034.

Credit: Precedence Research

This segment focuses on on-demand, decentralized manufacturing, customization, and agility. The integration of AI-driven design and process optimization enables every stage of printing from generative design to real-time quality control. Moreover, advanced materials with progress in carbon fiber composites, high-performance polymers, and multi-material printing create parts with varied mechanical or tactile properties.

North America leads the sector with over 35% of revenue share, while Europe is the fastest-growing region. Industrial 3D printers account for 77% of market revenue, with automotive and prototyping applications being major drivers.

LIQTRA of Germany enhances production speed and strength with its multi-nozzle fused filament fabrication/fused deposition modeling (FFF/FDM) technology. It is specifically tailored for medical device manufacturing. Spanish startup REINFORCE3D advances continuous fiber injection techniques to create lighter yet stronger printed components for aerospace, automotive, and sporting goods.

Similarly, Vikela in the UK integrates smart materials and ergonomic design to deliver personalized safety solutions, including advanced ballistic protection. Meanwhile, a surge of sustainable material startups introduces innovative filaments derived from recycled plastics and biodegradable sources.

The sector’s next wave of growth will be enhanced by AI-driven optimization, advanced materials, supply chain resilience, and sustainability. This will enable the transition from prototyping to high-volume, high-value manufacturing.

PERFI Technologies offers Ultrafast Volumetric Additive Manufacturing

Danish startup PERFI Technologies develops advanced 3D printing solutions. It integrates tomographic volumetric printing to enable high-speed, precise, and customizable manufacturing. Its proprietary algorithm converts digital designs into a series of images projected onto a rotating cylinder containing photosensitive polymers. This allows all points of an object to solidify simultaneously and eliminates the limitations of traditional layer-by-layer printing.

The startup produces smooth surfaces without inter-layer defects, requires minimal post-processing, and supports complex designs without additional structural supports. The solutions span across audiology, dental, and research applications, including personalized earmolds, dental crowns, nightguards, aligners, and scientific prototypes.

Jabi TDD Solutions builds a Personalized Drug Delivery System

Canadian startup Jabi TDD Solutions offers a personalized drug printing and delivery system. The startup uses semi-solid extrusion (SSE) with a proprietary gel-based ink made from alginate and high-amylose corn starch. This produces patient-specific oral tablets in small batches. Further, the system enables customization of dosage, shape, flavor, and controlled-release properties while reducing production time and material waste.

An integrated in-line quality control system with optical, infrared, and load cell sensors monitors tablet weight, structure, and drug consistency in real time. It ensures accuracy and safety. By allowing pharmacists to create on-demand, multi-drug tablets tailored to individual needs, Jabi TDD Solutions addresses challenges like age-appropriate formulations, patient compliance, and polypharmacy simplification.

5. Focus on Sustainable Printing: Asia Pacific Grows Fastest at 9.8% CAGR

The global sustainable printing market is projected to reach a size of USD 2.17 billion in 2025 at a CAGR of 7.5%. It is expected to reach around USD 3.35 billion by 2030.

Credit: Grand View Research

North America’s growth rate is 6.5% per year compounded annually. Europe leads with strong regulation and a CAGR of 7.4%, while Asia-Pacific is the fastest-growing at 9.8% CAGR due to industrialization and policy support.

This growth is rooted in adopting eco-friendly materials, such as recycled paper, soy-based, and water-based inks.

Also, it extends to biodegradable packaging alternatives that break down faster and reduce toxic emissions. In parallel, energy-efficient printers utilizing LED UV and thermal curing technologies offer lower power consumption and reduced heat emissions.

The USA alone discards the equivalent of 1 billion trees every year. AI-driven optimization and automation reduce paper waste. They also decrease downtime through predictive maintenance to enhance production reliability.

Further, the increasing adoption of digital presses and cloud-based print management simplifies workflows, optimizes resource efficiency, and reduces the industry’s ecological footprint. G&G, a company that recycles cartridges and remanufactures toner, utilizes water-based and UV-curable inks.

The inks emphasize recycled materials in printers, which collectively reduce volatile organic compounds (VOCs) and plastic waste. Likewise, such companies push forward with vegetable-based inks (soy, linseed, algae), bamboo, and agricultural waste-based papers. The development and recycling of ink cartridges that account for around 25% of the print consumables market reduced plastic waste by up to 40%.

SwellCycle makes a Plant-based 3D-printed Surfboard Blank

US-based startup SwellCycle makes plant-based 3D-printed surfboard cores. The startup leverages an additive manufacturing process that builds each board from the inside out. For this, it uses a precision-printed lattice structure tailored to the surfer’s needs by eliminating foam cutting and material waste.

This process enables parametric customization and allows shapers to adjust dimensions, flex patterns, and responsiveness while maintaining consistent, high-resolution accuracy. Thus, by using bio-based thermoplastic materials made from renewable resources like corn starch, SwellCycle promotes eco-friendly production. It supports circularity and enables used cores to be upcycled into new products.

Filaret converts Cigarette Butts to 3D Printing Filament

Estonian startup Filaret develops sustainable 3D printing materials by upcycling cigarette butt waste into bioplastics and printing filament. The startup collects discarded cigarette butts through its branded bins, partner programs, and individual contributions.

Then, it separates and detoxifies the filters before blending them with eco-friendly polymers to create compostable plastic granules. Further, these granules are processed into 3D printing filament used to produce various objects while supporting waste reduction and resource recovery.

6. Rise of Web to Print Solutions: Market to Reach USD 35.07B by 2030

The W2P industry is reshaping traditional print services by enabling online customization, ordering, and production management.

Credit: Mordor Intelligence

The global W2P market size is projected to reach USD 35.07 billion by 2030 at a CAGR of 5.69%. Additionally, over 72% of printing companies adopted W2P solutions in 2024, and cloud-based platforms accounted for 61% of new deployments.

The fully customizable or design-it-yourself segment witnesses major growth as businesses and consumers increasingly demand personalized print solutions. North America currently leads adoption with over 40% of the global market share, while Asia-Pacific contributes to about 22% of the market volume.

However, the high upfront cost of implementing advanced W2P platforms, including integration and maintenance, is a substantial barrier. Furthermore, data security is an ongoing concern. 26% of businesses cite cloud security as a major deterrent to cloud adoption, which decelerates W2P market growth.

To solve these issues, print business owners leverage automation across all stages of production, from order management to prepress, design customization, and inventory management. It improves print quality, reduces operational costs, minimizes material waste, and enhances competitive positioning.

The integration of AI represents one of the leading trends in W2P technology. AI-powered design tools enable automated design generation, smart image editing with background removal capabilities, and dynamic personalization through variable data printing (VDP).

One of the central trends driving the web-to-print market is the accelerating demand for personalized print products. For instance, Shutterfly and Custom Ink allow customers to create custom photo books and apparel. Such personalized marketing materials achieve a 42% higher response rate than standard alternatives.

Augmented Reality (AR) is another major differentiator that offers interactive, real-time visualization of print designs before ordering. For instance, Snapchat users create event filters and preview their print designs on various materials.

ImprintNext offers an Online Designer Tool

US-based startup ImprintNext provides an AI-powered web-to-print software that enables businesses to design, customize, and manage personalized products across a range of printing processes. The software integrates an online design studio, product configurator, and production management system. This allows customers to create and preview designs in real-time using 3D visualization and augmented reality.

Moreover, its AI engine recommends the best printing methods, generates accurate virtual samples, and supports diverse printing techniques. These techniques include screen printing, direct-to-garment (DTG), sublimation, engraving, and large-format printing. Additionally, the software automates order processing, quotation management, and workflow tracking to ensure smooth coordination between customers, printers, and vendors.

Zyng AI provides AI-Powered W2P Image Editing

Indian startup Zyng AI offers an AI-powered image editing platform that automates bulk print processing for e-commerce, fashion, and digital content businesses. The platform simplifies workflows by combining tools such as background removal, face retouching, model swapping, subject-aware cropping, generative fill, and AI-generated backgrounds.

Further, it processes multiple images simultaneously to deliver consistent, high-quality results across JPEG, PNG, TIFF, PSD, and other formats while supporting up to 8K resolution. Zyng AI integrates customizable templates and automated workflows to enable users to edit, resize, and optimize images quickly for marketplaces like Amazon, Shopify, and Flipkart.

7. Advanced Cloud Printing Technologies: 12.86B Market by 2032

The global cloud printing market has increased from USD 6.07 billion in 2025 to USD 12.86 billion in 2032 at a CAGR of 11.3%. One of the main driving forces behind this growth includes the permanent shift to hybrid and remote work models.

Credit: Fortune Business Insights

Serverless printing allows businesses to remove expensive on-premises print servers while still keeping centralized control and strong security. On average, maintaining a traditional print server costs around USD 2K-3K per year per server. This makes cloud migration a cost-effective choice.

With rising risks of data breaches and privacy violations, enterprise IT departments look for better protection. Thus, modern cloud printing platforms include zero-trust security architectures, which require user authentication and use end-to-end encryption for all print tasks.

In distributed work environments, protecting sensitive documents is a major challenge. This led to the widespread use of secure pull printing. Here, documents remain stored in encrypted cloud queues until users authenticate themselves at the printer. An example of this trend is Microsoft’s Universal Print anywhere feature that allows employees to print from any corporate printer while keeping strict security controls through authentication.

Similarly, Star Micronics’ StarIO.Online managed service removes the need for local print servers at retail locations and provides centralized printer management through Star’s hosted cloud infrastructure.

Moreover, AI-powered predictive maintenance aids in monitoring key health metrics of the printers, like temperature, usage patterns, and component wear. Using IoT connectivity, printers communicate with other smart devices to optimize workflows and reduce downtime.

Also, companies focus on reducing their environmental impact by cutting paper waste and optimizing resource usage to support sustainability. Integration with digital document management systems reduces printing volumes, while cloud infrastructure itself lowers carbon footprints. Additionally, cloud analytics allow organizations to track and manage print usage to enable more effective sustainability policies.

CredsNow builds an Event Badge Print App

US-based startup CredsNow offers a cloud-based event badging and printing app that simplifies the creation, management, and distribution of event badges. The platform integrates a print app that enables distributed, on-demand badge printing across multiple locations while maintaining speed and scalability.

Further, the platform supports end-to-end event workflows by combining badge design, data integration, printer assignments, registration categories, and onsite check-in through customizable kiosk templates. It allows for designing badges, previewing merged layouts in real time, and tracking production and shipping directly within the system. Also, it offers live dashboards, real-time printer monitoring, and automated data synchronization. This ensures accurate, efficient, and consistent badge production for events of any size.

Cronus develops a Printing House Automation System

Slovenian startup Cronus provides a cloud-based modular printing house automation system that manages planning, execution, and control across the entire production workflow. The system integrates print calculation algorithms that automatically select the most economical production process while optimizing pricing, quoting, and order management. It connects machine operations, production planning, and warehouse management with real-time data to enable coordination from design to delivery.

Through its centralized analytics dashboard, Cronus uses AI-driven insights to monitor operations, predict issues, and improve efficiency across prepress, digital printing, offset printing, and finishing. The system also includes a fully integrated W2P interface for business-to-business (B2B) and business-to-customer (B2C) customers for supporting product customization, automated order processing, and real-time tracking.

8. Emphasis on Print Security: 67% Faced Print Data Loss in 2023

The demand for print security is increasing due to the rise in cyber threats and stricter compliance. The global security printing market is valued at USD 37.93 billion in 2025 and is projected to reach USD 62.56 billion by 2032 at a 7.41% CAGR. Within this, the print security services market is expected to reach USD 48.43 billion by 2034.

Credit: Towards Packaging

In 2023, 67% suffered from print-related data loss. While 35% have implemented zero-trust architecture for their printers, 37% of organizations have conducted formal print security assessments.

Similarly, AI-powered systems detect anomalous printing patterns, identify unauthorized access attempts, and automatically respond to security incidents in real-time. Machine learning (ML) algorithms analyze print job data for embedded malicious code while enabling predictive maintenance that reduces downtime by up to 40%.

Y Soft’s SAFEQ platform offers enterprise-grade security with zero-trust architecture, end-to-end data encryption, role-based access control, and multi-factor authentication.

Additionally, companies like PaperCut emphasize cloud-based print management, automated supply management, and intelligent document processing with secure printing.

Print security solutions must address increasingly stringent regulatory requirements, including General Data Protection Regulation (GDPR), Health Insurance Portability and Accountability Act (HIPAA), System and Organization Controls 2 (SOC 2), and industry-specific mandates.

The GDPR requires data minimization, explicit consent, breach notification within 72 hours, and imposes penalties up to EUR 20 million or 4% of annual global turnover. HIPAA compliance demands administrative, physical, and technical safeguards for electronic protected health information (ePHI). The penalties may reach USD 1.5 million per violation category per year.

The integration of blockchain technology for document authentication and traceability enables tamper-proof records of identity documents and enhanced verification capabilities. Nanotechnology applications in security printing create microscopic features impossible to replicate without specialized equipment.

Moreover, the adoption of IoT connectivity enables encrypted transmissions, remote monitoring, and network isolation to transform printers from vulnerabilities into fortified endpoints.

Molecular Gate offers Anti-Counterfeiting Technology

Spanish startup Molecular Gate develops Polargram, an anti-counterfeiting labeling technology to enhance product authentication in packaging and printing. The technology leverages ultrathin films of molecular electronic materials printed through digital drop-on-demand processes. It creates security elements that appear featureless under normal conditions but reveal hidden color-shifting patterns during verification.

The startup offers two complementary solutions: see-through Polargram and reflective Pologram. See-through Pologram is designed for transparent substrates like plastic films, which display hidden patterns when viewed against any LCD screen. Reflective Polargram is applied to aluminum foils or cartons, which reveal secure patterns when tilted under direct light sources such as sunlight or smartphone flash.

These printed security elements integrate with existing packaging workflows, reduce production costs due to minimal material usage, and provide flexibility for incorporating QR codes and customized designs. Thus, the startup protects brands, products, and consumers across industries such as pharmaceuticals, fashion, cosmetics, luxury goods, and currency authentication.

Distinkt offers Color-Changing Ink

Spanish startup Distinkt offers luminescent and color-changing inks that enable real-time product authentication and traceability. It embeds microscopic particles within inks that respond to near-infrared light to create unique visual transitions either visible to the naked eye or under UV exposure.

The startup’s product suite includes Distinkt_LUM, Distinkt_COLOR, and Distinkt_SEAL. Distinkt_LUM produces reversible fluorescent transitions under UV light. Distinkt_COLOR enables customizable visible color changes while Distinkt_SEAL creates permanent luminescent marks for long-term verification.

By integrating encrypted QR codes and universal product code (UPC) barcodes, the startup bridges physical and digital authentication and enables verification through smartphones for enhancing consumer engagement. Also, it is compatible with multiple printing methods, including screen, offset, and inkjet printing, to support flexible customization for brand-specific patterns, logos, and security elements. Thus, it protects products across sectors such as luxury goods, wine and beverages, pharmaceuticals, and collectibles.

9. Surge in Print-on-Demand Services: USD 59.3B Market by 2033

The print-on-demand (POD) market size has reached USD 8.3 billion in 2025 and is forecasted to climb toward USD 59.3 billion by 2033 with a CAGR of 27.8%.

Credit: Market.us

This expansion is a result of multiple factors. Firstly, personalization is no longer a niche demand. More than 30% of consumers now expect products tailored to their preferences, and nearly 50% wait longer for unique, customized items.

At the same time, AI and automation are becoming central to POD operations by enabling faster error detection, smarter inventory management, and automated design generation. These technologies reduce manual work, streamline production, and allow platforms to handle massive volumes of orders and data with high accuracy.

With increasing operational costs, supply chain disruptions, and inflation pressures, companies invest heavily in automation, workflow optimization, and advanced equipment. This aids in improving efficiency and reducing dependency on volatile resources.

Sustainability has also emerged as a defining priority. While POD inherently minimizes waste compared to bulk printing, providers further adopt eco-friendly materials, greener production processes, and AI-driven analytics.

Meanwhile, most of the print-on-demand providers offer integrations with e-commerce platforms like Shopify, Etsy, and Amazon. It enables sellers to automate order fulfillment, enhance operational scalability, and reach global customers effortlessly.

For instance, Tapstitch emphasizes extensive customization options, no minimum order quantities, and promotes sustainable, zero-inventory production. It mitigates waste and improves cash flow for small businesses.

Another company, Modalyst, combines automated dropshipping with print-on-demand to enable sellers to create highly tailored, branded merchandise without heavy inventory or logistics. Similarly, Printy6 focuses on eco-friendly production and affordable apparel and footwear customization, with global shipping and expanding US and European fulfillment.

JUNOdts offers Direct to Shape Printing

US-based startup JUNOdts develops Juno Studio, a direct-to-shape digital printing platform. It enables high-speed, high-resolution, and fully customizable printing on virtually any object, surface, size, or material. It integrates cloud-based automation, internet of things (IoT) connectivity, and data analytics to print designs directly on products. This eliminates the need for labels, shrink sleeves, and excess packaging waste.

The platform supports artwork uploads, real-time production tracking, and on-demand printing without minimum order requirements to make it suitable for personalized packaging and localized manufacturing.

Blinkstore provides a Print-on-Demand Store Builder

Indian startup Blinkstore provides a print-on-demand dropshipping platform that allows businesses to launch and run online merchandise stores without inventory. The startup hosts an inbuilt storefront, so users design products, set pricing on top of a base cost, and publish a store URL or custom domain.

Further, the platform supports 50+ product types with color and size options, 48-hour dispatch targets, no minimum orders, custom branding and packaging, and a mobile app for fast setup. It integrates via APIs with Shopify and WooCommerce and offers an AI mockup generator. Moreover, it provides barcode-free order management and store analytics with Facebook Pixel and Google Analytics.

10. Adoption of Hybrid Printing: USD 16.53B Market by 2034

Hybrid printing integrates UV inkjet systems with analog printing stations to create a single-pass process that leverages the strengths of both methodologies. Digital components handle variable data printing, personalization, and complex graphics. At the same time, analog stations manage consistent background colors, spot colors, metallics, and various finishing processes, including varnishing, foiling, and die-cutting.

Credit: Precedence Research

The market is expected to grow from USD 5.8 billion in 2025 to USD 16.53 billion by 2034 at a CAGR of 12.3%. Growing demand for customized printing, quicker turnaround, and the rise of e-commerce and smart packaging enable this market growth. Companies increasingly seek flexible solutions such as variable data printing, QR codes, and short-run jobs that deliver premium quality.

Moreover, AI and automation play increasingly important roles in optimizing production workflows. For instance, AI-driven color correction systems, automated workflow management, and predictive maintenance, when integrated into hybrid platforms, improve consistency, reduce errors, and minimize waste. Digital embellishment technologies are rapidly advancing, with new capabilities in raised textures, metallic inks, and digital foiling.

HP, for instance, expanded its hybrid capabilities by launching systems like the HP Indigo 120K Digital Press and HP Latex R530 hybrid printer that combine offset-matching image quality with digital flexibility. Besides, Heidelberg established its Shift 2025 platform to guide the digital transformation of print shops. It emphasizes hybrid production environments with AI-driven workflows.

Similarly, Domino’s N610i integration module enables integration of digital inkjet printing with traditional flexographic presses. It allows full-color, high-quality hybrid label production in a single efficient process.

Likewise, the hybrid printing market is evolving rapidly as advanced solutions tackle integration challenges that once limited efficiency. Managing separate digital and analog production lines traditionally required complex color matching, multi-system training, and cumbersome workflows.

However, modern hybrid platforms overcome these hurdles through unified control systems, automated color management, and streamlined interfaces to enable single-operator control of multi-technology production. While upfront capital costs remain significant, faster setups, reduced waste, and the ability to handle diverse job types offer a compelling return on investment.

Kento Digital Printing provides Hybrid Single Pass Printing

Spanish startup Kento Digital Printing develops Kento Hybrid, a modular hybrid printing technology line. It integrates single-pass digital inkjet with high-definition flexographic printing and in-line rotary die-cutting for corrugated cardboard. The line prints backgrounds, spot colors, and variable graphics in one pass on substrates from 0.8-12 mm. For this, it uses a 2100 mm print width with 1300 mm or 1600 mm repeat, and runs up to 80 m/min or 8000 sheets/hour with bottom feed and automated stacking.

The line employs an open ink system approved to food-contact standards, supports recyclable/repulpable inks, and centralizes control through proprietary software and electronics. Further, it handles short-to-mid runs efficiently and reduces setup waste. Thus, it shortens lead times and delivers higher-margin, customized corrugated packaging at industrial speed and quality.

TracXon offers Hybrid Printed Electronics

Dutch startup TracXon offers hybrid printed electronics (HPE) using advanced sheet-to-sheet (S2S) and roll-to-roll (R2R) manufacturing processes combined with component assembly. The startup integrates conductive, dielectric, resistive, electroluminescent, and piezoelectric inks. Also, it uses techniques such as flat-bed and R2R screen printing, photonic sintering, surface mount device (SMD) assembly, lamination, and high-pressure forming to produce functional circuits on thin, flexible substrates.

The startup’s proprietary process enables precise and cost-efficient production to support applications in healthcare, automotive, lighting, consumer electronics, and battery systems. Through co-design and prototyping, it creates products with innovative form factors, reduced material usage, and improved integration possibilities.

Discover all Printing Industry Trends, Technologies & Startups

The printing industry is shifting from traditional processes to tech-driven, personalized, and sustainable solutions. Emerging trends like AI-powered workflows, hybrid printing, W2P platforms, and on-demand customization are redefining production efficiency and customer experience.

Upcoming technologies such as blockchain-based print security, AR-enabled interactive prints, volumetric 3D printing, quantum dot inks, and biodegradable smart materials are expected to further transform the sector. Companies adopting these innovations early will gain a competitive edge by reducing costs, enhancing sustainability, and creating new value-driven printing experiences.

The Printing Industry Trends & Startups outlined in this report only scratch the surface of trends that we identified during our data-driven innovation & startup scouting process. Identifying new opportunities & emerging technologies to implement into your business goes a long way in gaining a competitive advantage.

![Explore the Top 10 Printing Industry Trends & Innovations [2026]](https://www.startus-insights.com/wp-content/uploads/2025/09/Printing-Industry-Trends-SharedImg-StartUs-Insights-noresize-420x236.webp)